P1089 INFINITI QX56 2011 Factory Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2011, Model line: QX56, Model: INFINITI QX56 2011Pages: 5598, PDF Size: 94.53 MB

Page 2030 of 5598

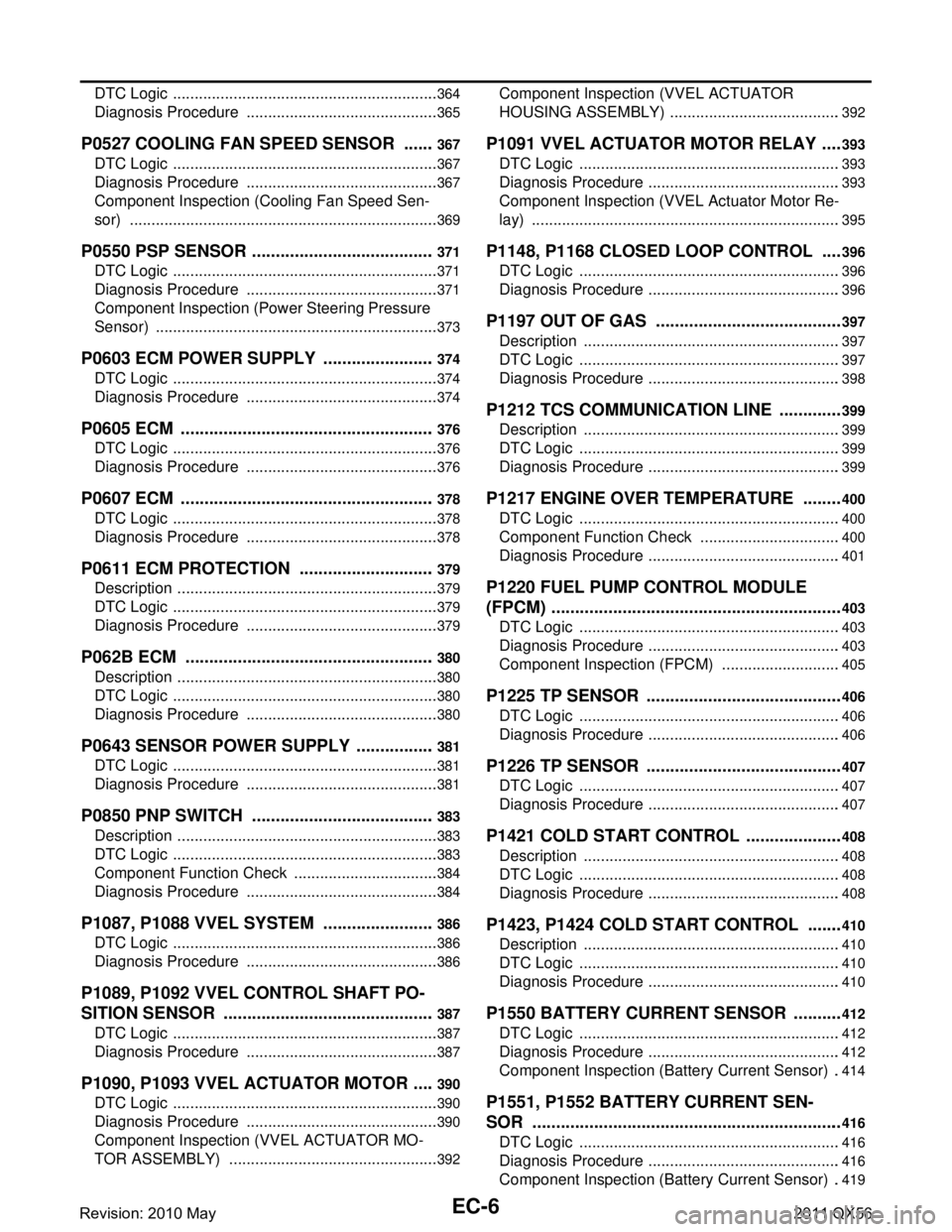

EC-6

DTC Logic ..............................................................364

Diagnosis Procedure .............................................365

P0527 COOLING FAN SPEED SENSOR .......367

DTC Logic ............................................................ ..367

Diagnosis Procedure .............................................367

Component Inspection (Cooling Fan Speed Sen-

sor) ........................................................................

369

P0550 PSP SENSOR .......................................371

DTC Logic ............................................................ ..371

Diagnosis Procedure .............................................371

Component Inspection (Power Steering Pressure

Sensor) ..................................................................

