sensor ISUZU AXIOM 2002 Service Repair Manual

[x] Cancel search | Manufacturer: ISUZU, Model Year: 2002, Model line: AXIOM, Model: ISUZU AXIOM 2002Pages: 2100, PDF Size: 19.35 MB

Page 659 of 2100

5A±40BRAKE CONTROL SYSTEM

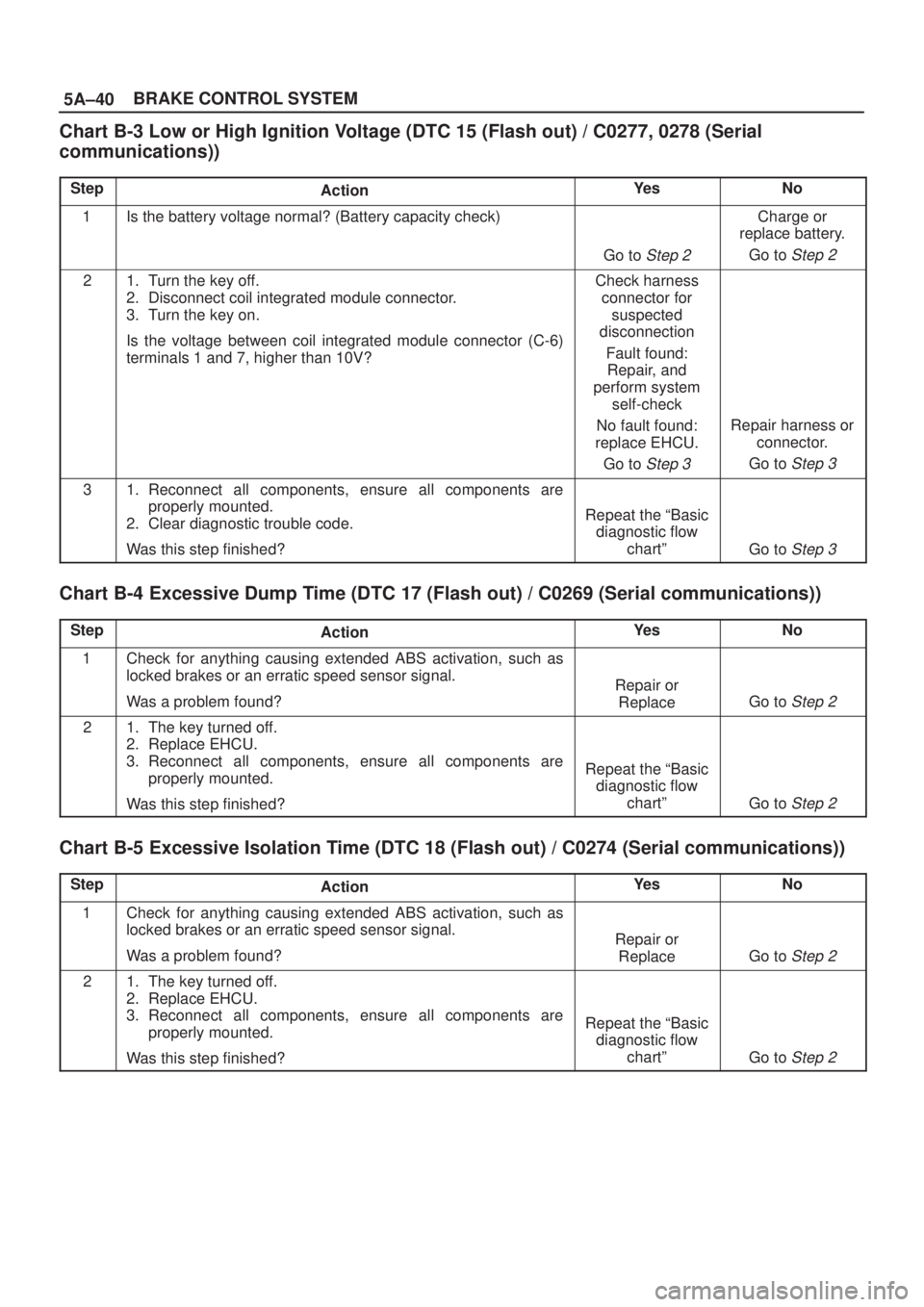

Chart B-3 Low or High Ignition Voltage (DTC 15 (Flash out) / C0277, 0278 (Serial

communications))

StepActionYe sNo

1Is the battery voltage normal? (Battery capacity check)

Go to Step 2

Charge or

replace battery.

