Neutral switch ISUZU KB P190 2007 Workshop Repair Manual

[x] Cancel search | Manufacturer: ISUZU, Model Year: 2007, Model line: KB P190, Model: ISUZU KB P190 2007Pages: 6020, PDF Size: 70.23 MB

Page 303 of 6020

3B-42 POWER-ASSISTED STEERING SYSTEM

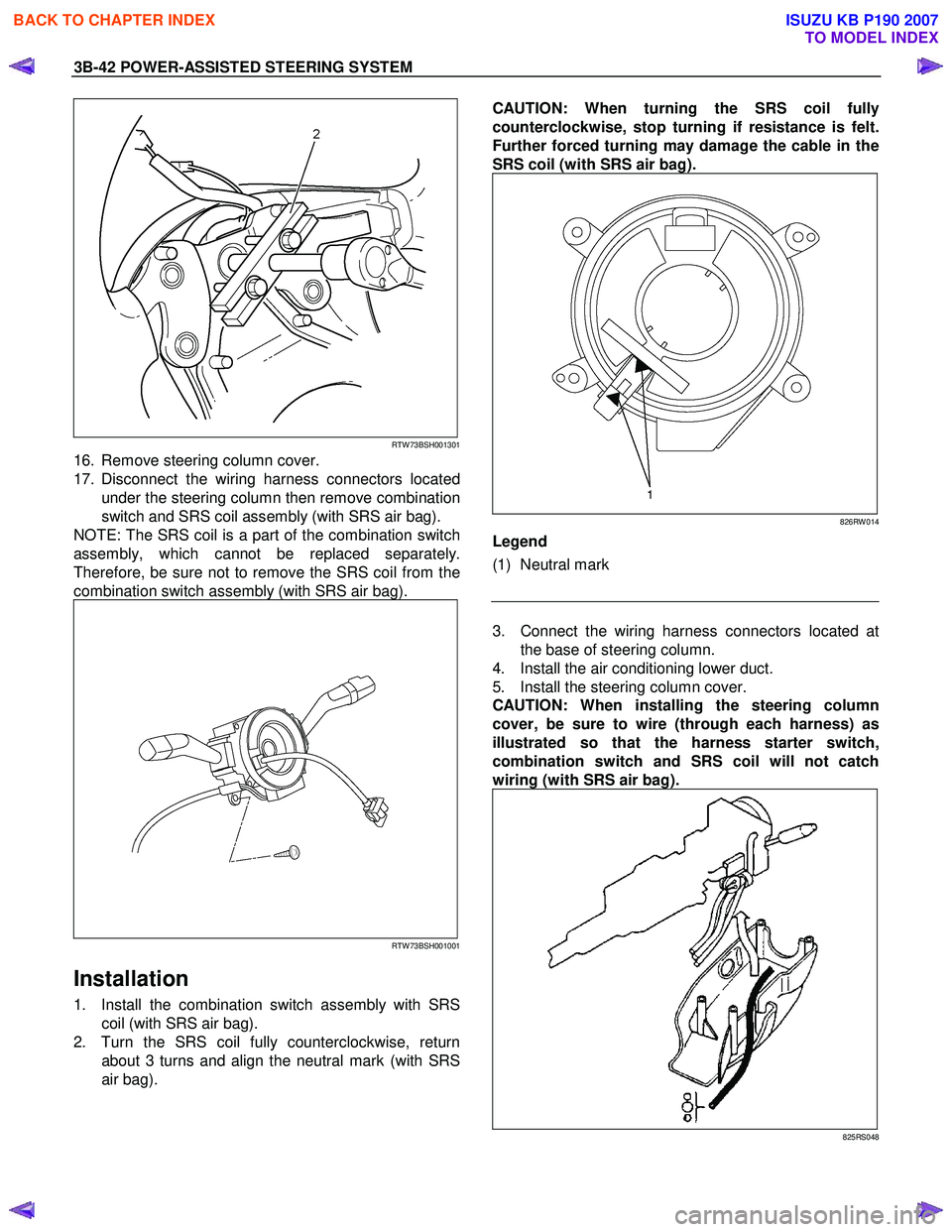

CAUTION: When turning the SRS coil fully

counterclockwise, stop turning if resistance is felt.

Further forced turning may damage the cable in the

SRS coil (with SRS air bag).

826RW 014

Legend

(1) Neutral mark

RTW 73BSH001301

16. Remove steering column cover.

17. Disconnect the wiring harness connectors located under the steering column then remove combination

switch and SRS coil assembly (with SRS air bag).

NOTE: The SRS coil is a part of the combination switch

assembly, which cannot be replaced separately.

Therefore, be sure not to remove the SRS coil from the

combination switch assembly (with SRS air bag).

RTW 73BSH001001

Installation

1. Install the combination switch assembly with SRS coil (with SRS air bag).

2. Turn the SRS coil fully counterclockwise, return about 3 turns and align the neutral mark (with SRS

air bag).

3. Connect the wiring harness connectors located at the base of steering column.

4. Install the air conditioning lower duct.

5. Install the steering column cover.

CAUTION: When installing the steering column

cover, be sure to wire (through each harness) as

illustrated so that the harness starter switch,

combination switch and SRS coil will not catch

wiring (with SRS air bag).

825RS048

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 309 of 6020

3B-48 POWER-ASSISTED STEERING SYSTEM

430R300007

17. Remove steering column cover.

18. Disconnect the wiring harness connectors located under the steering column.

19. Remove the combination switch assembly with SRS coil.

NOTE: The SRS coil is a part of the combination switch

assembly, which cannot be replaced separately.

Therefore, be sure not to remove the SRS coil from the

combination switch assembly (with SRS air bag).

RTW 73BSH001001

20. Turn the ignition switch to the ACC position.

21. Insert a pin (1) into the hole and push on it. Pull the

key cylinder free.

