ground INFINITI QX56 2011 Factory Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2011, Model line: QX56, Model: INFINITI QX56 2011Pages: 5598, PDF Size: 94.53 MB

Page 3423 of 5598

LAN

LAN-3

C

DE

F

G H

I

J

K L

B

A

O P

N

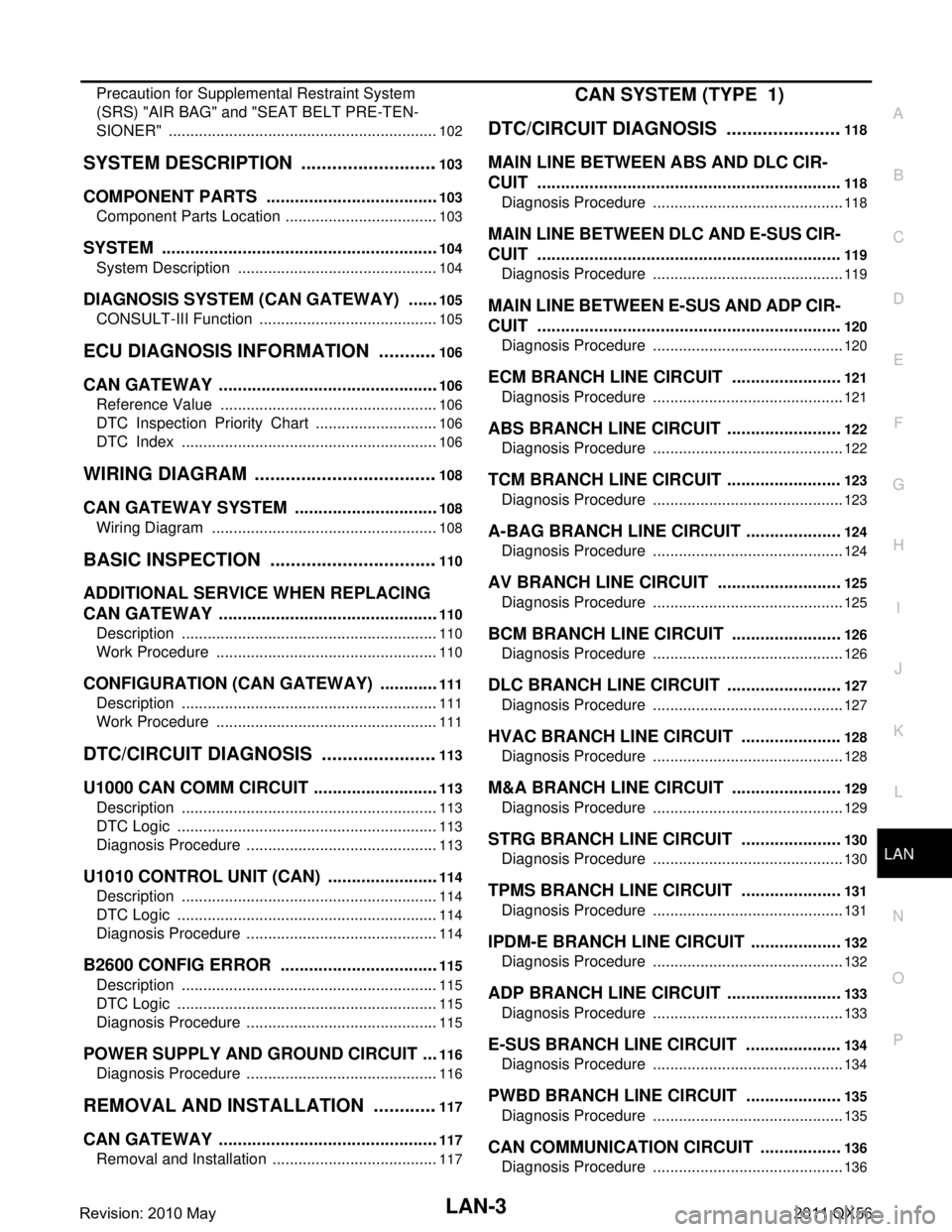

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" .............................................................

