roof rack INFINITI QX56 2011 Factory Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2011, Model line: QX56, Model: INFINITI QX56 2011Pages: 5598, PDF Size: 94.53 MB

Page 368 of 5598

AV-220

< REMOVAL AND INSTALLATION >

ROOF SPEAKER

ROOF SPEAKER

Removal and InstallationINFOID:0000000006216386

REMOVAL

1. Remove roof garnish. Refer to INT-28, "Exploded View".

2. Remove roof speaker mounting screws from bracket.

3. Disconnect roof speaker connector to remove roof speaker.

INSTALLATION

Install in the reverse order of removal.

Revision: 2010 May2011 QX56

Page 679 of 5598

BRM-4

< PRECAUTION >

REPAIRING HIGH STRENGTH STEEL

PRECAUTION

REPAIRING HIGH STRENGTH STEEL

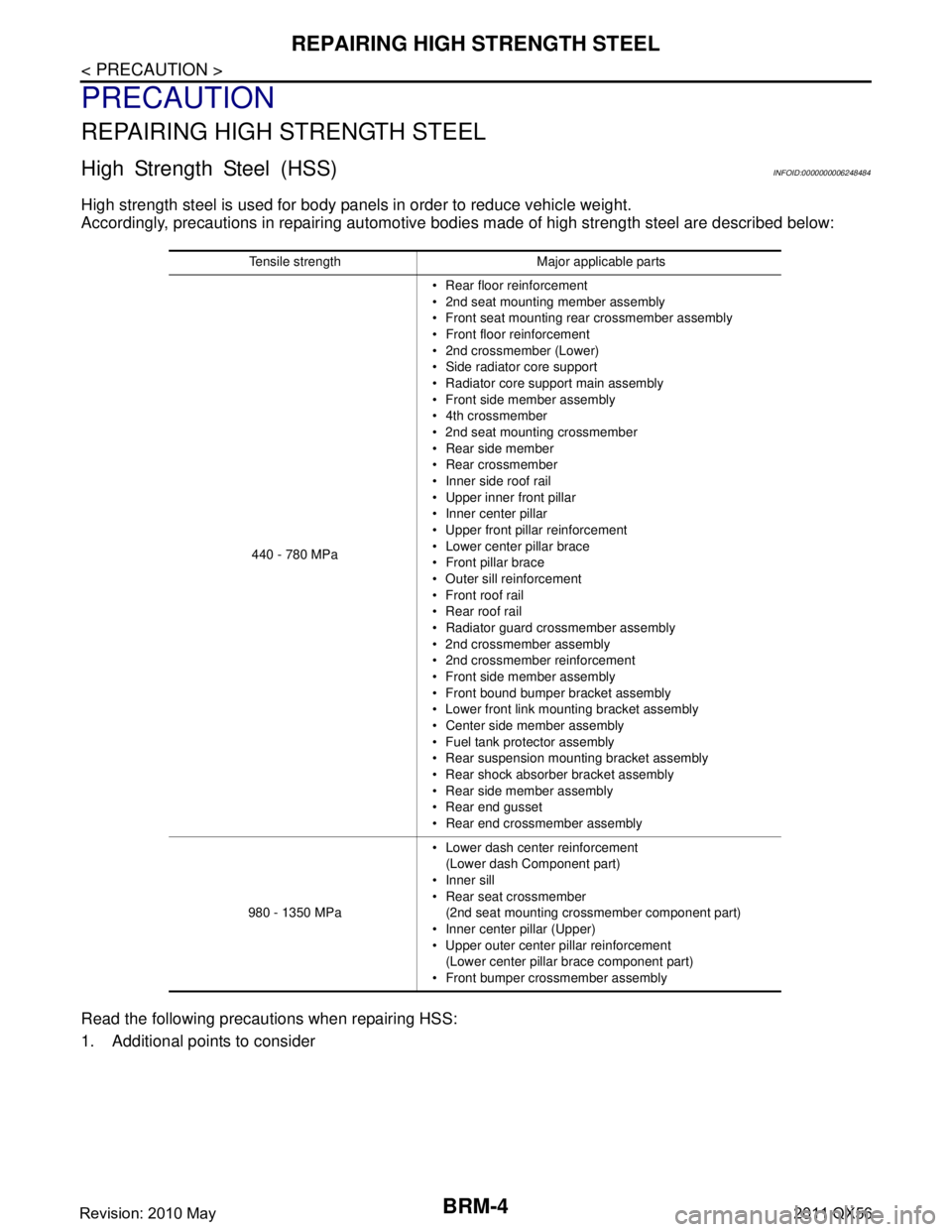

High Strength Steel (HSS)INFOID:0000000006248484

High strength steel is used for body panels in order to reduce vehicle weight.