RUW 53BSH000101

Installation

1. Install lock cylinder assembly.

2. Install the combination switch assembly with SRS coil (with SRS air bag).

3. Turn the SRS coil fully counterclockwise, return about 3 turns and align the neutral mark (with SRS

air bag).

CAUTION: When turning the SRS coil fully

counterclockwise, stop turning if resistance is felt.

Further forced turning may damage the cable in the

SRS coil (with SRS air bag).

826RW 014

Legend

(1) Neutral mark

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 317 of 6020

3B-56 POWER-ASSISTED STEERING SYSTEM

9. Turn the SRS coil fully counterclockwise, return

about 3 turns and align the neutral mark (1). (with

SRS air bag)

CAUTION: When turning the SRS coil fully

counterclockwise, stop turning if resistance is felt.

Further forced turning may damage to the cable in

the SRS coil.

826RW 014

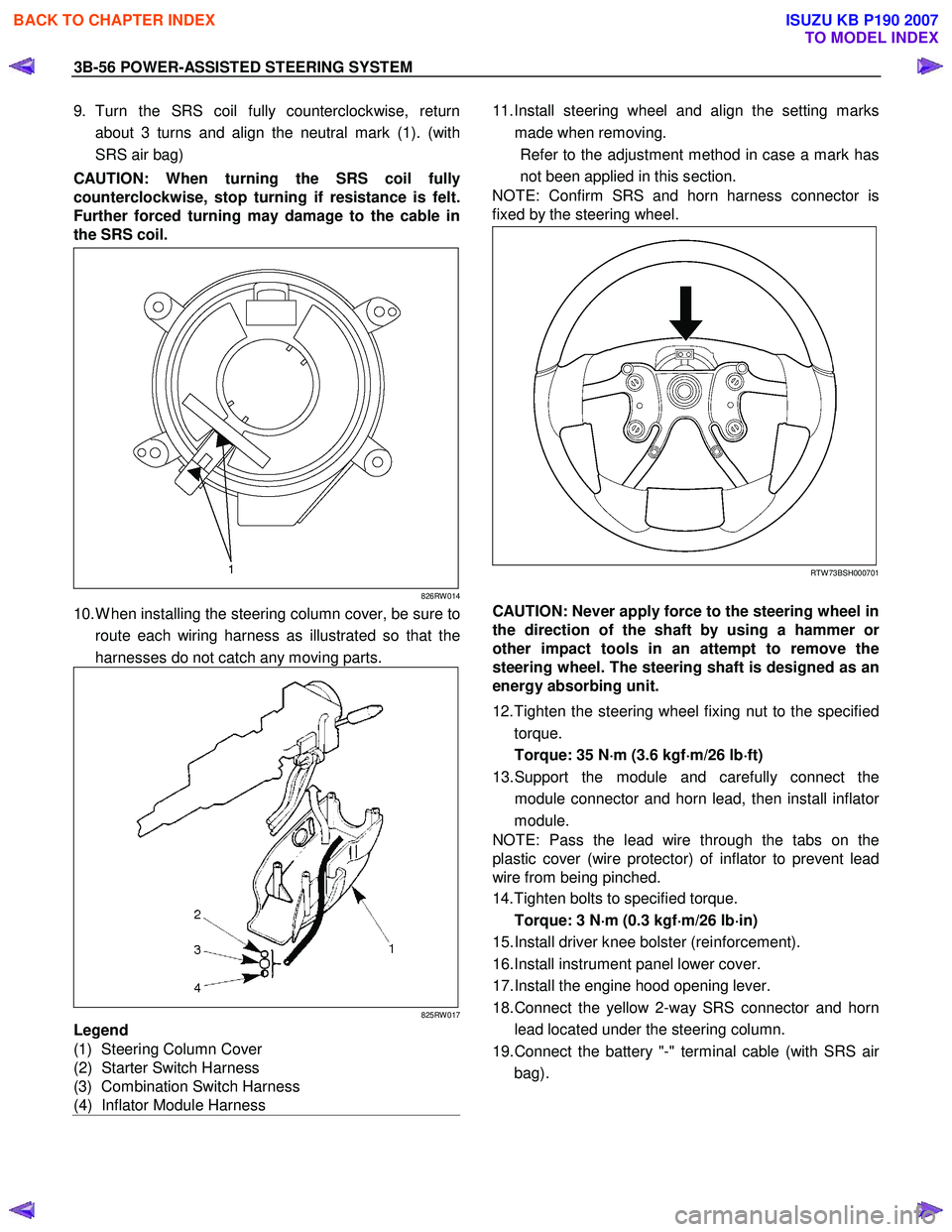

10. W hen installing the steering column cover, be sure to

route each wiring harness as illustrated so that the

harnesses do not catch any moving parts.

825RW 017

Legend

(1) Steering Column Cover

(2) Starter Switch Harness

(3) Combination Switch Harness

(4) Inflator Module Harness

11. Install steering wheel and align the setting marks

made when removing. Refer to the adjustment method in case a mark has

not been applied in this section.

NOTE: Confirm SRS and horn harness connector is

fixed by the steering wheel.

RTW 73BSH000701

CAUTION: Never apply force to the steering wheel in

the direction of the shaft by using a hammer o

r

other impact tools in an attempt to remove the

steering wheel. The steering shaft is designed as an

energy absorbing unit.

12. Tighten the steering wheel fixing nut to the specified torque.

Torque: 35 N ⋅

⋅⋅

⋅

m (3.6 kgf ⋅

⋅⋅

⋅

m/26 lb ⋅

⋅⋅

⋅

ft)

13. Support the module and carefully connect the module connector and horn lead, then install inflato

r

module.

NOTE: Pass the lead wire through the tabs on the

plastic cover (wire protector) of inflator to prevent lead

wire from being pinched.