..

102

SYSTEM DESCRIPTION ...........................103

COMPONENT PARTS ................................... ..103

Component Parts Location .................................. ..103

SYSTEM ...........................................................104

System Description ............................................. ..104

DIAGNOSIS SYSTEM (CAN GATEWAY) .......105

CONSULT-III Function ........................................ ..105

ECU DIAGNOSIS INFORMATION ............106

CAN GATEWAY ............................................. ..106

Reference Value ................................................. ..106

DTC Inspection Priority Chart .............................106

DTC Index ............................................................106

WIRING DIAGRAM ....................................108

CAN GATEWAY SYSTEM ............................. ..108

Wiring Diagram ................................................... ..108

BASIC INSPECTION .................................110

ADDITIONAL SERVICE WHEN REPLACING

CAN GATEWAY ............................................. ..

110

Description .......................................................... ..110

Work Procedure ....................................................110

CONFIGURATION (CAN GATEWAY) .............111

Description .......................................................... ..111

Work Procedure ....................................................111

DTC/CIRCUIT DIAGNOSIS .......................113

U1000 CAN COMM CIRCUIT ......................... ..113

Description .......................................................... ..113

DTC Logic .............................................................113

Diagnosis Procedure .............................................113

U1010 CONTROL UNIT (CAN) ........................114

Description .......................................................... ..114

DTC Logic .............................................................114

Diagnosis Procedure .............................................114

B2600 CONFIG ERROR ..................................115

Description .......................................................... ..115

DTC Logic .............................................................115

Diagnosis Procedure .............................................115

POWER SUPPLY AND GROUND CIRCUIT ....116

Diagnosis Procedure ........................................... ..116

REMOVAL AND INSTALLATION .............117

CAN GATEWAY ............................................. ..117

Removal and Installation ..................................... ..117

CAN SYSTEM (TYPE 1)

DTC/CIRCUIT DIAGNOSIS .......................

118

MAIN LINE BETWEEN ABS AND DLC CIR-

CUIT ................................................................

118

Diagnosis Procedure ........................................... ..118

MAIN LINE BETWEEN DLC AND E-SUS CIR-

CUIT ................................................................

119

Diagnosis Procedure .............................................119

MAIN LINE BETWEEN E-SUS AND ADP CIR-

CUIT ................................................................

120

Diagnosis Procedure .............................................120

ECM BRANCH LINE CIRCUIT .......................121

Diagnosis Procedure .............................................121

ABS BRANCH LINE CIRCUIT ........................122

Diagnosis Procedure .............................................122

TCM BRANCH LINE CIRCUIT ........................123

Diagnosis Procedure .............................................123

A-BAG BRANCH LINE CIRCUIT ....................124

Diagnosis Procedure .............................................124

AV BRANCH LINE CIRCUIT ..........................125

Diagnosis Procedure .............................................125

BCM BRANCH LINE CIRCUIT .......................126

Diagnosis Procedure .............................................126

DLC BRANCH LINE CIRCUIT ........................127

Diagnosis Procedure .............................................127

HVAC BRANCH LINE CIRCUIT .....................128

Diagnosis Procedure .............................................128

M&A BRANCH LINE CIRCUIT .......................129

Diagnosis Procedure .............................................129

STRG BRANCH LINE CIRCUIT .....................130

Diagnosis Procedure .............................................130

TPMS BRANCH LINE CIRCUIT .....................131

Diagnosis Procedure .............................................131

IPDM-E BRANCH LINE CIRCUIT ...................132

Diagnosis Procedure .............................................132

ADP BRANCH LINE CIRCUIT ........................133

Diagnosis Procedure .............................................133

E-SUS BRANCH LINE CIRCUIT ....................134

Diagnosis Procedure .............................................134

PWBD BRANCH LINE CIRCUIT ....................135

Diagnosis Procedure .............................................135

CAN COMMUNICATION CIRCUIT .................136

Diagnosis Procedure .............................................136

Revision: 2010 May2011 QX56

Page 3431 of 5598

![INFINITI QX56 2011 Factory Service Manual

LAN

TROUBLE DIAGNOSISLAN-11

< SYSTEM DESCRIPTION > [CAN FUNDAMENTAL]

