ISUZU AXIOM 2002 Service Repair Manual

Manufacturer: ISUZU, Model Year: 2002,

Model line: AXIOM,

Model: ISUZU AXIOM 2002

Pages: 2100, PDF Size: 19.35 MB

ISUZU AXIOM 2002 Service Repair Manual

AXIOM 2002

ISUZU

ISUZU

https://www.carmanualsonline.info/img/61/57174/w960_57174-0.png

ISUZU AXIOM 2002 Service Repair Manual

Trending: ECU, remote control, air suspension, oil, relay, heater, transmission fluid

Page 941 of 2100

6D2±6

IGNITION SYSTEM (6VE1 3.5L)

Crankshaft Position Sensor

Removal

1. Disconnect battery ground cable

2. Wiring connector from crankshaft position sensor.

3. Remove crankshaft position sensor from cylinder

block.

012RS008

Installation

1. Install crankshaft position sensor into the cylinder

block.

Before installation,apply small amount of engine oil to

the O±ring.

Torque: 10 N´m (87 lb in)

2. Reconnect wiring connector to crankshaft position

sensor.

Page 942 of 2100

6D2±7

IGNITION SYSTEM (6VE1 3.5L)

Main Data and Specifications

General Specifications

Ignition System

Ignition FormElectronic Ignition System (El system) with Crankshaft position Sensor

Spark Plug

TypeK16PR±P11

RC10PYP4

PK16PR11

Plug gap1.0 mm ± 1.1 mm (0.0394 in ± 0.0433 in)

Torque18 N´m (13lb ft)

Torque Specifications

E06R100003

Page 943 of 2100

6D3±1

STARTING AND CHARGING SYSTEM (6VE1 3.5L)

AXIOM

ENGINE

STARTING AND CHARGING SYSTEM (6VE1 3.5L)

CONTENTS

Service Precaution 6D3±1. . . . . . . . . . . . . . . . . . . . . .

Starting System 6D3±2. . . . . . . . . . . . . . . . . . . . . . . . .

General Description 6D3±2. . . . . . . . . . . . . . . . . . . . .

Diagnosis 6D3±4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Starter 6D3±5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Removal 6D3±5. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 6D3±5. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Disassembled View 6D3±7. . . . . . . . . . . . . . . . . . . .

Disassembly 6D3±8. . . . . . . . . . . . . . . . . . . . . . . . . .

Inspection and Repair 6D3±10. . . . . . . . . . . . . . . . . .

Reassembly 6D3±13. . . . . . . . . . . . . . . . . . . . . . . . . .

Main Data and Specifications 6D3±14. . . . . . . . . . .

Charging System 6D3±17. . . . . . . . . . . . . . . . . . . . . . . . General Description 6D3±17. . . . . . . . . . . . . . . . . . . .

General On±Vehicle Inspection 6D3±17. . . . . . . . . . .

Generator 6D3±18. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Removal 6D3±18. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Inspection 6D3±18. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 6D3±19. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Disassembled View 6D3±19. . . . . . . . . . . . . . . . . . . .

Disassembly 6D3±20. . . . . . . . . . . . . . . . . . . . . . . . . .

Inspection and Repair 6D3±21. . . . . . . . . . . . . . . . . .

Reassembly 6D3±23. . . . . . . . . . . . . . . . . . . . . . . . . .

Bench Test 6D3±24. . . . . . . . . . . . . . . . . . . . . . . . . . .

Main Data and Specifications 6D3±25. . . . . . . . . . . . .

Service Precaution

WARNING: THIS VEHICLE HAS A SUPPLEMENTAL

RESTRAINT SYSTEM (SRS). REFER TO THE SRS

COMPONENT AND WIRING LOCATION VIEW IN

ORDER TO DETERMINE WHETHER YOU ARE

PERFORMING SERVICE ON OR NEAR THE SRS

COMPONENTS OR THE SRS WIRING. WHEN YOU

ARE PERFORMING SERVICE ON OR NEAR THE SRS

COMPONENTS OR THE SRS WIRING, REFER TO

THE SRS SERVICE INFORMATION. FAILURE TO

FOLLOW WARNINGS COULD RESULT IN POSSIBLE

AIR BAG DEPLOYMENT, PERSONAL INJURY, OR

OTHERWISE UNNEEDED SRS SYSTEM REPAIRS.CAUTION: Always use the correct fastener in the

proper location. When you replace a fastener, use

ONLY the exact part number for that application.