14. Tighten bolts to specified torque.

Torque: 3 N ⋅

⋅⋅

⋅

m (0.3 kgf ⋅

⋅⋅

⋅

m/26 lb ⋅

⋅⋅

⋅

in)

15. Install driver knee bolster (reinforcement).

16. Install instrument panel lower cover.

17. Install the engine hood opening lever.

18. Connect the yellow 2-way SRS connector and horn lead located under the steering column.

19. Connect the battery "-" terminal cable (with SRS ai

r

bag).

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 1048 of 6020

6E-14 Engine Control System (4JH1)

A/C & Neutral Switch Resister, CKP Sensor, APP Sensor and Idle Switch

RTW 76EXF003201

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 1050 of 6020

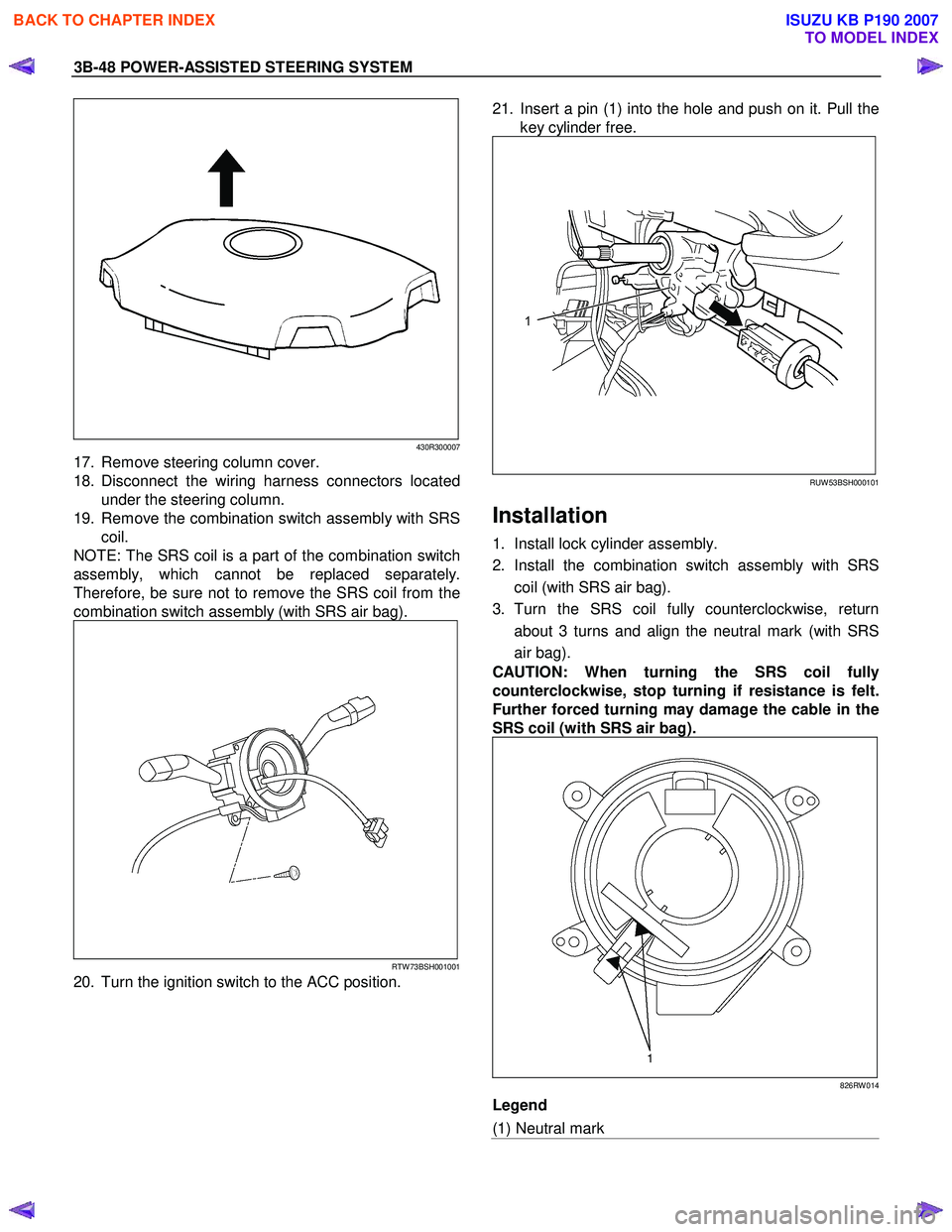

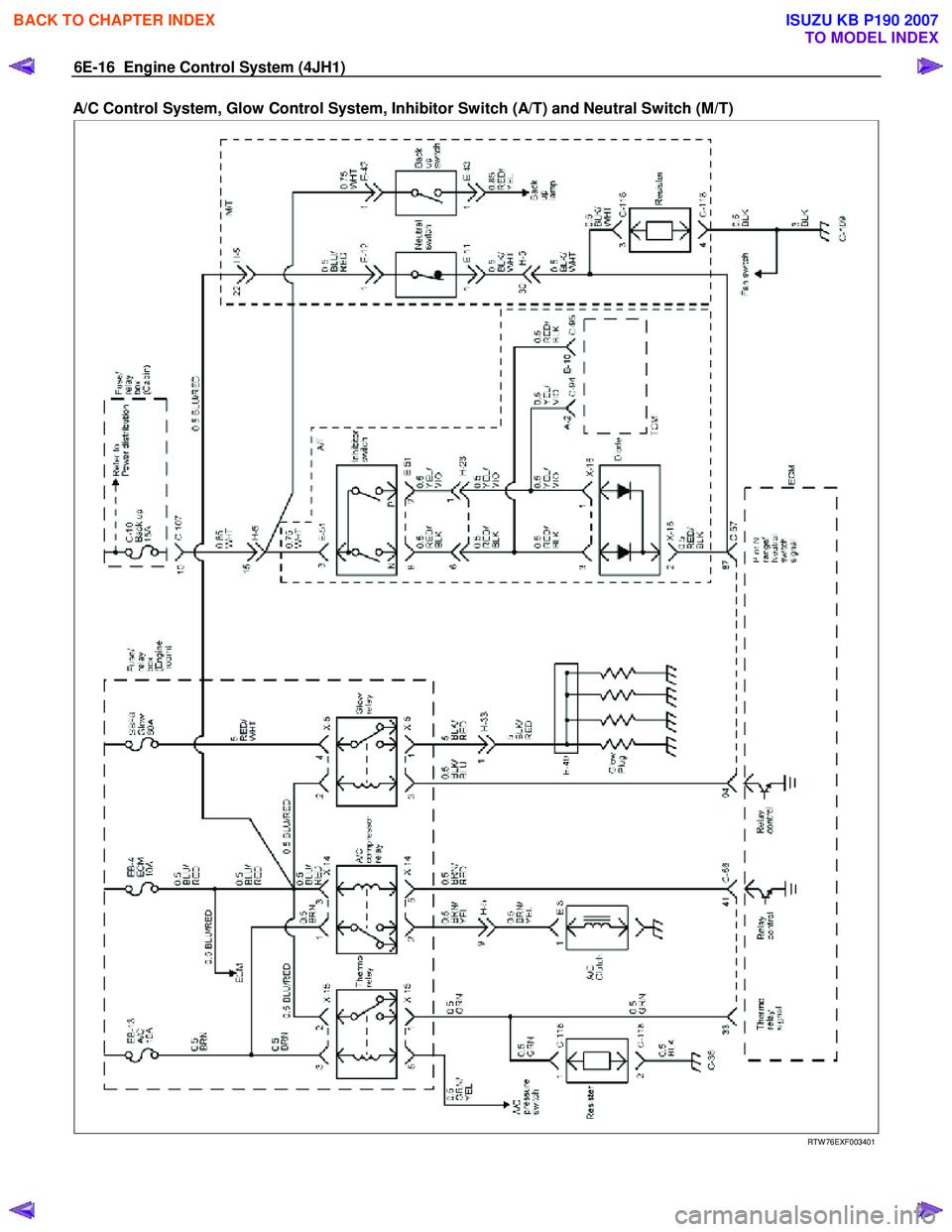

6E-16 Engine Control System (4JH1)

A/C Control System, Glow Control System, Inhibitor Switch (A/T) and Neutral Switch (M/T)

RTW 76EXF003401

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 1058 of 6020

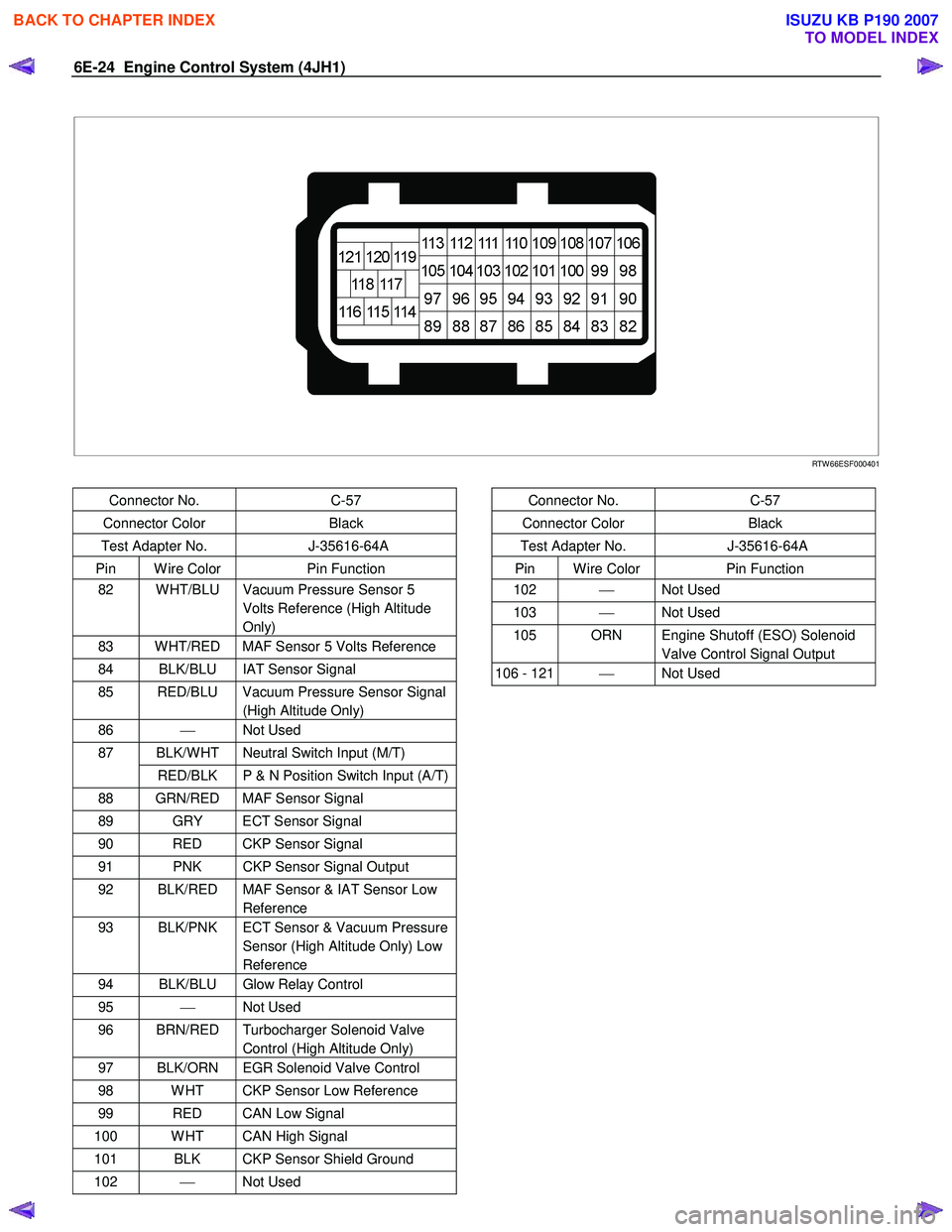

6E-24 Engine Control System (4JH1)

