window INFINITI QX56 2011 Factory Manual PDF

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2011, Model line: QX56, Model: INFINITI QX56 2011Pages: 5598, PDF Size: 94.53 MB

Page 1549 of 5598

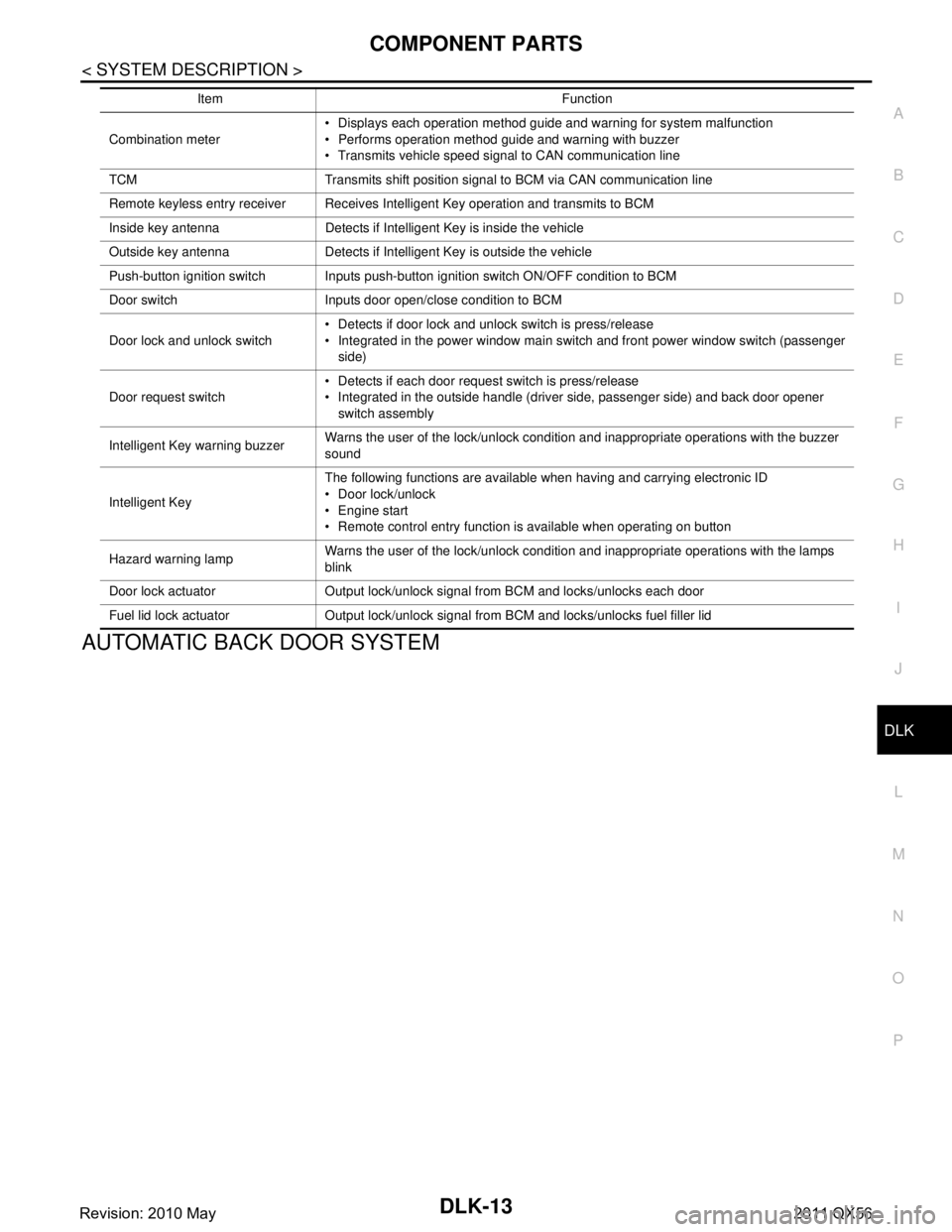

COMPONENT PARTSDLK-13

< SYSTEM DESCRIPTION >

C

DE

F

G H

I

J

L

M A

B

DLK

N

O P

AUTOMATIC BACK DOOR SYSTEM

Combination meter Displays each operation method guide and warning for system malfunction

Performs operation method guide and warning with buzzer

Transmits vehicle speed signal to CAN communication line

TCM Transmits shift position signal to BCM via CAN communication line

Remote keyless entry receiver Receives Intelligent Key operation and transmits to BCM

