display INFINITI QX56 2011 Factory Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2011, Model line: QX56, Model: INFINITI QX56 2011Pages: 5598, PDF Size: 94.53 MB

Page 3895 of 5598

![INFINITI QX56 2011 Factory Service Manual

PCS-54

< BASIC INSPECTION >[POWER DISTRIBUTION SYSTEM]

DIAGNOSIS AND REPAIR WORK FLOW

1.GET INFORMATION ABOUT SYMPTOM

Get detailed information from the customer about the symptom (the condition and INFINITI QX56 2011 Factory Service Manual

PCS-54

< BASIC INSPECTION >[POWER DISTRIBUTION SYSTEM]

DIAGNOSIS AND REPAIR WORK FLOW

1.GET INFORMATION ABOUT SYMPTOM

Get detailed information from the customer about the symptom (the condition and](/img/42/57033/w960_57033-3894.png)

PCS-54

< BASIC INSPECTION >[POWER DISTRIBUTION SYSTEM]

DIAGNOSIS AND REPAIR WORK FLOW

1.GET INFORMATION ABOUT SYMPTOM

Get detailed information from the customer about the symptom (the condition and the environment when the

incident/malfunction occurs).

>> GO TO 2.

2.CHECK DTC

1. Check DTC for BCM and IPDM E/R.

2. Perform the following procedure if DTC is displayed.

- Record DTC and freeze frame data (Pri nt them out with CONSULT-III.)

- Erase DTC.

- Study the relationship between the cause detected by DTC and the symptom described by the customer.

3. Check related service bulletins for information.

Are any symptoms described and any DTC detected?

Symptom is described, DTC is displayed>>GO TO 3.

Symptom is described, DTC is not displayed>>GO TO 4.

Symptom is not described, DTC is displayed>>GO TO 5.

3.CONFIRM THE SYMPTOM

Confirm the symptom described by the customer.

Connect CONSULT-III to the vehicle in the “DATA MO NITOR” mode and check real time diagnosis results.

Verify relation between the symptom and the condition when the symptom is detected.

>> GO TO 5.

4.CONFIRM THE SYMPTOM

Confirm the symptom described by the customer.

Connect CONSULT-III to the vehicle in the “DATA MO NITOR ” mode and check real time diagnosis results.

Verify relation between the symptom and the condition when the symptom is detected.

>> GO TO 6.

5.PERFORM DTC CONFIRMATION PROCEDURE

Perform DTC Confirmation Procedure for the display ed DTC, and then check that DTC is detected again.

At this time, always connect CONSULT-III to the vehicle, and check diagnostic results in real time.

If two or more DTCs are detected, refer to BCS-56, "

DTCInspectionPriorityChart", and determine trouble

diagnosis order.

NOTE:

Perform Component Function Check if DTC Confirmati on Procedure is not included in Service Manual. This

simplified check procedure is an effective alternativ e, although DTC cannot be detected during this check.

If the result of Component Function Check is NG, it is the same as the detection of DTC by DTC Confirmation

Procedure.

Is DTC detected?

YES >> GO TO 7.

NO >> Refer to GI-40, "

Intermittent Incident".

6.DETECT MALFUNCTIONING SYSTEM BY SYMPTOM DIAGNOSIS

Detect malfunctioning system according to SYMPTOM DIAGNOSIS based on the confirmed symptom in step

4, and determine the trouble diagnosis order based on possible causes and symptom.

>> GO TO 7.

7.DETECT MALFUNCTIONING PART BY DIAGNOSTIC PROCEDURE

Inspect according to Diagnostic Procedure of the system.

NOTE:

The Diagnostic Procedure described based on open circuit inspection. A short circuit inspection is also

required for the circuit check in the Diagnostic Procedure.

Revision: 2010 May2011 QX56

Page 3896 of 5598

![INFINITI QX56 2011 Factory Service Manual

PCS

DIAGNOSIS AND REPAIR WORK FLOWPCS-55

< BASIC INSPECTION > [POWER DISTRIBUTION SYSTEM]

C

D

E

F

G H

I

J

K L

B A

O P

N

Is malfunctioning part detected?

