engine INFINITI QX56 2011 Factory Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2011, Model line: QX56, Model: INFINITI QX56 2011Pages: 5598, PDF Size: 94.53 MB

Page 1 of 5598

A

B

D

E

F

G

H

I

J

K

L

M

N

P

O

C

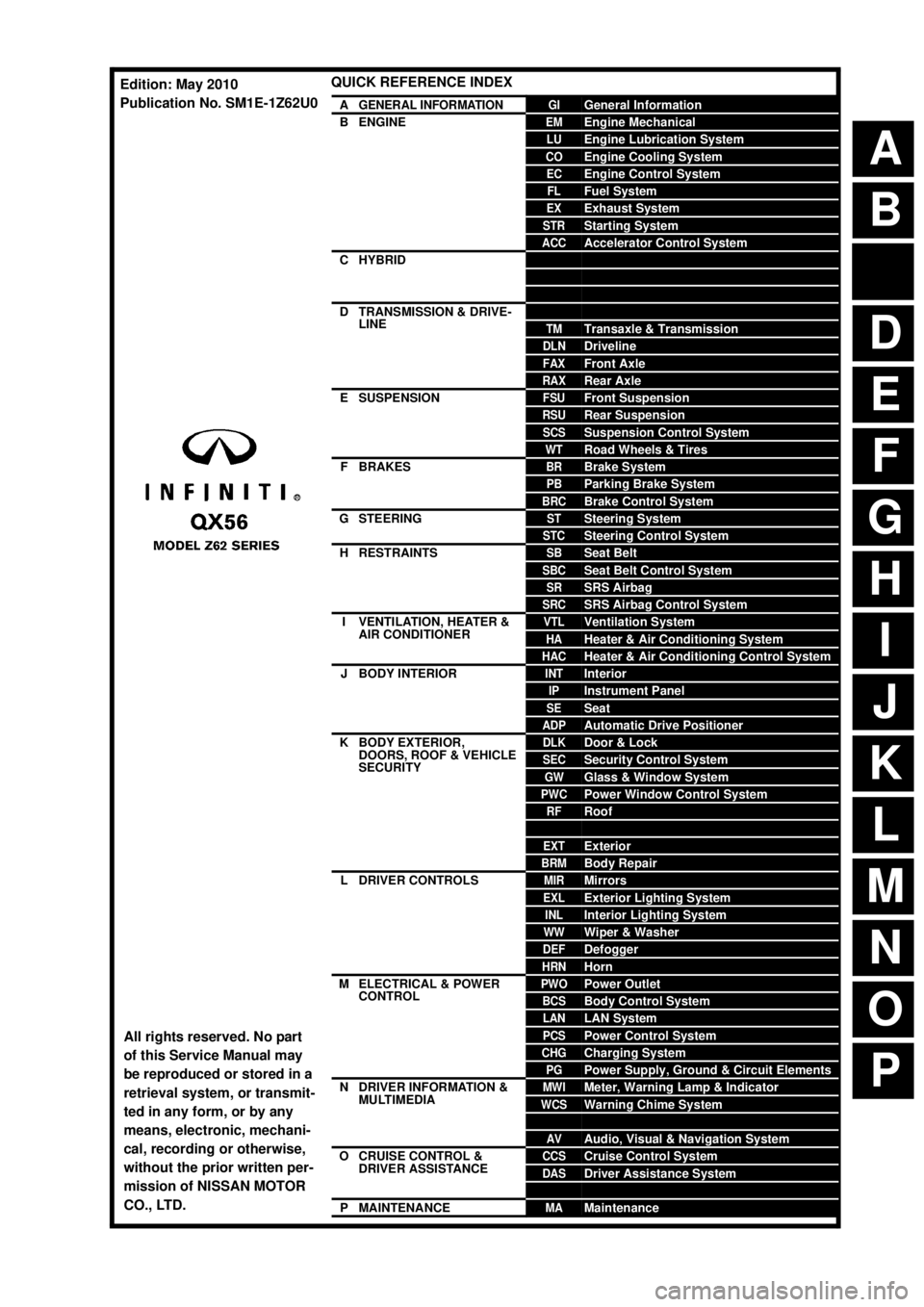

QUICK REFERENCE INDEX

AGENERAL INFORMATIONGIGeneral Information

BENGINEEMEngine Mechanical

LUEngine Lubrication System

COEngine Cooling System

ECEngine Control System

FLFuel System

EXExhaust System

STRStarting System

ACCAccelerator Control System

CHYBRIDHBCHybrid Control System

HBBHybrid Battery System

HBRHybrid Brake System

DTRANSMISSION & DRIVE-

LINECLClutch

TMTransaxle & Transmission

DLNDriveline

FAXFront Axle

RAXRear Axle

ESUSPENSIONFSUFront Suspension

RSURear Suspension

SCSSuspension Control System

WTRoad Wheels & Tires

FBRAKESBRBrake System

PBParking Brake System

BRCBrake Control System

GSTEERINGSTSteering System

STCSteering Control System

HRESTRAINTSSBSeat Belt

SBCSeat Belt Control System

SRSRS Airbag

SRCSRS Airbag Control System

IVENTILATION, HEATER &

AIR CONDITIONERVTLVentilation System

HAHeater & Air Conditioning System

HACHeater & Air Conditioning Control System

JBODY INTERIORINTInterior

IPInstrument Panel

SESeat

ADPAutomatic Drive Positioner

KBODY EXTERIOR,

DOORS, ROOF & VEHICLE

SECURITYDLKDoor & Lock

SECSecurity Control System

GWGlass & Window System

PWCPower Window Control System