Inside key antenna Detects if Intelligent Key is inside the vehicle

Outside key antenna Detects if Intelligent Key is outside the vehicle

Push-button ignition switch Inputs push-button ignition switch ON/OFF condition to BCM

Door switch Inputs door open/close condition to BCM

Door lock and unlock switch Detects if door lock and unlock switch is press/release

Integrated in the power window main switch and front power window switch (passenger

side)

Door request switch Detects if each door request switch is press/release

Integrated in the outside handle (driver side, passenger side) and back door opener

switch assembly

Intelligent Key warning buzzer Warns the user of the lock/unlock condition and inappropriate operations with the buzzer

sound

Intelligent Key The following functions are available when having and carrying electronic ID

Door lock/unlock

Engine start

Remote control entry function is available when operating on button

Hazard warning lamp Warns the user of the lock/unlock condition and inappropriate operations with the lamps

blink

Door lock actuator Output lock/unlock signal from BCM and locks/unlocks each door

Fuel lid lock actuator Output lock/unlock signal from BCM and locks/unlocks fuel filler lid Item Function

Revision: 2010 May2011 QX56

Page 1552 of 5598

DLK-16

< SYSTEM DESCRIPTION >

SYSTEM (POWER DOOR LOCK SYSTEM)

SYSTEM (POWER DOOR LOCK SYSTEM)

System DiagramINFOID:0000000006225837

System DescriptionINFOID:0000000006225838

DOOR LOCK FUNCTION

Door Lock and Unlock Switch

The door lock and unlock switch (driver side) is build into power window main switch.

The door lock and unlock switch (passenger side) is build into front power window switch (passenger side).

Interlocked with the locking operation of door lock and unlock switch, door lock actuators of all doors and

fuel lid lock actuator are locked.

Interlocked with the unlocking operation of door lock and unlock switch, door lock actuators of all doors actu-

ator and fuel lid lock actuator are unlocked.

Door Key Cylinder Switch

With the mechanical key inserted in the door key cylinder on driver side, turning it to lock position, locks door

lock actuator of all doors and fuel lid lock actuator.

With the mechanical key inserted in the door key cylinder on driver side, turning it to unlock position once

unlocks the driver side door, turning it to unlock posit ion again within 60 seconds after the first unlock opera-

tion unlocks all of the other doors actuator and fuel lid lock actuator. (SELECTIVE UNLOCK OPERATION)

Selective unlock operation mode can be changed using CONSULT-III.

Refer to DLK-39, "

DOOR LOCK : CONSULT-III Function (BCM - DOOR LOCK)".

DOOR KEY CYLINDER SWITCH POWER WINDOW FUNCTION

Driver side door key cylinder LOCK/UNLOCK oper ation can activate power window. Refer to PWC-8, "System

Description".

IGNITION POSITION WARNING FUNCTION

When door lock and unlock switch are operated while dr iver side door is open and ignition position is ACC or

ON, door locks once but immediately unlocks.

INTERIOR ROOM LAMP CONTROL FUNCTION

Interior room lamp is controlled according to door lock/unlock state, refer to INL-6, "INTERIOR ROOM LAMP

CONTROL SYSTEM : System Description".

AUTOMATIC DOOR LOCK/UNLOCK FUNCTION (LOCK OPERATION)

The interlock door lock function is the function that locks all doors linked with the vehicle speed or shift posi-

tion. It has 2 types as per the following items.

Vehicle Speed Sensing Auto Door Lock

All doors are locked when the vehicle speed reaches 24 km/h (15 MPH) or more.

BCM outputs the lock signal to all door lock actuators when it detects that the ignition switch is turned ON, all

doors are closed and the vehicle speed received from the combination meter via CAN communication

becomes 24 km/h (15 MPH) or more.

JMKIA5278GB

Revision: 2010 May2011 QX56

Page 1555 of 5598

SYSTEM (INTELLIGENT KEY SYSTEM)

DLK-19

< SYSTEM DESCRIPTION >

C

D E

F

G H

I

J

L

M A

B

DLK

N

O P

DOOR LOCK FUNCTION

DOOR LOCK FUNCTION : System DiagramINFOID:0000000006225841

DOOR LOCK FUNCTION : System DescriptionINFOID:0000000006225842

Only when pressing the door request switch, it is possi ble to lock and unlock the door by carrying the Intelli-

gent Key.

