dimensions INFINITI QX56 2011 Factory Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2011, Model line: QX56, Model: INFINITI QX56 2011Pages: 5598, PDF Size: 94.53 MB

Page 164 of 5598

AV-16

< SYSTEM DESCRIPTION >

SYSTEM

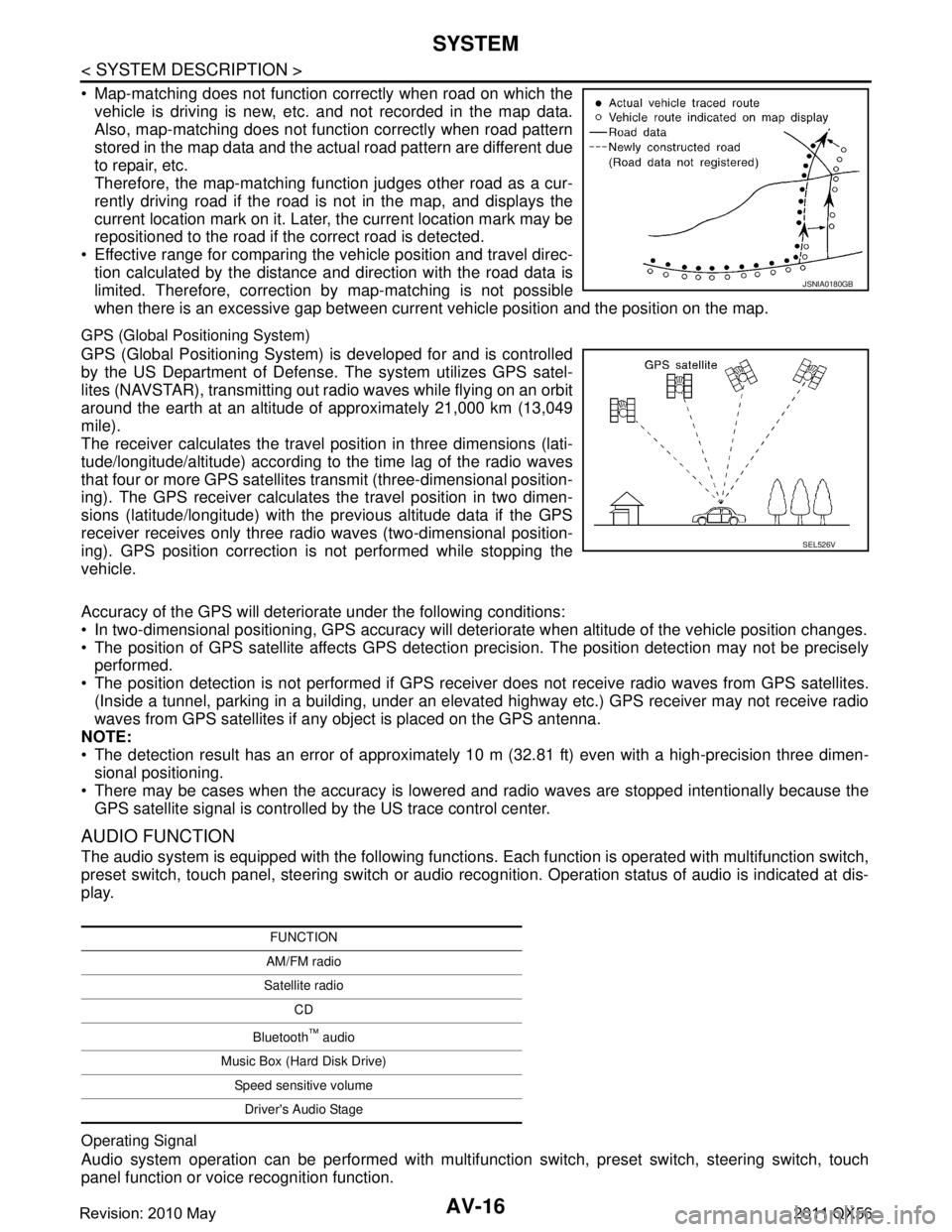

Map-matching does not function correctly when road on which thevehicle is driving is new, etc. and not recorded in the map data.

Also, map-matching does not function correctly when road pattern

stored in the map data and the actual road pattern are different due

to repair, etc.