YES >> GO TO 8.

NO >> Check voltage of related INFINITI QX56 2011 Factory Service Manual

PCS

DIAGNOSIS AND REPAIR WORK FLOWPCS-55

< BASIC INSPECTION > [POWER DISTRIBUTION SYSTEM]

C

D

E

F

G H

I

J

K L

B A

O P

N

Is malfunctioning part detected?

YES >> GO TO 8.

NO >> Check voltage of related](/img/42/57033/w960_57033-3895.png)

PCS

DIAGNOSIS AND REPAIR WORK FLOWPCS-55

< BASIC INSPECTION > [POWER DISTRIBUTION SYSTEM]

C

D

E

F

G H

I

J

K L

B A

O P

N

Is malfunctioning part detected?

YES >> GO TO 8.

NO >> Check voltage of related BCM terminals using CONSULT-III.

8.REPAIR OR REPLACE THE MALFUNCTIONING PART

1. Repair or replace the malfunctioning part.

2. Reconnect parts or connectors disconnected during Diagnostic Procedure again after repair and replace-

ment.

3. Check DTC. If DTC is displayed, erase it.

>> GO TO 9.

9.FINAL CHECK

When DTC was detected in step 2, perform DTC C onfirmation Procedure or Component Function Check

again, and then check that the malfunction is repaired securely.

When symptom was described by the customer, refer to c onfirmed symptom in step 3 or 4, and check that the

symptom is not detected.

Does the symptom reappear?

YES (DTC is detected)>>GO TO 7.

YES (Symptom remains)>>GO TO 6.

NO >> INSPECTION END

Revision: 2010 May2011 QX56

Page 3904 of 5598

![INFINITI QX56 2011 Factory Service Manual

PCS

B2618 BCMPCS-63

< DTC/CIRCUIT DIAGNOSIS > [POWER DISTRIBUTION SYSTEM]

C

D

E

F

G H

I

J

K L

B A

O P

N

B2618 BCM

DTC LogicINFOID:0000000006220212

DTC DETECTION LOGIC

NOTE:

If DTC B2618 is displaye INFINITI QX56 2011 Factory Service Manual

PCS

B2618 BCMPCS-63

< DTC/CIRCUIT DIAGNOSIS > [POWER DISTRIBUTION SYSTEM]

C

D

E

F

G H

I

J

K L

B A

O P

N

B2618 BCM

DTC LogicINFOID:0000000006220212

DTC DETECTION LOGIC

NOTE:

If DTC B2618 is displaye](/img/42/57033/w960_57033-3903.png)

PCS

B2618 BCMPCS-63

< DTC/CIRCUIT DIAGNOSIS > [POWER DISTRIBUTION SYSTEM]

C

D

E

F

G H

I

J

K L

B A

O P

N

B2618 BCM

DTC LogicINFOID:0000000006220212

DTC DETECTION LOGIC

NOTE:

If DTC B2618 is displayed with DTC U1000, first per

form the trouble diagnosis for DTC U1000. Refer to

BCS-70, "

DTC Logic".

If DTC B2618 is displayed with DTC U1010, first per form the trouble diagnosis for DTC U1010. Refer to

BCS-71, "

DTC Logic".

DTC CONFIRMATION PROCEDURE

1.PERFORM DTC CONFIRMATION PROCEDURE

1. Turn ignition switch ON under the following conditions, and wait for 1 second or more.

- Selector lever is in the P or N position

- Do not depress brake pedal

2. Check “Self-diagnosis result” of BCM with CONSULT-III.

Is DTC detected?

YES >> Go to PCS-63, "Diagnosis Procedure".

NO >> INSPECTION END

Diagnosis ProcedureINFOID:0000000006220213

1.INSPECTION START

1. Turn ignition switch ON.

2. Select “Self-diagnosis resu lt” of BCM with CONSULT-III.

3. Touch “ERASE”.

4. Perform DTC Confirmation Procedure. See PCS-63, "

DTC Logic".