C

D

E

F

G H

I

J

K L

B A

O P

N

TROUBLE DIAGNOSIS

Condition of Error DetectionINFOID:0000000006220517

DTC of CAN communication is in INFINITI QX56 2011 Factory Service Manual

LAN

TROUBLE DIAGNOSISLAN-11

< SYSTEM DESCRIPTION > [CAN FUNDAMENTAL]

C

D

E

F

G H

I

J

K L

B A

O P

N

TROUBLE DIAGNOSIS

Condition of Error DetectionINFOID:0000000006220517

DTC of CAN communication is in](/img/42/57033/w960_57033-3430.png)

LAN

TROUBLE DIAGNOSISLAN-11

< SYSTEM DESCRIPTION > [CAN FUNDAMENTAL]

C

D

E

F

G H

I

J

K L

B A

O P

N

TROUBLE DIAGNOSIS

Condition of Error DetectionINFOID:0000000006220517

DTC of CAN communication is indicated on SELF-DIA

G RESULTS on CONSULT-III if a CAN communication

signal is not transmitted or received between units for 2 seconds or more.

NOTE:

DTCs of CAN communication are as follows:

U0101

U0140

U0164

U1000

U1001

U1507

U1508

CAN COMMUNICATION SYSTEM ERROR

CAN communication line open (CAN-H, CAN-L, or both)

CAN communication line short (ground, betw een CAN communication lines, other harnesses)

Error of CAN communication control circuit of the unit connected to CAN communication line

WHEN DTC OF CAN COMMUNICATION IS I NDICATED EVEN THOUGH CAN COMMUNICATION

SYSTEM IS NORMAL

Removal/installation of parts: Error may be detec ted when removing and installing CAN communication unit

and related parts while turning the ignition switch ON. (A DTC except for CAN communication may be

detected.)

Fuse blown out (removed): CAN communication of the unit may cease.

Voltage drop: Error may be detected if voltage drops due to discharged battery when turning the ignition

switch ON (Depending on the control unit which carries out CAN communication).

Error may be detected if the power supply circuit of the control unit, which carries out CAN communication,

malfunctions (Depending on the control unit which carries out CAN communication).

Error may be detected if reprogramming is not completed normally.

CAUTION:

CAN communication system is normal if DTC of CAN communication is indicated on SELF-DIAG

RESULTS of CONSULT-III under th e above conditions. Erase the memo ry of the self-diagnosis of each

unit.

Symptom When Error Occurs in CAN Communication SystemINFOID:0000000006220518

In CAN communication system, multiple units mutually transmit and receive signals. Each unit cannot transmit

and receive signals if any error occurs on CAN communicati on line. Under this condition, multiple control units

related to the root cause malfunction or go into fail-safe mode.

ERROR EXAMPLE

NOTE:

Each vehicle differs in symptom of each unit under fail-safe mode and CAN communication line wiring.

Refer to LAN-23, "

Abbreviation List" for the unit abbreviation.

Revision: 2010 May2011 QX56

Page 3488 of 5598

![INFINITI QX56 2011 Factory Service Manual

LAN-68

< DTC/CIRCUIT DIAGNOSIS >[CAN]

ECM BRANCH LINE CIRCUIT

ECM BRANCH LINE CIRCUIT

Diagnosis ProcedureINFOID:0000000006220544

1.CHECK CONNECTOR

1. Turn the ignition switch OFF.

2. Disconnect the b INFINITI QX56 2011 Factory Service Manual

LAN-68

< DTC/CIRCUIT DIAGNOSIS >[CAN]