Therefore, the map-matching func tion judges other road as a cur-

rently driving road if the road is not in the map, and displays the

current location mark on it. Later, the current location mark may be

repositioned to the road if t he correct road is detected.

Effective range for comparing the vehicle position and travel direc- tion calculated by the distance and direction with the road data is

limited. Therefore, correction by map-matching is not possible

when there is an excessive gap between current vehicle position and the position on the map.

GPS (Global Positioning System)

GPS (Global Positioning System) is developed for and is controlled

by the US Department of Defens e. The system utilizes GPS satel-

lites (NAVSTAR), transmitting out radio waves while flying on an orbit

around the earth at an altitude of approximately 21,000 km (13,049

mile).

The receiver calculates the travel position in three dimensions (lati-

tude/longitude/altitude) according to the time lag of the radio waves

that four or more GPS satellites transmit (three-dimensional position-

ing). The GPS receiver calculates the travel position in two dimen-

sions (latitude/longitude) with the previous altitude data if the GPS

receiver receives only three radio waves (two-dimensional position-

ing). GPS position correction is not performed while stopping the

vehicle.

Accuracy of the GPS will deteriorate under the following conditions:

In two-dimensional positioning, GPS accuracy will det eriorate when altitude of the vehicle position changes.

The position of GPS satellite affects GPS detection pr ecision. The position detection may not be precisely

performed.

The position detection is not performed if GPS receiver does not receive radio waves from GPS satellites.

(Inside a tunnel, parking in a building, under an elevat ed highway etc.) GPS receiver may not receive radio

waves from GPS satellites if any object is placed on the GPS antenna.

NOTE:

The detection result has an error of approximately 10 m (32.81 ft) even with a high-precision three dimen- sional positioning.

There may be cases when the accuracy is lowered and radio waves are stopped intentionally because the GPS satellite signal is controlled by the US trace control center.

AUDIO FUNCTION

The audio system is equipped with the following functions. Each function is operated with multifunction switch,

preset switch, touch panel, steering switch or audio rec ognition. Operation status of audio is indicated at dis-

play.

Operating Signal

Audio system operation can be performed with multifuncti on switch, preset switch, steering switch, touch

panel function or voice recognition function.

JSNIA0180GB

SEL526V

FUNCTION

AM/FM radio

Satellite radio CD

Bluetooth

™ audio

Music Box (Hard Disk Drive) Speed sensitive volumeDriver's Audio Stage

Revision: 2010 May2011 QX56

Page 723 of 5598

BRM-48

< SERVICE DATA AND SPECIFICATIONS (SDS)

BODY ALIGNMENT

SERVICE DATA AND SPECIFICATIONS (SDS)

BODY ALIGNMENT

Body Center MarksINFOID:0000000006248507

A mark is placed on each part of the body to indicate the vehicle center. When repairing the vehicle frame

(members, pillars, etc.) damaged by an accident which it enables more accurate and effective repair by using

these marks together with body alignment specifications.

Unit: mm (in)

DescriptionINFOID:0000000006248508

All dimensions indicated in the figures are actual.

When using a tracking gauge, adjust both pointers to equal length. Then check the pointers and gauge itself

to make sure there is no free play.

: Vehicle front

Points Portion Marks

A Upper dash Hole 7 ×12 (0.28 ×0.47)

B Cowl top Embossment

C Rear roof Indent

JSKIA1895ZZ

Revision: 2010 May2011 QX56

Page 724 of 5598

BODY ALIGNMENTBRM-49

< SERVICE DATA AND SPECIFICATIONS (SDS)

C

DE

F

G H

I

J

L

M A

B

BRM

N

O P

When a measuring tape is used, check to be su re there is no elongation, twisting or bending.

Measurements should be taken at the center of the mounting holes.

An asterisk (*) following the value at the measuring poi nt indicates that the measuring point on the other side

is symmetrically the same value.

The coordinates of the measurement points are the distances measured from the standard line of ″X ″, ″Y ″

and ″Z ″.

″Z ″: Imaginary base line [300 mm (11.81 in) below datum line ( ″0Z ″ at design plan)]

Engine CompartmentINFOID:0000000006248509

Measurement

Dimensions marked with ″*″ indicate symmetrically identical dimensions on both the right and left hand of the

vehicle.