Go to

Step 2

21. Turn the key off.

2. Disconnect coil integrated module connector.

3. Turn the key on.

Is the voltage between coil integrated module connector (C-6)

terminals 1 and 7, higher than 10V?Check harness

connector for

suspected

disconnection

Fault found:

Repair, and

perform system

self-check

No fault found:

replace EHCU.

Go to

Step 3

Repair harness or

connector.

Go to

Step 3

31. Reconnect all components, ensure all components are

properly mounted.

2. Clear diagnostic trouble code.

Was this step finished?

Repeat the ªBasic

diagnostic flow

chartº

Go to Step 3

Chart B-4 Excessive Dump Time (DTC 17 (Flash out) / C0269 (Serial communications))

StepActionYe sNo

1Check for anything causing extended ABS activation, such as

locked brakes or an erratic speed sensor signal.

Was a problem found?

Repair or

Replace

Go to Step 2

21. The key turned off.

2. Replace EHCU.

3. Reconnect all components, ensure all components are

properly mounted.

Was this step finished?

Repeat the ªBasic

diagnostic flow

chartº

Go to Step 2

Chart B-5 Excessive Isolation Time (DTC 18 (Flash out) / C0274 (Serial communications))

StepActionYe sNo

1Check for anything causing extended ABS activation, such as

locked brakes or an erratic speed sensor signal.

Was a problem found?

Repair or

Replace

Go to Step 2

21. The key turned off.

2. Replace EHCU.

3. Reconnect all components, ensure all components are

properly mounted.

Was this step finished?