ECM BRANCH LINE CIRCUIT

ECM BRANCH LINE CIRCUIT

Diagnosis ProcedureINFOID:0000000006220544

1.CHECK CONNECTOR

1. Turn the ignition switch OFF.

2. Disconnect the b](/img/42/57033/w960_57033-3487.png)

LAN-68

< DTC/CIRCUIT DIAGNOSIS >[CAN]

ECM BRANCH LINE CIRCUIT

ECM BRANCH LINE CIRCUIT

Diagnosis ProcedureINFOID:0000000006220544

1.CHECK CONNECTOR

1. Turn the ignition switch OFF.

2. Disconnect the battery cable from the negative terminal.

3. Check the terminals and connectors of the ECM for damage, bend and loose connection (unit side and connector side).

Is the inspection result normal?

YES >> GO TO 2.

NO >> Repair the terminal and connector.

2.CHECK HARNESS FOR OPEN CIRCUIT

1. Disconnect the connector of ECM.

2. Check the resistance between the ECM harness connector terminals.

Is the measurement value within the specification?

YES >> GO TO 3.

NO >> Repair the ECM branch line.

3.CHECK POWER SUPPLY AND GROUND CIRCUIT

Check the power supply and the ground circuit of the ECM. Refer to EC-168, "

Diagnosis Procedure".

Is the inspection result normal?

YES (Present error)>>Replace the ECM. Refer to EC-535, "Removal and Installation".

YES (Past error)>>Error was detected in the ECM branch line.

NO >> Repair the power supply and the ground circuit.

ECM harness connector Resistance (Ω)

Connector No. Terminal No.

E80 146 151 Approx. 108 – 132

Revision: 2010 May2011 QX56

Page 3489 of 5598

![INFINITI QX56 2011 Factory Service Manual

LAN

4WD BRANCH LINE CIRCUITLAN-69

< DTC/CIRCUIT DIAGNOSIS > [CAN]

C

D

E

F

G H

I

J

K L

B A

O P

N

4WD BRANCH LINE CIRCUIT

Diagnosis ProcedureINFOID:0000000006220545

1.CHECK CONNECTOR

1. Turn the igniti INFINITI QX56 2011 Factory Service Manual

LAN

4WD BRANCH LINE CIRCUITLAN-69

< DTC/CIRCUIT DIAGNOSIS > [CAN]

C

D

E

F

G H

I

J

K L

B A

O P

N

4WD BRANCH LINE CIRCUIT

Diagnosis ProcedureINFOID:0000000006220545

1.CHECK CONNECTOR

1. Turn the igniti](/img/42/57033/w960_57033-3488.png)

LAN

4WD BRANCH LINE CIRCUITLAN-69

< DTC/CIRCUIT DIAGNOSIS > [CAN]

C

D

E

F

G H

I

J

K L

B A

O P

N

4WD BRANCH LINE CIRCUIT

Diagnosis ProcedureINFOID:0000000006220545

1.CHECK CONNECTOR

1. Turn the ignition switch OFF.

2. Disconnect the battery cabl e from the negative terminal.

3. Check the terminals and connectors of the trans fer control unit for damage, bend and loose connection

(unit side and connector side).

Is the inspection result normal?

YES >> GO TO 2.

NO >> Repair the terminal and connector.

2.CHECK HARNESS FOR OPEN CIRCUIT

1. Disconnect the connector of transfer control unit.

2. Check the resistance between the transfe r control unit harness connector terminals.

Is the measurement value within the specification?

YES >> GO TO 3.

NO >> Repair the transfer control unit branch line.

3.CHECK POWER SUPPLY AND GROUND CIRCUIT

Check the power supply and the ground circuit of the transfer control unit. Refer to DLN-93, "

Diagnosis Proce-

dure".

Is the inspection result normal?

YES (Present error)>>Replace the transfer control unit. Refer to DLN-107, "Removal and Installation".

YES (Past error)>>Error was detected in the transfer control unit branch line.