Is the 1st trip DTC B2618 displayed again?

YES >> Replace BCM. Refer to BCS-81, "Removal and Installation"

NO >> INSPECTION END

DTC No.Trouble diagnosis

name DTC detecting condition Possible cause

B2618 BCM An immediate operation of ignition relay (IPDM E/R) is re-

quested by BCM, but there is no response for more than

1 second BCM

Revision: 2010 May2011 QX56

Page 3905 of 5598

![INFINITI QX56 2011 Factory Service Manual

PCS-64

< DTC/CIRCUIT DIAGNOSIS >[POWER DISTRIBUTION SYSTEM]

B261A PUSH-BUTTON IGNITION SWITCH

B261A PUSH-BUTTON IGNITION SWITCH

DTC LogicINFOID:0000000006220214

DTC DETECTION LOGIC

NOTE:

If DTC B26 INFINITI QX56 2011 Factory Service Manual

PCS-64

< DTC/CIRCUIT DIAGNOSIS >[POWER DISTRIBUTION SYSTEM]

B261A PUSH-BUTTON IGNITION SWITCH

B261A PUSH-BUTTON IGNITION SWITCH

DTC LogicINFOID:0000000006220214

DTC DETECTION LOGIC

NOTE:

If DTC B26](/img/42/57033/w960_57033-3904.png)

PCS-64

< DTC/CIRCUIT DIAGNOSIS >[POWER DISTRIBUTION SYSTEM]

B261A PUSH-BUTTON IGNITION SWITCH

B261A PUSH-BUTTON IGNITION SWITCH

DTC LogicINFOID:0000000006220214

DTC DETECTION LOGIC

NOTE:

If DTC B261A is displayed with DTC U1000, first

perform the trouble diagnosis for DTC U1000. Refer to

BCS-70, "

DTC Logic".

If DTC B261A is displayed with DTC U1010, first perform the trouble diagnosis for DTC U1010. Refer to

BCS-71, "

DTC Logic".

DTC CONFIRMATION PROCEDURE

1.PERFORM DTC CONFIRMATION PROCEDURE

1. Press the push-button ignition switch under the fo llowing conditions, and wait for 1 second or more.

- Selector lever is in the P or N position

- Do not depress brake pedal

2. Check “Self-diagnosis result” of BCM with CONSULT-III.

Is DTC detected?

YES >> Go to PCS-64, "Diagnosis Procedure".

NO >> INSPECTION END

Diagnosis ProcedureINFOID:0000000006220215

1.CHECK IGNITION SWITCH OUTPUT SIGNAL (PUSH-BUTTON IGNITION SWITCH)

1. Disconnect push-button ignition swit ch connector and IPDM E/R connector.

2. Check voltage between push-button ignition switch harness connector and ground.

Is the inspection result normal?

YES >> GO TO 3.

NO >> GO TO 2.

2.CHECK PUSH-BUTTON IGNITION SWITCH CIRCUIT (BCM)

1. Disconnect BCM connector.

2. Check continuity between BCM harness connector and push-button ignition switch harness connector.

3. Check continuity between push-button ignition switch harness connector and ground.

DTC No.Trouble diagnosis

name DTC detecting condition Possible cause

B261A PUSH-BTN IGN SW BCM detects a difference of signal for 1 second or

more between the following items.

Push-button ignition switch signal

Push-button ignition switch status signal (CAN) Harness or connectors

(Push-button ignition switch circuit

is open or shorted.)

BCM

IPDM E/R

(+)

(–)Voltage (V)

(Approx.)