Repeat the ªBasic

diagnostic flow

chartº

Go to Step 2

Page 660 of 2100

5A±41

BRAKE CONTROL SYSTEM

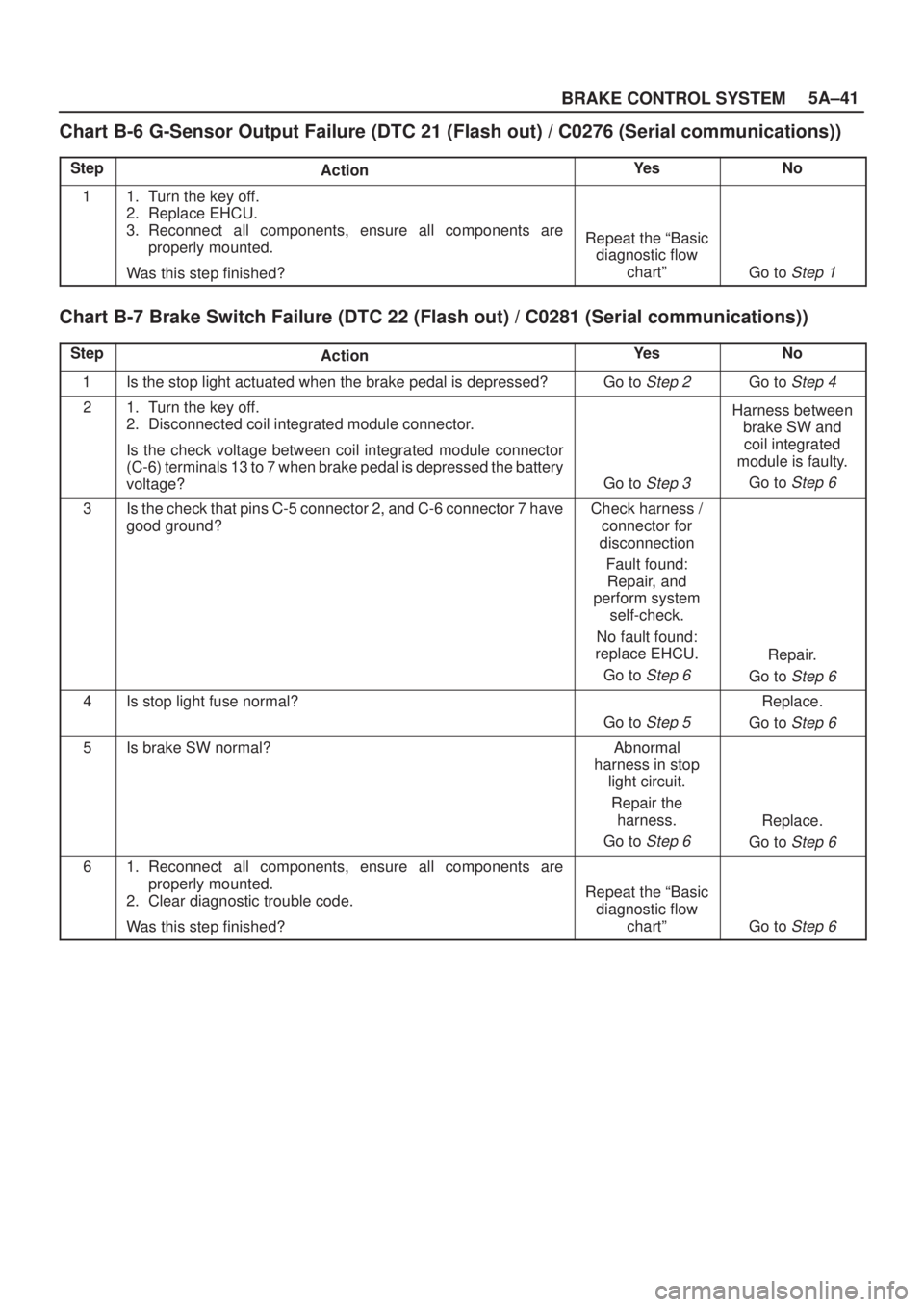

Chart B-6 G-Sensor Output Failure (DTC 21 (Flash out) / C0276 (Serial communications))

StepActionYe sNo

11. Turn the key off.

2. Replace EHCU.

3. Reconnect all components, ensure all components are

properly mounted.

Was this step finished?

Repeat the ªBasic

diagnostic flow

chartº

Go to Step 1

Chart B-7 Brake Switch Failure (DTC 22 (Flash out) / C0281 (Serial communications))

StepActionYe sNo

1Is the stop light actuated when the brake pedal is depressed?Go to Step 2Go to Step 4

21. Turn the key off.

2. Disconnected coil integrated module connector.

Is the check voltage between coil integrated module connector

(C-6) terminals 13 to 7 when brake pedal is depressed the battery

voltage?

Go to Step 3

Harness between

brake SW and

coil integrated

module is faulty.

Go to

Step 6

3Is the check that pins C-5 connector 2, and C-6 connector 7 have

good ground?Check harness /

connector for

disconnection

Fault found:

Repair, and

perform system

self-check.

No fault found:

replace EHCU.

Go to

Step 6

Repair.

Go to

Step 6

4Is stop light fuse normal?

Go to Step 5

Replace.

Go to

Step 6

5Is brake SW normal?Abnormal

harness in stop

light circuit.

Repair the

harness.

Go to

Step 6

Replace.

Go to

Step 6

61. Reconnect all components, ensure all components are

properly mounted.

2. Clear diagnostic trouble code.

Was this step finished?

Repeat the ªBasic

diagnostic flow

chartº

Go to Step 6

Page 664 of 2100

5A±45

BRAKE CONTROL SYSTEM

Chart B-16 Rear Dump Solenoid Coil Failure (DTC 46 (Flash out) / C0252, C0254 (Serial

communications))

StepActionYe sNo

1Was the ªEHCU Connector Pin±out Checksº performed?

Go to Step 2

Go to ªEHCU

Connector

Pin±out Checks.º

21. Turn the key switch to off.

2. Disconnect the 2±way EHCU connector (C±5) from the

EHCU.

3. Inspect the connector for damage or corrosion.

Is the connector free from damage or corrosion?

Go to Step 3

Repair the

connector.

Repeat the ªBasic

Diagnostic Flow

Chart.º

31. Replace the Coil Integrated Module.

2. Reconnect all components, ensure all components are

properly mounted.

Was this step finished?