ISUZU will call out those fasteners that require a

replacement after removal. ISUZU will also call out

the fasteners that require thread lockers or thread

sealant. UNLESS OTHERWISE SPECIFIED, do not

use supplemental coatings (Paints, greases, or other

corrosion inhibitors) on threaded fasteners or

fastener joint interfaces. Generally, such coatings

adversely affect the fastener torque and the joint

clamping force, and may damage the fastener. When

you install fasteners, use the correct tightening

sequence and specifications. Following these

instructions can help you avoid damage to parts and

systems.

Page 944 of 2100

6D3±2

STARTING AND CHARGING SYSTEM (6VE1 3.5L)

Starting System

General Description

Cranking Circuit

The cranking system consists of a battery, starter, starter

switch, starter relay, etc. These main components are

connected.

Starter

The cranking system employs a magnetic type reduction

starter in which the motor shaft is also used as a pinion

shaft. When the starter switch is turned on, the contacts of

magnetic switch are closed, and the armature rotates. At

the same time, the plunger is attracted, and the pinion is

pushed forward by the shift lever to mesh with the ring

gear.

Then, the ring gear runs to start the engine. When the

engine starts and the starter switch is turned off, the

plunger returns, the pinion is disengaged from the ring

gear, and the armature stops rotation. When the engine

speed is higher than the pinion, the pinion idles, so that

the armature is not driven.

Page 945 of 2100

6D3±3

STARTING AND CHARGING SYSTEM (6VE1 3.5L)

060R200062

Page 946 of 2100

6D3±4

STARTING AND CHARGING SYSTEM (6VE1 3.5L)

Diagnosis

ConditionPossible causeCorrection

Starter does not runCharging failureRepair charging system

Battery FailureReplace Battery

Terminal connection failureRepair or replace terminal connector

and/or wiring harness

Starter switch failureRepair or replace starter switch

Starter relay failureReplace

Starter failureRepair or replace starter

Page 947 of 2100

6D3±5

STARTING AND CHARGING SYSTEM (6VE1 3.5L)

