steering INFINITI QX56 2011 Factory Manual Online

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2011, Model line: QX56, Model: INFINITI QX56 2011Pages: 5598, PDF Size: 94.53 MB

Page 443 of 5598

BCS

BCM

BCS-55

< ECU DIAGNOSIS INFORMATION >

C

D E

F

G H

I

J

K L

B A

O P

N

B2603: SHIFT POSI STATUS Inhibit steering lock

500 ms after any of the following BCM recognition conditions are fulfilled

Status 1

- Ignition switch is in the ON position

- Selector lever P position switch signal: Except P position (12 V)

- Selector lever P/N position signal: Except P and N positions (0 V)

Status 2

- Ignition switch is in the ON position

- Selector lever P position switch signal: P position (0 V)

- Selector lever P/N position signal: P or N positions (12 V)

B2604: PNP/CLUTCH SW Inhibit steering lock 500 ms after any of the following BCM recognition conditions are fulfilled

Status 1

- Ignition switch is in the ON position

- Selector lever P/N position signal: P or N position (12 V)

- Shift position signal (CAN): P or N position

Status 2

- Ignition switch is in the ON position

- Selector lever P/N position signal: Except P and N positions (0 V)

- Shift position signal (CAN): Except P and N position

B2605: PNP/CLUTCH SW Inhibit steering lock 500 ms after any of the following BCM recognition conditions are fulfilled

Status 1

- Power position: IGN

- Selector lever P/N position signal: Except P and N positions (0 V)

- Interlock/PNP switch signal (CAN): OFF

Status 2

- Ignition switch is in the ON position

- Selector lever P/N position signal: P or N position (12 V)

- Interlock/PNP switch signal (CAN): ON

B2608: STARTER RELAY Inhibit engine cranking 500 ms after the following signal communication status becomes con-

sistent

Starter motor re

lay control signal

Starter relay status signal (CAN)

B2609: S/L STATUS Inhibit engine crank-

ing

Inhibit steering lock When the following steering lock conditions agree

BCM steering lock control status

Steering lock condition No. 1 signal status

Steering lock condition No. 2 signal status

B260B: STEERING LOCK UNIT Inhibit steering lock Erase DTC

B260D: STEERING LOCK UNIT Inhibit steering lock Erase DTC

B260F: ENG STATE SIG LOST Inhibit engine cranking When any of the following conditions are fulfilled

Power position changes to ACC

Receives engine status signal (CAN)

B2612: S/L STATUS Inhibit engine crank-

ing

Inhibit steering lock When any of the following conditions are fulfilled

Steering lock unit status signal (CAN) is received normally

The BCM steering lock control status matches the steering lock status

recognized by the steering lock unit status signal (CAN from IPDM E/

R)

B2619: BCM Inhibit engine cranking 1 second after the steering lock unit power supply output control inside

BCM becomes normal

B26EF: STRG LCK RELAY OFF Inhibit engine cranking When the following conditions are fulfilled

Steering lock relay signal (CAN): ON

Steering lock unit status signal (CAN): ON

B26F0: STRG LCK RELAY ON Inhibit engine cranking When the following conditions are fulfilled

Steering lock relay signal (CAN): OFF

Steering lock unit status signal (CAN): OFF

B26F1: IGN RELAY OFF Inhibit engine cranking When the following conditions are fulfilled

Ignition switch ON signal (CAN: Transmitted from BCM): ON

Ignition switch ON signal (CAN: Transmitted from IPDM E/R): ON

B26F2: IGN RELAY ON Inhibit engine cranking When the following conditions are fulfilled

Ignition switch ON signal (CAN: Transmitted from BCM): OFF

Ignition switch ON signal (CAN: Transmitted from IPDM E/R): OFF

Display contents of CONSULT Fail-safe Cancellation

Revision: 2010 May2011 QX56

Page 444 of 5598

BCS-56

< ECU DIAGNOSIS INFORMATION >

BCM

FAIL-SAFE CONTROL BY RAIN SENSOR MALFUNCTION

BCM detects the light and rain sensor serial link error and the rain sensor malfunction.