RFRoof

HDHood

EXTExterior

BRMBody Repair

LDRIVER CONTROLSMIRMirrors

EXLExterior Lighting System

INLInterior Lighting System

WWWiper & Washer

DEFDefogger

HRNHorn

MELECTRICAL & POWER

CONTROLPWOPower Outlet

BCSBody Control System

LANLAN System

PCSPower Control System

CHGCharging System

PGPower Supply, Ground & Circuit Elements

NDRIVER INFORMATION &

MULTIMEDIAMWIMeter, Warning Lamp & Indicator

WCSWarning Chime System

SNSonar System

AVAudio, Visual & Navigation System

OCRUISE CONTROL &

DRIVER ASSISTANCECCSCruise Control System

DASDriver Assistance System

DMSDrive Mode System

PMAINTENANCEMAMaintenance

All rights reserved. No part

of this Service Manual may

be reproduced or stored in a

retrieval system, or transmit-

ted in any form, or by any

means, electronic, mechani-

cal, recording or otherwise,

without the prior written per-

mission of NISSAN MOTOR

CO., LTD.

Edition: May 2010

Publication No. SM1E-1Z62U0

Page 3 of 5598

QUICK REFERENCE CHART QX56

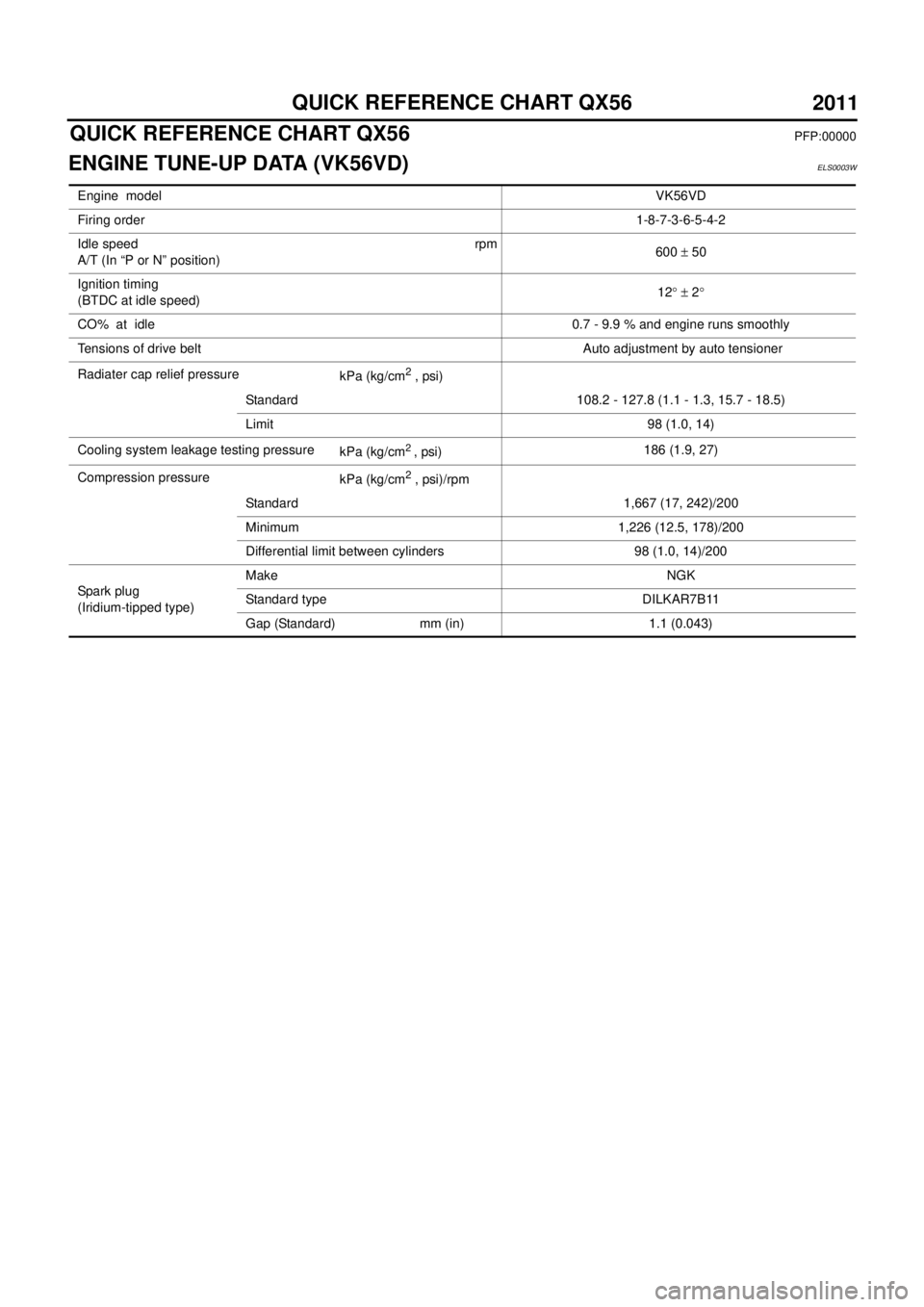

QUICK REFERENCE CHART QX56PFP:00000

ENGINE TUNE-UP DATA (VK56VD)ELS0003W

Engine modelVK56VD

Firing order 1-8-7-3-6-5-4-2

Idle speed

A/T (In “P or N” position) rpm

600 ± 50

Ignition timing

(BTDC at idle speed) 12

° ± 2 °

CO% at idle 0.7 - 9.9 % and engine runs smoothly

Tensions of drive belt Auto adjustment by auto tensioner

Radiater cap relief pressure kPa (kg/cm

2 , psi)