1. Vehicle center 2. Front axle center 3. Imaginary base line

JSKIA0073GB

Revision: 2010 May2011 QX56

Page 727 of 5598

BRM-52

< SERVICE DATA AND SPECIFICATIONS (SDS)

BODY ALIGNMENT

Underbody

INFOID:0000000006248510

Measurement

Dimensions marked with ″*″ indicate symmetrically identical dimensions on both the right and left hand of the

vehicle.

The following figure shows a bottom view and a side view of the vehicle.

JSKIA1948GB

Revision: 2010 May2011 QX56

Page 729 of 5598

BRM-54

< SERVICE DATA AND SPECIFICATIONS (SDS)

BODY ALIGNMENT

Passenger Compartment

INFOID:0000000006248511

Measurement

Dimensions marked with ″*″ indicate symmetrically identical dimensions on both the right and left hand of the

vehicle.

«The others»

c −

289.6

( − 11 . 4 0 2 ) 0.2

(0.008) 305.8

(12.039) Hole

φ19 (0.75) J, j ±

501.7

( ± 19.752) 3750.7

(147.665) 378.4

(14.898) Hole

φ8 (0.31)

D, d ±

461.8

( ± 18.181) 807.5

(31.791) 104.1

(4.098) Hole

φ10 (0.39) K, k ±

561.6

( ± 22.110) 4050.0

(159.449) 337.0

(13.268) Hole

φ15 (0.59)

E, e ±

592.0

( ± 23.307) 1320.0

(51.968) 98.3

(3.870) Hole 20

×8

(0.79 ×0.31) M, m

±

498.4

( ± 19.622) -29.6

(-1.165) 519.2

(20.441) Hole

φ70 (2.76)

Points

Coordinates

Remarks Points Coordinates

Remarks

XYZ XYZ

Unit: mm (in)

JSKIA1900GB

Revision: 2010 May2011 QX56

Page 731 of 5598

BRM-56

< SERVICE DATA AND SPECIFICATIONS (SDS)

BODY ALIGNMENT

Unit: mm (in)