BCM controls the following fail-safe when rain sensor has a malfunction.

Front wiper switch AUTO and sensing rain drop: The condition just before the activation of fail-safe is main-

tained until the front wiper switch is turned OFF.

Front wiper switch AUTO and not sensing rain drop: Front wiper is LO operation until the front wiper switch is

turned off.

REAR WIPER MOTOR PROTECTION

BCM detects the rear wiper stopping position acco rding to the rear wiper stop position signal.

When the rear wiper stop position signal does not c hange for more than 5 seconds while driving the rear

wiper, BCM stops power supply to protect the rear wiper motor.

Condition of cancellation

1. More than 1 minute is passed after the rear wiper stop.

2. Turn rear wiper switch OFF.

3. Operate the rear wiper swit ch or rear washer switch.

FAIL-SAFE CONTROL OF COMBINATION SWITCH READING FUNCTION CAUSED BY LOW

POWER SUPPLY VOLTAGE

If voltage of battery power supply lower, BCM maintain s combination switch reading to the status when input

voltage is less than approximately 9 V.

NOTE:

When voltage of battery power supply is approximately 9 V or more, combination switch reading function

returns to normal operation.

DTC Inspection Priority ChartINFOID:0000000006274821

If some DTCs are displayed at the same time, perfo rm inspections one by one based on the following priority

chart.

B26F3: START CONT RLY ON Inhibit engine cranking When the following conditions are fulfilled

Starter control relay signal (CAN: Transmitted from BCM): OFF

Starter control relay signal (CAN: Transmitted from IPDM E/R): OFF

B26F4: START CONT RLY OFF Inhibit engine cranking When the following conditions are fulfilled

Starter control relay signal (CAN: Transmitted from BCM): ON

Starter control relay signal (CAN: Transmitted from IPDM E/R): ON

B26F7: BCM Inhibit engine cranking

by Intelligent Key sys-

temWhen room antenna and luggage room antenna functions normally

U0415: VEHICLE SPEED Inhibit steering lock When vehicle speed signal (Meter) (CAN) is received normally

Display contents of CONSULT Fail-safe Cancellation

Priority DTC

1 B2562: LOW VOLTAGE

2 U1000: CAN COMM

U1010: CONTROL UNIT (CAN)

3 B2192: ID DISCORD BCM-ECM

B2193: CHAIN OF BCM-ECM

B2195: ANTI-SCANNING

B2198: NATS ANTENNA AMP

Revision: 2010 May2011 QX56

Page 445 of 5598

BCS

BCM

BCS-57

< ECU DIAGNOSIS INFORMATION >

C

D E

F

G H

I

J

K L

B A

O P

N

DTC IndexINFOID:0000000006274822

NOTE:

The details of time display are as follows.

CRNT: A malfunction is detected now.

PAST: A malfunction was detected in the past.

IGN counter is displayed on Freeze Frame Data. For details of Freeze Frame Data, refer to

BCS-14, "

COM-

MON ITEM : CONSULT-III Function (BCM - COMMON ITEM)".