RTW 66ESF000401

Connector No. C-57

Connector Color Black

Test Adapter No. J-35616-64A

Pin W ire Color Pin Function

82 W HT/BLU Vacuum Pressure Sensor 5

Volts Reference (High Altitude

Only)

83 W HT/RED MAF Sensor 5 Volts Reference

84 BLK/BLU IAT Sensor Signal

85 RED/BLU Vacuum Pressure Sensor Signal (High Altitude Only)

86 Not Used

BLK/W HT Neutral Switch Input (M/T) 87

RED/BLK P & N Position Switch Input (A/T)

88 GRN/RED MAF Sensor Signal

89 GRY ECT Sensor Signal

90 RED CKP Sensor Signal

91 PNK CKP Sensor Signal Output

92 BLK/RED MAF Sensor & IAT Sensor Low Reference

93 BLK/PNK ECT Sensor & Vacuum Pressure Sensor (High Altitude Only) Low

Reference

94 BLK/BLU Glow Relay Control

95 Not Used

96 BRN/RED Turbocharger Solenoid Valve

Control (High Altitude Only)

97 BLK/ORN EGR Solenoid Valve Control

98 W HT CKP Sensor Low Reference

99 RED CAN Low Signal

100 W HT CAN High Signal

101 BLK CKP Sensor Shield Ground

102 Not Used

Connector No. C-57

Connector Color Black

Test Adapter No. J-35616-64A

Pin W ire Color Pin Function

102 Not Used

103 Not Used

105 ORN Engine Shutoff (ESO) Solenoid

Valve Control Signal Output

106 - 121 Not Used

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 1070 of 6020

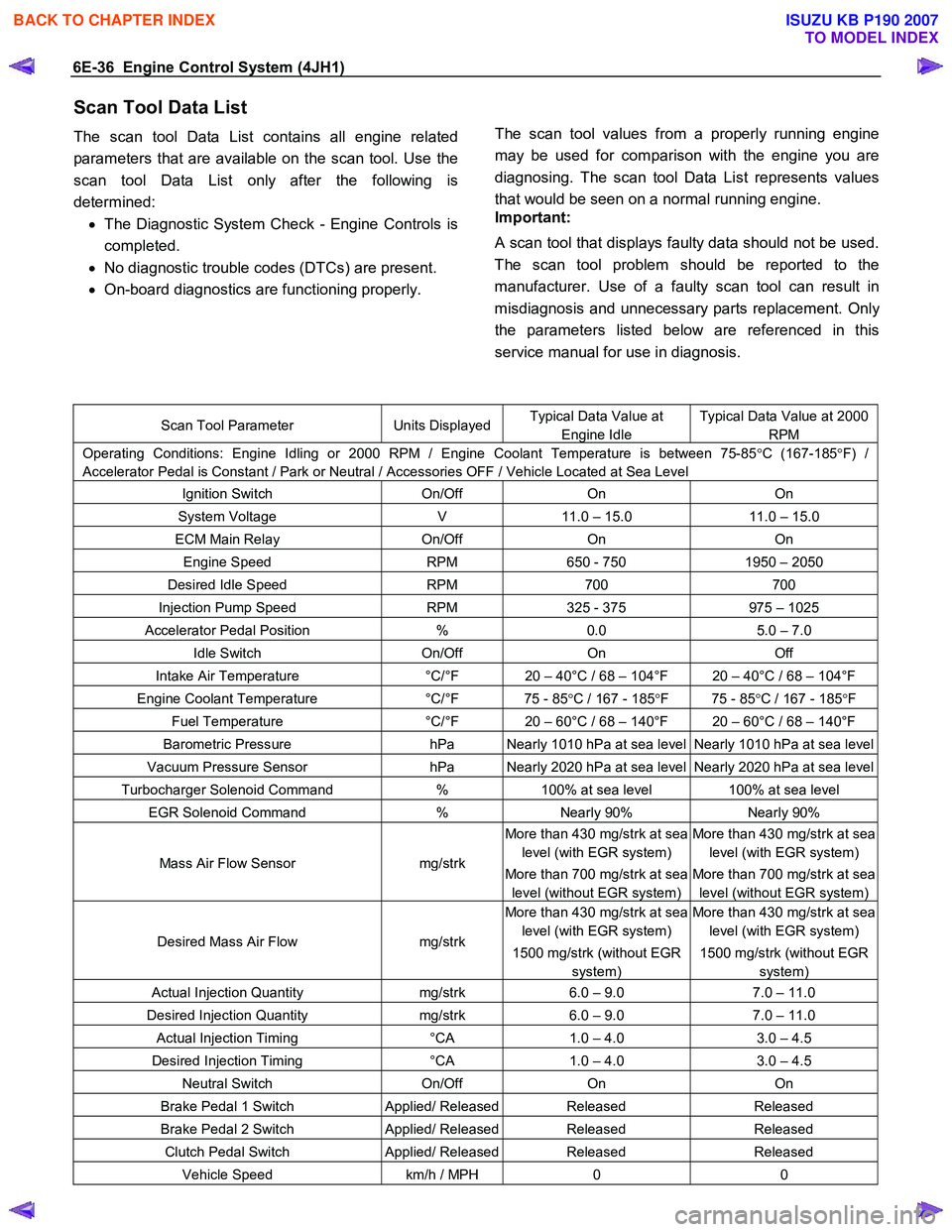

6E-36 Engine Control System (4JH1)

Scan Tool Data List

The scan tool Data List contains all engine related

parameters that are available on the scan tool. Use the

scan tool Data List only after the following is

determined: • The Diagnostic System Check - Engine Controls is

completed.