Accordingly, precautions in repairing automotive bodies made of high strength steel are described below:

Read the following precautions when repairing HSS:

1. Additional points to consider

Tensile strength Major applicable parts 440 - 780 MPa Rear floor reinforcement

2nd seat mounting member assembly

Front seat mounting rear crossmember assembly

Front floor reinforcement

2nd crossmember (Lower)

Side radiator core support

Radiator core support main assembly

Front side member assembly

4th crossmember

2nd seat mounting crossmember

Rear side member

Rear crossmember

Inner side roof rail

Upper inner front pillar

Inner center pillar

Upper front pillar reinforcement

Lower center pillar brace

Front pillar brace

Outer sill reinforcement

Front roof rail

Rear roof rail

Radiator guard crossmember assembly

2nd crossmember assembly

2nd crossmember reinforcement

Front side member assembly

Front bound bumper bracket assembly

Lower front link mounting bracket assembly

Center side member assembly

Fuel tank protector assembly

Rear suspension mounting bracket assembly

Rear shock absorber bracket assembly

Rear side member assembly

Rear end gusset

Rear end crossmember assembly

980 - 1350 MPa Lower dash center reinforcement

(Lower dash Component part)

Inner sill

Rear seat crossmember

(2nd seat mounting crossmember component part)

Inner center pillar (Upper)

Upper outer center pillar reinforcement

(Lower center pillar brace component part)