373

P0603 ECM POWER SUPPLY ........................374

DTC Logic ............................................................ ..374

Diagnosis Procedure .............................................374

P0605 ECM ......................................................376

DTC Logic ............................................................ ..376

Diagnosis Procedure .............................................376

P0607 ECM ......................................................378

DTC Logic ............................................................ ..378

Diagnosis Procedure .............................................378

P0611 ECM PROTECTION .............................379

Description ........................................................... ..379

DTC Logic ..............................................................379

Diagnosis Procedure .............................................379

P062B ECM .....................................................380

Description ........................................................... ..380

DTC Logic ..............................................................380

Diagnosis Procedure .............................................380

P0643 SENSOR POWER SUPPLY .................381

DTC Logic ............................................................ ..381

Diagnosis Procedure .............................................381

P0850 PNP SWITCH .......................................383

Description ........................................................... ..383

DTC Logic ..............................................................383

Component Function Check ..................................384

Diagnosis Procedure .............................................384

P1087, P1088 VVEL SYSTEM ........................386

DTC Logic ............................................................ ..386

Diagnosis Procedure .............................................386

P1089, P1092 VVEL CONTROL SHAFT PO-

SITION SENSOR .............................................

387

DTC Logic ............................................................ ..387

Diagnosis Procedure .............................................387

P1090, P1093 VVEL ACTUATOR MOTOR .....390

DTC Logic ............................................................ ..390

Diagnosis Procedure .............................................390

Component Inspection (VVEL ACTUATOR MO-

TOR ASSEMBLY) .................................................

392

Component Inspection (VVEL ACTUATOR

HOUSING ASSEMBLY) ......... ...............................

392

P1091 VVEL ACTUATOR MOTOR RELAY ... ..393

DTC Logic ............................................................ .393

Diagnosis Procedure .............................................393

Component Inspection (VVEL Actuator Motor Re-

lay) ....................................................................... .

395

P1148, P1168 CLOSED LOOP CONTROL .....396

DTC Logic ............................................................ .396

Diagnosis Procedure .............................................396

P1197 OUT OF GAS ........................................397

Description ........................................................... .397

DTC Logic .............................................................397

Diagnosis Procedure .............................................398

P1212 TCS COMMUNICATION LINE ..............399

Description ........................................................... .399

DTC Logic .............................................................399

Diagnosis Procedure .............................................399

P1217 ENGINE OVER TEMPERATURE .........400

DTC Logic ............................................................ .400

Component Function Check .................................400

Diagnosis Procedure .............................................401

P1220 FUEL PUMP CONTROL MODULE

(FPCM) ..............................................................

403

DTC Logic ............................................................ .403

Diagnosis Procedure .............................................403

Component Inspection (FPCM) ............................405

P1225 TP SENSOR ..........................................406

DTC Logic ............................................................ .406

Diagnosis Procedure .............................................406

P1226 TP SENSOR ..........................................407

DTC Logic ............................................................ .407

Diagnosis Procedure .............................................407

P1421 COLD START CONTROL .....................408

Description ........................................................... .408

DTC Logic .............................................................408

Diagnosis Procedure .............................................408

P1423, P1424 COLD START CONTROL ........410

Description ........................................................... .410

DTC Logic .............................................................410

Diagnosis Procedure .............................................410

P1550 BATTERY CURRENT SENSOR ...........412

DTC Logic ............................................................ .412

Diagnosis Procedure .............................................412

Component Inspection (Battery Current Sensor) ..414

P1551, P1552 BATTERY CURRENT SEN-

SOR ..................................................................

416

DTC Logic ............................................................ .416

Diagnosis Procedure .............................................416

Component Inspection (Battery Current Sensor) ..419

Revision: 2010 May2011 QX56

Page 2119 of 5598

![INFINITI QX56 2011 Factory Service Manual

ECM

EC-95

< ECU DIAGNOSIS INFORMATION > [VK56VD]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

P062B ECM Type1

Engine torque is limited.

Idle engine speed is increased.

Fuel injector power supply shut-off.

INFINITI QX56 2011 Factory Service Manual

ECM

EC-95

< ECU DIAGNOSIS INFORMATION > [VK56VD]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

P062B ECM Type1

Engine torque is limited.

Idle engine speed is increased.

Fuel injector power supply shut-off.

](/img/42/57033/w960_57033-2118.png)

ECM

EC-95

< ECU DIAGNOSIS INFORMATION > [VK56VD]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

P062B ECM Type1

Engine torque is limited.

Idle engine speed is increased.