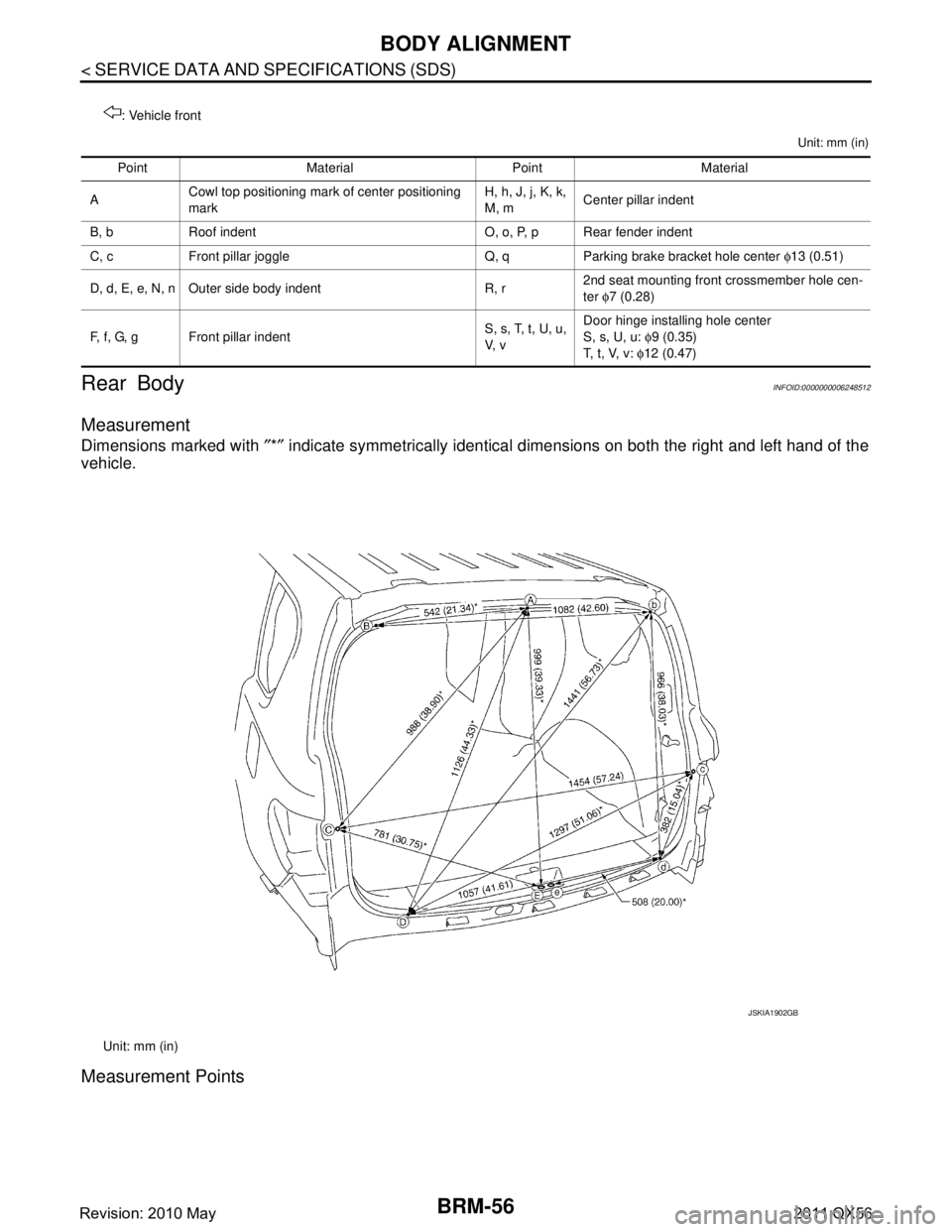

Rear BodyINFOID:0000000006248512

Measurement

Dimensions marked with ″*″ indicate symmetrically identical dimensions on both the right and left hand of the

vehicle.

Measurement Points

: Vehicle front

Point Material Point Material

A Cowl top positioning mark of center positioning

mark H, h, J, j, K, k,

M, m

Center pillar indent

B, b Roof indent O, o, P, p Rear fender indent

C, c Front pillar joggle Q, q Parking brake bracket hole center φ13 (0.51)

D, d, E, e, N, n Outer side body indent R, r 2nd seat mounting front crossmember hole cen-

ter

φ7 (0.28)

F, f, G, g Front pillar indent S, s, T, t, U, u,

V, vDoor hinge installing hole center

S, s, U, u:

φ9 (0.35)

T, t, V, v: φ12 (0.47)

Unit: mm (in)

JSKIA1902GB

Revision: 2010 May2011 QX56

Page 2567 of 5598

PRECAUTIONSEM-5

< PRECAUTION >

C

DE

F

G H

I

J

K L

M A

EM

NP

O

Avoid damaging sliding or mating surfaces. Completely re

move foreign materials such as cloth lint or dust.

Before assembly, oil sliding surfaces well.

Release air within route when refilling after draining engine coolant.

After repairing, start engine and increase engine speed to check engine coolant, fuel, engine oil, and

exhaust gases for leakage.

Parts Requiring Angle TighteningINFOID:0000000006289515

Use angle wrench [SST: KV10112100 (BT8653-A)] for the final tightening of the following engine parts:

- Cylinder head bolts

- Main bearing cap bolts

- Main bearing cap sub bolts

- Connecting rod cap bolts

- Crankshaft pulley bolt (No angle wrench is required as the bolt flange is provided with notches for angletightening)

Ensure thread and seat surfaces are clean and coated with engine oil.