Front bumper crossmember assembly

Revision: 2010 May2011 QX56

Page 687 of 5598

BRM-12

< PREPARATION >

BODY COMPONENT PARTS

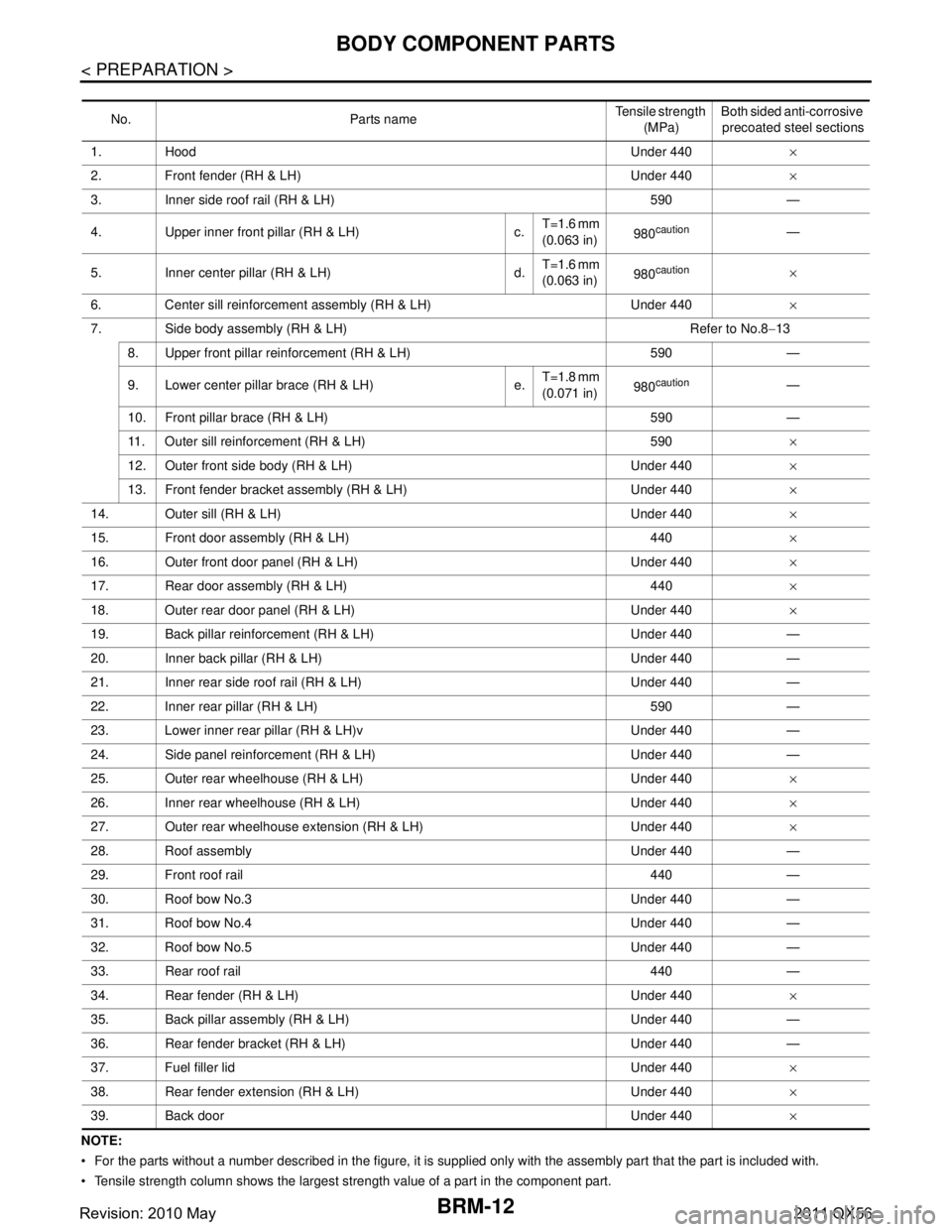

NOTE:

For the parts without a number described in the figure, it is supplied only with the assembly part that the part is included with.

Tensile strength column shows the largest strength value of a part in the component part. No. Parts name

Tensile strength

(MPa) Both sided anti-corrosive

precoated steel sections

1. Hood Under 440×

2. Front fender (RH & LH) Under 440 ×

3. Inner side roof rail (RH & LH) 590 —

4. Upper inner front pillar (RH & LH) c. T=1.6 mm

(0.063 in)

980

caution—

5. Inner center pillar (RH & LH) d. T=1.6 mm

(0.063 in)

980

caution×

6. Center sill reinforcement assembly (RH & LH) Under 440 ×

7. Side body assembly (RH & LH) Refer to No.8 −13

8. Upper front pillar reinforcement (RH & LH) 590 —

9. Lower center pillar brace (RH & LH) e. T=1.8 mm

(0.071 in)