NO >> Repair the power supply and the ground circuit.

Transfer control unit harness connector Resistance (Ω)

Connector No. Terminal No.

E59 12 13 Approx. 54 – 66

Revision: 2010 May2011 QX56

Page 3490 of 5598

![INFINITI QX56 2011 Factory Service Manual

LAN-70

< DTC/CIRCUIT DIAGNOSIS >[CAN]

ABS BRANCH LINE CIRCUIT

ABS BRANCH LINE CIRCUIT

Diagnosis ProcedureINFOID:0000000006220546

1.CHECK CONNECTOR

1. Turn the ignition switch OFF.

2. Disconnect the b INFINITI QX56 2011 Factory Service Manual

LAN-70

< DTC/CIRCUIT DIAGNOSIS >[CAN]

ABS BRANCH LINE CIRCUIT

ABS BRANCH LINE CIRCUIT

Diagnosis ProcedureINFOID:0000000006220546

1.CHECK CONNECTOR

1. Turn the ignition switch OFF.

2. Disconnect the b](/img/42/57033/w960_57033-3489.png)

LAN-70

< DTC/CIRCUIT DIAGNOSIS >[CAN]

ABS BRANCH LINE CIRCUIT

ABS BRANCH LINE CIRCUIT

Diagnosis ProcedureINFOID:0000000006220546

1.CHECK CONNECTOR

1. Turn the ignition switch OFF.

2. Disconnect the battery cable from the negative terminal.

3. Check the terminals and connectors of the ABS act uator and electric unit (control unit) for damage, bend

and loose connection (unit side and connector side).

Is the inspection result normal?

YES >> GO TO 2.

NO >> Repair the terminal and connector.

2.CHECK HARNESS FOR OPEN CIRCUIT

1. Disconnect the connector of ABS actuat or and electric unit (control unit).

2. Check the resistance between the ABS actuator and electric unit (control unit) harness connector termi-

nals.

Is the measurement value within the specification?

YES >> GO TO 3.

NO >> Repair the ABS actuator and electric unit (control unit) branch line.

3.CHECK POWER SUPPLY AND GROUND CIRCUIT

Check the power supply and the ground circuit of the AB S actuator and electric unit (control unit). Refer to

BRC-113, "

Diagnosis Procedure".

Is the inspection result normal?

YES (Present error)>>Replace the ABS actuator and electric unit (control unit). Refer to BRC-137, "Removal

and Installation".

YES (Past error)>>Error was detected in the ABS ac tuator and electric unit (control unit) branch line.

NO >> Repair the power supply and the ground circuit.

ABS actuator and electric unit (c ontrol unit) harness connector

Resistance (Ω)

Connector No. Terminal No.

E36 41 27 Approx. 54 – 66

Revision: 2010 May2011 QX56

Page 3491 of 5598

![INFINITI QX56 2011 Factory Service Manual

LAN

TCM BRANCH LINE CIRCUITLAN-71

< DTC/CIRCUIT DIAGNOSIS > [CAN]

C

D

E

F

G H

I

J

K L

B A

O P

N

TCM BRANCH LINE CIRCUIT

Diagnosis ProcedureINFOID:0000000006220547

1.CHECK CONNECTOR

1. Turn the igniti INFINITI QX56 2011 Factory Service Manual

LAN

TCM BRANCH LINE CIRCUITLAN-71

< DTC/CIRCUIT DIAGNOSIS > [CAN]

C

D

E

F

G H

I

J

K L

B A

O P

N

TCM BRANCH LINE CIRCUIT

Diagnosis ProcedureINFOID:0000000006220547

1.CHECK CONNECTOR

1. Turn the igniti](/img/42/57033/w960_57033-3490.png)

LAN

TCM BRANCH LINE CIRCUITLAN-71

< DTC/CIRCUIT DIAGNOSIS > [CAN]

C

D

E

F

G H

I

J

K L

B A

O P

N

TCM BRANCH LINE CIRCUIT

Diagnosis ProcedureINFOID:0000000006220547

1.CHECK CONNECTOR

1. Turn the ignition switch OFF.

2. Disconnect the battery cabl e from the negative terminal.

3. Check the following terminals and connectors for damage, bend and loose connection (unit side and con- nector side).

- A/T assembly

- Harness connector F1

- Harness connector E7

Is the inspection result normal?