Repeat the ªBasic

diagnostic flow

chartº

Go to Step 3

Chart B-17 FL Speed Sensor Open or Shorted (DTC 51 (Flash out) / C0225 (Serial

communications))

StepActionYe sNo

11. Turn the key off.

2. Disconnect coil integrated module connector.

3. Measure the resistance between coil integrated module

connector (C-6) terminals 2 and 10.

Is the resistance between 2.0k and 2.8k ohms?Check for faults

in harness

between speed

sensor and coil

integrated

module.

Fault found:

Repair, and

perform system

self-check.

No fault found:

Replace coil

integrated

module.

Go to

Step 3Go to Step 2

2Measure the FL speed sensor resistance at the sensor connector.

Is the resistance between 2.0k and 2.8k ohms?Repair harness

abnormality

between sensors

and coil

integrated

module.

Go to

Step 3

Replace sensor.

Go to

Step 3

31. Reconnect all components, ensure all components are

properly mounted.

2. Clear diagnostic trouble code.

Was this step finished?

Repeat the ªBasic

diagnostic flow

chartº

Go to Step 3

Page 665 of 2100

5A±46BRAKE CONTROL SYSTEM

Chart B-18 FR Speed Sensor Open or Shorted (DTC 52 (Flash out) / C0221 (Serial

communications))

StepActionYe sNo

11. Turn the key off.

2. Disconnect coil integrated module connector.

3. Measure the resistance between coil integrated module

connector (C-6) terminals 3 and 11.

Is the resistance between 2.0k and 2.8k ohms?Check for faults

in harness

between speed

sensor and coil

integrated

module.

Fault found:

Repair, and

perform system

self-check.

No fault found:

Replace coil

integrated

module.

Go to

Step 3Go to Step 2

2Measure the FR speed sensor resistance at the sensor

connector.

Is the resistance between 2.0k and 2.8k ohms?Repair harness

abnormality

between sensors

and coil

integrated

module.

Go to

Step 3

Replace sensor.

Go to

Step 3

31. Reconnect all components, ensure all components are

properly mounted.

2. Clear diagnostic trouble code.

Was this step finished?

Repeat the ªBasic

diagnostic flow

chartº

Go to Step 3

Page 666 of 2100

5A±47

BRAKE CONTROL SYSTEM

Chart B-19 Rear Speed Sensor Open or Shorted (DTC 53 (Flash out) / C0235 (Serial

communications))

StepActionYe sNo

11. Turn the key off.

2. Disconnect coil integrated module connector.

3. Measure the resistance between coil integrated module

connector (C-6) terminals 4 and 12.

Is the resistance between 1.0k and 1.7k ohms?Check for faults

in harness

between speed

sensor and coil

integrated

module.

Fault found:

Repair, and

perform system

self-check.

No fault found:

Replace EHCU.

Go to

Step 3Go to Step 2

2Measure the Rear speed sensor resistance at the sensor

connector.

Is the resistance between 1.0k and 1.7k ohms?Repair harness

abnormality

between sensors

and coil

integrated

module.

Go to

Step 3

Replace sensor.

Go to

Step 3

31. Reconnect all components, ensure all components are

properly mounted.

2. Clear diagnostic trouble code.

Was this step finished?

Repeat the ªBasic

diagnostic flow

chartº

Go to Step 3

Page 667 of 2100

5A±48BRAKE CONTROL SYSTEM

Chart B-20 FL Speed Sensor Missing Signal (DTC 61 (Flash out) / C0226, C0227 (Serial

communications))

StepActionYe sNo

11. Turn the key off.

2. Disconnect coil integrated module connector.

3. Measure the FL speed sensor resistance between coil

integrated module connector (C-6) terminals 2 and 10.

Is the resistance between 2.0k and 2.8k ohms?

Go to Step 2Go to Step 3

2Is there play sensor/sensor rotor?Repair.

Go to

Step 6Go to Step 4

3Measure the FL speed sensor resistance at the sensor connector.

Is the resistance between 2.0k and 2.8k ohms?Repair harness

abnormality

between sensors

and coil

integrated

module.

Go to

Step 6

Replace sensor.

Go to

Step 6

4Damage and powdered iron sticking to sensor/sensor ring?Repair.