Starter

Removal

1. Battery ground cable.

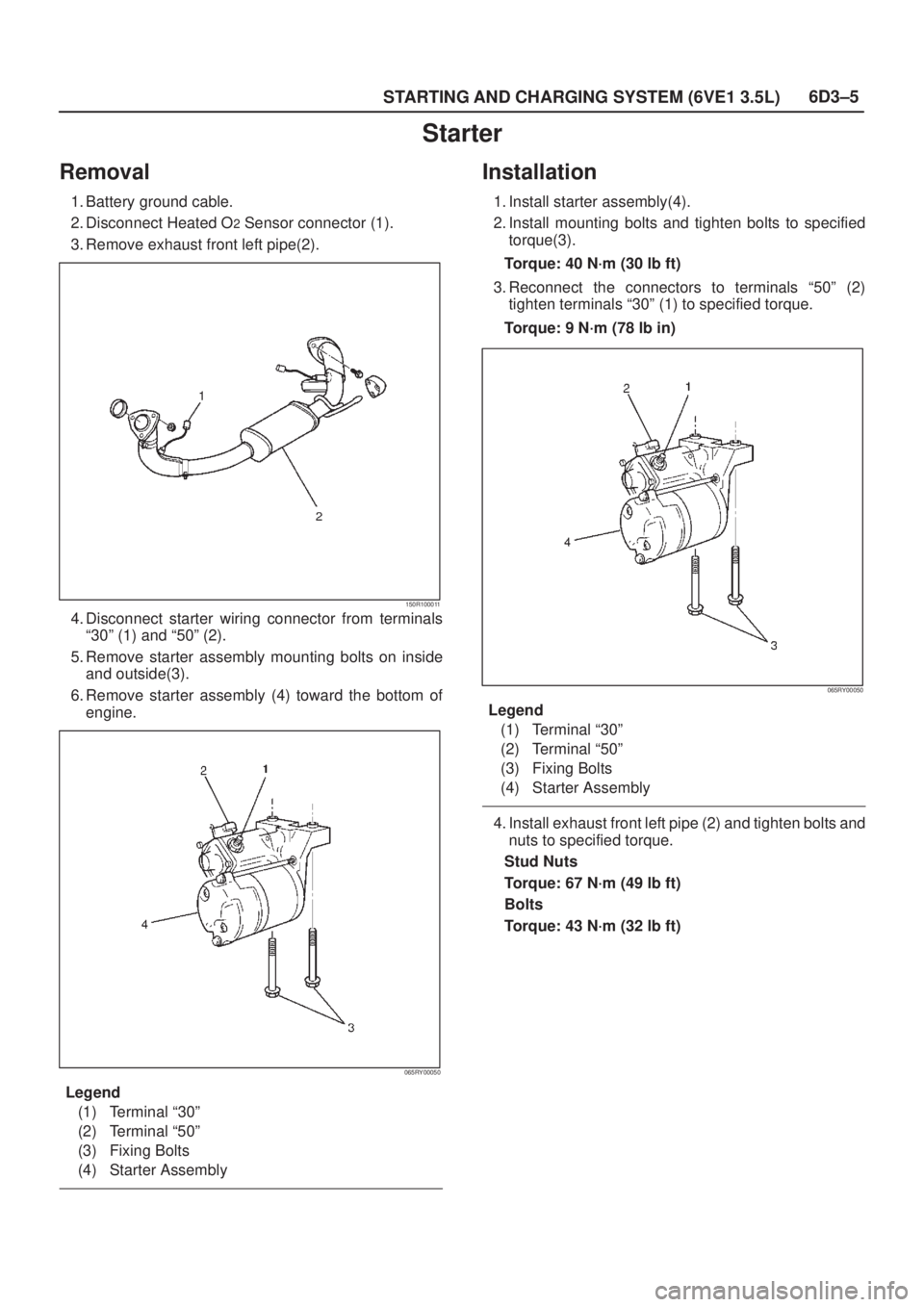

2. Disconnect Heated O

2 Sensor connector (1).

3. Remove exhaust front left pipe(2).

150R100011

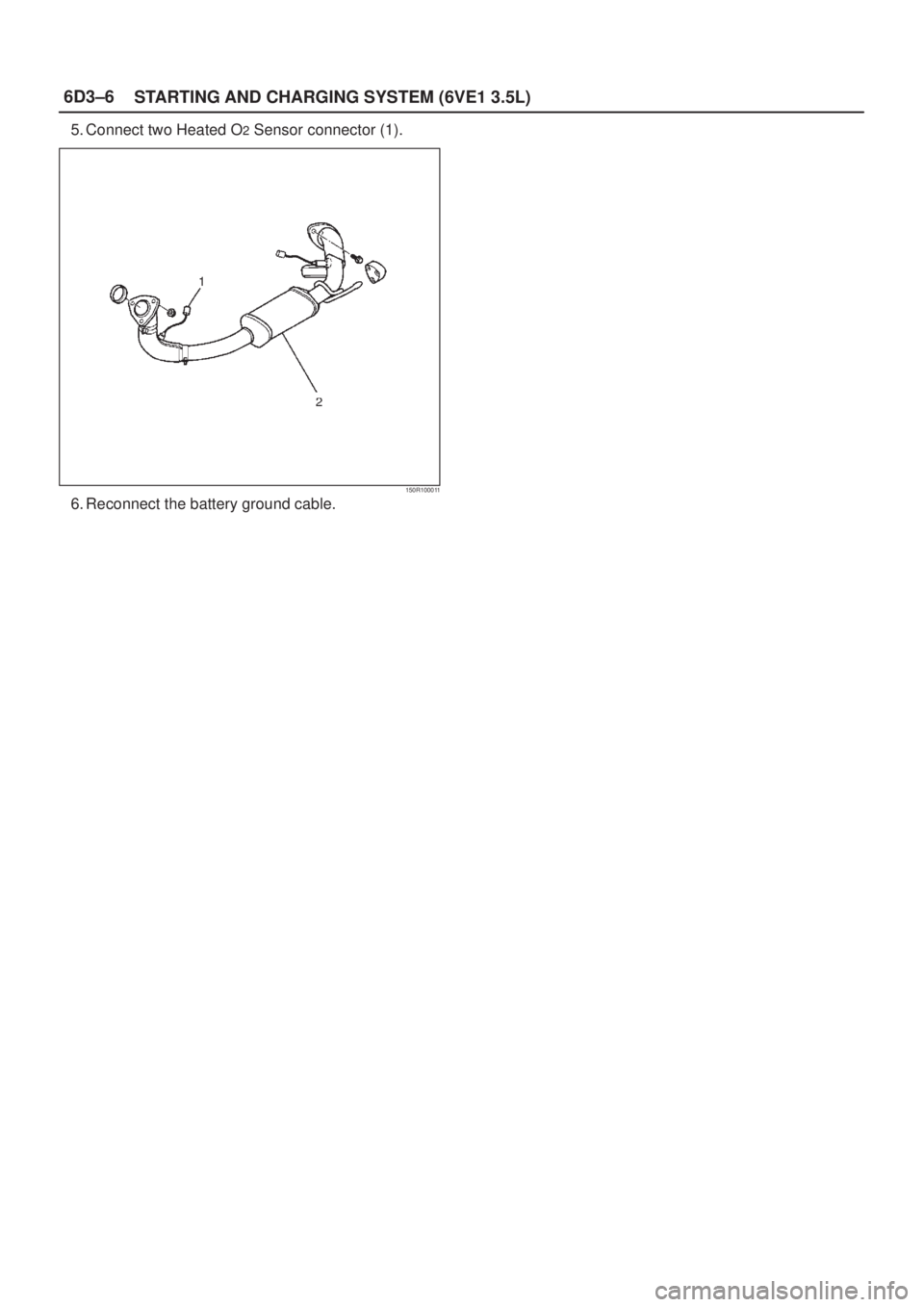

4. Disconnect starter wiring connector from terminals

ª30º (1) and ª50º (2).

5. Remove starter assembly mounting bolts on inside

and outside(3).

6. Remove starter assembly (4) toward the bottom of

engine.

065RY00050

Legend

(1) Terminal ª30º

(2) Terminal ª50º

(3) Fixing Bolts

(4) Starter Assembly

Installation

1. Install starter assembly(4).

2. Install mounting bolts and tighten bolts to specified

torque(3).

Torque: 40 N´m (30 lb ft)

3. Reconnect the connectors to terminals ª50º (2)

tighten terminals ª30º (1) to specified torque.

Torque: 9 N´m (78 lb in)

065RY00050

Legend

(1) Terminal ª30º

(2) Terminal ª50º

(3) Fixing Bolts

(4) Starter Assembly

4. Install exhaust front left pipe (2) and tighten bolts and

nuts to specified torque.

Stud Nuts

Torque: 67 N´m (49 lb ft)

Bolts

Torque: 43 N´m (32 lb ft)

Page 948 of 2100

6D3±6

STARTING AND CHARGING SYSTEM (6VE1 3.5L)