Standard 108.2 - 127.8 (1.1 - 1.3, 15.7 - 18.5)

Limit 98 (1.0, 14)

Cooling system leakage testing pressure kPa (kg/cm

2 , psi)186 (1.9, 27)

Compression pressure kPa (kg/cm

2 , psi)/rpm

Standard 1,667 (17, 242)/200

Minimum 1,226 (12.5, 178)/200

Differential limit between cylinders 98 (1.0, 14)/200

Spark plug

(Iridium-tipped type) Make NGK

Standard type DILKAR7B11

Gap (Standard) mm (in) 1.1 (0.043)

2011

Page 4 of 5598

QUICK REFERENCE CHART QX56

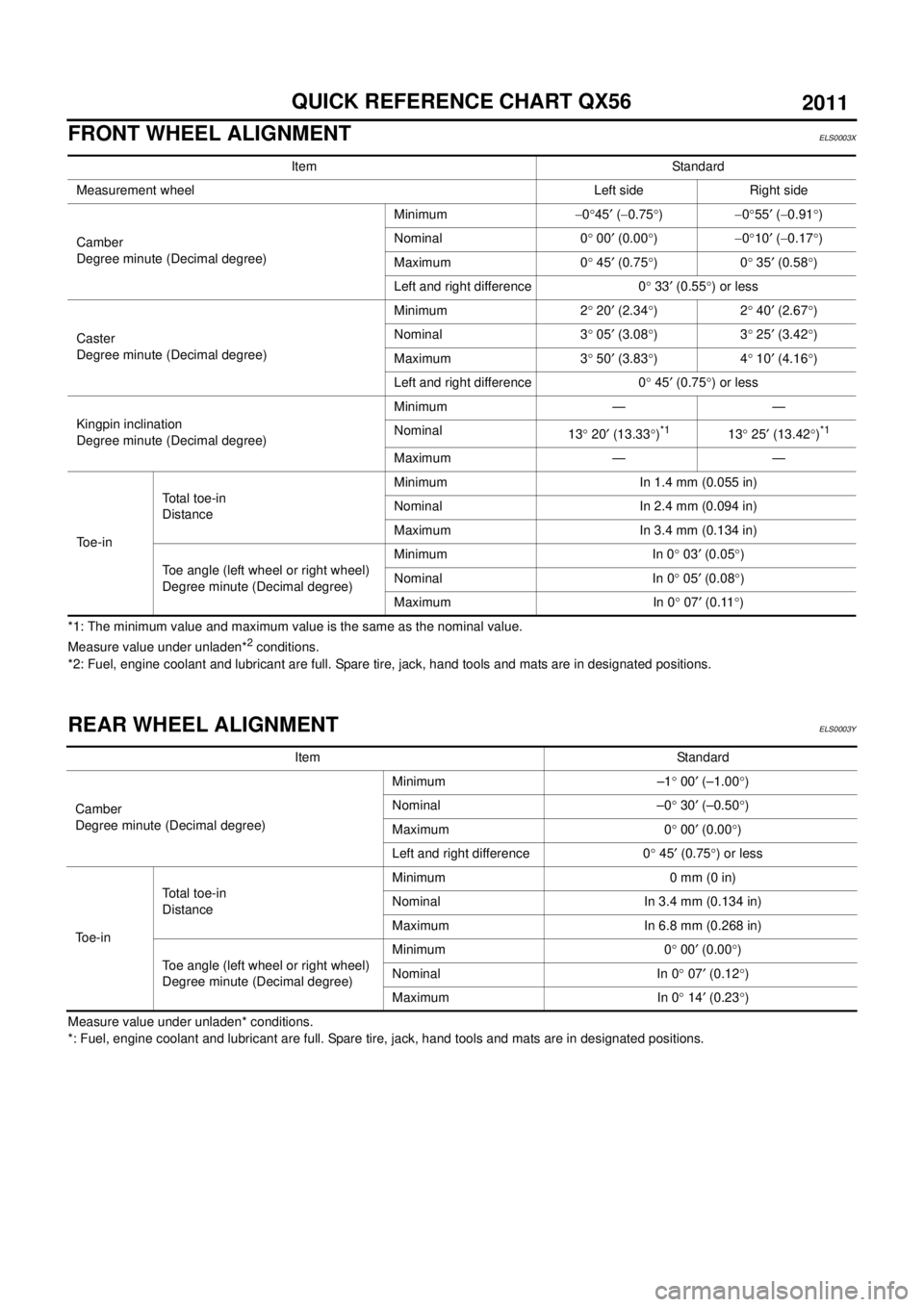

FRONT WHEEL ALIGNMENT

ELS0003X

*1: The minimum value and maximum value is the same as the nominal value.

Measure value under unladen*2 conditions.

*2: Fuel, engine coolant and lubricant are full. Spare tire, jack, hand tools and mats are in designated positions.

REAR WHEEL ALIGNMENTELS0003Y

Measure value under unladen* conditions.