YES >> GO TO 2.

NO >> Repair the terminal and connector.

2.CHECK HARNESS FOR OPEN CIRCUIT

1. Disconnect the connector of A/T assembly.

2. Check the resistance between the A/T assembly harness connector terminals.

Is the measurement value within the specification?

YES >> GO TO 3.

NO >> Repair the TCM branch line.

3.CHECK HARNESS FOR OPEN CIRCUIT

1. Remove the joint connector. Refer to TM-182, "

Removal and Installation".

2. Check the continuity between the A/T assembly harness connector side and the TCM harness connector

side of the joint connector.

Is the inspection result normal?

YES >> GO TO 4.

NO >> Replace the joint connector.

4.CHECK POWER SUPPLY AND GROUND CIRCUIT

Check the power supply and the ground circuit of the TCM. Refer to TM-151, "

Diagnosis Procedure".

Is the inspection result normal?

YES (Present error)>>Replace the control valve & TCM. Refer to TM-182, "Removal and Installation".

YES (Past error)>>Error was detected in the TCM branch line.

NO >> Repair the power supply and the ground circuit.

A/T assembly harness connector Resistance (Ω)

Connector No. Terminal No.

F51 3 8 Approx. 54 – 66

A/T assembly harness connector side TCM harness connector side Continuity

Terminal No. Terminal No.

33Existed

88Existed

Revision: 2010 May2011 QX56

Page 3493 of 5598

![INFINITI QX56 2011 Factory Service Manual

LAN

AFS BRANCH LINE CIRCUITLAN-73

< DTC/CIRCUIT DIAGNOSIS > [CAN]

C

D

E

F

G H

I

J

K L

B A

O P

N

AFS BRANCH LINE CIRCUIT

Diagnosis ProcedureINFOID:0000000006220549

1.CHECK CONNECTOR

1. Turn the igniti INFINITI QX56 2011 Factory Service Manual

LAN

AFS BRANCH LINE CIRCUITLAN-73

< DTC/CIRCUIT DIAGNOSIS > [CAN]

C

D

E

F

G H

I

J

K L

B A

O P

N

AFS BRANCH LINE CIRCUIT

Diagnosis ProcedureINFOID:0000000006220549

1.CHECK CONNECTOR

1. Turn the igniti](/img/42/57033/w960_57033-3492.png)

LAN

AFS BRANCH LINE CIRCUITLAN-73

< DTC/CIRCUIT DIAGNOSIS > [CAN]

C

D

E

F

G H

I

J

K L

B A

O P

N

AFS BRANCH LINE CIRCUIT

Diagnosis ProcedureINFOID:0000000006220549

1.CHECK CONNECTOR

1. Turn the ignition switch OFF.

2. Disconnect the battery cabl e from the negative terminal.

3. Check the terminals and connectors of the AFS c ontrol unit for damage, bend and loose connection (unit

side and connector side).

Is the inspection result normal?

YES >> GO TO 2.

NO >> Repair the terminal and connector.

2.CHECK HARNESS FOR OPEN CIRCUIT

1. Disconnect the connector of AFS control unit.

2. Check the resistance between the AFS control unit harness connector terminals.

Is the measurement value within the specification?

YES >> GO TO 3.

NO >> Repair the AFS control unit branch line.

3.CHECK POWER SUPPLY AND GROUND CIRCUIT

Check the power supply and the ground circui t of the AFS control unit. Refer to EXL-84, "

AFS CONTROL

UNIT : Diagnosis Procedure".

Is the inspection result normal?

YES (Present error)>>Replace the AFS control unit. Refer to EXL-135, "Removal and Installation".

