service reset INFINITI QX56 2011 Factory Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2011, Model line: QX56, Model: INFINITI QX56 2011Pages: 5598, PDF Size: 94.53 MB

Page 60 of 5598

INSPECTION AND ADJUSTMENTADP-51

< BASIC INSPECTION >

C

DE

F

G H

I

K L

M A

B

ADP

N

O P

INSPECTION AND ADJUSTMENT

ADDITIONAL SERVICE WHEN REMOVING BATTERY NEGATIVE TERMINAL

ADDITIONAL SERVICE WHEN REMOVING BATTERY NEGATIVE TERMINAL : De-

scription

INFOID:0000000006248324

Each function is reset to the following condition when the battery terminal is disconnected.

*1: Default value is 40 mm.

NOTE:

Notice that disconnecting the battery when detect ed DTC are present will erase the DTC memory.

ADDITIONAL SERVICE WHEN REMOVING BATTERY NEGATIVE TERMINAL : Spe-

cial Repair Requirement

INFOID:0000000006248325

1.SYSTEM INITIALIZATION

Perform system initialization. Refer to ADP-52, "

SYSTEM INITIALIZATION : Special Repair Requirement".

>> GO TO 2.

2.MEMORY STORAGE

Perform memory storage. Refer to ADP-53, "

MEMORY STORING : Special Repair Requirement".

>> GO TO 3.

3.INTELLIGENT KEY INTERLOCK STORAGE

Perform Intelligent Key interlock storage. Refer to ADP-54, "

INTELLIGENT KEY INTERLOCK STORING :

Special Repair Requirement".

>> GO TO 4.

4.SYSTEM SETTING

Perform system setting. Refer to ADP-55, "

SYSTEM SETTING : Special Repair Requirement".

>> END

ADDITIONAL SERVICE WHEN REPLACING CONTROL UNIT

ADDITIONAL SERVICE WHEN REPL ACING CONTROL UNIT : Description

INFOID:0000000006248326

Each function is reset to the following condition when the driver seat control unit is replaced.

Function Condition Procedure

Memory (Seat, stee ring, mirror) Erased Perform storing

Entry/exit assist ON Perform initialization

Set slide amount

*1

Intelligent Key interlock Erased

Perform initialization

Perform storing

Function Condition Procedure

Memory (Seat, stee ring, mirror) Erased Perform storing

Entry/exit assist ON Perform initialization

Set slide amount

*1

Revision: 2010 May2011 QX56

Page 1844 of 5598

![INFINITI QX56 2011 Factory Service Manual

DLN-42

< BASIC INSPECTION >[TRANSFER: ATX90A]

ADDITIONAL SERVICE WHEN

REPLACING TRANSFER ASSEMBLY

ADDITIONAL SERVICE WHEN REPLACING TRANSFER ASSEMBLY

DescriptionINFOID:0000000006222236

Perform writi INFINITI QX56 2011 Factory Service Manual

DLN-42

< BASIC INSPECTION >[TRANSFER: ATX90A]

ADDITIONAL SERVICE WHEN

REPLACING TRANSFER ASSEMBLY

ADDITIONAL SERVICE WHEN REPLACING TRANSFER ASSEMBLY

DescriptionINFOID:0000000006222236

Perform writi](/img/42/57033/w960_57033-1843.png)

DLN-42

< BASIC INSPECTION >[TRANSFER: ATX90A]

ADDITIONAL SERVICE WHEN

REPLACING TRANSFER ASSEMBLY

ADDITIONAL SERVICE WHEN REPLACING TRANSFER ASSEMBLY

DescriptionINFOID:0000000006222236

Perform writing unit parameter, transfer fluid viscosity learning and initial calibration after replacing transfer

assembly. Refer to DLN-42, "

Work Procedure".

Work ProcedureINFOID:0000000006222237

NOTE:

In fail-safe mode, can not perform work s upport. (Except that DTC P181F is detected.)

1.WRITE UNIT PARAMETER

Perform writing unit parameter to control unit. Refer to DLN-48, "

Work Procedure".

>> GO TO 2.

2.PREPARATION BEFORE WORK

With CONSULT-III

1. Start the engine. CAUTION:

Never drive the vehicle.

2. Check “4WD MODE”, “T/M RANGE”, “COMER V HCL SPEED”, “MOTOR POWER SUP” of CONSULT-III

“DATA MONITOR” for “ALL MODE AWD/4WD”.