*: Fuel, engine coolant and lubricant are full. Spare tire, jack, hand tools and mats are in designated positions. Item Standard

Measurement wheel Left side Right side

Camber

Degree minute (Decimal degree) Minimum

−0 °45 ′ ( −0.75 °) −0°55 ′ ( −0.91 °)

Nominal 0 ° 00 ′ (0.00 °) −0°10 ′ ( −0.17 °)

Maximum 0 ° 45 ′ (0.75 °)0 ° 35 ′ (0.58 °)

Left and right difference 0 ° 33 ′ (0.55 °) or less

Caster

Degree minute (Decimal degree) Minimum 2

° 20 ′ (2.34 °)2 ° 40 ′ (2.67 °)

Nominal 3 ° 05 ′ (3.08 °)3 ° 25 ′ (3.42 °)

Maximum 3 ° 50 ′ (3.83 °)4 ° 10 ′

(4.16 °)

Left and right difference 0 ° 45 ′ (0.75 °) or less

Kingpin inclination

Degree minute (Decimal degree) Minimum — —

Nominal

13° 20 ′ (13.33 °)

*113 ° 25 ′ (13.42 °)*1

Maximum — —

Toe-in Total toe-in

Distance

Minimum In 1.4 mm (0.055 in)

Nominal In 2.4 mm (0.094 in)

Maximum In 3.4 mm (0.134 in)

Toe angle (left wheel or right wheel)

Degree minute (Decimal degree) Minimum In 0

° 03 ′ (0.05 °)

Nominal In 0 ° 05 ′ (0.08 °)

Maximum In 0 ° 07 ′ (0.11 °)

Item Standard

Camber

Degree minute (Decimal degree) Minimum –1

° 00 ′ (–1.00 °)

Nominal –0 ° 30 ′ (–0.50 °)

Maximum 0 ° 00 ′ (0.00 °)

Left and right difference 0 ° 45 ′ (0.75 °) or less

To e - i n Total toe-in

Distance

Minimum 0 mm (0 in)

Nominal In 3.4 mm (0.134 in)

Maximum In 6.8 mm (0.268 in)

Toe angle (left wheel or right wheel)

Degree minute (Decimal degree) Minimum 0

° 00 ′ (0.00 °)

Nominal In 0 ° 07 ′ (0.12 °)

Maximum In 0 ° 14 ′ (0.23 °)

2011

Page 5 of 5598

QUICK REFERENCE CHART QX56

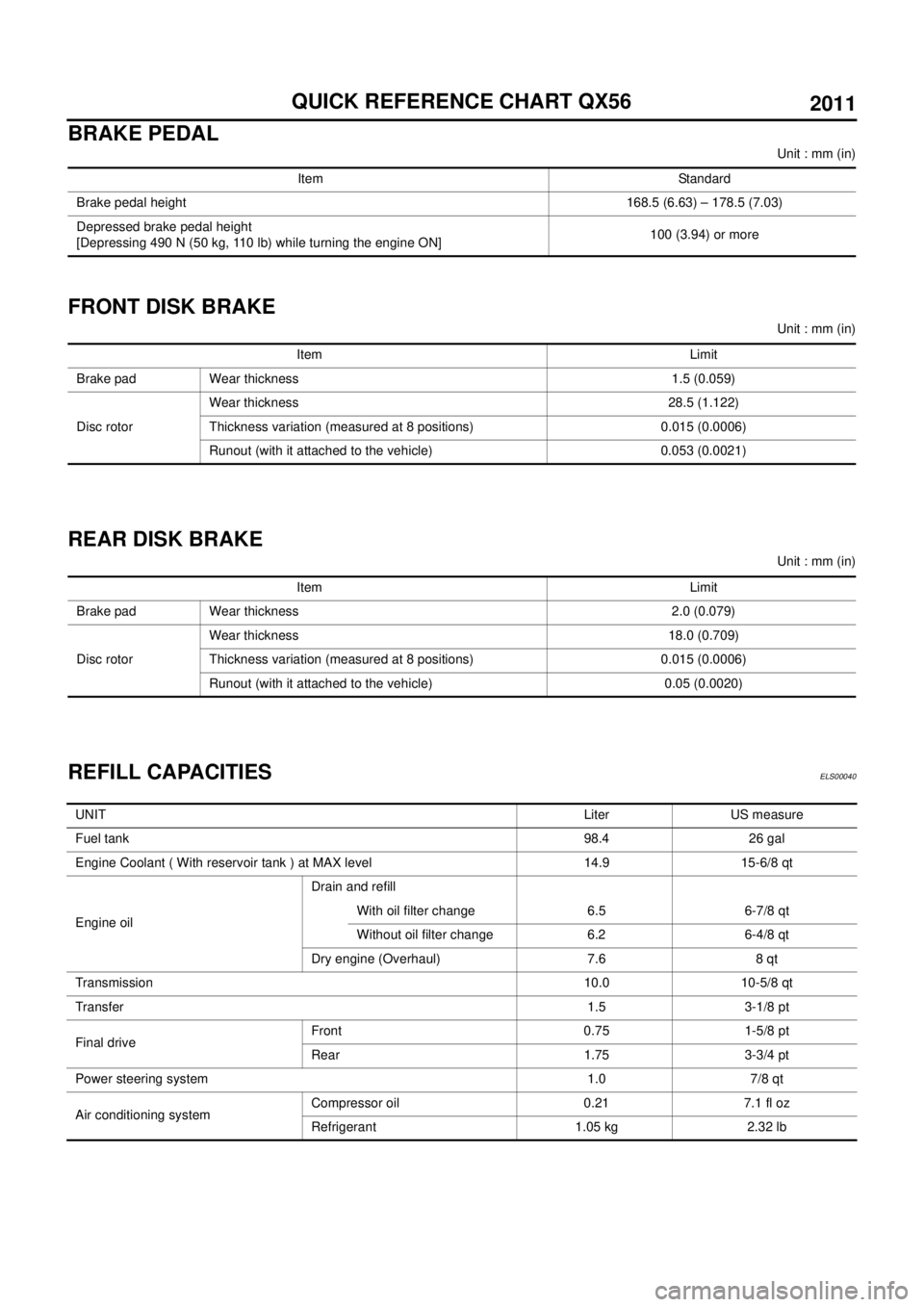

BRAKE PEDAL

Unit : mm (in)