980

caution—

10. Front pillar brace (RH & LH) 590 —

11. Outer sill reinforcement (RH & LH) 590 ×

12. Outer front side body (RH & LH) Under 440 ×

13. Front fender bracket assembly (RH & LH) Under 440 ×

14. Outer sill (RH & LH) Under 440 ×

15. Front door assembly (RH & LH) 440 ×

16. Outer front door panel (RH & LH) Under 440 ×

17. Rear door assembly (RH & LH) 440 ×

18. Outer rear door panel (RH & LH) Under 440 ×

19. Back pillar reinforcement (RH & LH) Under 440 —

20. Inner back pillar (RH & LH) Under 440 —

21. Inner rear side roof rail (RH & LH) Under 440 —

22. Inner rear pillar (RH & LH) 590 —

23. Lower inner rear pillar (RH & LH)v Under 440 —

24. Side panel reinforcement (RH & LH) Under 440 —

25. Outer rear wheelhouse (RH & LH) Under 440 ×

26. Inner rear wheelhouse (RH & LH) Under 440 ×

27. Outer rear wheelhouse extension (RH & LH) Under 440 ×

28. Roof assembly Under 440 —

29. Front roof rail 440 —

30. Roof bow No.3 Under 440 —

31. Roof bow No.4 Under 440 —

32. Roof bow No.5 Under 440 —

33. Rear roof rail 440 —

34. Rear fender (RH & LH) Under 440 ×

35. Back pillar assembly (RH & LH) Under 440 —

36. Rear fender bracket (RH & LH) Under 440 —

37. Fuel filler lid Under 440 ×

38. Rear fender extension (RH & LH) Under 440 ×

39. Back door Under 440 ×

Revision: 2010 May2011 QX56

Page 698 of 5598

BODY CONSTRUCTIONBRM-23

< REMOVAL AND INSTALLATION >

C

DE

F

G H

I

J

L

M A

B

BRM

N

O P

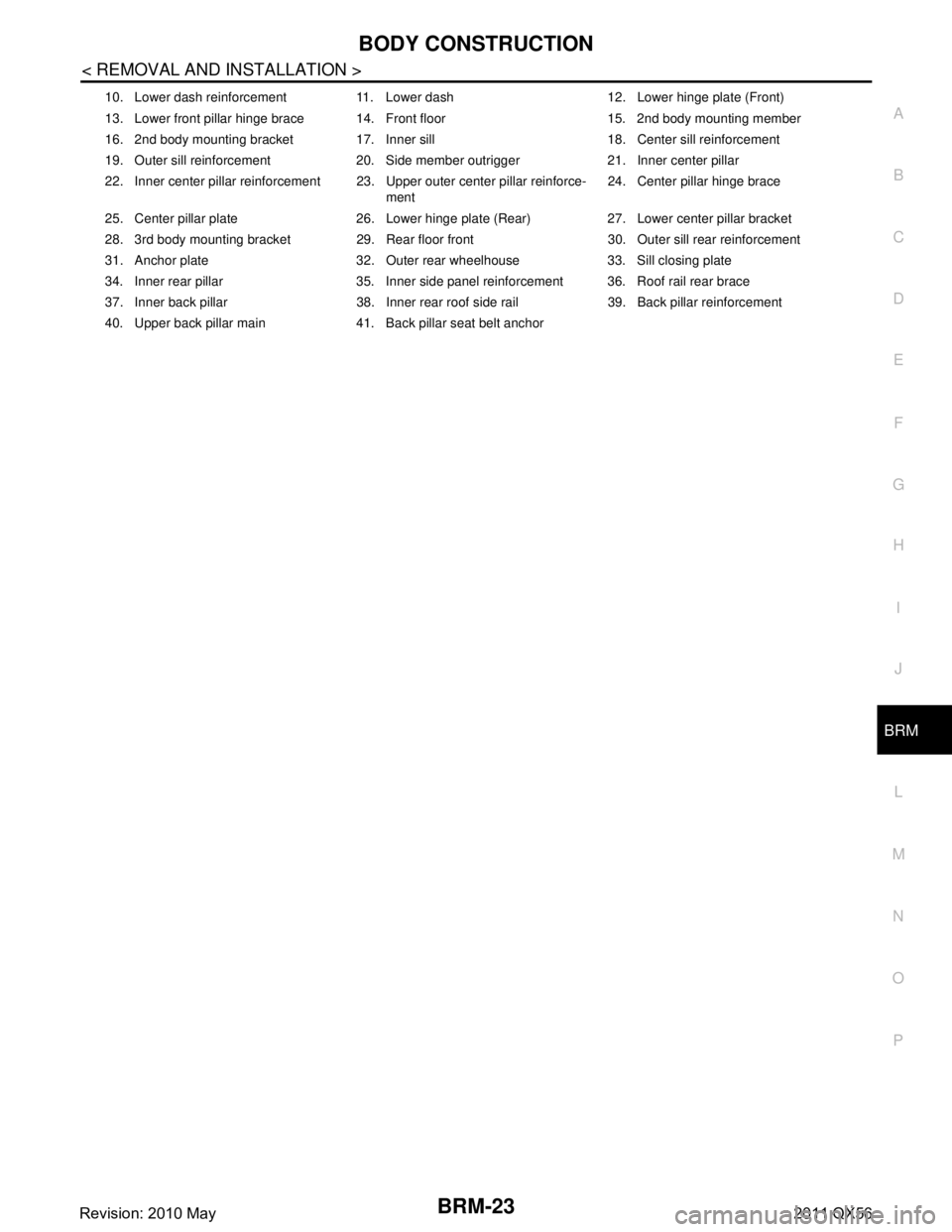

10. Lower dash reinforcement 11. Lower dash 12. Lower hinge plate (Front)

13. Lower front pillar hinge brace 14. Front floor 15. 2nd body mounting member

16. 2nd body mounting bracket 17. Inner sill 18. Center sill reinforcement

19. Outer sill reinforcement 20. Side member outrigger 21. Inner center pillar

22. Inner center pillar reinforcement 23. Upper outer center pillar reinforce- ment24. Center pillar hinge brace

25. Center pillar plate 26. Lower hinge plate (Rear) 27. Lower center pillar bracket

28. 3rd body mounting bracket 29. Rear floor front 30. Outer sill rear reinforcement

31. Anchor plate 32. Outer rear wheelhouse 33. Sill closing plate

34. Inner rear pillar 35. Inner side panel reinforcement 36. Roof rail rear brace

37. Inner back pillar 38. Inner rear roof side rail 39. Back pillar reinforcement

40. Upper back pillar main 41. Back pillar seat belt anchor

Revision: 2010 May2011 QX56

Page 723 of 5598

BRM-48

< SERVICE DATA AND SPECIFICATIONS (SDS)

BODY ALIGNMENT

SERVICE DATA AND SPECIFICATIONS (SDS)

BODY ALIGNMENT

Body Center MarksINFOID:0000000006248507

A mark is placed on each part of the body to indicate the vehicle center. When repairing the vehicle frame

(members, pillars, etc.) damaged by an accident which it enables more accurate and effective repair by using

these marks together with body alignment specifications.