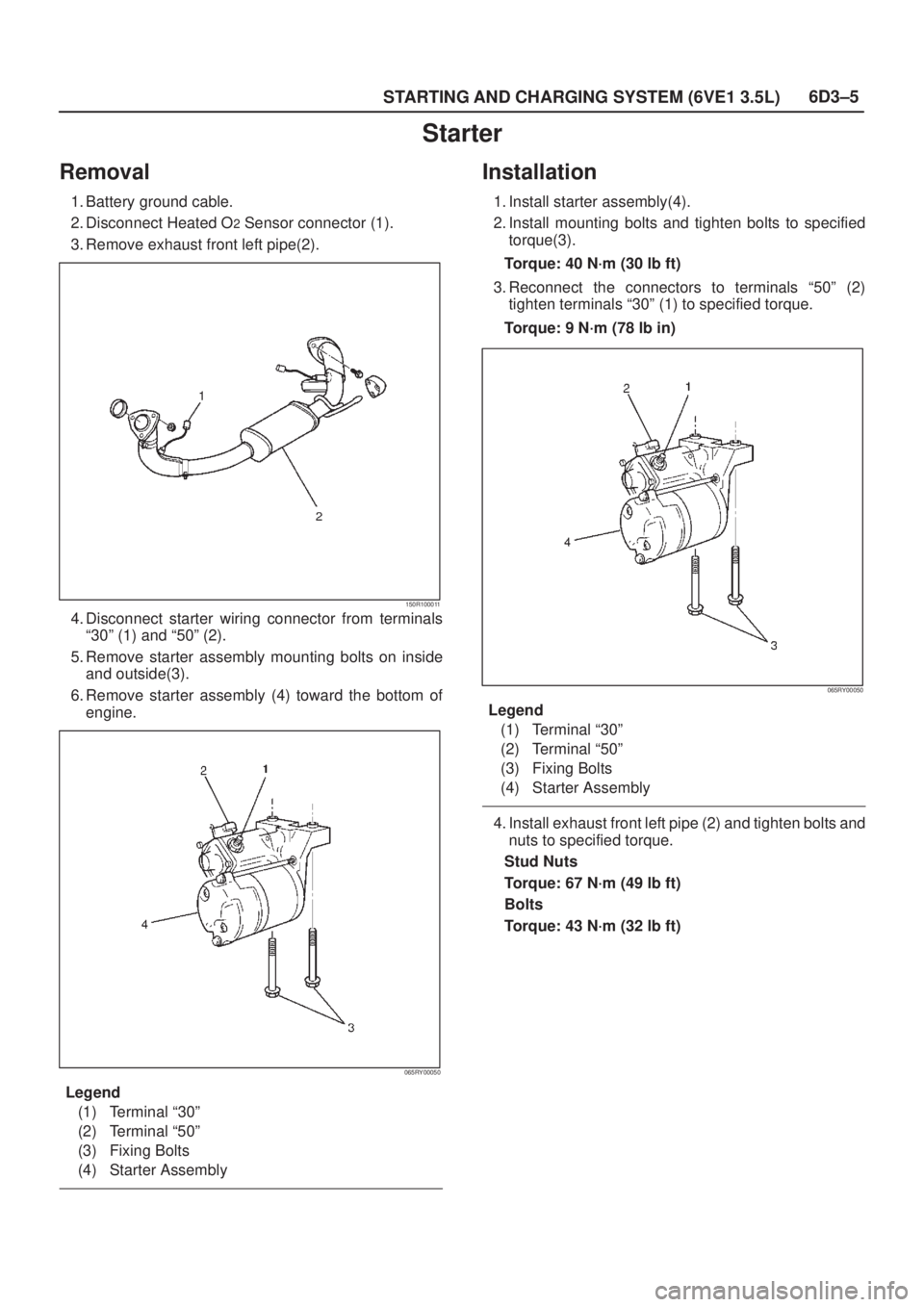

5. Connect two Heated O2 Sensor connector (1).

150R100011

6. Reconnect the battery ground cable.

Page 949 of 2100

6D3±7

STARTING AND CHARGING SYSTEM (6VE1 3.5L)

Disassembled View

065R100012

Legend

(1) Lead Wire

(2) Through Bolt

(3) Yoke Assembly

(4) Yoke Cover

(5) Brush and Brush Holder

(6) Armature(7) Housing

(8) Over Running Clutch

(9) Return Spring

(10) Steel Ball

(11) Idle Pinion

(12) Retainer

(13) Magnetic Switch

Page 950 of 2100

6D3±8

STARTING AND CHARGING SYSTEM (6VE1 3.5L)

Disassembly

1. Remove the lead wire (1) from the magnetic switch.

2. Remove the through bolts (2).

065RY00053

Legend

(1) Lead Wire

(2) Through Bolt

3. Remove the yoke from the magnetic.

4. Remove the yoke cover.

5. Use the long nose pliers to remove the brush and

brush holder.

065RY00054

065RY00055

Legend

(1) Spring

(2) Brush

6. Remove the armature.

7. Remove the housing.

8. Remove the overrunning clutch from the housing.

065RY00056

Trending: child seat, suspension 3f, fuel type, battery capacity, sport mode, spare tire, air conditioning