3. Continue the following condition more than 10 seconds.

>> GO TO 3.

3.PERFORM TRANSFER FLUID VISCOSITY LEARNING

With CONSULT-III

1. Select “OIL DETERIORATION INFO RESET” of CONSULT-III “WORK SUPPORT” for “ALL MODE AWD/

4WD”.

2. Select “Start”.

>> GO TO 4.

4.INITIAL CALIBRATION

With CONSULT-III

1. Select “START CALIBRATION” of CONSULT- III “WORK SUPPORT” for “ALL MODE AWD/4WD”.

2. Wait until the motor operation stop. (After approximately 10 seconds)

>> GO TO 5.

5.PERFORM SELF-DIAGNOSIS

With CONSULT-III

1. Erase self-diagnosis result for “ALL MODE AWD/4WD”.

2. Turn the ignition switch ON to OFF. CAUTION:

Wait for 10 seconds after turn ing ignition switch OFF.

3. Start the engine. CAUTION:

Never drive the vehicle.

4. Perform self-diagnosis for “ALL MODE AWD/4WD”.

4WD MODE : AUTO

T/M RANGE : N

COMPER VHCL SPEED : 0 km/h (Never drive the vehicle)

MOTOR POWER SUP : More than 11 V

Revision: 2010 May2011 QX56

Page 3064 of 5598

HA-8

< PRECAUTION >

PRECAUTIONS

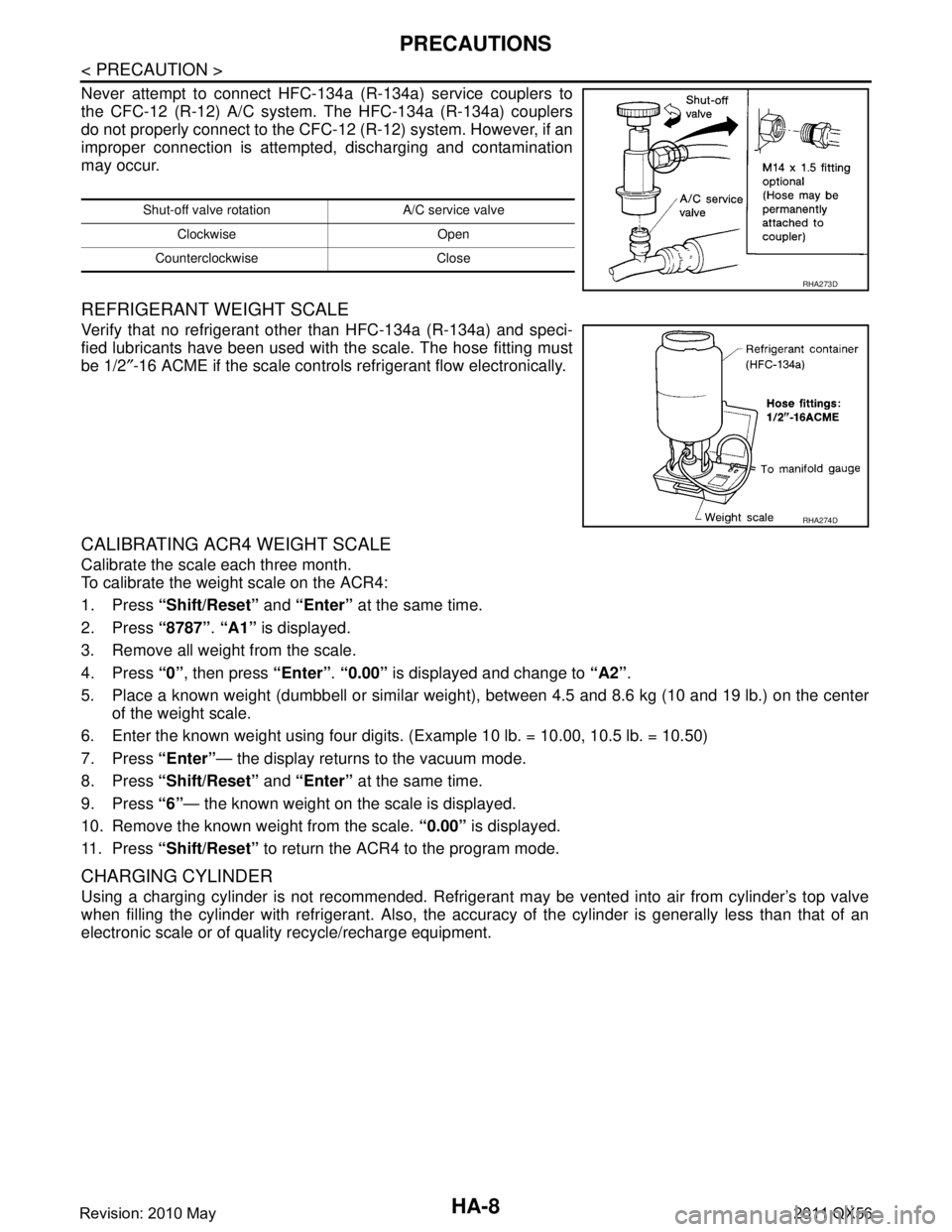

Never attempt to connect HFC-134a (R-134a) service couplers to

the CFC-12 (R-12) A/C system. The HFC-134a (R-134a) couplers

do not properly connect to the CFC-12 (R-12) system. However, if an

improper connection is attempted, discharging and contamination

may occur.

REFRIGERANT WEIGHT SCALE

Verify that no refrigerant other than HFC-134a (R-134a) and speci-

fied lubricants have been used with the scale. The hose fitting must

be 1/2″-16 ACME if the scale controls refrigerant flow electronically.

CALIBRATING ACR4 WEIGHT SCALE

Calibrate the scale each three month.

To calibrate the weight scale on the ACR4:

1. Press “Shift/Reset” and “Enter” at the same time.

2. Press “8787”. “A1” is displayed.

3. Remove all weight from the scale.

4. Press “0”, then press “Enter”. “0.00” is displayed and change to “A2”.

5. Place a known weight (dumbbell or similar weight ), between 4.5 and 8.6 kg (10 and 19 lb.) on the center

of the weight scale.

6. Enter the known weight using four digi ts. (Example 10 lb. = 10.00, 10.5 lb. = 10.50)

7. Press “Enter”— the display returns to the vacuum mode.

8. Press “Shift/Reset” and “Enter” at the same time.