Precaution for Liquid GasketINFOID:0000000006289516

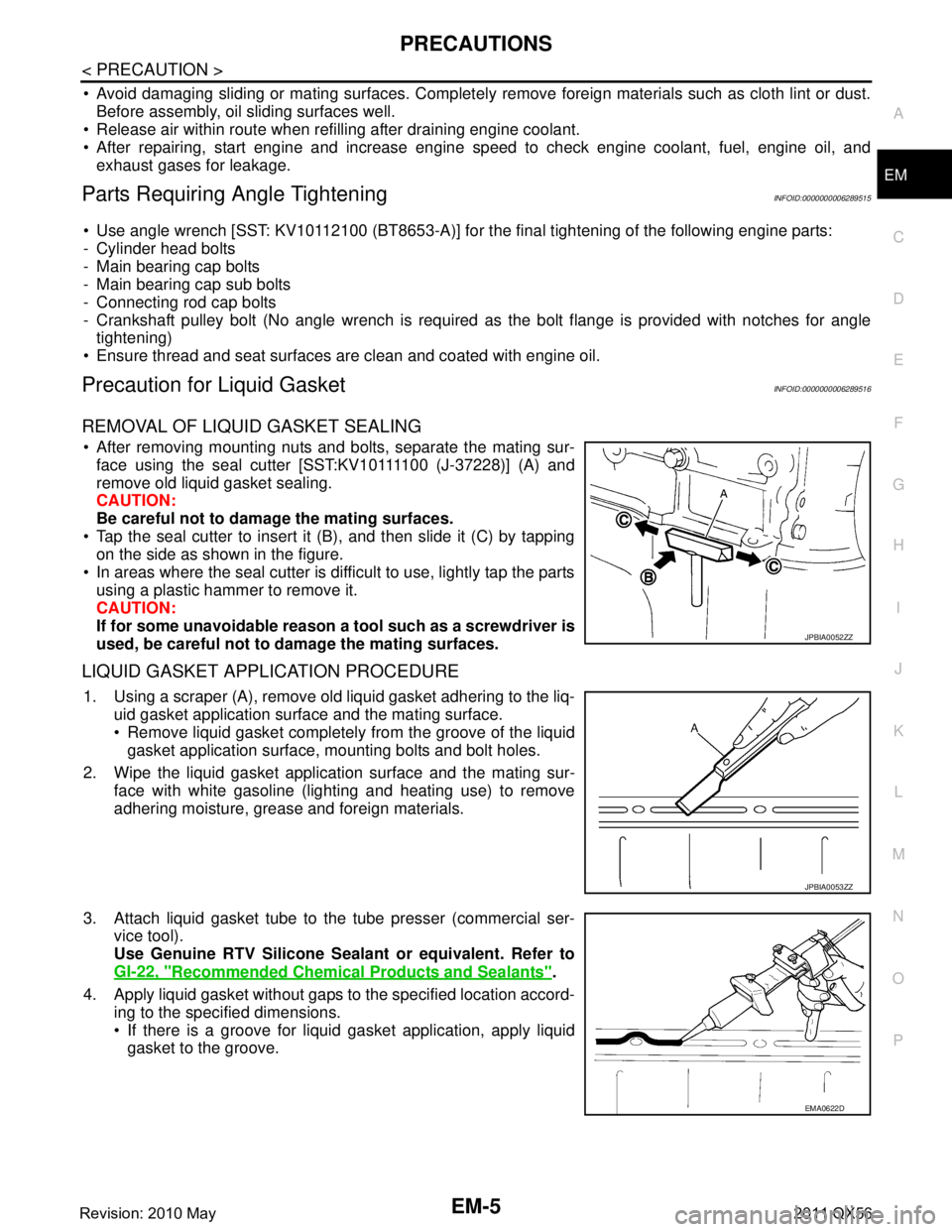

REMOVAL OF LIQUID GASKET SEALING

After removing mounting nuts and bolts, separate the mating sur- face using the seal cutter [SST:KV10111100 (J-37228)] (A) and

remove old liquid gasket sealing.

CAUTION:

Be careful not to damage the mating surfaces.

Tap the seal cutter to insert it (B), and then slide it (C) by tapping on the side as shown in the figure.

In areas where the seal cutter is difficult to use, lightly tap the parts using a plastic hammer to remove it.

CAUTION:

If for some unavoidable reason a tool such as a screwdriver is

used, be careful not to damage the mating surfaces.

LIQUID GASKET APPLICATION PROCEDURE

1. Using a scraper (A), remove old liquid gasket adhering to the liq- uid gasket application surface and the mating surface.

Remove liquid gasket completely from the groove of the liquidgasket application surface, mounting bolts and bolt holes.

2. Wipe the liquid gasket application surface and the mating sur- face with white gasoline (lighting and heating use) to remove

adhering moisture, grease and foreign materials.

3. Attach liquid gasket tube to the tube presser (commercial ser- vice tool).

Use Genuine RTV Silicone Seal ant or equivalent. Refer to

GI-22, "

Recommended Chemical Products and Sealants".

4. Apply liquid gasket without gaps to the specified location accord- ing to the specified dimensions.

If there is a groove for liquid gasket application, apply liquidgasket to the groove.