Unit: mm (in)

DescriptionINFOID:0000000006248508

All dimensions indicated in the figures are actual.

When using a tracking gauge, adjust both pointers to equal length. Then check the pointers and gauge itself

to make sure there is no free play.

: Vehicle front

Points Portion Marks

A Upper dash Hole 7 ×12 (0.28 ×0.47)

B Cowl top Embossment

C Rear roof Indent

JSKIA1895ZZ

Revision: 2010 May2011 QX56

Page 731 of 5598

BRM-56

< SERVICE DATA AND SPECIFICATIONS (SDS)

BODY ALIGNMENT

Unit: mm (in)

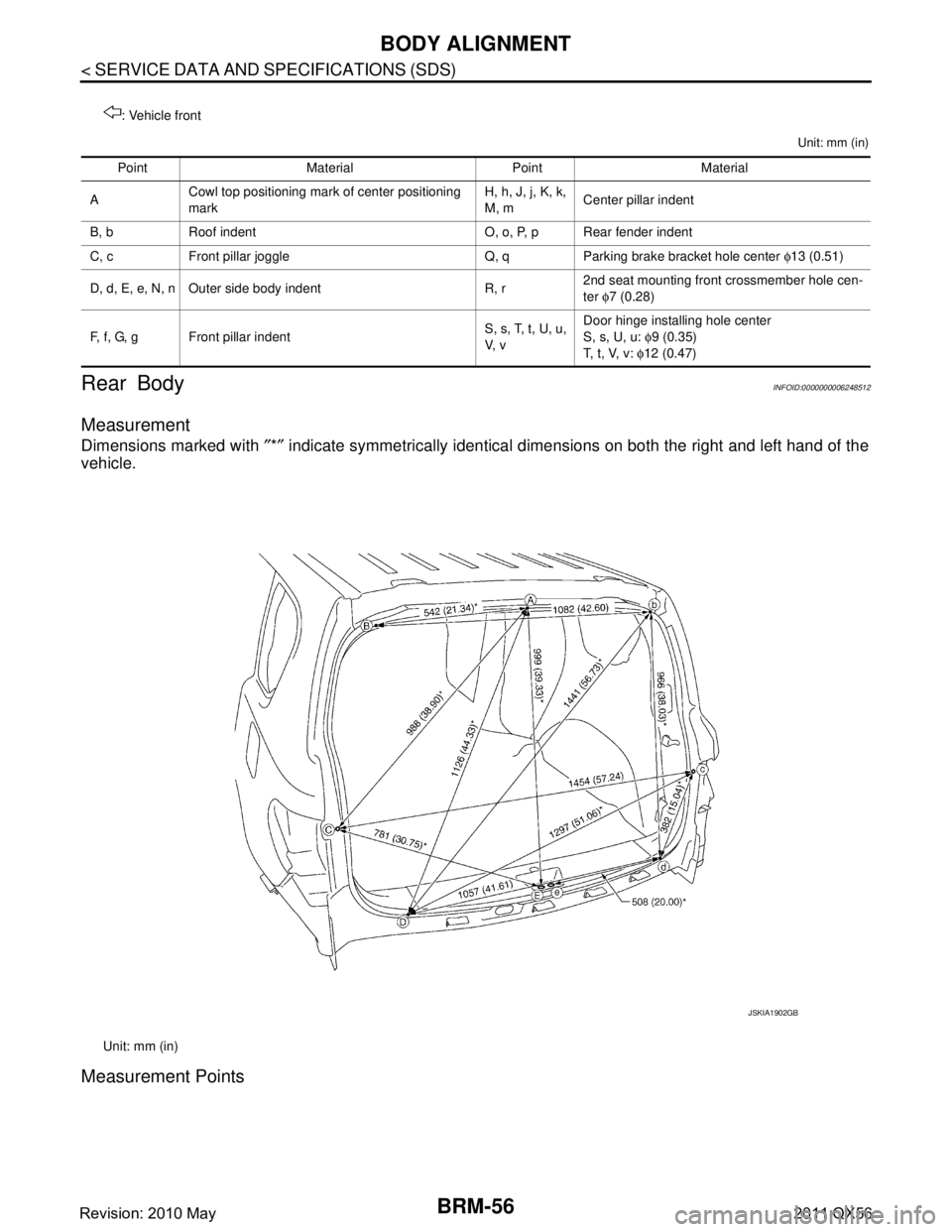

Rear BodyINFOID:0000000006248512

Measurement

Dimensions marked with ″*″ indicate symmetrically identical dimensions on both the right and left hand of the