OPERATION DESCRIPTION

When the BCM detects that each door request switch is pressed, it activates the outside key antenna and

inside key antenna corresponding to the pressed door reques t switch and transmits the request signal to the

Intelligent Key. And then, check that the Intelligent Key is near the door.

If the Intelligent Key is within the outside key ant enna detection area, it receives the request signal and

transmits the key ID signal to the BCM via remote keyless entry receiver.

BCM receives the key ID signal and compares it with the registered key ID.

BCM locks/unlocks each doors (except back door).

BCM sounds Intelligent Key warning buzzer (lock: 2 ti mes, unlock: 1 time) and blinks hazard warning lamps

(lock: 2 times, unlock: 1 time) at the same time as a reminder.

Key reminder The key reminder buzzer sounds a warning if the door is locked with the key left

inside the vehicle DLK-26

Welcome lightWhen the Intelligent Key is carried, and vehicle doors are approached, the BCM

illuminates interior room lamps and operates heart beat operation of the push-

button ignition switch DLK-26

Warning

If an action that does not meet the operating condition of the Intelligent Key sys-

tem is taken, the buzzer sounds to inform the driver DLK-27

Engine start The engine can be turned on while carrying the Intelligent Key

SEC-12

Interior room lamp control Interior room lamp is controlled according to door lock/unlock state INL-6

Power window Power window can be operated by Intelligent Key button operationPWC-8

Automatic drive positioner Automatic drive positioner system can be operated by door unlock operationADP-11

Panic alarm When Intelligent Key panic alarm button is pressed, horn soundsSEC-18

Function Description Refer

JMKIA5068GB

Revision: 2010 May2011 QX56

Page 1574 of 5598

DLK-38

< SYSTEM DESCRIPTION >

DIAGNOSIS SYSTEM (BCM)

DIAGNOSIS SYSTEM (BCM)

COMMON ITEM

COMMON ITEM : CONSULT-III Function (BCM - COMMON ITEM)INFOID:0000000006307583

APPLICATION ITEM

CONSULT-III performs the following functions via CAN communication with BCM.

SYSTEM APPLICATION

BCM can perform the following functions for each system.

NOTE:

It can perform the diagnosis modes except the following for all sub system selection items.

×: Applicable item

*: This item is indicated, but not used.

FREEZE FRAME DATA (FFD)

The BCM records the following vehicle condition at the time a particular DTC is detected, and displays on

CONSULT-III.

Diagnosis mode Function Description

Work Support Changes the setting for each system function.

Self Diagnostic Result Displays the diagnosis results judged by BCM. Refer to BCS-57, "

DTCIndex".

CAN Diag Support Monitor Monitors the reception status of CAN communication viewed from BCM. Refer to CONSULT-III opera-

tion manual.

Data Monitor The BCM input/output signals are displayed.

Active Test The signals used to activate ea ch device are forcibly supplied from BCM.

Ecu Identification The BCM part number is displayed.

Configuration Read and save the vehicle specification.

Write the vehicle specification when replacing BCM.

System Sub system selection item Diagnosis mode

Work Support Data Monitor Active Test

Door lock DOOR LOCK ×××

Rear window defogger REAR DEFOGGER ××

Warning chime BUZZER ××

Interior room lamp timer INT LAMP ×××

Exterior lamp HEAD LAMP ×××

Wiper and washer WIPER ×××

Turn signal and hazard warning lamps FLASHER ×××

— AIR CONDITONER* ××

Intelligent Key system

Engine start system INTELLIGENT KEY

×××

Combination switch COMB SW ×

Body control system BCM ×

IVIS IMMU ×××

Interior room lamp battery saver BATTERY SAVER ×××

Back door TRUNK ×

Vehicle security system THEFT ALM ×××

RAP system RETAINED PWR ×

Signal buffer system SIGNAL BUFFER ××

Revision: 2010 May2011 QX56

Page 1580 of 5598

DLK-44

< SYSTEM DESCRIPTION >

DIAGNOSIS SYSTEM (BCM)