Fuel injector power supply shut-off.

High fuel pressure limitation.

Typ e2

Engine torque is limited.

Fuel injection shut-off of malfunction cylinder.

Mixture ratio feedback control does not function.

Idle engine speed is increased.

P0643 Sensor power supply ECM stops the electric throttle control actuator control, throttle valve is maintained at a

fixed opening (approx. 5 degrees) by the return spring.

P1087

P1088 VVEL control function VVEL of no

rmal bank is controlled at VVEL angle of abnormal bank.

Engine speed will not rise more than 3,500 rpm due to the fuel cut.

P1089

P1092 VVEL control shaft position

sensor VVEL value is maintained at a fixed angle.

Engine speed will not rise more than 3,500 rpm due to the fuel cut

P1197 Out of gas Engine torque is limited.

VVEL value is maintained at a fixed angle.

P1608 VVEL control shaft position

sensor VVEL actuator motor relay is turned off, an

d VVEL value is become at a minimum angle.

Engine speed will not rise more than 3,500 rpm due to the fuel cut.

P1090

P1093 VVEL actuator motor VVEL of no

rmal bank is controlled at VVEL angle of abnormal bank.

Engine speed will not rise more than 3,500 rpm due to the fuel cut.

VVEL actuator motor relay is turned off, an d VVEL value is become at a minimum angle.

Engine speed will not rise more than 3,500 rpm due to the fuel cut.

P1091 VVEL actuator motor rela

y VVEL actuator motor relay is turned off, an d VVEL value is become at a minimum angle.

Engine speed will not rise more than 3,500 rpm due to the fuel cut.

P1197 Out of gas Engine torque is limited.

VVEL value is maintained at a fixed angle.

P2101 Electric throttle control

function ECM stops the electric throttle control actuator control, throttle valve is maintained at a

fixed opening (approx. 5 degrees) by the return spring.

P2118 Throttle control motor ECM stops the electric throttle control actuator control, throttle valve is maintained at a

fixed opening (approx. 5 degrees) by the return spring.

P2119 Electric throttle control ac-

tuator

(When electric throttle control actuator does not function properly due to the return spring

malfunction:)

ECM controls the electric throttle actuator by regulating the throttle opening around the

idle position. The engine speed will not rise more than 2,000 rpm.

(When throttle valve opening angle in fail-safe mode is not in specified range:)

ECM controls the electric throttle control actuator because of regulating the throttle open-

ing to 20 degrees or less.

(When ECM detects the throttle valve is stuck open:)

While the vehicle is being driven, it slows down gradually by fuel cut. After the vehicle

stops, the engine stalls.

The engine can restart in the N or P position, and engine speed will not exceed 1,000 rpm

or more.

P1290

P2100

P2103 Throttle control motor relay ECM stops the electric throttle control actuator control, throttle valve is maintained at a

fixed opening (approx. 5 degrees) by the return spring.

P1606 VVEL control module VVEL

actuator motor relay is turned off, and VVEL value is become at a minimum angle.

Engine speed will not rise more than 3,500 rpm due to the fuel cut.

P1805 Brake switch ECM controls the electric throttle control

actuator by regulating the throttle opening to a

small range.

Therefore, acceleration will be poor.

Vehicle condition Driving condition

When engine is idling Normal

When accelerating Poor acceleration

DTC No. Detected items Engine operating condition in fail-safe mode

Revision: 2010 May2011 QX56

Page 2121 of 5598

![INFINITI QX56 2011 Factory Service Manual

ECM

EC-97

< ECU DIAGNOSIS INFORMATION > [VK56VD]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

Priority Detected items (DTC)

1 U0101 CAN communication line U0113 U1003 CAN communication line

U1001 CAN commun INFINITI QX56 2011 Factory Service Manual

ECM

EC-97

< ECU DIAGNOSIS INFORMATION > [VK56VD]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

Priority Detected items (DTC)

1 U0101 CAN communication line U0113 U1003 CAN communication line

U1001 CAN commun](/img/42/57033/w960_57033-2120.png)

ECM

EC-97

< ECU DIAGNOSIS INFORMATION > [VK56VD]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

Priority Detected items (DTC)