Push-button ignition switch

Connector Terminal M101 4 Ground 12

BCM Push-button ignition switch Continuity

Connector Terminal Connector Terminal

M71 100 M101 4 Existed

Push-button ignition switch GroundContinuity

Connector Terminal

M101 4 Not existed

Revision: 2010 May2011 QX56

Page 3911 of 5598

![INFINITI QX56 2011 Factory Service Manual

PCS-70

< DTC/CIRCUIT DIAGNOSIS >[POWER DISTRIBUTION SYSTEM]

B26F6 BCM

B26F6 BCM

DTC LogicINFOID:0000000006220220

DTC DETECTION LOGIC

NOTE:

If DTC B26F6 is displayed with DTC U1000, first perform th INFINITI QX56 2011 Factory Service Manual

PCS-70

< DTC/CIRCUIT DIAGNOSIS >[POWER DISTRIBUTION SYSTEM]

B26F6 BCM

B26F6 BCM

DTC LogicINFOID:0000000006220220

DTC DETECTION LOGIC

NOTE:

If DTC B26F6 is displayed with DTC U1000, first perform th](/img/42/57033/w960_57033-3910.png)

PCS-70

< DTC/CIRCUIT DIAGNOSIS >[POWER DISTRIBUTION SYSTEM]

B26F6 BCM

B26F6 BCM

DTC LogicINFOID:0000000006220220

DTC DETECTION LOGIC

NOTE:

If DTC B26F6 is displayed with DTC U1000, first perform the trouble diagnosis for DTC U1000. Refer to

BCS-70, "

DTC Logic".

If DTC B26F6 is displayed with DTC U1010, first perform the trouble diagnosis for DTC U1010. Refer to BCS-71, "

DTC Logic".

DTC CONFIRMATION PROCEDURE

1.PERFORM DTC CONFIRMATION PROCEDURE

1. Turn ignition switch ON under the following conditions, and wait for 1 second or more.

- Selector lever is in the P or N position

- Do not depress brake pedal

2. Check “Self-diagnosis result” of BCM with CONSULT-III.

Is DTC detected?

YES >> Go to PCS-70, "Diagnosis Procedure".

NO >> INSPECTION END

Diagnosis ProcedureINFOID:0000000006220221

1.INSPECTION START

1. Turn ignition switch ON.

2. Select “Self-diagnosis result” of BCM with CONSULT-III.

3. Touch “ERASE”.

4. Perform DTC Confirmation Procedure. See PCS-70, "

DTC Logic".

Is DTC detected?

YES >> Replace BCM. Refer to BCS-81, "Removal and Installation"

NO >> INSPECTION END

DTC No.Trouble diagnosis

name DTC detecting condition Possible cause

B26F6 BCM Ignition relay ON signal is not transmitted from IPDM E/

R when BCM turns ignition relay ON. BCM

Revision: 2010 May2011 QX56

Page 4096 of 5598

DIAGNOSIS SYSTEM (BCM)PWC-11

< SYSTEM DESCRIPTION >

C

DE

F

G H

I

J

L

M A

B

PWC

N

O P

DIAGNOSIS SYSTEM (BCM)

COMMON ITEM

COMMON ITEM : CONSULT-III Fu nction (BCM - COMMON ITEM)INFOID:0000000006217269

APPLICATION ITEM

CONSULT-III performs the following functions via CAN communication with BCM.

SYSTEM APPLICATION

BCM can perform the following functions for each system.

NOTE:

It can perform the diagnosis modes except the following for all sub system selection items.

×: Applicable item

*: This item is indicated, but not used.

FREEZE FRAME DATA (FFD)

The BCM records the following vehicle condition at the time a particular DTC is detected, and displays on

CONSULT-III.

Diagnosis mode Function Description

Work Support Changes the setting for each system function.

Self Diagnostic Result Displays the diagnosis results judged by BCM. Refer to BCS-57, "

DTCIndex".

CAN Diag Support Monitor Monitors the reception status of CAN communication viewed from BCM. Refer to CONSULT-III opera-

tion manual.

Data Monitor The BCM input/output signals are displayed.

Active Test The signals used to activate each device are forcibly supplied from BCM.

Ecu Identification The BCM part number is displayed.

Configuration Read and save the vehicle specification.

Write the vehicle specification when replacing BCM.