TRUNK

TRUNK : CONSULT-III Function (BCM - TRUNK)INFOID:0000000006225857

DATA MONITOR

LCD This test is able to check meter display information

Engine start information displays when “BP N” on CONSULT-III screen is touched

Engine start information displays when “BP I” on CONSULT-III screen is touched

Key ID warning displays when “ID NG” on CONSULT-III screen is touched

Steering lock information displays when “ROTAT” on CONSULT-III screen is touched

P position warning displays when “SFT P” on CONSULT-III screen is touched

INSRT: This item is displayed, but cannot be monitored

BATT: This item is displayed, but cannot be monitored

Take away through window warning displays

when “NO KY” on CONSULT-III screen is

touched

Take away warning display when “OUTKEY” on CONSULT-III screen is touched

OFF position warning display when “LK WN” on CONSULT-III screen is touched

FLASHER This test is able to check security hazard lamp operation

The hazard lamps are activated after “LH/RH/Off” on CONSULT-III screen is touched

P RANGE This test is able to check A/T shift selector power supply

On: Operate

Off: Non-operation

ENGINE SW ILLUMI This test is able to check push-button ignition switch illumination operation

Push-ignition switch illumination illuminates when “ON” on CONSULT-III screen is touched

LOCK INDICATOR This test is able to check LOCK indicato

r (push-button ignition switch) operation

On: Operate

Off: Non-operation

ACC INDICATOR This test is able to check ACC indicator (push-button ignition switch) operation

On: Operate

Off: Non-operation

IGNITION ON IND This test is able to check ON indicator (push-button ignition switch) operation

On: Operate

Off: Non-operation

HORN This test is able to check horn operation

On: Operate

Off: Non-operation

TRUNK/BACK DOOR NOTE:

This item is displayed, but cannot be used

Test item Description

Monitor Item Contents

PUSH SW Indicates [On/Off] condition of push switch

UNLK SEN -DR Indicates [On/Off] condition of unlock sensor

VEH SPEED 1 Indicates [Km/h] condition of ve hicle speed signal from combination meter

TR/BD OPEN SW Indicates [On/Off] condition of back door opener switch

TRNK/HAT MNTR NOTE:

This item is displayed, but cannot be monitored

RKE-TR/BD NOTE:

This item is displayed, but cannot be monitored

Revision: 2010 May2011 QX56

Page 1658 of 5598

DLK-122

< DTC/CIRCUIT DIAGNOSIS >

DOOR LOCK AND UNLOCK SWITCH

DOOR LOCK AND UNLOCK SWITCH

DRIVER SIDE

DRIVER SIDE : Component Function CheckINFOID:0000000006225927

1.CHECK FUNCTION

1. Select “DOOR LOCK” of “BCM” using CONSULT-III.

2. Select “CDL LOCK SW”, “CDL UNLOCK SW” in “DATA MONITOR” mode.

3. Check that the function operates normall y according to the following conditions.

Is the inspection result normal?

YES >> Door lock and unlock switch is OK.

NO >> Refer to DLK-122, "

DRIVER SIDE : Diagnosis Procedure".

DRIVER SIDE : Diagnosis ProcedureINFOID:0000000006225928

1.CHECK POWER WINDOW SWITCH

1. Turn ignition switch ON.

2. Check power window operation.

Does power window operate?

YES >> Replace power window main switch.

NO >> Refer to PWC-61, "

Diagnosis Procedure".

PASSENGER SIDE

PASSENGER SIDE : Component Function CheckINFOID:0000000006225929

1.CHECK FUNCTION

1. Select “DOOR LOCK” of “BCM” using CONSULT-III.

2. Select “CDL LOCK SW”, “CDL UNLOCK SW” in “DATA MONITOR” mode.

3. Check that the function operates normall y according to the following conditions.

Is the inspection result normal?

YES >> Door lock and unlock switch is OK.

NO >> Refer to DLK-122, "

PASSENGER SIDE : Diagnosis Procedure".

PASSENGER SIDE : Diagnosis ProcedureINFOID:0000000006225930

1.CHECK POWER WINDOW SWITCH

1. Turn ignition switch ON.

2. Check power window operation.

Does power window operate?

YES >> Replace front power window switch (passenger side).

NO >> Refer to PWC-61, "

Diagnosis Procedure".

Monitor item Condition Status

CDL LOCK SW Door lock and unlock switchLock ON

Unlock OFF

CDL UNLOCK SW Lock OFF

Unlock ON

Monitor item Condition Status

CDL LOCK SW Door lock and unlock switchLock ON

Unlock OFF

CDL UNLOCK SW Lock OFF

Unlock ON

Revision: 2010 May2011 QX56

Page 1668 of 5598

DLK-132

< DTC/CIRCUIT DIAGNOSIS >

DOOR KEY CYLINDER SWITCH

DOOR KEY CYLINDER SWITCH

Component Function CheckINFOID:0000000006225944

1.CHECK FUNCTION

1. Select “DOOR LOCK” of “BCM” using CONSULT-III.

2. Select “KEY CYL LK-SW”, “KEY CY L UN-SW” in “DATA MONITOR” mode.

3. Check that the function operates normall y according to the following conditions.

Is the inspection result normal?