9. Press “6”— the known weight on the scale is displayed.

10. Remove the known weight from the scale. “0.00” is displayed.

11. Press “Shift/Reset” to return the ACR4 to the program mode.

CHARGING CYLINDER

Using a charging cylinder is not recommended. Refrigerant may be vented into air from cylinder’s top valve

when filling the cylinder with refrigerant. Also, the accu racy of the cylinder is generally less than that of an

electronic scale or of quality recycle/recharge equipment.

Shut-off valve rotati on A/C service valve

Clockwise Open

Counterclockwise Close

RHA273D

RHA274D

Revision: 2010 May2011 QX56

Page 4083 of 5598

PG-164

< REMOVAL AND INSTALLATION >

BATTERY

REMOVAL AND INSTALLATION

BATTERY

Exploded ViewINFOID:0000000006275779

Removal and InstallationINFOID:0000000006275780

REMOVAL

1. Remove cover of battery positive terminal.

2. Loosen battery terminal nuts, and disconnect both battery cables from battery terminals.

CAUTION:

When disconnecting, disconnect the battery cable from the negative terminal first.

3. Remove battery fix frame mounting nuts and battery fix frame.

4. Remove battery.

INSTALLATION

Install in the reverse order of removal.

CAUTION:

When connecting, connect the battery cable to the positive terminal first.

Reset electronic systems as necessary. Refer to GI-65, "

ADDITIONAL SERVICE WHEN REMOVING BAT-

TERY NEGATIVE TERMINAL : Required Procedure After Battery Disconnection".

1 : Battery fix frame

Refer to GI-4, "

Components" for symbols in the figure.

JSMIA0238GB

Revision: 2010 May2011 QX56

Page 4231 of 5598

INSPECTION AND ADJUSTMENTRF-17

< BASIC INSPECTION >

C

DE

F

G H

I

J

L

M A

B

RF

N

O P

INSPECTION AND ADJUSTMENT

ADDITIONAL SERVICE WHEN REPLACING CONTROL UNIT

ADDITIONAL SERVICE WHEN REPL ACING CONTROL UNIT : Description

INFOID:0000000006141230

MEMORY RESET PROCEDURE

1. Please observe the following instructi ons at confirming the sunroof operation.

NOTE:

Do not disconnect the electronic power while the sunroof is operating or within 5 seconds after the sunroof

stops (to wipe-out the memory of lid position and operating friction).