System Sub system selection item Diagnosis mode

Work Support Data Monitor Active Test

Door lock DOOR LOCK ×××

Rear window defo gger REAR DEFOGGER ××

Warning chime BUZZER ××

Interior room lamp timer INT LAMP ×××

Exterior lamp HEAD LAMP ×××

Wiper and washer WIPER ×××

Turn signal and hazard warning lamps FLASHER ×××

— AIR CONDITONER* ××

Intelligent Key system

Engine start system INTELLIGENT KEY

×××

Combination switch COMB SW ×

Body control system BCM ×

NATS IMMU ×××

Interior room lamp battery saver BATTERY SAVER ×××

Back door TRUNK ×

Vehicle security system THEFT ALM ×××

RAP system RETAINED PWR ×

Signal buffer system SIGNAL BUFFER ××

Revision: 2010 May2011 QX56

Page 4261 of 5598

RSU-6

< PERIODIC MAINTENANCE >

WHEEL ALIGNMENT

WHEEL ALIGNMENT

InspectionINFOID:0000000006225661

DESCRIPTION

Measure wheel alignment under unladen conditions.

NOTE:

“Unladen conditions” means that fuel, engine coolant, and lubricant are full. Spare tire, jack, hand tools and

mats are in designated positions.

PRELIMINARY CHECK

Check the following:

Tires for improper air pressure and wear

Road wheels for runout. Refer to WT-64, "

Inspection".

Wheel bearing axial end play. Refer to RAX-5, "

Inspection".

Ball joint axial end play of suspension arm and front lower link. Refer to RSU-20, "

Ball Joint".

Shock absorber operation

Each mounting point of axle and suspension for looseness and deformation

Each of front lower link, rear lower link, rear suspension member, suspension arm and shock absorber for

cracks, deformation, and other damage

Vehicle height (posture)

GENERAL INFORMATION AND RECOMMENDATIONS

A four-wheel thrust alignment should be performed.

- This type of alignment is recomm ended for any NISSAN/INFINITI vehicle.

- The four-wheel “thrust” process helps ensure that t he vehicle is properly aligned and the steering wheel is

centered.

- The alignment rack itself should be capable of accepting any NISSAN/INFINITI vehicle.

- The rack should be checked to ensure that it is level.

Make sure the machine is properly calibrated.

- Your alignment equipment should be regularly calib rated in order to give correct information.

- Check with the manufacturer of your specific equi pment for their recommended Service/Calibration Sched-

ule.

ALIGNMENT PROCESS

IMPORTANT:

Use only the alignment specifications listed in this Service Manual.

When displaying the alignment settings, many alignment machines use “indicators”: (Green/red, plus or

minus, Go/No Go). Never use these indicators.

- The alignment specifications programmed into your machine that operate these indicators may not be cor-

rect.

- This may result in an ERROR.

Some newer alignment machines are equipped with an optional “Rolling Compensation” method to “com- pensate” the sensors (alignment targets or head units). Never use this “Rolling Compensation” method.

- Use the “Jacking Compensation Method”. After installi ng the alignment targets or head units, raise the vehi-

cle and rotate the wheels 1/2 turn both ways.

- See Instructions in the alignment machine you're using for more information on this.

AdjustmentINFOID:0000000006225662

CAMBER

Revision: 2010 May2011 QX56

Page 4306 of 5598

SYSTEMSBC-9

< SYSTEM DESCRIPTION >

C

DE

F

G

I

J

K L

M A

B

SBC

N

O P

PRE-CRASH SEAT BELT SYSTEM : Fail SafeINFOID:0000000006237879

When a system malfunction is detected, deactivates a part of the system or all functions depending on the

malfunctioning part.

When the malfunction condition recovers to the norma l condition, the system returns to the normal opera-

tion.

*1: The deactivation mode differs depending on the internal malfunctioning condition of control unit Display contents of CONSULT-III Fail-safe

U0126 STRG ANG SEN SIG Stops the operation in the conditions as per the following.