YES (Past error)>>Error was detected in the AFS control unit branch line.

NO >> Repair the power supply and the ground circuit.

AFS control unit harness connector Resistance (Ω)

Connector No. Terminal No.

M135 30 7 Approx. 54 – 66

Revision: 2010 May2011 QX56

Page 3494 of 5598

![INFINITI QX56 2011 Factory Service Manual

LAN-74

< DTC/CIRCUIT DIAGNOSIS >[CAN]

AV BRANCH LINE CIRCUIT

AV BRANCH LINE CIRCUIT

Diagnosis ProcedureINFOID:0000000006220550

1.CHECK CONNECTOR

1. Turn the ignition switch OFF.

2. Disconnect the bat INFINITI QX56 2011 Factory Service Manual

LAN-74

< DTC/CIRCUIT DIAGNOSIS >[CAN]

AV BRANCH LINE CIRCUIT

AV BRANCH LINE CIRCUIT

Diagnosis ProcedureINFOID:0000000006220550

1.CHECK CONNECTOR

1. Turn the ignition switch OFF.

2. Disconnect the bat](/img/42/57033/w960_57033-3493.png)

LAN-74

< DTC/CIRCUIT DIAGNOSIS >[CAN]

AV BRANCH LINE CIRCUIT

AV BRANCH LINE CIRCUIT

Diagnosis ProcedureINFOID:0000000006220550

1.CHECK CONNECTOR

1. Turn the ignition switch OFF.

2. Disconnect the battery cable from the negative terminal.

3. Check the following terminals and connectors fo r damage, bend and loose connection (unit side and con-

nector side).

- AV control unit

- Harness connector M222

- Harness connector M119

Is the inspection result normal?

YES >> GO TO 2.

NO >> Repair the terminal and connector.

2.CHECK HARNESS FOR OPEN CIRCUIT

1. Disconnect the connector of AV control unit.

2. Check the resistance between the AV control unit harness connector terminals.

Is the measurement value within the specification?

YES >> GO TO 3.

NO >> Repair the AV control unit branch line.

3.CHECK POWER SUPPLY AND GROUND CIRCUIT

Check the power supply and the ground circuit of the AV control unit. Refer to AV-161, "

AV CONTROL UNIT :

Diagnosis Procedure".

Is the inspection result normal?

YES (Present error)>>Replace the AV control unit. Refer to AV-212, "Removal and Installation".

YES (Past error)>>Error was detected in the AV control unit branch line.

NO >> Repair the power supply and the ground circuit.

AV control unit harness connector Resistance (Ω)

Connector No. Terminal No.

M210 90 74 Approx. 54 – 66

Revision: 2010 May2011 QX56

Page 3495 of 5598

![INFINITI QX56 2011 Factory Service Manual

LAN

BCM BRANCH LINE CIRCUITLAN-75

< DTC/CIRCUIT DIAGNOSIS > [CAN]

C

D

E

F

G H

I

J

K L

B A

O P

N

BCM BRANCH LINE CIRCUIT

Diagnosis ProcedureINFOID:0000000006220551

1.CHECK CONNECTOR

1. Turn the igniti INFINITI QX56 2011 Factory Service Manual

LAN

BCM BRANCH LINE CIRCUITLAN-75

< DTC/CIRCUIT DIAGNOSIS > [CAN]

C

D

E

F

G H

I

J

K L

B A

O P

N

BCM BRANCH LINE CIRCUIT

Diagnosis ProcedureINFOID:0000000006220551

1.CHECK CONNECTOR

1. Turn the igniti](/img/42/57033/w960_57033-3494.png)

LAN

BCM BRANCH LINE CIRCUITLAN-75

< DTC/CIRCUIT DIAGNOSIS > [CAN]

C

D

E

F

G H

I

J

K L

B A

O P

N

BCM BRANCH LINE CIRCUIT

Diagnosis ProcedureINFOID:0000000006220551

1.CHECK CONNECTOR

1. Turn the ignition switch OFF.

2. Disconnect the battery cabl e from the negative terminal.

3. Check the terminals and connectors of the BC M for damage, bend and loose connection (unit side and

connector side).