JPBIA0052ZZ

JPBIA0053ZZ

EMA0622D

Revision: 2010 May2011 QX56

Page 2572 of 5598

EM-10

< PREPARATION >

PREPARATION

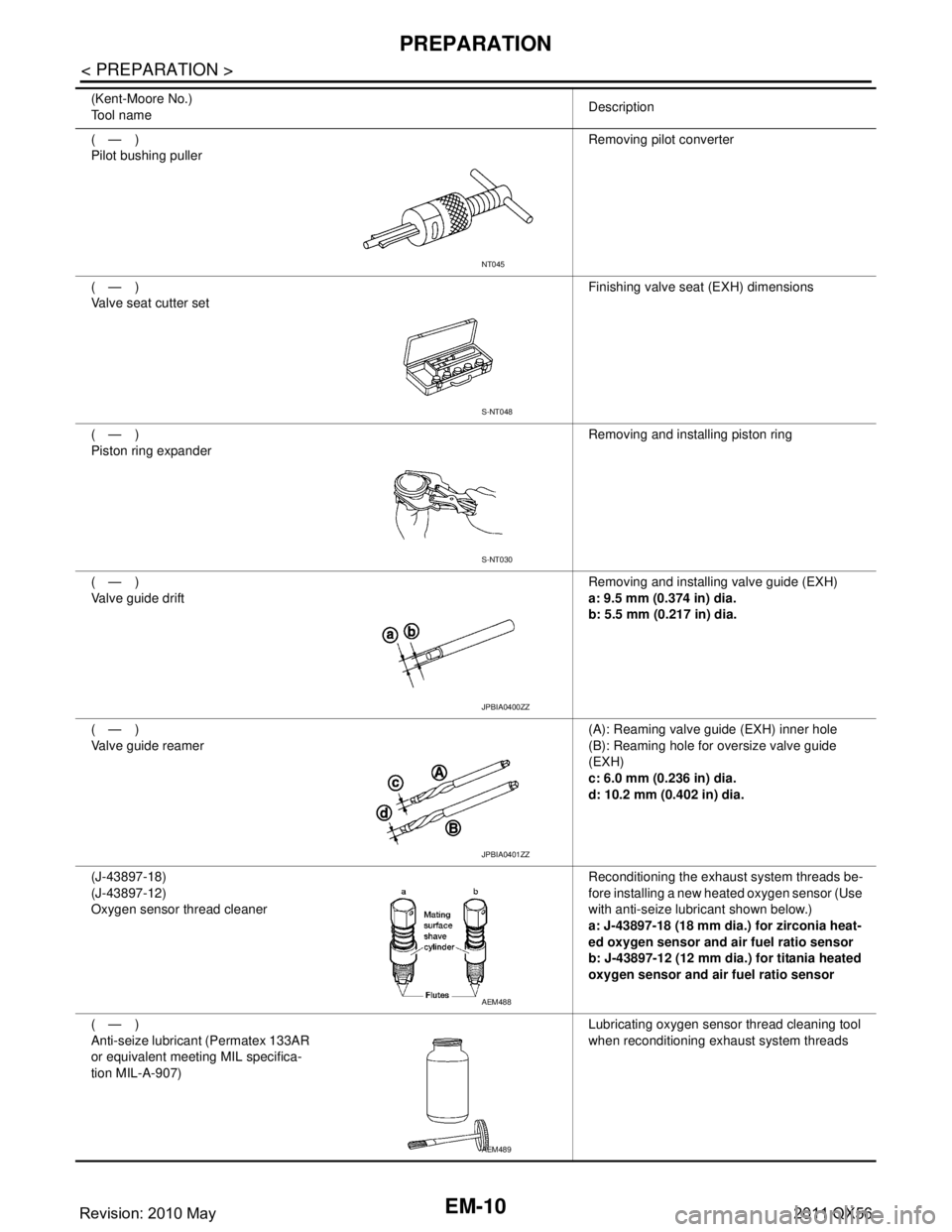

(—)

Pilot bushing pullerRemoving pilot converter

(—)

Valve seat cutter set Finishing valve seat (EXH) dimensions

(—)

Piston ring expander Removing and installing piston ring

(—)

Valve guide drift Removing and installing valve guide (EXH)

a: 9.5 mm (0.374 in) dia.

b: 5.5 mm (0.217 in) dia.