FRONT DISK BRAKE

Unit : mm (in)

REAR DISK BRAKE

Unit : mm (in)

REFILL CAPACITIESELS00040

Item Standard

Brake pedal height 168.5 (6.63) – 178.5 (7.03)

Depressed brake pedal height

[Depressing 490 N (50 kg, 110 lb) while turning the engine ON] 100 (3.94) or more

Item Limit

Brake pad Wear thickness 1.5 (0.059)

Disc rotor Wear thickness 28.5 (1.122)

Thickness variation (measured at 8 positions) 0.015 (0.0006)

Runout (with it attached to the vehicle) 0.053 (0.0021)

Item Limit

Brake pad Wear thickness 2.0 (0.079)

Disc rotor Wear thickness 18.0 (0.709)

Thickness variation (measured at 8 positions) 0.015 (0.0006)

Runout (with it attached to the vehicle) 0.05 (0.0020)

UNIT

Liter US measure

Fuel tank 98.4 26 gal

Engine Coolant ( With reservoir tank ) at MAX level 14.9 15-6/8 qt

Engine oil Drain and refill

With oil filter change 6.5 6-7/8 qt

Without oil filter change 6.2 6-4/8 qt

Dry engine (Overhaul) 7.6 8 qt

Transmission 10.0 10-5/8 qt

Transfer 1.5 3-1/8 pt

Final drive Front 0.75 1-5/8 pt

Rear 1.75 3-3/4 pt

Power steering system 1.0 7/8 qt

Air conditioning system Compressor oil 0.21 7.1 fl oz

Refrigerant 1.05 kg 2.32 lb

2011

Page 6 of 5598

ACC-1

ENGINE

C

DE

F

G H

I

J

K L

M

SECTION ACC

A

ACC

N

O P

CONTENTS

ACCELERATOR CONTROL SYSTEM

PRECAUTION ................ ...............................2

PRECAUTIONS .............................................. .....2

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ............................................................. ......

2

REMOVAL AND INSTALLATION ................3

ACCELERATOR CONTROL SYSTEM .......... .....3

MODELS WITHOUT DISTANCE CONTROL AS-

SIST SYSTEM ....................................... ......................

3

MODELS WITHOUT DISTANCE CONTROL AS-

SIST SYSTEM : Exploded View ................................

3

MODELS WITHOUT DISTANCE CONTROL AS-

SIST SYSTEM : Removal an d Installation ...............

3

MODELS WITHOUT DISTANCE CONTROL AS-

SIST SYSTEM : Inspection ......................................

3

MODELS WITH DISTANCE CONTROL ASSIST

SYSTEM .......... ............................................................

4

MODELS WITH DISTANCE CONTROL ASSIST

SYSTEM : Exploded View ................................... .....

4

MODELS WITH DISTANCE CONTROL ASSIST

SYSTEM : Removal and Installation ........................

4

MODELS WITH DISTANCE CONTROL ASSIST

SYSTEM : Inspection ...............................................

4

Revision: 2010 May2011 QX56

Page 7 of 5598

ACC-2

< PRECAUTION >

PRECAUTIONS

PRECAUTION

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000006289699

The Supplemental Restraint System such as “A IR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severi ty of injury to the driver and front passenger for certain

types of collision. This system includes seat belt switch inputs and dual stage front air bag modules. The SRS

system uses the seat belt switches to determine the front air bag deployment, and may only deploy one front

air bag, depending on the severity of a collision and w hether the front occupants are belted or unbelted.

Information necessary to service the system safely is included in the “SRS AIR BAG” and “SEAT BELT” of this

Service Manual.

WARNING:

• To avoid rendering the SRS inopera tive, which could increase the risk of personal injury or death in

the event of a collision that would result in air bag inflation, all maintenance must be performed by

an authorized NISS AN/INFINITI dealer.

Improper maintenance, including in correct removal and installation of the SRS, can lead to personal

injury caused by unintent ional activation of the system. For re moval of Spiral Cable and Air Bag

Module, see the “SRS AIR BAG”.

Do not use electrical test equipmen t on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harnesses can be identi fied by yellow and/or orange harnesses or har-

ness connectors.

PRECAUTIONS WHEN USING POWER TOOLS (AIR OR ELECTRIC) AND HAMMERS

WARNING:

When working near the Air Bag Diagnosis Sensor Unit or other Air Bag System sensors with the ignition ON or engine running, DO NOT use air or electric power tools or strike near the sensor(s)

with a hammer. Heavy vibration could activate the sensor(s) and deploy the air bag(s), possibly

causing serious injury.

When using air or electric power tools or hammers , always switch the ignition OFF, disconnect the

battery, and wait at least 3 minu tes before performing any service.

Revision: 2010 May2011 QX56

Page 14 of 5598

PRECAUTIONSADP-5

< PRECAUTION >

C

DE

F

G H

I

K L

M A

B

ADP

N

O P

PRECAUTION

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000006248300

The Supplemental Restraint System such as “A IR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severi ty of injury to the driver and front passenger for certain

types of collision. This system includes seat belt switch inputs and dual stage front air bag modules. The SRS

system uses the seat belt switches to determine the front air bag deployment, and may only deploy one front

air bag, depending on the severity of a collision and whether the front occupants are belted or unbelted.

Information necessary to service the system safely is included in the “SRS AIR BAG” and “SEAT BELT” of this

Service Manual.