4 B2013: ID DISCORD BCM-S/L

B2014: CHAIN OF S/L-BCM

B2555: STOP LAMP

B2556: PUSH-BTN IGN SW

B2557: VEHICLE SPEED

B2601: SHIFT POSITION

B2602: SHIFT POSITION

B2603: SHIFT POSI STATUS

B2604: PNP/CLUTCH SW

B2605: PNP/CLUTCH SW

B2608: STARTER RELAY

B2609: S/L STATUS

B260B: STEERING LOCK UNIT

B260C: STEERING LOCK UNIT

B260D: STEERING LOCK UNIT

B260F: ENG STATE SIG LOST

B2612: S/L STATUS

B2614: BCM

B2615: BCM

B2616: BCM

B2618: BCM

B2619: BCM

B261A: PUSH-BTN IGN SW

B26E9: LOCK MALFUNCTION

B26EF: STRG LCK RELAY OFF

B26F0: STRG LCK RELAY ON

B26F1: IGN RELAY OFF

B26F2: IGN RELAY ON

B26F3: START CONT RLY ON

B26F4: START CONT RLY OFF

B26F5: STRG LCK STS SW

B26F6: BCM

B26F7: BCM

B26F8: BCM

B26F9: CRANK REQ CIR SHORT

B26FA: CRANK REQ CIR OPEN

B26FC: KEY REGISTRATION

U0415: VEHICLE SPEED

5 B2621: INSIDE ANTENNA

B2622: INSIDE ANTENNA

B2623: INSIDE ANTENNA

6 B2626: OUTSIDE ANTENNA

B2627: OUTSIDE ANTENNA

B2628: OUTSIDE ANTENNA

7 B26E7: TPMS CAN COMM

Priority DTC

Revision: 2010 May2011 QX56

Page 446 of 5598

BCS-58

< ECU DIAGNOSIS INFORMATION >

BCM

CONSULT display Fail-safeFreeze Frame Data

Vehicle Speed

Odo/Trip Meter

Vehicle Condition Intelligent Key warn-

ing lamp ON Reference

page

No DTC is detected.

further testing

may be required. ————

U1000: CAN COMM — — — BCS-70

U1010: CONTROL UNIT (CAN) — — —BCS-71

U0415: VEHICLE SPEED×— ×BCS-72

B2013: ID DISCORD BCM-S/L ××× SEC-69

B2014: CHAIN OF S/L-BCM××× SEC-70

B2192: ID DISCORD BCM-ECM×—— SEC-60

B2193: CHAIN OF BCM-ECM ×—— SEC-61

B2195: ANTI-SCANNING ×—— SEC-62

B2196: DONGLE NG ×—— SEC-63

B2198: NATS ANTENNA AMP ×—— SEC-65

B2555: STOP LAMP — ××SEC-73

B2556: PUSH-BTN IGN SW — ××SEC-76

B2557: VEHICLE SPEED ××× SEC-78

B2562: LOW VOLTAGE — ×—BCS-73

B2601: SHIFT POSITION ××× SEC-79

B2602: SHIFT POSITION××× SEC-82

B2603: SHIFT POSI STATUS××× SEC-85

B2604: PNP/CLUTCH SW××× SEC-89

B2605: PNP/CLUTCH SW××× SEC-91

B2608: STARTER RELAY××× SEC-93

B2609: S/L STATUS××× SEC-95

B260B: STEERING LOCK UNIT××× SEC-98

B260C: STEERING LOCK UNIT — ××SEC-99

B260D: STEERING LOCK UNIT ××× SEC-100

B260F: ENG STATE SIG LOST××× SEC-101

B2612: S/L STATUS××× SEC-102

B2614: BCM — ××PCS-56

B2615: BCM — ××PCS-59

B2616: BCM — ××PCS-61

B2618: BCM — ××PCS-63

B2619: BCM ××× SEC-105

B261A: PUSH-BTN IGN SW — ××PCS-64

B2621: INSIDE ANTENNA — ×—DLK-104

B2622: INSIDE ANTENNA — ×—DLK-106

B2623: INSIDE ANTENNA — ×—DLK-108

B2626: OUTSIDE ANTENNA — ×—DLK-110

B2627: OUTSIDE ANTENNA — ×—DLK-112

B2628: OUTSIDE ANTENNA — ×—DLK-114

B26E7: TPMS CAN COMM — — — BCS-74

Revision: 2010 May2011 QX56

Page 470 of 5598

BCS-82

< REMOVAL AND INSTALLATION >

COMBINATION SWITCH

COMBINATION SWITCH

Exploded ViewINFOID:0000000006274846

Removal and InstallationINFOID:0000000006274847

REMOVAL

1. Remove steering column cover. Refer to IP-13, "Exploded View".

2. Remove screws.

3. Disconnect the connector.

4. Pull up the combination switch to remove it.

INSTALLATION

Install in the reverse order of removal.