1 U0101 CAN communication line U0113 U1003 CAN communication line

U1001 CAN communication line

U1024 VVEL CAN communication line

P006A P0101 P0102 P0103 Mass air flow sensor

P010A Manifold absolute pressure sensor

P0112 P0113 P0127 Intake air temperature sensor

P0116 P0117 P0118 P0125 Engine coolant temperature sensor

P0122 P0123 P0222 P0223 P1225 P1226 P2135 Throttle position sensor

P0128 Thermostat function

P0181 P0182 P0183 Fuel tank temperature sensor

P0196 P0197 P0198 Engine oil temperature sensor

P0327 P0328 P0332 P0333 Knock sensor

P0335 Crankshaft position sensor

P0340 P0345 Camshaft position sensor

P0460 P0461 P0462 P0463 Fuel level sensor

P0500 Vehicle speed sensor

P0527 Cooling fan speed sensor

P0605 P0607 P0611 P062B ECM

P0643 Sensor power supply

P0700 TCM

P0705 P0850 Transmission range switch

P1089 P1092 P1608 VVEL control shaft position sensor

P1197 Out of gas*

P1220 Fuel pump control module (FPCM)

P1421 P1423 P1424 Cold start control

P1550 P1551 P1552 P1553 P1554 Battery current sensor

P1556 P1557 Battery temperature sensor

P1606 P1607 VVEL control module

P1610 - P1615 NATS

P2122 P2123 P2127 P2128 P2138 Accelerator pedal position sensor

P2539 P2541 P2542 Low fuel pressure sensor

Revision: 2010 May2011 QX56

Page 2126 of 5598

![INFINITI QX56 2011 Factory Service Manual

EC-102

< ECU DIAGNOSIS INFORMATION >[VK56VD]

ECM

P0731 0731

1GR INCORRECT RATIO*7—2 ×TM-118

P0732 0732

2GR INCORRECT RATIO*7—2 ×TM-120

P0733 0733

3GR INCORRECT RATIO*7—2 ×TM-122

P0734 0734

4 INFINITI QX56 2011 Factory Service Manual

EC-102

< ECU DIAGNOSIS INFORMATION >[VK56VD]

ECM

P0731 0731

1GR INCORRECT RATIO*7—2 ×TM-118

P0732 0732

2GR INCORRECT RATIO*7—2 ×TM-120

P0733 0733

3GR INCORRECT RATIO*7—2 ×TM-122

P0734 0734

4](/img/42/57033/w960_57033-2125.png)

EC-102

< ECU DIAGNOSIS INFORMATION >[VK56VD]

ECM

P0731 0731

1GR INCORRECT RATIO*7—2 ×TM-118

P0732 0732

2GR INCORRECT RATIO*7—2 ×TM-120

P0733 0733

3GR INCORRECT RATIO*7—2 ×TM-122

P0734 0734

4GR INCORRECT RATIO*7—2 ×TM-124

P0735 0735

5GR INCORRECT RATIO*7—2 ×TM-126

P0740 0740 TORQUE CONVERTER — 2 ×TM-128

P0744 0744 TORQUE CONVERTER — 2 ×TM-129

P0745 0745 PC SOLENOID A — 2 ×TM-131

P0750 0750 SHIFT SOLENOID A — 2 ×TM-132

P0775 0775 PC SOLENOID B — 2 ×TM-133

P0780 0780 SHIFT — 1 ×TM-134

P0795 0795 PC SOLENOID C — 2 ×TM-136

P0850 0850 P-N POS SW/CIRCUIT — 2 ×EC-383

P1087 1087 VVEL SYSTEM-B1 — 1 ×EC-386

P1088 1088 VVEL SYSTEM-B2 — 1 ×EC-386

P1089 1089 VVEL POS SEN/CIRC-B1 — 1 ×EC-387

P1090 1090 VVEL ACTR MOT-B1 — 1 ×EC-390

P1091 1091 VVEL ACTR MOT PWR — 1 ×EC-393

P1092 1092 VVEL POS SEN/CIRC-B2 — 1 ×EC-387

P1093 1093 VVEL ACTR MOT-B2 — 1 ×EC-390

P1148 1148 CLOSED LOOP-B1 — 1 ×EC-396

P1168 1168 CLOSED LOOP-B2 — 1 ×EC-396

P1197 1197 FUEL RUN OUT — 2 — EC-397

P1212 1212 TCS/CIRC — 2 — EC-399

P1217 1217 ENG OVER TEMP — 1×EC-400

P1220 1220 FPCM — 1 — EC-403

P1225 1225 CTP LEARNING-B1 — 2 —EC-406

P1226 1226 CTP LEARNING-B1 — 2 —EC-407

P1421 1421 COLD START CONTROL — 2×EC-408

P1423 1423 COLD START CONTROL — 2 ×EC-410

P1424 1424 COLD START CONTROL — 2 ×EC-410

P1550 1550 BAT CURRENT SENSOR — 2 — EC-412

P1551 1551 BAT CURRENT SENSOR — 2 —EC-416

P1552 1552 BAT CURRENT SENSOR — 2 —EC-416

P1553 1553 BAT CURRENT SENSOR — 2 —EC-420

P1554 1554 BAT CURRENT SENSOR — 2 —EC-424

P1556 1556 BAT TMP SEN/CIRC — 2 —EC-428

P1557 1557 BAT TMP SEN/CIRC — 2 —EC-428

P1564 1564 ASCD SW — 1 —EC-431(with ASCD)