When lateral slippage during cornering occurs

When steering wheel is rotated for emergency

A part of comfort function

U0428 STRG ANGL CAL Stops the operation in the conditions as per the following.

When lateral slippage during cornering occurs

When steering wheel is rotated for emergency

A part of comfort function

U1000 CAN communication circuit Stops the operation in the conditions as per the following. *

1

During emergency brake operation

When ABS continuously operates

When lateral slippage during cornering occurs

When Intelligent brake assistance operates

When steering wheel is rotated for emergency

When the vehicle inclined excessively

A part or the whole comfort function

B2451 SEAT BLT MTR DR CIRC Fully deactivates the whole operation.

B2452 SEAT BLT MTR AS CIRC Deactivate s a part of comfort function.

B2453 BR_STROKE_SEN_CIRC Stops the operation in the conditions as per the following.

During emergency brake operation

When ABS continuously operates

A part of comfort function

B2454 SEAT BLT PWR DR CIRC Fully deactivates the whole operation.

B2455 CONTROL UNIT DR Stops the operation in the conditions as per the following. *

1

During emergency brake operation

When ABS continuously operates

When lateral slippage during cornering occurs

When Intelligent brake assistance operates

When steering wheel is rotated for emergency

When the vehicle inclined excessively

A part or the whole comfort function

B2456 SEAT BLT PWR AS Deactivates a part of comfort function.

B2457 CONTROL UNIT AS Deactivates a part of comfort function.

B2458 LOCAL COMM Deactivates a part of comfort function.

B2461 VHCL SPEED SIGNAL Stops the operation in the conditions as per the following.

During emergency brake operation

When ABS continuously operates

When lateral slippage during cornering occurs

When steering wheel is rotated for emergency

When the vehicle inclined excessively

When comfort function operates

B2463 ROLLOVER SIGNAL Stops the operation in the conditions as per the following.

When the vehicle inclined excessively

A part or the whole comfort function

B2466 DR/AS CONTROL UNIT Deactivates a part of comfort function.

B2470 SYS HEAT PROTC DR Fully deactivates the whole operation.