1. Combination switch 2. Combination switch connector

JMMIA0328ZZ

Revision: 2010 May2011 QX56

Page 471 of 5598

BR-1

BRAKES

C

DE

G H

I

J

K L

M

SECTION BR

A

B

BR

N

O P

CONTENTS

BRAKE SYSTEM

PRECAUTION ................ ...............................3

PRECAUTIONS .............................................. .....3

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ............................................................. ......

3

Precaution Necessary for Steering Wheel Rota-

tion after Battery Disconnect .....................................

3

Precaution for Procedure without Cowl Top Cover ......4

Precaution for Brake system .....................................4

PREPARATION ............................................5

PREPARATION .............................................. .....5

Commercial Service Tools .................................. ......5

SYMPTOM DIAGNOSIS ...............................6

NOISE, VIBRATION AND HARSHNESS

(NVH) TROUBLESHOOTING ........................ .....

6

NVH Troubleshooting Chart ................................ ......6

PERIODIC MAINTENANCE ..........................7

BRAKE PEDAL .............................................. .....7

Inspection and Adjustment .................................. ......7

BRAKE FLUID ....................................................10

Inspection ............................................................ ....10

Draining ...................................................................10

Refilling ...................................................................11

Bleeding Brake System ...........................................11

HYDRAULIC BOOSTER ASSEMBLY ...............15

Inspection ............................................................ ....15

FRONT DISC BRAKE .................................... ....16

BRAKE PAD .......................................................... ....16

BRAKE PAD : Inspection and Adjustment ..............16

DISC ROTOR ......................................................... ....16

DISC ROTOR : Inspection and Adjustment ............16

REAR DISC BRAKE .........................................18

BRAKE PAD .......................................................... ....18

BRAKE PAD : Inspection and Adjustment ...............18

DISC ROTOR ......................................................... ....18

DISC ROTOR : Inspection and Adjustment .............18

REMOVAL AND INSTALLATION ...............20

BRAKE PEDAL ................................ .................20

Exploded View ..................................................... ....20

Removal and Installation .........................................20

Inspection and Adjustment ......................................21

BRAKE PIPING ................................ .................22

FRONT ................................................................... ....22

FRONT : Exploded View .........................................22

FRONT : Hydraulic Piping .......................................23

FRONT : Removal and Installation ..........................23

FRONT : Inspection .................................................24

REAR ..................................................................... ....24

REAR : Exploded View ............................................25

REAR : Hydraulic Piping ..........................................25

REAR : Removal and Installation ............................26

REAR : Inspection ...................................................26

HYDRAULIC BOOSTER ASSEMBLY ..............28

Exploded View .........................................................28

Removal and Installation .........................................29

Disassembly and Assembly .....................................30

Inspection and Adjustment ......................................32

Disposal ...................................................................33

FRONT DISC BRAKE .......................................34

BRAKE PAD .......................................................... ....34

BRAKE PAD : Exploded View .................................34

BRAKE PAD : Removal and Installation ..................34

BRAKE PAD : Inspection . ........................................36

Revision: 2010 May2011 QX56

Page 473 of 5598

PRECAUTIONSBR-3

< PRECAUTION >

C

DE

G H

I

J

K L

M A

B

BR

N

O P

PRECAUTION

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000006228171

The Supplemental Restraint System such as “A IR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severi ty of injury to the driver and front passenger for certain

types of collision. This system includes seat belt switch inputs and dual stage front air bag modules. The SRS

system uses the seat belt switches to determine the front air bag deployment, and may only deploy one front

air bag, depending on the severity of a collision and whether the front occupants are belted or unbelted.

Information necessary to service the system safely is included in the “SRS AIR BAG” and “SEAT BELT” of this

Service Manual.