EC-434

(with ICC)

P1568 1568 ICC COMMAND VALUE — 1 — EC-437

DTC*1

Items

(CONSULT-III screen terms) SRT code Trip MIL Reference

page

CONSULT-III

GST*

2ECM*3

Revision: 2010 May2011 QX56

Page 2411 of 5598

![INFINITI QX56 2011 Factory Service Manual

P1089, P1092 VVEL CONTROL SHAFT POSITION SENSOR

EC-387

< DTC/CIRCUIT DIAGNOSIS > [VK56VD]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

P1089, P1092 VVEL CONTROL

SHAFT POSITION SENSOR

DTC LogicINFOID:000000000621 INFINITI QX56 2011 Factory Service Manual

P1089, P1092 VVEL CONTROL SHAFT POSITION SENSOR

EC-387

< DTC/CIRCUIT DIAGNOSIS > [VK56VD]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

P1089, P1092 VVEL CONTROL

SHAFT POSITION SENSOR

DTC LogicINFOID:000000000621](/img/42/57033/w960_57033-2410.png)

P1089, P1092 VVEL CONTROL SHAFT POSITION SENSOR

EC-387

< DTC/CIRCUIT DIAGNOSIS > [VK56VD]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

P1089, P1092 VVEL CONTROL

SHAFT POSITION SENSOR

DTC LogicINFOID:0000000006217894

DTC DETECTION LOGIC

NOTE:

If DTC P1089 or P1092 is displayed with DTC P1608, first perform the trouble diagnosis for DTC P1608.

Refer to EC-453, "

DTC Logic".

DTC CONFIRMATION PROCEDURE

1.PRECONDITIONING

1. Turn ignition switch OFF and wait at least 10 seconds.

2. Turn ignition switch ON.

3. Turn ignition switch OFF and wait at least 10 seconds.

TESTING CONDITION:

Before performing the following procedure, confi rm that battery voltage is 10 V or more at idle.

>> GO TO 2.

2.PERFORM DTC CONFIRMATION PROCEDURE

1. Start engine and let it idle for 1 second.

2. Check DTC.

Is DTC detected?

YES >> Go to EC-387, "Diagnosis Procedure".

NO >> INSPECTION END

Diagnosis ProcedureINFOID:0000000006217895

1.VVEL CONTROL SHAFT POSITION SENSOR POWER SUPPLY CIRCUIT

1. Disconnect VVEL control shaft pos ition sensor harness connector.

2. Turn ignition switch ON.

3. Check the voltage between VVEL control shaf t position sensor harness connector and ground.

Is the inspection result normal?

YES >> GO TO 3.

NO >> GO TO 2.

2.DETECT MALFUNCTIONING PART

Check the following.

DTC No. Trouble diagnosis name

(Trouble diagnosis content) DTC detecting condition Possible cause

P1089 VVEL POS SEN/CIRC-B1

[VVEL control shaf

t position sen-

sor (bank 1) circuit] An excessively low voltage from the sensor

is sent to VVEL control module.

An excessively high voltage from the sensor is sent to VVEL control module.

Rationally incorrect voltage is sent to VVEL control module compared with the signals

from VVEL control shaft position sensor 1

and VVEL control shaft position sensor 2. Harness or connectors

(VVEL control shaft position sen-

sor circuit is open or shorted.)