vehicle.

Measurement Points

: Vehicle front

Point Material Point Material

A Cowl top positioning mark of center positioning

mark H, h, J, j, K, k,

M, m

Center pillar indent

B, b Roof indent O, o, P, p Rear fender indent

C, c Front pillar joggle Q, q Parking brake bracket hole center φ13 (0.51)

D, d, E, e, N, n Outer side body indent R, r 2nd seat mounting front crossmember hole cen-

ter

φ7 (0.28)

F, f, G, g Front pillar indent S, s, T, t, U, u,

V, vDoor hinge installing hole center

S, s, U, u:

φ9 (0.35)

T, t, V, v: φ12 (0.47)

Unit: mm (in)

JSKIA1902GB

Revision: 2010 May2011 QX56

Page 1748 of 5598

DLK-212

< SYMPTOM DIAGNOSIS >

SQUEAK AND RATTLE TROUBLE DIAGNOSES

Most of these incidents can be repaired by adjusting, securing or insulating the item(s) or component(s) caus-

ing the noise.

SUNROOF/HEADLINING

Noises in the sunroof/headlining area c an often be traced to one of the following:

1. Sunroof lid, rail, linkage or seals making a rattle or light knocking noise

2. Sunvisor shaft shaking in the holder

3. Front or rear windshield touching headlining and squeaking

Again, pressing on the components to stop the noise while duplicating the conditions can isolate most of these

incidents. Repairs usually consist of insulating with felt cloth tape.

SEATS

When isolating seat noise it is important to note t he position the seat is in and the load placed on the seat

when the noise is present. These conditions should be duplicated when verifying and isolating the cause of

the noise.

Cause of seat noise include:

1. Headrest rods and holder

2. A squeak between the seat pad cushion and frame

3. Rear seatback lock and bracket

These noises can be isolated by moving or pressing on the suspected components while duplicating the con-

ditions under which the noise occurs. Most of thes e incidents can be repaired by repositioning the component

or applying urethane tape to the contact area.

UNDERHOOD

Some interior noise may be caused by components under the hood or on the engine wall. The noise is then

transmitted into the passenger compartment.

Causes of transmitted underhood noise include:

1. Any component mounted to the engine wall

2. Components that pass through the engine wall

3. Engine wall mounts and connectors

4. Loose radiator mounting pins

5. Hood bumpers out of adjustment

6. Hood striker out of adjustment

These noises can be difficult to isolate since they cannot be reached from the interior of the vehicle. The best

method is to secure, move or insulate one component at a time and test drive the \

vehicle. Also, engine RPM

or load can be changed to isolate the noise. Repairs can usually be made by moving, adjusting, securing, or

insulating the component causing the noise.

Revision: 2010 May2011 QX56

Page 1768 of 5598

DLK-232

< REMOVAL AND INSTALLATION >

BACK DOOR

BACK DOOR

Exploded ViewINFOID:0000000006226086

BACK DOOR ASSEMBLY

BACK DOOR ASSEMBLY : Removal and InstallationINFOID:0000000006226087

CAUTION:

Operate with two workers, because of its heavy weight.

Use protective tape or cloth to protect fr om damage during remove and installation.

REMOVAL

1. Remove stud ball of back door support rod. Refer to DLK-247, "BACK DOOR SUPPORT ROD : Removal

and Installation".

2. Remove roof garnish. Refer to INT-29, "

Removal and Installation".

1. Back door hinge 2. TORX bolt 3. Back door striker

4. Back door weather-strip 5. Stopper seal 6. Back door stay bracket

7. Back door stay 8. Back door lower bracket 9. Bumper rubber (side)

10. Bumper rubber bracket 11. Drain plug 12. Bumper rubber (lower)

13. Back door assembly

A : Center mark

B: Seam

Refer to GI-4, "

Components" for symbols in the figure.