WARNING:

• To avoid rendering the SRS inoper ative, which could increase the risk of personal injury or death in

the event of a collision that would result in air ba g inflation, all maintenance must be performed by

an authorized NISSAN/INFINITI dealer.

Improper maintenance, including in correct removal and installation of the SRS, can lead to personal

injury caused by unintentional act ivation of the system. For removal of Spiral Cable and Air Bag

Module, see the “SRS AIR BAG”.

Do not use electrical test equipm ent on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harnesses can be identi fied by yellow and/or orange harnesses or har-

ness connectors.

PRECAUTIONS WHEN USING POWER TOOLS (AIR OR ELECTRIC) AND HAMMERS

WARNING:

When working near the Air Bag Diagnosis Sensor Unit or other Air Bag System sensors with the

ignition ON or engine running, DO NOT use air or electric power tools or strike near the sensor(s)

with a hammer. Heavy vibration could activate the sensor(s) and deploy the air bag(s), possibly

causing serious injury.

When using air or electric power tools or hammers , always switch the ignition OFF, disconnect the

battery, and wait at least 3 minutes before performing any service.

Precaution Necessary for Steering Wh eel Rotation after Battery Disconnect

INFOID:0000000006228172

NOTE:

Before removing and installing any control units, first tu rn the push-button ignition switch to the LOCK posi-

tion, then disconnect both battery cables.

After finishing work, confirm that all control unit connectors are connected properly, then re-connect both

battery cables.

Always use CONSULT-III to perform self-diagnosis as a part of each function inspection after finishing work.

If a DTC is detected, perform trouble diagnos is according to self-diagnosis results.

For vehicle with steering lock unit, if the battery is disconnected or discharged, the steering wheel will lock and

cannot be turned.

If turning the steering wheel is required with the batte ry disconnected or discharged, follow the operation pro-

cedure below before starting the repair operation.

OPERATION PROCEDURE

1. Connect both battery cables. NOTE:

Supply power using jumper cables if battery is discharged.

2. Turn the push-button ignition switch to ACC position. (At this time, the steering lock will be released.)

3. Disconnect both battery cables. The steering lock wil l remain released with both battery cables discon-

nected and the steering wheel can be turned.

4. Perform the necessary repair operation.

Revision: 2010 May2011 QX56

Page 474 of 5598

BR-4

< PRECAUTION >

PRECAUTIONS

5. When the repair work is completed, re-connect both battery cables. With the brake pedal released, turn

the push-button ignition switch from ACC position to ON position, then to LOCK position. (The steering

wheel will lock when the push-button igniti on switch is turned to LOCK position.)

6. Perform self-diagnosis check of all control units using CONSULT-III.

Precaution for Procedure without Cowl Top CoverINFOID:0000000006228173

When performing the procedure after removing cowl top cover, cover

the lower end of windshield with urethane, etc.

Precaution for Brake systemINFOID:0000000006222459

WARNING:

Clean any dust from the front brake and rear brake wi th a vacuum dust collector. Never blow with com-

pressed air.

Brake fluid use refer to MA-10, "

Fluids and Lubricants".

Never reuse drained brake fluid.

Never spill or splash brake fluid on painted surfaces. Brake fluid may seriously damage paint. Wipe it off

immediately and wash with water if it gets on a painted surface.

Always confirm the specified tightening torque when installing the brake pipes.

After pressing the brake pedal more deeply or harder t han normal driving, such as air bleeding, check each

item of brake pedal. Adjust brake pedal if it is outside the standard value.

Always clean with new brake fluid when cleaning the brake caliper and other components.

Never use mineral oils such as gasoline or light oil to clean. They may damage rubber parts and cause

improper operation.

Always loosen the brake tube flar e nut with a flare nut wrench.