2. Initialization of system should be conducted after the following conditions.

When the sunroof motor is changed.

When the sunroof does not operate normally. (Incomplete initialization conditions)

ADDITIONAL SERVICE WHEN REPLACING CONTROL UNIT : Special Repair Re-

quirement

INFOID:0000000006141231

INITIALIZATION PROCEDURE

If the sunroof does not close or open automatically, us e the following procedure to return sunroof operation to

normal.

1. Press the tilt up switch and start the tilt up operation.

2. Release the tilt up switch once, press the tilt up switch again, press and hold the switch until lid pops up.

3. The glass lid moves slight toward tilt up direction then stop. (Press and hold the switch during this opera- tion)

4. Release the switch again, and press the tilt up s witch within the first 10 seconds. (Press and hold the

switch)

5. After 4 seconds, the glass lid will be automatically operated in sequence of tilt down, slide open and slide

close.

6. After the glass lid stops, release the switch 0.5 second later. (Press and hold the switch during this opera-

tion)

7. If slide switch operates normally, this initialization is done.

ANTI-PINCH FUNCTION

1. Full open the sunroof.

2. Place a wooden piece (wooden hammer handle, etc.) at near fully closed position.

3. Close the sunroof completely with auto-slide close.

Check that sunroof lowers for approximately 150 mm (5 .91in) or 2 seconds with out pinching a wooden piece

and stops.

CAUTION:

Never check with hands and other part of body because they may be pinched. Never get pinched.

Depending on environment and driving conditions, if a similar impact or lord is applied to the sun-

roof it may lower.

Check that auto-slide operates before inspect ion when system initialization is performed.

Perform initial setting when auto-slide operatio n or anti-pinch function does not operate normally.

Revision: 2010 May2011 QX56

Page 4307 of 5598

SBC-10

< SYSTEM DESCRIPTION >

SYSTEM

SEAT BELT WARNING LAMP SYSTEM

SEAT BELT WARNING LAMP SYSTEM : System DiagramINFOID:0000000006237880

SEAT BELT WARNING LAMP SYSTEM : System DescriptionINFOID:0000000006237881

Turns ON seat belt warning lamp, when the Occupant Detection System judges adult or child in the front

passenger seat and the passenger seat belt buckle switch is OFF.

Operation of air bag diagnosis sensor unit when air bag diagnosis sensor unit receives information from

Occupant Detection System.

In addition, seat belt warning lamp illuminates, when t he driver side seat belt is not fasten. This does not

relate to the air bag diagnosis sensor unit.

For driver seat belt function, refer to MWI-16, "

MASTER WARNING LAMP : System Diagram"

JMHIA0685GB

Status (front passenger seat) Seat belt warning lamp (When front passenger seat is unbuck-

led)

Empty OFF

An object OFF

Child/ child-seat ON

Adult ON

Malfunction OFF

Zero point reset

Not yet performed (service parts only) OFF

Revision: 2010 May2011 QX56

Page 4794 of 5598

SRC-1

RESTRAINTS

C

DE

F

G

I

J

K L

M

SECTION SRC

A

B

SRC

N

O P

CONTENTS

SRS AIRBAG CONTROL SYSTEM

PRECAUTION ................ ...............................6

PRECAUTIONS .............................................. .....6

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ............................................................. ......

6

Service ......................................................................6

SYSTEM DESCRIPTION ..............................8

COMPONENT PARTS ................................... .....8

Component Parts Location .................................. ......8

Component Description .............................................9

SYSTEM .............................................................11

System Diagram .................................................. ....11

System Description .................................................12

DIAGNOSIS SYSTEM (AIR BAG) .....................14

Description .......................................................... ....14

On Board Diagnosis Function .................................14

CONSULT-III Function ............................................19

DIAGNOSIS SYSTEM (OCCUPANT DETEC-

TION SYSTEM) .............................................. ....

21

CONSULT-III Function ........................................ ....21

ECU DIAGNOSIS INFORMATION ..............22

DIAGNOSIS SENSOR UNIT .......................... ....22

DTC Index .......................................................... ....22

WIRING DIAGRAM ......................................27

SRS AIR BAG SYSTEM ................................. ....27

Wiring Diagram ................................................... ....27

BASIC INSPECTION ...................................36

DIAGNOSIS AND REPAIR WORK FLOW .... ....36

Work Flow ........................................................... ....36

INSPECTION AND ADJUSTMENT ....................39

ADDITIONAL SERVICE WHEN REPLACING

CONTROL UNIT .................................................... ....