VVEL control shaft position sen- sor

VVEL control module

P1092 VVEL POS SEN/CIRC-B2

[VVEL control shaf

t position sen-

sor (bank 2) circuit]

DTC No. VVEL control shaft position sensor

Ground Voltage (V)

Bank Connector Terminal

P1089 1 F72 3

Ground Approx. 5

6

P1092 2 F70 3

6

Revision: 2010 May2011 QX56

Page 2412 of 5598

![INFINITI QX56 2011 Factory Service Manual

EC-388

< DTC/CIRCUIT DIAGNOSIS >[VK56VD]

P1089, P1092 VVEL CONTRO

L SHAFT POSITION SENSOR

Harness for open or short between VVEL control shaft position sensor and VVEL control module

Loose or po INFINITI QX56 2011 Factory Service Manual

EC-388

< DTC/CIRCUIT DIAGNOSIS >[VK56VD]

P1089, P1092 VVEL CONTRO

L SHAFT POSITION SENSOR

Harness for open or short between VVEL control shaft position sensor and VVEL control module

Loose or po](/img/42/57033/w960_57033-2411.png)

EC-388

< DTC/CIRCUIT DIAGNOSIS >[VK56VD]

P1089, P1092 VVEL CONTRO

L SHAFT POSITION SENSOR

Harness for open or short between VVEL control shaft position sensor and VVEL control module

Loose or poor connection for each connector and harness

>> Repair open circuit, short to ground or short to power in harness or connectors.

3.CHECK VVEL CONTROL SHAFT POSITION SENSOR GROUND CIRCUIT FOR OPEN AND SHORT

1. Turn ignition switch OFF.

2. Disconnect VVEL control module harness connector.

3. Check the continuity between VVEL control shaf t position sensor harness connector and VVEL control

module harness connector.

4. Also check harness for short to ground and power.

Is the inspection result normal?

YES >> GO TO 5.

NO >> GO TO 4.

4.DETECT MALFUNCTIONING PART

Check the following.

Harness for open or short between VVEL control shaft position sensor and VVEL control module

Loose or poor connection for each connector and harness

>> Repair open circuit, short to ground or short to power in harness or connectors.

5.VVEL CONTROL SHAFT POSITI ON SENSOR INPUT SIGNAL CIRCUIT FOR OPEN AND SHORT

1. Check the continuity between VVEL control shaf t position sensor harness connector and VVEL control

module harness connector.

2. Also check harness for short to ground and power.

Is the inspection result normal?

YES >> GO TO 7.

NO >> GO TO 6.

6.DETECT MALFUNCTIONING PART

Check the following.

Harness for open or short between VVEL control shaft position sensor and VVEL control module

Loose or poor connection for each connector and harness

>> Repair open circuit, short to ground or short to power in harness or connectors.

7.CHECK INTERMITTENT INCIDENT

Refer to GI-40, "

Intermittent Incident".

DTC No. VVEL control shaft position

sensor VVEL control module

Continuity

Bank Connector Terminal Connector Terminal

P1089 1 F72 2

F56 6

Existed

519

P1092 2 F70 24

517

DTC No.VVEL control shaft position

sensor VVEL control module

Continuity

Bank Connector Terminal Connector Terminal

P1089 1 F72 1

F56 3

Existed

416

P1092 2 F70 15

418

Revision: 2010 May2011 QX56

Page 2413 of 5598

![INFINITI QX56 2011 Factory Service Manual

P1089, P1092 VVEL CONTROL SHAFT POSITION SENSOR

EC-389

< DTC/CIRCUIT DIAGNOSIS > [VK56VD]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

Is the inspection result normal?

YES >> GO TO 8.

NO >> Repair or replace.

8.R INFINITI QX56 2011 Factory Service Manual

P1089, P1092 VVEL CONTROL SHAFT POSITION SENSOR

EC-389

< DTC/CIRCUIT DIAGNOSIS > [VK56VD]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

Is the inspection result normal?

YES >> GO TO 8.

NO >> Repair or replace.

8.R](/img/42/57033/w960_57033-2412.png)

P1089, P1092 VVEL CONTROL SHAFT POSITION SENSOR

EC-389

< DTC/CIRCUIT DIAGNOSIS > [VK56VD]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

Is the inspection result normal?

YES >> GO TO 8.

NO >> Repair or replace.

8.REPLACE VVEL CONTROL MODULE

1. Replace VVEL control module.

2. Perform additional service when replacing VVEL control module. Refer to EC-144, "

Work Procedure".

>> GO TO 9.

9.PERFORM DTC CONFIRMATION PROCEDURE

1. Turn ignition switch ON.

2. Erase DTC.

3. Perform DTC Confirmation Procedure. See EC-387, "

DTC Logic".

Is the DTC P1089 or P1092 displayed again?

YES >> GO TO 10.

NO >> INSPECTION END

10.REPLACE VVEL ACTUATOR LADDER ASSEMBLY

Replace VVEL actuator ladder assembly. Refer to EM-75, "

Removal and Installation".

>> INSPECTION END

Revision: 2010 May2011 QX56