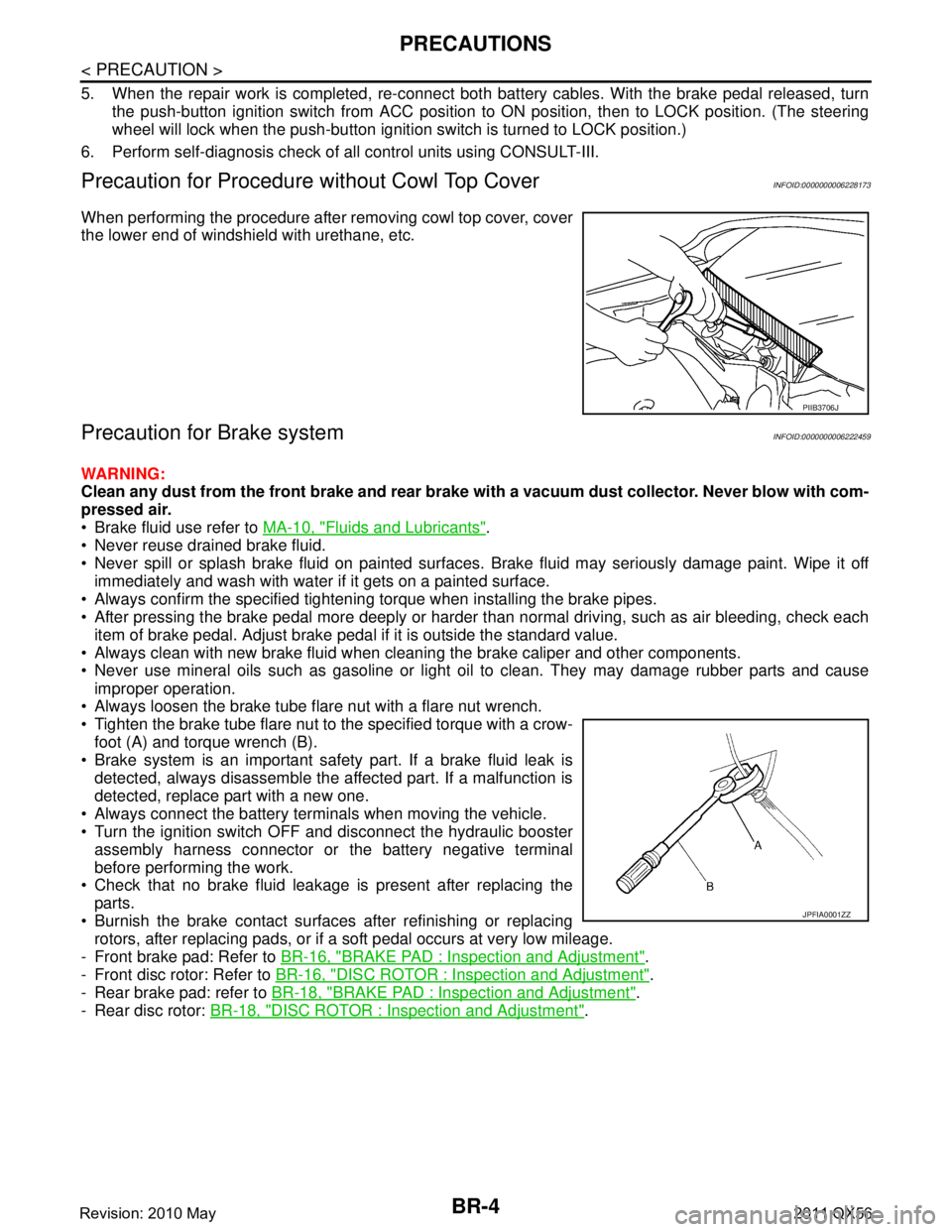

Tighten the brake tube flare nut to the specified torque with a crow-

foot (A) and torque wrench (B).

Brake system is an important safety part. If a brake fluid leak is detected, always disassemble the affected part. If a malfunction is

detected, replace part with a new one.

Always connect the battery terminals when moving the vehicle.