Operation return

- 1 time operation becomes possible after approximately 30 seconds

- Returns to the initial condition after approximately 8 minutes

Revision: 2010 May2011 QX56

Page 4308 of 5598

DIAGNOSIS SYSTEM (PRE-CRASH SEAT BELT)SBC-11

< SYSTEM DESCRIPTION >

C

DE

F

G

I

J

K L

M A

B

SBC

N

O P

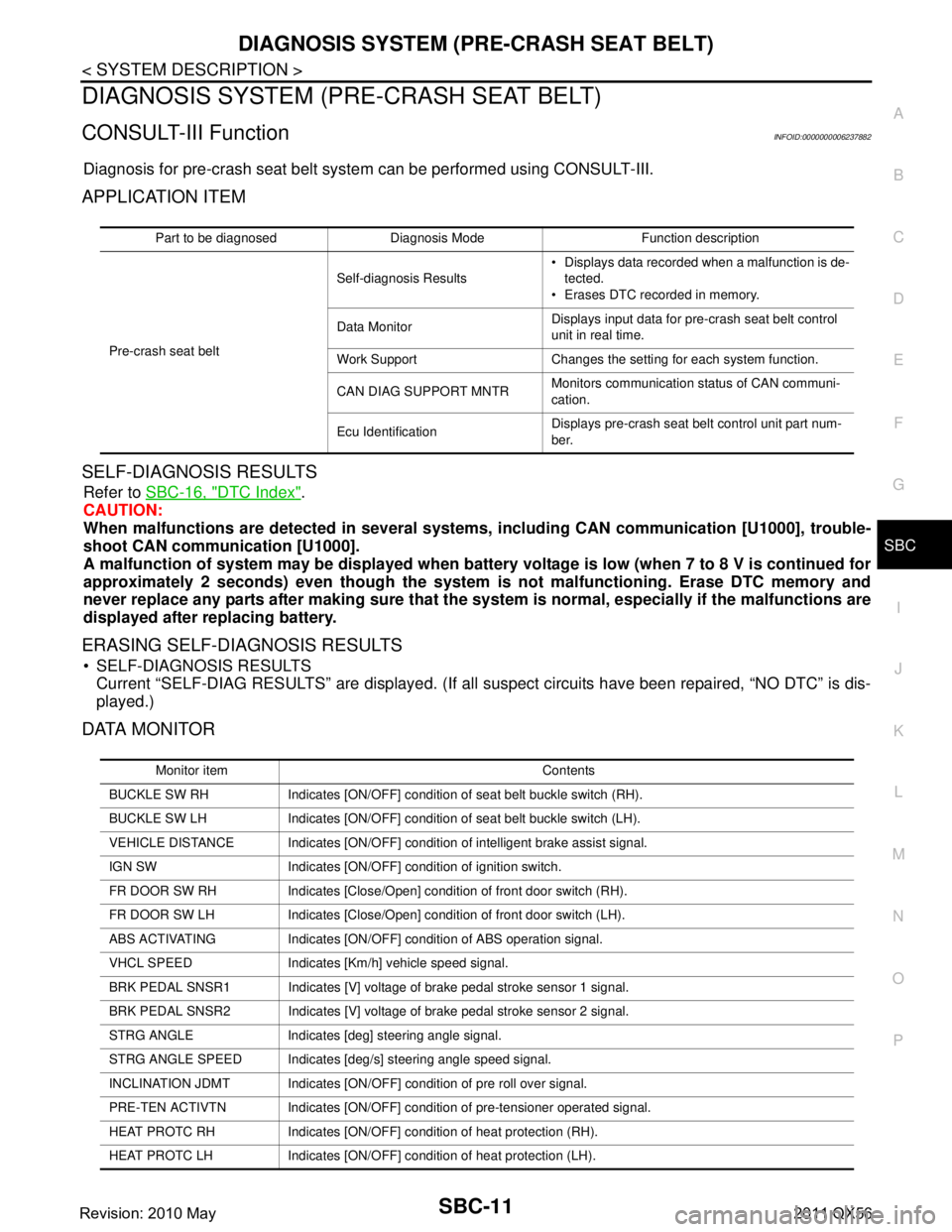

DIAGNOSIS SYSTEM (P RE-CRASH SEAT BELT)

CONSULT-III FunctionINFOID:0000000006237882

Diagnosis for pre-crash seat belt syst em can be performed using CONSULT-III.

APPLICATION ITEM

SELF-DIAGNOSIS RESULTS

Refer to SBC-16, "DTC Index".

CAUTION:

When malfunctions are detect ed in several systems, includin g CAN communication [U1000], trouble-

shoot CAN communication [U1000].

A malfunction of system may be disp layed when battery voltage is low (when 7 to 8 V is continued for

approximately 2 seconds) even though the system is not malfunctioning. Erase DTC memory and

never replace any parts after making sure that the syst em is normal, especially if the malfunctions are

displayed after replacing battery.

ERASING SELF-DIAGNOSIS RESULTS

SELF-DIAGNOSIS RESULTS Current “SELF-DIAG RESULTS” are displayed. (If all suspect circuits have been repaired, “NO DTC” is dis-

played.)

DATA MONITOR

Part to be diagnosed Diagnosis Mode Function description

Pre-crash seat belt Self-diagnosis Results

Displays data recorded when a malfunction is de-

tected.

Erases DTC recorded in memory.

Data Monitor Displays input data for pre-crash seat belt control

unit in real time.

Work Support Changes the setting for each system function.

CAN DIAG SUPPORT MNTR Monitors communication status of CAN communi-

cation.

Ecu Identification Displays pre-crash seat belt control unit part num-

ber.

Monitor item Contents

BUCKLE SW RH Indicates [ON/OFF] condition of seat belt buckle switch (RH).

BUCKLE SW LH Indicates [ON/OFF] condition of seat belt buckle switch (LH).