WARNING:

• To avoid rendering the SRS inoper ative, which could increase the risk of personal injury or death in

the event of a collision that would result in air ba g inflation, all maintenance must be performed by

an authorized NISSAN/INFINITI dealer.

Improper maintenance, including in correct removal and installation of the SRS, can lead to personal

injury caused by unintentional act ivation of the system. For removal of Spiral Cable and Air Bag

Module, see the “SRS AIR BAG”.

Do not use electrical test equipm ent on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harnesses can be identi fied by yellow and/or orange harnesses or har-

ness connectors.

PRECAUTIONS WHEN USING POWER TOOLS (AIR OR ELECTRIC) AND HAMMERS

WARNING:

When working near the Air Bag Diagnosis Sensor Unit or other Air Bag System sensors with the

ignition ON or engine running, DO NOT use air or electric power tools or strike near the sensor(s)

with a hammer. Heavy vibration could activate the sensor(s) and deploy the air bag(s), possibly

causing serious injury.

When using air or electric power tools or hammers , always switch the ignition OFF, disconnect the

battery, and wait at least 3 minutes before performing any service.

Revision: 2010 May2011 QX56

Page 154 of 5598

AV-6

< PRECAUTION >

PRECAUTIONS

PRECAUTION

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000006225819

The Supplemental Restraint System such as “A IR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severi ty of injury to the driver and front passenger for certain

types of collision. This system includes seat belt switch inputs and dual stage front air bag modules. The SRS

system uses the seat belt switches to determine the front air bag deployment, and may only deploy one front

air bag, depending on the severity of a collision and w hether the front occupants are belted or unbelted.

Information necessary to service the system safely is included in the “SRS AIR BAG” and “SEAT BELT” of this

Service Manual.

WARNING:

• To avoid rendering the SRS inopera tive, which could increase the risk of personal injury or death in

the event of a collision that would result in air bag inflation, all maintenance must be performed by

an authorized NISS AN/INFINITI dealer.

Improper maintenance, including in correct removal and installation of the SRS, can lead to personal

injury caused by unintent ional activation of the system. For re moval of Spiral Cable and Air Bag

Module, see the “SRS AIR BAG”.

Do not use electrical test equipmen t on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harnesses can be identi fied by yellow and/or orange harnesses or har-

ness connectors.

PRECAUTIONS WHEN USING POWER TOOLS (AIR OR ELECTRIC) AND HAMMERS

WARNING:

When working near the Air Bag Diagnosis Sensor Unit or other Air Bag System sensors with the ignition ON or engine running, DO NOT use air or electric power tools or strike near the sensor(s)

with a hammer. Heavy vibration could activate the sensor(s) and deploy the air bag(s), possibly

causing serious injury.

When using air or electric power tools or hammers , always switch the ignition OFF, disconnect the

battery, and wait at least 3 minu tes before performing any service.

Precaution for Trouble DiagnosisINFOID:0000000006216211

AV COMMUNICATION SYSTEM

Do not apply voltage of 7.0 V or higher to the measurement terminals.

Use the tester with its open terminal voltage being 7.0 V or less.

Be sure to turn ignition switch OFF and disconnect the battery cable from the negative terminal before

checking the circuit.

Precaution for Harness RepairINFOID:0000000006216212

AV COMMUNICATION SYSTEM

Solder the repaired parts, and wrap with tape. [Frays of twisted line must be within 110 mm (4.33 in).]