Go to

Step 6Go to Step 5

5Is sensor output normal? (Chart C-1-1 or TC-1)Check for faults

in harness

between speed

sensor and coil

integrated

module.

Fault found:

repair, and

perform system

self-check.

No fault found:

replace EHCU.

Go to

Step 6

Replace sensor.

Go to

Step 6

61. Reconnect all components, ensure all components are

properly mounted.

2. Clear diagnostic trouble code.

Was this step finished?

Repeat the ªBasic

diagnostic flow

chartº

Go to Step 6

NOTE: Even after repairing the faulty part the warning

light (W/L) does not go out if the vehicle is at a stop. Turn

the ignition switch to the ON position and drive the vehicle

at 12 km/h (8 mph) or higher to make sure that the

warning light goes out.

Page 668 of 2100

5A±49

BRAKE CONTROL SYSTEM

Chart B-21 FR Speed Sensor Missing Signal (DTC 62 (Flash out) / C0222, C0223 (Serial

communications))

StepActionYe sNo

11. Turn the key off.

2. Disconnect coil integrated module connector.

3. Measure the FR speed sensor resistance between coil

integrated module connector (C-6) terminals 3 and 11.

Is the resistance between 2.0k and 2.8k ohms?

Go to Step 2Go to Step 3

2Is there play sensor/sensor rotor?Repair.

Go to

Step 6Go to Step 4

3Measure the FR speed sensor resistance at the sensor

connector.

Is the resistance between 2.0k and 2.8k ohms?Repair harness

abnormality

between sensors

and coil

integrated

module.

Go to

Step 6

Replace sensor.

Go to

Step 6

4Damage and powered iron sticking to sensor/sensor ring?Repair.

Go to

Step 6Go to Step 5

5Is sensor output normal? (Chart C-1-2 or TC-1)Check for faults

in harness

between speed

sensor and coil

integrated

module.

Fault found:

repair, and

perform system

self-check.

No fault found:

replace EHCU.

Go to

Step 6

Replace sensor.

Go to

Step 6

61. Reconnect all components, ensure all components are

properly mounted.

2. Clear diagnostic trouble code.

Was this step finished?

Repeat the ªBasic

diagnostic flow

chartº

Go to Step 6

NOTE: Even after repairing the faulty part the warning

light (W/L) does not go out if the vehicle is at a stop. Turn

the ignition switch to the ON position and drive the vehicle

at 12 km/h (8 mph) or higher to make sure that the

warning light goes out.

Page 669 of 2100

5A±50BRAKE CONTROL SYSTEM

Chart B-22 Rear Speed Sensor Missing Signal (DTC 63 (Flash out) / C0236, C0237 (Serial

communications))

StepActionYe sNo

11. Turn the key off.

2. Disconnect coil integrated module connector.

3. Measure the Rear speed sensor resistance between coil

integrated module connector (C-6) terminals 4 and 12.

Is the resistance between 1.0k and 1.7k ohms?

Go to Step 2Go to Step 3

2Is there play sensor/sensor rotor?Repair.

Go to

Step 6Go to Step 4

3Measure the rear speed sensor resistance at the sensor

connector.

Is the resistance between 1.0k and 1.7k ohms?Repair harness

abnormality

between sensors

and coil

integrated

module.

Go to

Step 6

Replace sensor.

Go to

Step 6

4Damage and powered iron sticking to sensor/sensor ring?Repair.

Go to

Step 6Go to Step 5

5Is sensor output normal? (Chart C-1-3 or TC-1)Check for faults

in harness

between speed

sensor and coil

integrated

module.

Fault found:

repair, and

perform system

self-check.

No fault found:

replace EHCU.

Go to

Step 6

Replace sensor.

Go to

Step 6

61. Reconnect all components, ensure all components are

properly mounted.

2. Clear diagnostic trouble code.

Was this step finished?

Repeat the ªBasic

diagnostic flow

chartº

Go to Step 6

NOTE: Even after repairing the faulty part the warning

light (W/L) does not go out if the vehicle is at a stop. Turn

the ignition switch to the ON position and drive the vehicle

at 12 km/h (8 mph) or higher to make sure that the

warning light goes out.