VEHICLE DISTANCE Indicates [ON/OFF] condit ion of intelligent brake assist signal.

IGN SW Indicates [ON/OFF] condition of ignition switch.

FR DOOR SW RH Indicates [Close/Open] condition of front door switch (RH).

FR DOOR SW LH Indicates [Close/Open] condition of front door switch (LH).

ABS ACTIVATING Indicates [ON/OFF] co ndition of ABS operation signal.

VHCL SPEED Indicates [Km/h] vehicle speed signal.

BRK PEDAL SNSR1 Indicates [V] voltage of brake pedal stroke sensor 1 signal.

BRK PEDAL SNSR2 Indicates [V] voltage of brake pedal stroke sensor 2 signal.

STRG ANGLE Indicates [deg] steering angle signal.

STRG ANGLE SPEED Indicates [deg/s] steering angle speed signal.

INCLINATION JDMT Indicates [ON/OFF] condition of pre roll over signal.

PRE-TEN ACTIVTN Indicates [ON/OFF] condition of pre-tensioner operated signal.

HEAT PROTC RH Indicates [ON/OFF] condition of heat protection (RH).

HEAT PROTC LH Indicates [ON/OFF] condition of heat protection (LH).

Revision: 2010 May2011 QX56

Page 4312 of 5598

PRE-CRASH SEAT BELT CONTROL UNIT (DRIVER SIDE)SBC-15

< ECU DIAGNOSIS INFORMATION >

C

DE

F

G

I

J

K L

M A

B

SBC

N

O P

*1: The deactivation mode differs depending on the internal malfunctioning condition of control unit Display contents of CONSULT-III Fail-safe

U0126 STRG ANG SEN SIG Stops the operation in the conditions as per the following.

When lateral slippage during cornering occurs

When steering wheel is rotated for emergency

A part of comfort function

U0428 STRG ANGL CAL Stops the operation in the conditions as per the following.

When lateral slippage during cornering occurs

When steering wheel is rotated for emergency

A part of comfort function

U1000 CAN communication circuit Stops the operation in the conditions as per the following. *

1

During emergency brake operation

When ABS continuously operates

When lateral slippage during cornering occurs

When Intelligent brake assistance operates

When steering wheel is rotated for emergency

When the vehicle inclined excessively

A part or the whole comfort function

B2451 SEAT BLT MTR DR CIRC Fully deactivates the whole operation.

B2452 SEAT BLT MTR AS CIRC Deactivate s a part of comfort function.

B2453 BR_STROKE_SEN_CIRC Stops the operation in the conditions as per the following.

During emergency brake operation

When ABS continuously operates

A part of comfort function

B2454 SEAT BLT PWR DR CIRC Fully deactivates the whole operation.

B2455 CONTROL UNIT DR Stops the operation in the conditions as per the following. *

1

During emergency brake operation

When ABS continuously operates

When lateral slippage during cornering occurs

When Intelligent brake assistance operates

When steering wheel is rotated for emergency

When the vehicle inclined excessively

A part or the whole comfort function

B2456 SEAT BLT PWR AS Deactivates a part of comfort function.

B2457 CONTROL UNIT AS Deactivates a part of comfort function.

B2458 LOCAL COMM Deactivates a part of comfort function.

B2461 VHCL SPEED SIGNAL Stops the operation in the conditions as per the following.

During emergency brake operation

When ABS continuously operates

When lateral slippage during cornering occurs

When steering wheel is rotated for emergency

When the vehicle inclined excessively

When comfort function operates

B2463 ROLLOVER SIGNAL Stops the operation in the conditions as per the following.

When the vehicle inclined excessively

A part or the whole comfort function

B2466 DR/AS CONTROL UNIT Deactivates a part of comfort function.

B2470 SYS HEAT PROTC DR Fully deactivates the whole operation.

Operation return

- 1 time operation becomes possible after approximately 30 seconds

- Returns to the initial condition after approximately 8 minutes

Revision: 2010 May2011 QX56