• No diagnostic trouble codes (DTCs) are present.

• On-board diagnostics are functioning properly.

The scan tool values from a properly running engine

may be used for comparison with the engine you are

diagnosing. The scan tool Data List represents values

that would be seen on a normal running engine.

Important:

A scan tool that displays faulty data should not be used.

The scan tool problem should be reported to the

manufacturer. Use of a faulty scan tool can result in

misdiagnosis and unnecessary parts replacement. Onl

y

the parameters listed below are referenced in this

service manual for use in diagnosis.

Scan Tool Parameter Units DisplayedTypical Data Value at

Engine Idle

Typical Data Value at 2000

RPM

Operating Conditions: Engine Idling or 2000 RPM / Engine Coolant Temperature is between 75-85 °C (167-185 °F) /

Accelerator Pedal is Constant / Park or Neutral / Accessories OFF / Vehicle Located at Sea Level

Ignition Switch On/Off On On

System Voltage V 11.0 – 15.0 11.0 – 15.0

ECM Main Relay On/Off On On

Engine Speed RPM 650 - 750 1950 – 2050

Desired Idle Speed RPM 700 700

Injection Pump Speed RPM 325 - 375 975 – 1025

Accelerator Pedal Position % 0.0 5.0 – 7.0

Idle Switch On/Off On Off

Intake Air Temperature °C/°F 20 – 40°C / 68 – 104°F 20 – 40°C / 68 – 104°F

Engine Coolant Temperature °C/°F 75 - 85 °C / 167 - 185 °F 75 - 85 °C / 167 - 185 °F

Fuel Temperature °C/°F 20 – 60°C / 68 – 140°F 20 – 60°C / 68 – 140°F

Barometric Pressure hPa Nearly 1010 hPa at sea level Nearly 1010 hPa at sea level

Vacuum Pressure Sensor hPa Nearly 2020 hPa at sea level Nearly 2020 hPa at sea level

Turbocharger Solenoid Command % 100% at sea level 100% at sea level

EGR Solenoid Command % Nearly 90% Nearly 90%

Mass Air Flow Sensor mg/strk

More than 430 mg/strk at sea

level (with EGR system)

More than 700 mg/strk at sea

level (without EGR system)

More than 430 mg/strk at sea

level (with EGR system)

More than 700 mg/strk at sea

level (without EGR system)

Desired Mass Air Flow mg/strk

More than 430 mg/strk at sea

level (with EGR system)

1500 mg/strk (without EGR

system)

More than 430 mg/strk at sea

level (with EGR system)

1500 mg/strk (without EGR

system)

Actual Injection Quantity mg/strk 6.0 – 9.0 7.0 – 11.0

Desired Injection Quantity mg/strk 6.0 – 9.0 7.0 – 11.0

Actual Injection Timing °CA 1.0 – 4.0 3.0 – 4.5

Desired Injection Timing °CA 1.0 – 4.0 3.0 – 4.5

Neutral Switch On/Off On On

Brake Pedal 1 Switch Applied/ ReleasedReleased Released

Brake Pedal 2 Switch Applied/ ReleasedReleased Released

Clutch Pedal Switch Applied/ ReleasedReleased Released

Vehicle Speed km/h / MPH 0 0

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 1072 of 6020

6E-38 Engine Control System (4JH1)

Intake Air Temperature

This parameter displays the temperature of the intake

air based on a voltage input from the intake ai

r

temperature (IAT) sensor to the ECM. The scan tool will

display a low temperature when signal voltage is high,

and high temperature when the signal voltage is low.

Note that the IAT sensor is internal to the mass air flo

w

(MAF) sensor and the MAF sensor is heated.

Engine Coolant Temperature

This parameter displays the temperature of the engine

coolant based on a voltage input from the engine

coolant temperature (ECT) sensor to the ECM. The

scan tool will display a low temperature when the signal

voltage is high, and a high temperature when the signal

voltage is low.

Fuel Temperature

This parameter displays the temperature of the fuel as

calculated by the fuel injection pump control unit (PCU)

using the signal from the fuel temperature sensor inside

of the PCU.

Barometric Pressure

This parameter displays the barometric pressure as

calculated by the ECM using the signal from the

barometric pressure (BARO) sensor inside of the ECM.

Vacuum Pressure Sensor (High altitude

specification only)

This parameter displays the amount of the vacuum

pressure to the turbocharger wastegate valve. W hen a

high vacuum pressure at a low vacuum pressure

amount to the turbocharger wastegate valve. The scan

tool will display doubled barometric pressure when the

ignition is ON with the engine OFF.

Turbocharger Solenoid Command (High altitude

specification only)

This parameter displays the turbocharger solenoid

valuve control duty ratio commanded by the ECM

terminal (pin 96) using the signal from various senso

r

inputs. W hen a low duty ratio, vacuum pressure to the

turbocharger wastegate valve is controlled to increase.

W hen a high duty ratio, vacuum pressure to the

turbochager wastegate valve is controlled to reduce.

EGR Solenoid Command

This parameter displays the EGR solenoid valve control

duty ratio commanded by the ECM terminal (pin 97)

using the signal from engine speed, and injection

volume and various sensor inputs. W hen a small dut

y

ratio, the EGR valve is controlled to close. W hen a large

duty ratio, the EGR valve is controlled to open.

Mass Air Flow Sensor

This parameter displays the air flow into the engine as

calculated by the ECM based on the mass air flo

w

(MAF) sensor input. The scan tool will display a high

value at higher engine speeds, and a low value at idle.

This can be compared to the Desired Mass Air Flow to

determine MAF sensor accuracy, EGR problem o

r

intake problem. Note that the MAF on the scan tool will

only update with the engine running.