PKIA0306E

Revision: 2010 May2011 QX56

Page 177 of 5598

AV

DIAGNOSIS SYSTEM (AV CONTROL UNIT)AV-29

< SYSTEM DESCRIPTION >

C

DE

F

G H

I

J

K L

M B A

O P

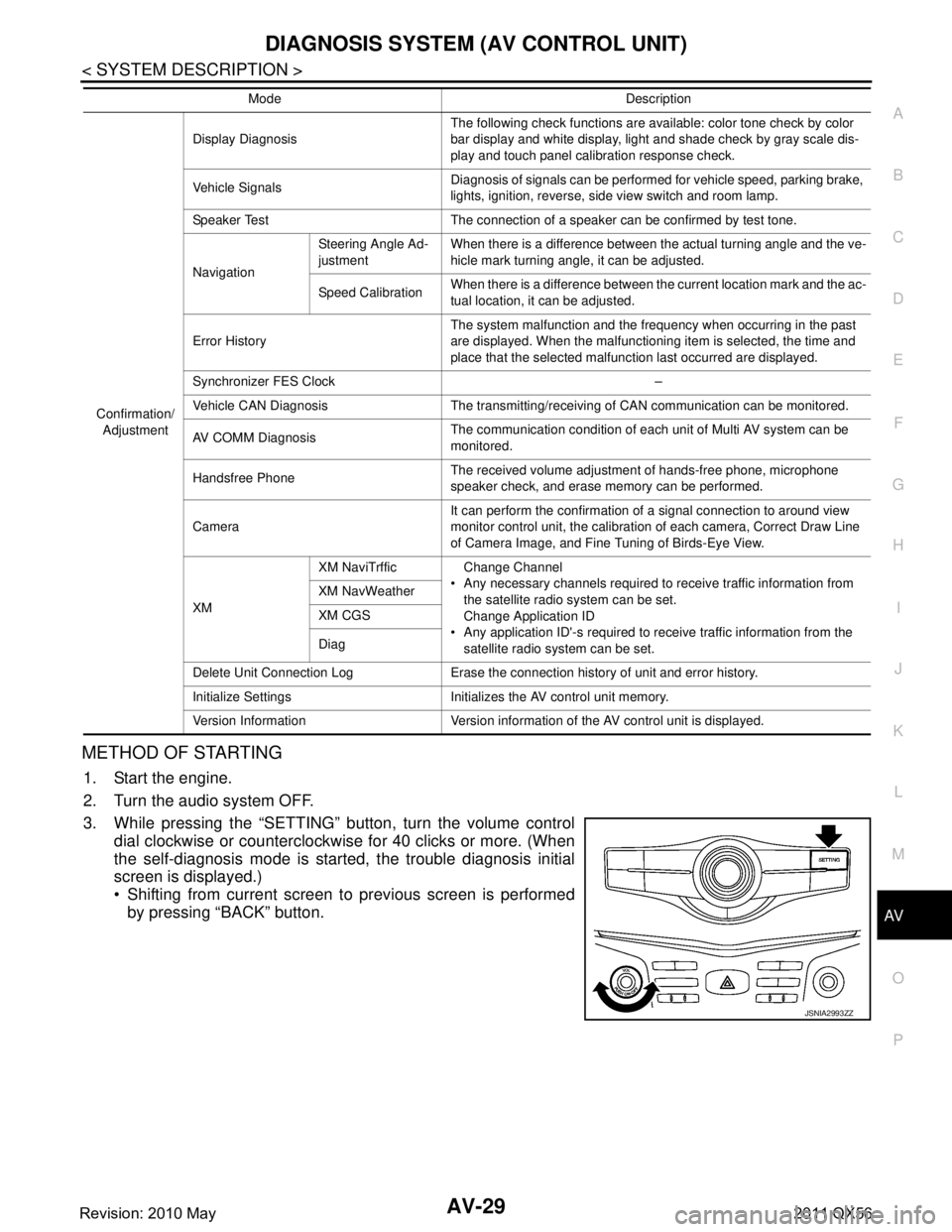

METHOD OF STARTING

1. Start the engine.

2. Turn the audio system OFF.

3. While pressing the “SETTING” button, turn the volume control dial clockwise or counterclockwise for 40 clicks or more. (When

the self-diagnosis mode is start ed, the trouble diagnosis initial

screen is displayed.)

Shifting from current screen to previous screen is performed

by pressing “BACK” button.

Confirmation/

Adjustment Display Diagnosis

The following check functions are available: color tone check by color

bar display and white display, light and shade check by gray scale dis-

play and touch panel calibration response check.

Vehicle Signals Diagnosis of signals can be performed for vehicle speed, parking brake,

lights, ignition, reverse, side view switch and room lamp.

Speaker Test The connection of a speaker can be confirmed by test tone.

Navigation Steering Angle Ad-

justment

When there is a difference between the actual turning angle and the ve-

hicle mark turning angle, it can be adjusted.

Speed Calibration When there is a difference between the current location mark and the ac-

tual location, it can be adjusted.

Error History The system malfunction and the frequency when occurring in the past

are displayed. When the malfunctioning item is selected, the time and

place that the selected malfunction last occurred are displayed.

Synchronizer FES Clock –

Vehicle CAN Diagnosis The transmitting/receiving of CAN communication can be monitored.

AV COMM Diagnosis The communication condition of each unit of Multi AV system can be

monitored.

Handsfree Phone The received volume adjustment of hands-free phone, microphone

speaker check, and erase memory can be performed.

Camera It can perform the confirmation of a signal connection to around view

monitor control unit, the calibration

of each camera, Correct Draw Line

of Camera Image, and Fine Tuning of Birds-Eye View.

XM XM NaviTrffic Change Channel

Any necessary channels required to receive traffic information from the satellite radio system can be set.

Change Application ID

Any application ID'-s required to receive traffic information from the satellite radio system can be set.

XM NavWeather

XM CGS

Diag

Delete Unit Connection Log Erase the connection history of unit and error history.

Initialize Settings Initializes the AV control unit memory.

Version Information Version information of the AV control unit is displayed. Mode Description