(—)

Valve guide reamer (A): Reaming valve guide (EXH) inner hole

(B): Reaming hole for oversize valve guide

(EXH)

c: 6.0 mm (0.236 in) dia.

d: 10.2 mm (0.402 in) dia.

(J-43897-18)

(J-43897-12)

Oxygen sensor thread cleaner Reconditioning the exhaust system threads be-

fore installing a new heated oxygen sensor (Use

with anti-seize lubricant shown below.)

a: J-43897-18 (18 mm dia.) for zirconia heat-

ed oxygen sensor and air fuel ratio sensor

b: J-43897-12 (12 mm dia.) for titania heated

oxygen sensor and air fuel ratio sensor

(—)

Anti-seize lubricant (Permatex 133AR

or equivalent meeting MIL specifica-

tion MIL-A-907) Lubricating oxygen sensor thread cleaning tool

when reconditioning exhaust system threads

(Kent-Moore No.)

Tool name

Description

NT045

S-NT048

S-NT030

JPBIA0400ZZ

JPBIA0401ZZ

AEM488

AEM489

Revision: 2010 May2011 QX56

Page 2652 of 5598

![INFINITI QX56 2011 Factory Service Manual

EM-90

< REMOVAL AND INSTALLATION >

CYLINDER HEAD

b. Drive out valve guide (EXH) with a press [under a 20 kN (2 ton,2.2 US ton, 2.0 lmp ton) pressure] or a hammer and the valve

guide drift (commercial INFINITI QX56 2011 Factory Service Manual

EM-90

< REMOVAL AND INSTALLATION >

CYLINDER HEAD

b. Drive out valve guide (EXH) with a press [under a 20 kN (2 ton,2.2 US ton, 2.0 lmp ton) pressure] or a hammer and the valve

guide drift (commercial](/img/42/57033/w960_57033-2651.png)

EM-90

< REMOVAL AND INSTALLATION >

CYLINDER HEAD

b. Drive out valve guide (EXH) with a press [under a 20 kN (2 ton,2.2 US ton, 2.0 lmp ton) pressure] or a hammer and the valve

guide drift (commercial service tool).

WARNING:

Cylinder head contains heat . When working, wear protec-

tive equipment to avo id getting burned.

ASSEMBLY

1. Install valve guide (EXH), if removed.

Replace with oversized [0.2 mm (0.008 in)] valve guide (EXH).

a. Using the valve guide reamer (commercial service tool) (A), ream cylinder head valve guide (EXH) hole.

b. Heat cylinder head to 110 to 130 °C (230 to 266 °F) by soaking in

heated oil (A).

c. Using the valve guide drift (commercial service tool), press valve guide (EXH) from camshaft side to the dimensions as shown in

the figure.

WARNING:

Cylinder head contains heat . When working, wear protec-

tive equipment to avo id getting burned.

SEM931C

Oversize (service) [0.2 mm (0.008 in)]:

: Refer to EM-135, "

CylinderHead".

JPBIA0185ZZ

JPBIA0184ZZ

Projection (A)

: Refer to EM-135, "

CylinderHead".