Desired Mass Air Flow

This parameter displays a mass air flow desired by the

ECM based on current driving condition.

Actual Injection Quantity

This parameter displays the injection quantity calculated

by the PCU based on the fuel injection solenoid valve

On time which compensated from the timing device

position and fuel temperature inputs. This can be

compared to the Desired Injection Quantity to determine

fuel system problem.

Desired Injection Quantity

This parameter displays an injection quantity desired b

y

the ECM based on current driving condition using target

injection maps.

Actual Injection Timing

This parameter displays the injection timing calculated

by the PCU based on the timing device position which

determined from the crankshaft position sensor and

camshaft position sensor inputs. This can be compared

to the Desired Injection Timing to determine timing

device problem or fuel system problem.

Desired Injection Timing

This parameter displays injection timing desired by the

ECM based on current driving condition using target

injection timing maps. This timing is compensated b

y

engine coolant temperature, altitude and intake ai

r

temperature, etc.

Neutral Switch

This parameter displays the state of the neutral switch

as determined by the ECM terminal (pin 87) based on

an input from the neutral switch or inhibitor switch.

Brake Pedal 1 Switch

This parameter displays the state of the brake pedal as

determined by the ECM terminal (pin 30) based on an

input from the brake pedal 1 switch. This switch turns

On the stop lamps when the brake pedal is depressed.

The scan tool will display Applied when the brake pedal

is depressed.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 1096 of 6020

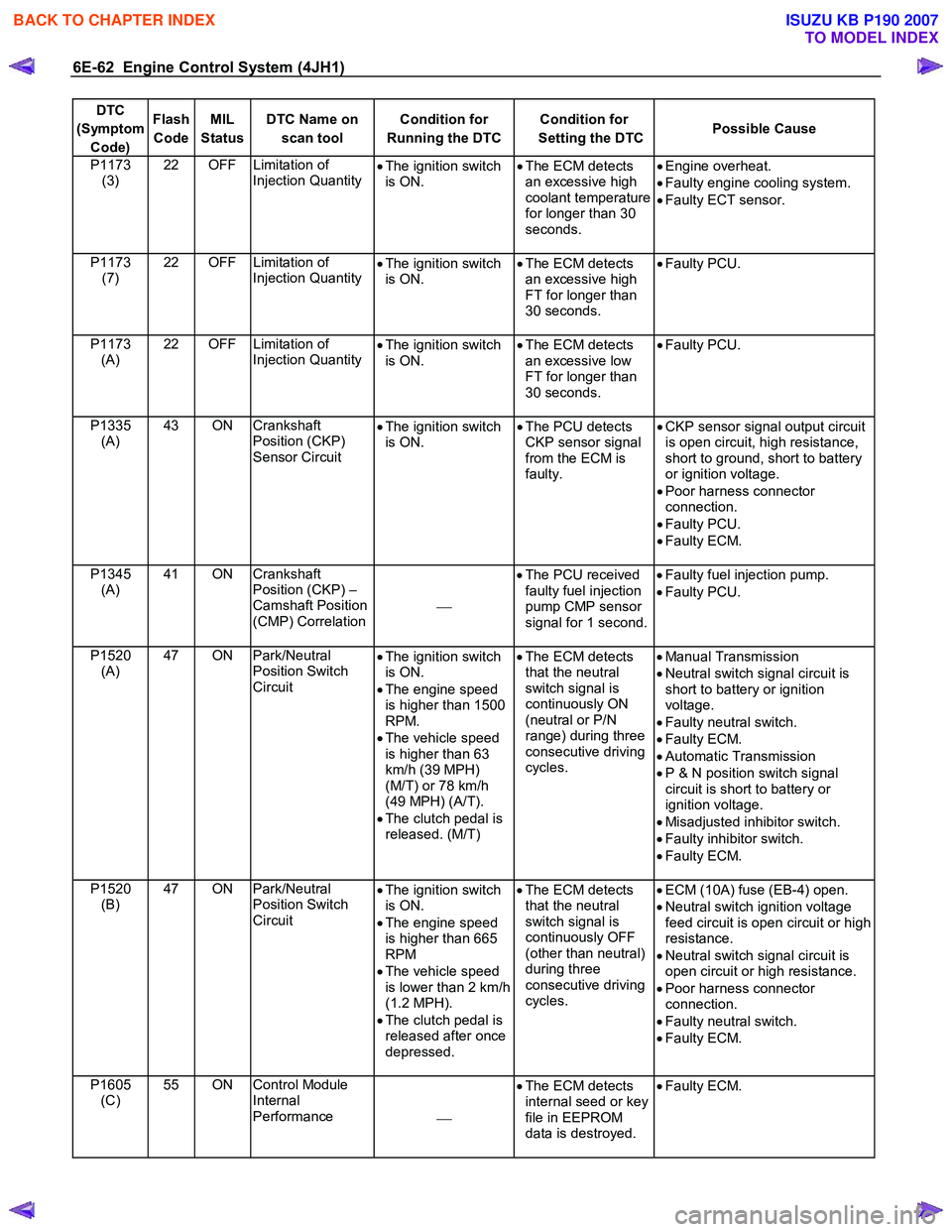

6E-62 Engine Control System (4JH1)

DTC

(Symptom Code) Flash

Code MIL

Status DTC Name on

scan tool Condition for

Running the DTC Condition for

Setting the DTC Possible Cause

P1173

(3) 22 OFF Limitation of

Injection Quantity •

The ignition switch

is ON. •

The ECM detects

an excessive high

coolant temperature

for longer than 30

seconds.

•

Engine overheat.

• Faulty engine cooling system.

• Faulty ECT sensor.

P1173 (7) 22 OFF Limitation of

Injection Quantity

•

The ignition switch

is ON. •

The ECM detects

an excessive high

FT for longer than

30 seconds.

•

Faulty PCU.