JMKIA5482GB

Revision: 2010 May2011 QX56

Page 2864 of 5598

SQUEAK AND RATTLE TROUBLE DIAGNOSESEXT-9

< SYMPTOM DIAGNOSIS >

C

DE

F

G H

I

J

L

M A

B

EXT

N

O P

1. Trunk lid dumpers out of adjustment

2. Trunk lid striker out of adjustment

3. Trunk lid torsion bars knocking together

4. A loose license plate or bracket

Most of these incidents can be repaired by adjusting, se curing, or insulating the item(s) or component(s) caus-

ing the noise.

SUNROOF/HEADLINING

Noises in the sunroof / headlining area can of ten be traced to one of the following items:

1. Sunroof lid, rail, linkage, or seals making a rattle or light knocking noise

2. Sunvisor shaft shaking in the holder

3. Front or rear windshield touching headlining and squeaking

Again, pressing on the components to stop the noise while duplicating the conditions can isolate most of these

incidents. Repairs usually consist of insulating with felt cloth tape.

SEATS

When isolating seat noise it is important to note the position the seat is in and the load placed on the seat

when the noise occurs. These conditions should be duplic ated when verifying and isolating the cause of the

noise.

Causes of seat noise include:

1. Headrest rods and holder

2. A squeak between the seat pad cushion and frame

3. The rear seatback lock and bracket

These noises can be isolated by moving or pressing on the suspected components while duplicating the con-

ditions under which the noise occurs. Most of thes e incidents can be repaired by repositioning the component

or applying urethane tape to the contact area.

UNDERHOOD

Some interior noise may be caused by components under the hood or on the engine wall. The noise is then

transmitted into the passenger compartment.

Causes of transmitted underhood noise include:

1. Any component mounted to the engine wall

2. Components that pass through the engine wall

3. Engine wall mounts and connectors

4. Loose radiator mounting pins

5. Hood bumpers out of adjustment

6. Hood striker out of adjustment

These noises can be difficult to isolate since they cannot be reached from the interior of the vehicle. The best

method is to secure, move, or insulate one component at a time and test drive the vehicle. Also, engine RPM

or load can be changed to isolate the noise. Repairs c an usually be made by moving, adjusting, securing, or

insulating the component causing the noise.

Revision: 2010 May2011 QX56

Page 3037 of 5598

GW-8

< SYMPTOM DIAGNOSIS >

SQUEAK AND RATTLE TROUBLE DIAGNOSES

3. The trunk lid torsion bars knocking together

4. A loose license plate or bracket

Most of these incidents can be repaired by adjusting, securing or insulatingthe item(s) or component(s) caus-

ing the noise.

SUNROOF/HEADLINING

Noises in the sunroof/headlining area c an often be traced to one of the following:

1. Sunroof lid, rail, linkage or seals making a rattle or light knockingnoise

2. Sunvisor shaft shaking in the holder

3. Front or rear windshield touching headlining and squeaking

Again, pressing on the components to stop the noise while duplicatingthe conditions can isolate most of these

incidents. Repairs usually consistof insulating with felt cloth tape.

SEATS

When isolating seat noise it's important to note the pos ition the seatis in and the load placed on the seat when

the noise is present. These conditionsshould be duplic ated when verifying and isolating the cause of the

noise.

Cause of seat noise include:

1. Headrest rods and holder

2. A squeak between the seat pad cushion and frame

3. The rear seatback lock and bracket

These noises can be isolated by moving or pressing on the suspectedcomponents while duplicating the condi-

tions under which the noise occurs. Most of these incidents can be repaired by repositioning the component

orapplying urethane tape to the contact area.

UNDERHOOD

Some interior noise may be caused by components under the hood or onthe engine wall. The noise is then

transmitted into the passenger compartment.

Causes of transmitted underhood noise include:

1. Any component mounted to the engine wall

2. Components that pass through the engine wall

3. Engine wall mounts and connectors

4. Loose radiator mounting pins

5. Hood bumpers out of adjustment

6. Hood striker out of adjustment

These noises can be difficult to isolate since they cannot be reached from the interior of the vehicle. The best

method is to secure, move or insulate one component at a time and test drive the \

vehicle. Also, engine RPM

or load can be changed to isolate the noise. Repairs can usually be made by moving, adjusting, securing, or

insulating the component causing the noise.

Revision: 2010 May2011 QX56