JPBIA0186ZZ

Revision: 2010 May2011 QX56

Page 2653 of 5598

CYLINDER HEADEM-91

< REMOVAL AND INSTALLATION >

C

DE

F

G H

I

J

K L

M A

EM

NP

O

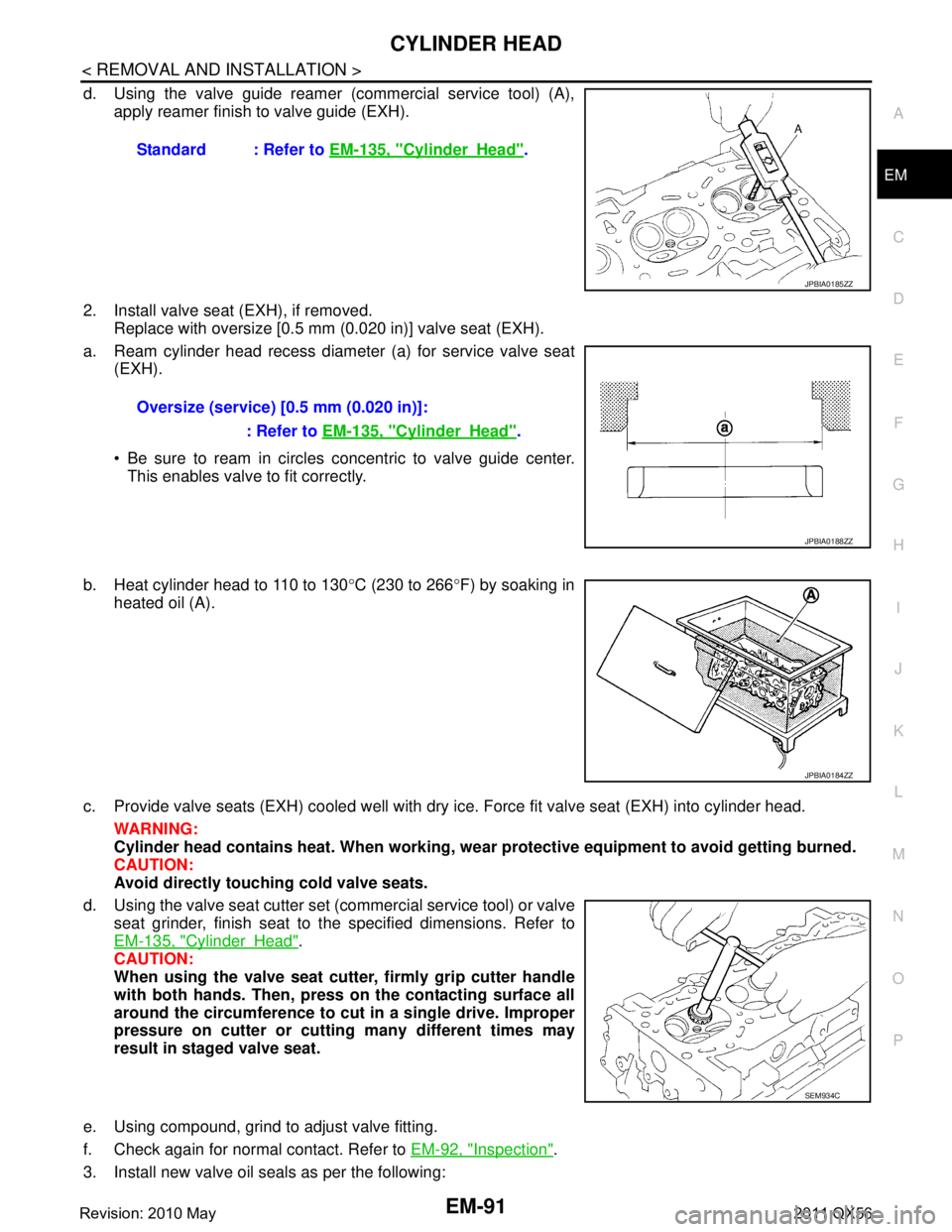

d. Using the valve guide reamer (commercial service tool) (A),

apply reamer finish to valve guide (EXH).

2. Install valve seat (EXH), if removed. Replace with oversize [0.5 mm (0.020 in)] valve seat (EXH).

a. Ream cylinder head recess diameter (a) for service valve seat (EXH).

Be sure to ream in circles concentric to valve guide center.

This enables valve to fit correctly.

b. Heat cylinder head to 110 to 130 °C (230 to 266 °F) by soaking in

heated oil (A).

c. Provide valve seats (EXH) cooled well with dry ice. Force fit valve seat (EXH) into cylinder head. WARNING:

Cylinder head contains heat. When working, w ear protective equipment to avoid getting burned.

CAUTION:

Avoid directly touching cold valve seats.

d. Using the valve seat cutter set (commercial service tool) or valve seat grinder, finish seat to the specified dimensions. Refer to

EM-135, "

CylinderHead".

CAUTION:

When using the valve seat cutt er, firmly grip cutter handle

with both hands. Then, press on the contacting surface all

around the circumference to cu t in a single drive. Improper

pressure on cutter or cutting many different times may

result in staged valve seat.

e. Using compound, grind to adjust valve fitting.

f. Check again for normal contact. Refer to EM-92, "

Inspection".

3. Install new valve oil seals as per the following: Standard : Refer to

EM-135, "

CylinderHead".

JPBIA0185ZZ

Oversize (service) [0.5 mm (0.020 in)]:

: Refer to EM-135, "

CylinderHead".

JPBIA0188ZZ

JPBIA0184ZZ

SEM934C

Revision: 2010 May2011 QX56