P1173 (A) 22 OFF Limitation of

Injection Quantity

•

The ignition switch

is ON. •

The ECM detects

an excessive low

FT for longer than

30 seconds.

•

Faulty PCU.

P1335 (A) 43 ON Crankshaft

Position (CKP)

Sensor Circuit •

The ignition switch

is ON. •

The PCU detects

CKP sensor signal

from the ECM is

faulty.

•

CKP sensor signal output circuit

is open circuit, high resistance,

short to ground, short to battery

or ignition voltage.

• Poor harness connector

connection.

• Faulty PCU.

• Faulty ECM.

P1345 (A) 41 ON Crankshaft

Position (CKP) –

Camshaft Position

(CMP) Correlation

•

The PCU received

faulty fuel injection

pump CMP sensor

signal for 1 second.

•

Faulty fuel injection pump.

• Faulty PCU.

P1520 (A) 47 ON Park/Neutral

Position Switch

Circuit •

The ignition switch

is ON.

• The engine speed

is higher than 1500

RPM.

• The vehicle speed

is higher than 63

km/h (39 MPH)

(M/T) or 78 km/h

(49 MPH) (A/T).

• The clutch pedal is

released. (M/T)

•

The ECM detects

that the neutral

switch signal is

continuously ON

(neutral or P/N

range) during three

consecutive driving

cycles.

•

Manual Transmission

• Neutral switch signal circuit is

short to battery or ignition

voltage.

• Faulty neutral switch.

• Faulty ECM.

• Automatic Transmission

• P & N position switch signal

circuit is short to battery or

ignition voltage.

• Misadjusted inhibitor switch.

• Faulty inhibitor switch.

• Faulty ECM.

P1520 (B) 47 ON Park/Neutral

Position Switch

Circuit •

The ignition switch

is ON.

• The engine speed

is higher than 665

RPM

• The vehicle speed

is lower than 2 km/h

(1.2 MPH).

• The clutch pedal is

released after once

depressed.

•

The ECM detects

that the neutral

switch signal is

continuously OFF

(other than neutral)

during three

consecutive driving

cycles.

•

ECM (10A) fuse (EB-4) open.

• Neutral switch ignition voltage

feed circuit is open circuit or high

resistance.

• Neutral switch signal circuit is

open circuit or high resistance.

• Poor harness connector

connection.

• Faulty neutral switch.

• Faulty ECM.

P1605 (C) 55 ON Control Module

Internal

Performance •

The ECM detects

internal seed or key

file in EEPROM

data is destroyed.

•

Faulty ECM.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 1244 of 6020

6E-210 Engine Control System (4JH1)

DTC P1520 (Symptom Code A) (Flash Code 47)

Circuit Description

(Manual Transmission)

The neutral switch is installed on the transmission gea

r

control box. W hen the gear position is neutral, the

switch is closed and the switch signal is provided to the

engine control module (ECM). If the ECM detects the

neutral switch signal is not changed from neutral during

the predetermined engine speed and vehicle speed

range, this DTC will set.

(Automatic Transmission)

The inhibitor switch is installed to the transmission case.

W hen the selector position is P or N range, the switch is

closed and the switch signal is provided to the Emir the

ECM detects the neutral switch signal is not changed

from P or N during the predetermined engine speed and

vehicle speed range, this DTC will set.

Condition for Running the DTC • The ignition switch is ON.

• The engine speed is higher than 1500 RPM.

• The vehicle speed is higher than 63 km/h (39

MPH) (M/T) or 78 km/h (49 MPH) (A/T).

• The clutch pedal is released. (M/T).

Condition for Setting the DTC

• The ECM detects that the neutral switch signal is

continuously ON (neutral or P/N range) during

three consecutive driving cycles.

Action Taken When the DTC Sets

• The ECM illuminates the malfunction indicato

r

lamp (MIL) when the diagnostic runs and fails.

Condition for Clearing the MIL/DTC

Important: • Following conditions must be met two consecutive

driving cycles. (One driving cycle: Ignition switch

ON > Engine run > Vehicle run > Ignition switch

OFF for 10 seconds)

- The engine speed is higher than 1500 RPM

- The vehicle speed is higher than 63 km/h (39 MPH) (M/T) or 78 km/h (49 MPH) (A/T)

- The clutch pedal is released (M/T)

- Other than neutral or P/N range

- After the above procedure is done, a history

DTC clears after 40 consecutive driving cycles

without a fault. Or clear with the scan tool.

Diagnostic Aids

• If an intermittent condition is suspected, refer to

Intermittent Conditions in this section.

DTC P1520 (Symptom Code A) (Flash Code 47)

Schematic Reference: Engine Controls Schematics

Connector End View Reference: Engine Controls

Connector End Views or Engine Control Module (ECM)

Connector End Views

Chart for M/T

Step Action Value(s) Yes No

1 Did you perform the Diagnostic System Check-

Engine Controls?

Go to Step 2 Go to Diagnostic

System Check-

Engine Controls

2 1. Install the scan tool. 2. Turn ON the ignition, with the engine OFF.

3. Observe the Neutral Switch parameter with the scan tool while shift to neutral and other

positions.

Does the scan tool indicate ON when the position is

neutral and OFF when other than the neutral?

Go to Diagnostic Aids Go to Step 3

3 1. Turn OFF the ignition. 2. Disconnect the neutral switch harness connector.

3. Turn ON the ignition, with the engine OFF.

4. Observe the Neutral Switch parameter with the scan tool.

Does the scan tool indicate ON?

Go to Step 4 Go to Step 5

4 1. Test the neutral switch input signal circuit between the engine control module (ECM) (pin

87 of C-57 connector) and the neutral switch (pin

1 of E-11 connector) for a short to battery or

ignition voltage.

2. Repair the circuit(s) as necessary.

Did you find and correct the condition?

Go to Step 7 Go to Step 6

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007