39

ADDITIONAL SERVICE WHEN REPLACING

CONTROL UNIT : Description .................................

39

ADDITIONAL SERVICE WHEN REPLACING

CONTROL UNIT : Special Repair Requirement ......

39

ZERO POINT RESET ............................................. ....39

ZERO POINT RESET : Description .........................39

ZERO POINT RESET : Special Repair Require-

ment .........................................................................

39

DTC/CIRCUIT DIAGNOSIS .........................41

B1001, B1002, B1003, B1004, B1005 DIAG-

NOSIS SENSOR UNIT ......................................

41

DTC Logic ............................................................ ....41

Diagnosis Procedure ...............................................41

B1006, B1007, B1008, B1009, B1010 DIAG-

NOSIS SENSOR UNIT ......................................

42

DTC Logic ................................................................42

Diagnosis Procedure ...............................................42

B1011, B1012, B1013, B1014, B1015 DIAG-

NOSIS SENSOR UNIT ......................................

43

DTC Logic ................................................................43

Diagnosis Procedure ...............................................43

B1017, B1020, B1021 OCCUPANT SENS C/U

...

44

Description ........................................................... ....44

DTC Logic ................................................................44

Diagnosis Procedure ...............................................44

B1018 OCCUPANT SENS ................................46

Description ........................................................... ....46

DTC Logic ................................................................46

Diagnosis Procedure ...............................................46

B1022 OCCUPANT SENS C/U .........................48

Description ...............................................................48

Revision: 2010 May2011 QX56

Page 4832 of 5598

INSPECTION AND ADJUSTMENTSRC-39

< BASIC INSPECTION >

C

DE

F

G

I

J

K L

M A

B

SRC

N

O P

INSPECTION AND ADJUSTMENT

ADDITIONAL SERVICE WHEN REPLACING CONTROL UNIT

ADDITIONAL SERVICE WHEN REPL ACING CONTROL UNIT : Description

INFOID:0000000006219959

When replacing or removing and installing passenger seat, always perform zero point reset so that Occupant

Detection System is activated normally.

ADDITIONAL SERVICE WHEN REPLACING CONTROL UNIT : Special Repair Re-

quirement

INFOID:0000000006219960

WORK PROCEDURE WHEN REPLACING CONTROL UNIT

1.PERFORM ZERO POINT RESET

Perform zero point reset. Refer to SRC-39, "

ZERO POINT RESET : Special Repair Requirement".

>> END

ZERO POINT RESET

ZERO POINT RESET : DescriptionINFOID:0000000006219961

Zero point reset is an initializing procedure for occupant detection sensor that must be performed when replac-

ing or removing and installing passenger seat.

If zero point reset is not performed, the initializati on is incomplete and Occupant Detection System does not

operate normally.

NOTE:

When replacing passenger seat with a NISSAN genuine part, air bag warning lamp blinks if zero point reset

is incomplete.

When zero point reset is performed once after removal and installation of passenger seat, CONSULT-III dis-

plays “complete” and air bag warning does not blink.

When reinstalling passenger seat after removal, the initial value for occupant detection sensor changes, and

Occupant Detection System does not operate normally.

Always perform zero point reset after performing the work as per the following.

- Reinstallation of passenger seat

- Replacement of passenger seat with a seat that is zero point reset complete.

ZERO POINT RESET : Special Repair RequirementINFOID:0000000006219962

1.PERFORM ZERO POINT RESET

1. Perform zero point reset. NOTE:

When performing zero point reset, be careful of the items described as per the following.

Perform zero point reset after installing passenger seat to the vehicle

Do not put any objects on passenger seat

Do not apply excessive vibration to the vehicle

Do not touch the vehicle

Do not tilt the vehicle

2. Select start on “Zero point reset function” scr een from, WORK SUPPORT of CONSULT-III “OCCUPANT

DETECTION”.

3. “Zero point reset” starts.

>> GO TO 2.

2.CONFIRMATION OF SETTING

1. Proceed to “Zero point reset function” screen fr om work support of CONSULT-III “OCCUPANT DETEC-

TION”.

2. Check that “Complete” or “Incomplete” is displayed on “Zero point reset status”.

CAUTION:

Revision: 2010 May2011 QX56