YES >> Door key cylinder switch is OK.

NO >> Refer to DLK-132, "

Diagnosis Procedure".

Diagnosis ProcedureINFOID:0000000006225945

1.CHECK DOOR KEY CYLINDER SWITCH INPUT SIGNAL

1. Turn ignition switch OFF.

2. Disconnect front door lock assembly (driver side) connector.

3. Check voltage between front door lock assembly (driver side) harness connector and ground.

Is the inspection result normal?

YES >> GO TO 3.

NO >> GO TO 2.

2.CHECK DOOR KEY CYLINDER SWITCH SIGNAL CIRCUIT

1. Disconnect power window main switch connector.

2. Check continuity between power window main s witch harness connector and front door lock assembly

(driver side) harness connector.

3. Check continuity between power window main switch harness connector and ground.

Is the inspection result normal?

YES >> Replace power window main switch. Refer to PWC-74, "Removal and Installation".

Monitor item Condition Status

KEY CYL LK-SW Driver side door key cylinder Lock ON

Neutral / Unlock OFF

KEY CYL UN-SW Unlock ON

Neutral / Lock OFF

(+)

(–)Vo l ta g e

(Approx.)

Front door lock assembly (driver side)

Connector Terminal

D9 5

Ground 5 V

6

Power window main switch Front do or lock assembly (driver side)

Continuity

Connector Terminal Connector Terminal

D5 4

D9 6

Existed

65

Power window main switch GroundContinuity

Connector Terminal

D5 4

Not existed

6

Revision: 2010 May2011 QX56

Page 1762 of 5598

DLK-226

< REMOVAL AND INSTALLATION >

FRONT DOOR

4. Temporarily tighten door hinge mounting nuts on door side.

5. Loosen door hinge mounting bolts on body side.

6. Raise front door at rear end to adjust clearance of the front door according to the fitting standard dimen-

sion.

7. After adjustment tighten bolts and nuts to the specified torque. CAUTION:

After installation, apply touch-up paint (the bo dy color) onto the head of hinge mounting bolts

and nuts.

Check door hinge rotating part for poor lubrication. If necessary, apply body grease.

8. Install front fender. Refer to refer to DLK-222, "

FRONT FENDER : Removal and Installation".

DOOR STRIKER ADJUSTMENT

Adjust door striker so that it becomes parallel with door lock insertion direction.

DOOR STRIKER

DOOR STRIKER : Removal and InstallationINFOID:0000000006226077

REMOVAL

Remove TORX bolts, and then remove door striker.

INSTALLATION

Note the following items, and then install in the reverse order of removal.

CAUTION:

Check front door open/close, operation after installation.

After installation, be sure to perf orm the fitting adjustment. Refer to DLK-225, "

DOOR ASSEMBLY :

Adjustment".

DOOR HINGE

DOOR HINGE : Removal and InstallationINFOID:0000000006226078

REMOVAL

CAUTION:

Perform work with 2 workers, because of its heavy weight.

When removing and installing front door assembly, support door with a jack and shop cloth to pro-

tect door and body.

1. Remove front fender. Refer to DLK-222, "

FRONT FENDER : Removal and Installation".

2. Remove front door assembly. Refer to DLK-224, "

DOOR ASSEMBLY : Removal and Installation".

3. Remove front door hinge mounting bolts (body side), and then remove front door hinge.

INSTALLATION

Note the following items, and then install in the reverse order of removal.

CAUTION:

Apply anticorrosive agent onto the mounting surface.

Check front door open/close, lock/un lock operation after installation.

Check door hinge rotating pa rt for poor lubrication. If necessary, apply body grease.

After installation, perform th e fitting adjustment. Refer to DLK-225, "

DOOR ASSEMBLY : Adjust-

ment".

After installation, apply touch-up paint (the body color) onto the head of door hinge mounting nuts.

DOOR CHECK LINK

DOOR CHECK LINK : Re moval and InstallationINFOID:0000000006226079

REMOVAL

1. Fully close the front door window.

2. Remove front door finisher. Refer to INT-14, "

Removal and Installation".