Is the inspection result normal?

YES >> GO TO 2.

NO >> Repair the terminal and connector.

2.CHECK HARNESS FOR OPEN CIRCUIT

1. Disconnect the connector of BCM.

2. Check the resistance between the BCM harness connector terminals.

Is the measurement value within the specification?

YES >> GO TO 3.

NO >> Repair the BCM branch line.

3.CHECK POWER SUPPLY AND GROUND CIRCUIT

Check the power supply and the ground circuit of the BCM. Refer to BCS-75, "

Diagnosis Procedure".

Is the inspection result normal?

YES (Present error)>>Replace the BCM. Refer to BCS-81, "Removal and Installation".

YES (Past error)>>Error was detected in the BCM branch line.

NO >> Repair the power supply and the ground circuit.

BCM harness connector Resistance (Ω)

Connector No. Terminal No.

M68 39 40 Approx. 54 – 66

Revision: 2010 May2011 QX56

Page 3496 of 5598

![INFINITI QX56 2011 Factory Service Manual

LAN-76

< DTC/CIRCUIT DIAGNOSIS >[CAN]

CGW BRANCH LINE CIRCUIT (CAN

COMMUNICATION CIRCUIT 1)

CGW BRANCH LINE CIRCUIT (CAN COMMUNICATION CIRCUIT 1)

Diagnosis ProcedureINFOID:0000000006220552

1.CHECK D INFINITI QX56 2011 Factory Service Manual

LAN-76

< DTC/CIRCUIT DIAGNOSIS >[CAN]

CGW BRANCH LINE CIRCUIT (CAN

COMMUNICATION CIRCUIT 1)

CGW BRANCH LINE CIRCUIT (CAN COMMUNICATION CIRCUIT 1)

Diagnosis ProcedureINFOID:0000000006220552

1.CHECK D](/img/42/57033/w960_57033-3495.png)

LAN-76

< DTC/CIRCUIT DIAGNOSIS >[CAN]

CGW BRANCH LINE CIRCUIT (CAN

COMMUNICATION CIRCUIT 1)

CGW BRANCH LINE CIRCUIT (CAN COMMUNICATION CIRCUIT 1)

Diagnosis ProcedureINFOID:0000000006220552

1.CHECK DTC

Check DTC of the CAN gateway with CONSULT-III.

Is U1010 or B2600 indicated?

YES >> Perform a diagnosis of the indicated DTC.

NO >> GO TO 2.

2.CHECK CONNECTOR

1. Turn the ignition switch OFF.

2. Disconnect the battery cable from the negative terminal.

3. Check the terminals and connectors of the CAN gateway for damage, bend and loose connection (unit side and connector side).

Is the inspection result normal?

YES >> GO TO 3.

NO >> Repair the terminal and connector.

3.CHECK HARNESS FOR OPEN CIRCUIT

1. Disconnect the connector of CAN gateway.

2. Check the resistance between the CAN gateway harness connector terminals.

Is the measurement value within the specification?

YES >> GO TO 4.

NO >> Repair the CAN gateway branch line (CAN communication circuit 1). Refer to LAN-57, "

System

Diagram".

4.CHECK POWER SUPPLY AND GROUND CIRCUIT

Check the power supply and the ground circ uit of the CAN gateway. Refer to LAN-116, "

Diagnosis Procedure".

Is the inspection result normal?

YES (Present error)>>Replace the CAN gateway. Refer to LAN-117, "Removal and Installation".

YES (Past error)>>Error was detected in the CAN gateway branch line (CAN communication circuit 1).

NO >> Repair the power supply and the ground circuit.

CAN gateway harness connector Resistance (Ω)

Connector No. Terminal No.

M125 1 7 Approx. 54 – 66

Revision: 2010 May2011 QX56