Page 670 of 2100

5A±51

BRAKE CONTROL SYSTEM

Chart B-23 Simultaneous Drop-out of Front Speed Sensor Signal (DTC 64 (Flash out) /

C0229 (Serial communications))

StepActionYe sNo

11. Turn the key off.

2. Disconnect coil integrated module connector.

3. Measure the FL speed sensor resistance between coil

integrated module connector (C-6) terminals 2 and 10.

Is the resistance between 2.0k and 2.8k ohms?

Go to Step 2Go to Step 3

2Measure the FR speed sensor resistance between coil integrated

module connector (C-6) terminals 3 and 11.

Is the resistance between 2.0k and 2.8 k ohms?

Go to Step 5Go to Step 4

3Measure the FL speed sensor resistance at the sensor connector.

Is the resistance between 2.0k and 2.8k ohms?Repair harness

abnormality

between sensors

and coil

integrated

module.

Go to

Step 2

Replace sensor.

Go to

Step 2

4Measure the FR speed sensor resistance at the sensor

connector.

Is the resistance between 2.0k and 2.8k ohms?Repair harness

abnormality

between sensors

and coil

integrated

module.

Go to

Step 5

Replace sensor.

Go to

Step 5

5Damage and powered iron sticking to sensor/sensor ring?Repair.

Go to

Step 6Go to Step 6

6Is there play sensor/sensor rotor?Repair.

Go to

Step 7Go to Step 7

7Is sensor output normal? (Chart C-1-1&C-1-2 or TC-1)Check for faults

in harness

between speed

sensor and coil

integrated

module.

Fault found:

repair, and

perform system

self-check.

No fault found:

replace EHCU.

Go to

Step 8

Replace sensor.

Go to

Step 8

81. Reconnect all components, ensure all components are

properly mounted.

2. Clear diagnostic trouble code.

Was this step finished?

Repeat ªBasic

diagnostic flow

chartº

Go to Step 8

NOTE: Even after repairing the faulty part the warning

light (W/L) does not go out if the vehicle is at a stop. Turn

the ignition switch to the ON position and drive the vehicle

at 12 km/h (8 mph) or higher to make sure that the

warning light goes out.

Page 671 of 2100

5A±52BRAKE CONTROL SYSTEM

Chart B-24 Wheel Speed Input Abnormality (DTC 65 (Flash out) / C0238 (Serial

communications))

StepActionYe sNo

1Using TECH 2?Go to Step 2Go to Step 3

21. Connect TECH 2.

2. Select Snap shot manual trigger.

3. With wheel speed data displayed, run the vehicle when speed

has arrived at 30 km/h (18 mph).

4. Check speed data on each wheel (refer to the criterion given

below). * 1

Is the abnormal sensor condition found?

Replace.

Go to

Step 8

Go to Step 3

All the sensors

should follow the

following

flowchart (without

using TECH 2).

3Is there play in sensor/sensor ring?Repair.

Go to

Step 8Go to Step 4

4Is there powdered iron sticking to sensor/sensor ring?Repair.

Go to

Step 8Go to Step 5

5Is there a broken tooth or indentation in sensor ring?Replace sensor

ring.

Go to

Step 8Go to Step 6

6Is there play in wheel bearing?Adjust or repair.

Go to

Step 8Go to Step 7

7Is the check wiring between sensor and coil integrated module

normal?

Replace EHCU.

Go to

Step 8

Repair, and

perform system

self-check.

Go to

Step 8

81. Reconnect all components, ensure all components are

properly mounted.

2. Clear diagnostic trouble code.

Was this step finished?

Repeat `Basic

diagnostic flow

chartº

Go to Step 8

Sensor Signal Abnormality Criteria using TECH 2

1. While driving, the speed of one or two wheels is 25%

or more higher or lower than that of the other wheels.

2. The speed of one or two wheels is 10 km/h (6 mph) or

more higher or lower than that of the other wheels.

3. During steady driving, wheel speed changes abruptly.

*1 The vehicle must run on a level paved road.

NOTE: Even after repairing the faulty part the warning

light (W/L) does not go out if the vehicle is at a stop.

Turn the ignition switch to the ON position and drive the

vehicle at 12 km/h (8 mph) or higher to make sure that the

warning light goes out.

It is important to verify that the correct tires are installed

on vehicle.