Turn the ignition switch OFF and disconnect the hydraulic booster assembly harness connector or the battery negative terminal

before performing the work.

Check that no brake fluid leakage is present after replacing the

parts.

Burnish the brake contact surfaces after refinishing or replacing rotors, after replacing pads, or if a soft pedal occurs at very low mileage.

- Front brake pad: Refer to BR-16, "

BRAKE PAD : Inspection and Adjustment".

- Front disc rotor: Refer to BR-16, "

DISC ROTOR : Inspection and Adjustment".

- Rear brake pad: refer to BR-18, "

BRAKE PAD : Inspection and Adjustment".

- Rear disc rotor: BR-18, "

DISC ROTOR : Inspection and Adjustment".

PIIB3706J

JPFIA0001ZZ

Revision: 2010 May2011 QX56

Page 476 of 5598

BR-6

< SYMPTOM DIAGNOSIS >

NOISE, VIBRATION AND HARSHNESS (NVH) TROUBLESHOOTING

SYMPTOM DIAGNOSIS

NOISE, VIBRATION AND HARSHNESS (NVH) TROUBLESHOOTING

NVH Troubleshooting ChartINFOID:0000000006222461

Use the chart below to find the cause of the symp tom. If necessary, repair or replace these parts.

×: ApplicableReference page

BR-16

,

BR-18

BR-16

, BR-18

BR-36

, BR-42

BR-16

, BR-18

BR-16

, BR-18

BR-16

, BR-18

BR-16

, BR-18

BR-16

, BR-18

BR-16

, BR-18

BR-16

, BR-18

NVH in PB section

NVH in DLN section

NHV in DLN section

NVH in FAX, RAX and FSU, RSU section

NVH in WT section

NVH in WT section

NVH in FAX, RAX section

NVH in ST section

Possible cause and

SUSPECTED PARTS

Pads damaged

Pads uneven wear

Shims damaged

Rotor imbalance

Rotor damage

Rotor runout

Rotor deformation

Rotor deflection

Rotor rust

Rotor thickness variation

Drum out of round

PROPELLER SHAFT

DIFFERENTIAL

AXLE AND SUSPENSION

TIRE

ROAD WHEEL

DRIVE SHAFT

STEERING

Symptom BRAKE Noise

××× ×× ×××