3. Remove front door speaker mounting bolts.

4. Disconnect connector and remove front door speaker.

Revision: 2010 May2011 QX56

Page 1767 of 5598

REAR DOORDLK-231

< REMOVAL AND INSTALLATION >

C

DE

F

G H

I

J

L

M A

B

DLK

N

O P

1. Fully close the rear door window.

2. Remove rear door finisher. Refer to INT-16, "

Removal and Installation".

3. Remove rear door speaker mounting bolts.

4. Disconnect connector and remove rear door speaker.

5. Remove mounting bolt of the check link on the vehicle.

6. Remove mounting nuts of the check link on door panel.

7. Take door check link out from the hole of door panel.

INSTALLATION

Note the following item, and then install in the reverse order of removal.

CAUTION:

Check rear door open/close operation after installation.

Revision: 2010 May2011 QX56

Page 2091 of 5598

![INFINITI QX56 2011 Factory Manual PDF

DIAGNOSIS SYSTEM (ECM)EC-67

< SYSTEM DESCRIPTION > [VK56VD]

C

D

E

F

G H

I

J

K L

M A

EC

NP

OLOAD SIGNAL ON/OFF

Indicates [ON/OFF] condition from the electrical

load signal.

ON: Rear window defogger INFINITI QX56 2011 Factory Manual PDF

DIAGNOSIS SYSTEM (ECM)EC-67

< SYSTEM DESCRIPTION > [VK56VD]

C

D

E

F

G H

I

J

K L

M A

EC

NP

OLOAD SIGNAL ON/OFF

Indicates [ON/OFF] condition from the electrical

load signal.

ON: Rear window defogger](/img/42/57033/w960_57033-2090.png)

DIAGNOSIS SYSTEM (ECM)EC-67

< SYSTEM DESCRIPTION > [VK56VD]

C

D

E

F

G H

I

J

K L

M A

EC

NP

OLOAD SIGNAL ON/OFF

Indicates [ON/OFF] condition from the electrical

load signal.

ON: Rear window defogger switch is ON and/or

lighting switch is in 2nd position.

OFF: Both rear window defogger switch and light-

ing switch are OFF.

IGNITION SW ON/OFF Indicates [ON/OFF] condition from ignition switch

signal.

HEATER FAN SW ON/OFF Indicates [ON/OFF] condition from the blower fan

ON signal.

BRAKE SW ON/OFF Indicates [ON/OFF] condition from the stop lamp

switch signal.

IGN TIMING BTDC Indicates the ignition timing computed by ECM ac-

cording to the input signals. When the engine is stopped,

a certain value is indicated.

COMBUSTION — These items are displayed but are not applicable to

this model.

CAL/LD VALUE % “Calculated load value” indicates the value of the

current air flow divided by peak air flow.

MASS AIRFLOW g/s Indicates the mass air flow computed by ECM ac-

cording to the signal voltage of the mass air flow

sensor.

PURG VOL C/V % Indicates the EVAP canister purge volume control

solenoid valve control value computed by the ECM

according to the input signals.

The opening becomes larger as the value increas-

es.

INT/V SOL (B1)

% The control value of the intake valve timing control

solenoid valve (determined by ECM according to

the input signals) is indicated.

The advance angle becomes larger as the value increases.

INT/V SOL (B2)

AIR COND RLY ON/OFF

The air conditioner relay control condition (deter-

mined by ECM according to the input signals) is in-

dicated.

VENT CONT/V ON/OFF The control condition of the EVAP canister vent

control valve (determined by ECM according to the

input signals) is indicated.

ON: Closed

OFF: Open

THRTL RELAY ON/OFF Indicates the throttle co

ntrol motor relay control

condition determined by the ECM according to the

input signals.

A/F S1 HTR (B1)

% Air fuel ratio (A/F) sensor 1 heater control value

computed by ECM according to the input signals.

The current flow to the heater becomes larger as the value increases.

A/F S1 HTR (B2)

HO2S2 HTR (B1)

ON/OFF Indicates [ON/OFF] condition of heated oxygen

sensor 2 heater determined by ECM according to

the input signals.

HO2S2 HTR (B2)

ALT DUTY SIG ON/OFF The control condition of the power generation volt-

age variable control (determined by ECM accord-

ing to the input signals) is indicated.

ON: Power generation voltage variable control is

active.

OFF: Power generation voltage variable control is

inactive.

I/P PULLY SPD rpm Indicates the engine speed computed from the in-

put speed sensor signal.

Monitored item Unit Description Remarks

Revision: 2010 May2011 QX56