JSNIA2993ZZ

Revision: 2010 May2011 QX56

Page 356 of 5598

AV-208

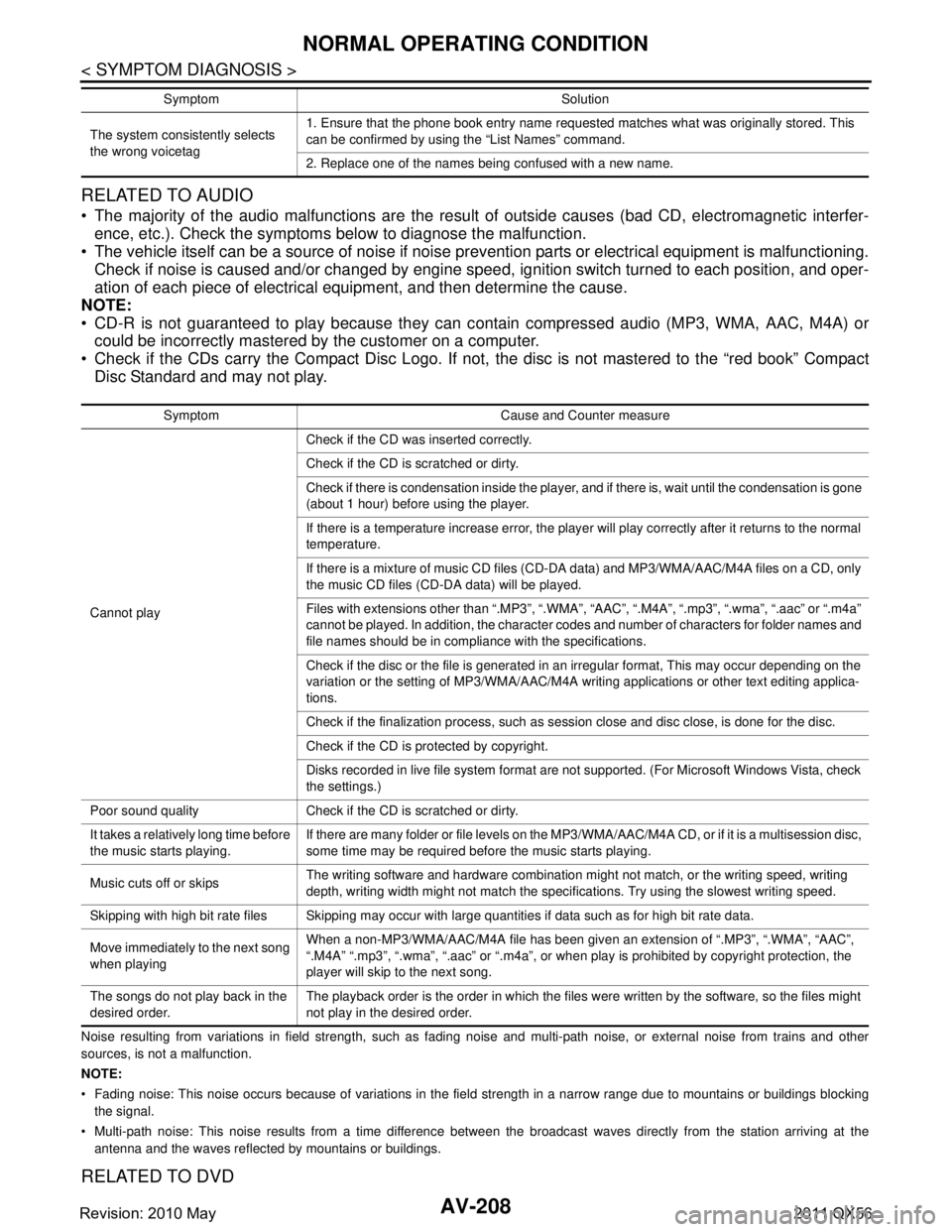

< SYMPTOM DIAGNOSIS >

NORMAL OPERATING CONDITION

RELATED TO AUDIO

The majority of the audio malfunctions are the result of outside causes (bad CD, electromagnetic interfer-

ence, etc.). Check the symptoms below to diagnose the malfunction.

The vehicle itself can be a source of noise if noise prevention parts or electrical equipment is malfunctioning.

Check if noise is caused and/or changed by engine speed, ignition switch turned to each position, and oper-

ation of each piece of electrical equipment, and then determine the cause.

NOTE:

CD-R is not guaranteed to play because they can c ontain compressed audio (MP3, WMA, AAC, M4A) or

could be incorrectly mastered by the customer on a computer.

Check if the CDs carry the Compact Disc Logo. If not, the disc is not mastered to the “red book” Compact

Disc Standard and may not play.

Noise resulting from variations in field strength, such as fading noise and multi-path noise, or external noise from trains and other

sources, is not a malfunction.

NOTE:

Fading noise: This noise occurs because of variations in the field strength in a narrow range due to mountains or buildings bl ocking

the signal.

Multi-path noise: This noise results from a time difference between the broadcast waves directly from the station arriving at the

antenna and the waves reflected by mountains or buildings.

RELATED TO DVD

The system consistently selects

the wrong voicetag 1. Ensure that the phone book entry name requested matches what was originally stored. This

can be confirmed by using the “List Names” command.

2. Replace one of the names being confused with a new name.

Symptom Solution

Symptom Cause and Counter measure

Cannot play Check if the CD was

inserted correctly.

Check if the CD is scratched or dirty.

Check if there is condensation inside the player, and if there is, wait until the condensation is gone

(about 1 hour) before using the player.

If there is a temperature increase error, the player will play correctly after it returns to the normal

temperature.

If there is a mixture of music CD files (CD-DA data) and MP3/WMA/AAC/M4A files on a CD, only

the music CD files (CD-DA data) will be played.

Files with extensions other than “.MP3”, “.WMA”, “AAC”, “.M4A”, “.mp3”, “.wma”, “.aac” or “.m4a”

cannot be played. In addition, the character codes and number of characters for folder names and

file names should be in compliance with the specifications.

Check if the disc or the file is generated in an irregular format, This may occur depending on the

variation or the setting of MP3/WMA/AAC/M4A writing applications or other text editing applica-

tions.

Check if the finalization process, such as session close and disc close, is done for the disc.

Check if the CD is protected by copyright.

Disks recorded in live file system format are not supported. (For Microsoft Windows Vista, check

the settings.)

Poor sound quality Check if the CD is scratched or dirty.

It takes a relatively long time before

the music starts playing. If there are many folder or file levels on the MP3/WMA/AAC/M4A CD, or if it is a multisession disc,

some time may be required before the music starts playing.

Music cuts off or skips The writing software and hardware combination might not match, or the writing speed, writing

depth, writing width might not match the specifications. Try using the slowest writing speed.

Skipping with high bit rate files Skipping may occur with large quantities if data such as for high bit rate data.

Move immediately to the next song

when playing When a non-MP3/WMA/AAC/M4A file has been given an extension of “.MP3”, “.WMA”, “AAC”,

“.M4A” “.mp3”, “.wma”, “.aac” or “.m4a”, or when play is prohibited by copyright protection, the

player will skip to the next song.

The songs do not play back in the

desired order. The playback order is the order in which the files were written by the software, so the files might

not play in the desired order.

Revision: 2010 May2011 QX56