××

Shake ×××××

××

Shimmy, Judder ××××××× ××× ×

Revision: 2010 May2011 QX56

Page 494 of 5598

BR-24

< REMOVAL AND INSTALLATION >

BRAKE PIPING

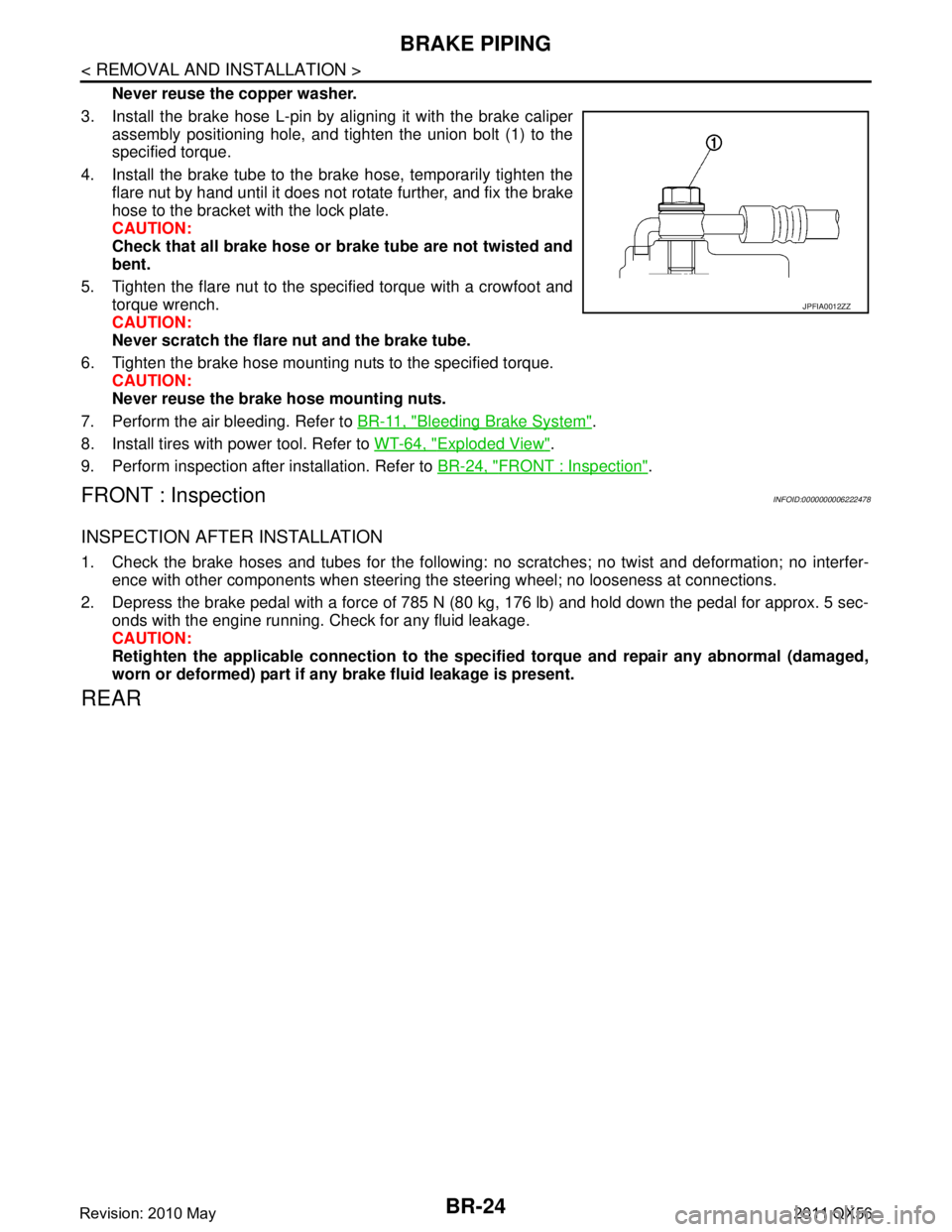

Never reuse the copper washer.

3. Install the brake hose L-pin by aligning it with the brake caliper assembly positioning hole, and tighten the union bolt (1) to the

specified torque.

4. Install the brake tube to the brake hose, temporarily tighten the flare nut by hand until it does not rotate further, and fix the brake

hose to the bracket with the lock plate.

CAUTION:

Check that all brake hose or brake tube are not twisted and

bent.

5. Tighten the flare nut to the specified torque with a crowfoot and torque wrench.

CAUTION:

Never scratch the flare nut and the brake tube.

6. Tighten the brake hose mounting nuts to the specified torque. CAUTION:

Never reuse the brake hose mounting nuts.

7. Perform the air bleeding. Refer to BR-11, "

Bleeding Brake System".

8. Install tires with power tool. Refer to WT-64, "

Exploded View".

9. Perform inspection after installation. Refer to BR-24, "

FRONT : Inspection".

FRONT : InspectionINFOID:0000000006222478

INSPECTION AFTER INSTALLATION

1. Check the brake hoses and tubes for the following: no scratches; no twist and deformation; no interfer-

ence with other components when steering the steering wheel; no looseness at connections.

2. Depress the brake pedal with a force of 785 N (80 kg, 176 lb) and hold down the pedal for approx. 5 sec- onds with the engine running. Check for any fluid leakage.

CAUTION:

Retighten the applicable connection to the specified torque and repair any abnormal (damaged,

worn or deformed) part if any brake fluid leakage is present.

REAR

JPFIA0012ZZ

Revision: 2010 May2011 QX56