lock ISUZU KB P190 2007 Workshop Owners Manual

[x] Cancel search | Manufacturer: ISUZU, Model Year: 2007, Model line: KB P190, Model: ISUZU KB P190 2007Pages: 6020, PDF Size: 70.23 MB

Page 618 of 6020

BRAKE CONTROL SYSTEM 5A-25

“ABS” Warning Lamp

W hen ABS and problems occur that actuate the “ABS”

warning lamp, the code corresponding to the problem is

stored in the EHCU. Only ordinary braking is available

when the ABS is deactivated. Even when the “ABS”

warning lamp is actuated, if the starter switch is set ON

after setting it OFF once, the EHCU checks up on the

entire system. If there is no abnormality, the EHCU

judges ABS to work correctly and the warning lamp is lit

normally, even though the problem code is stored.

NOTE: Illumination of the “ABS” warning lamp indicates

that anti-lock braking is no longer available. Power

assisted braking without anti-lock control is still

available.

Normal Operation

“ABS ” Warning Lamp

W hen the ignition is first moved from “OFF” to “RUN”,

the amber “ABS” warning lamp will turn “ON”. The

“ABS” warning lamp will turn “ON” during engine

starting and will usually stay “ON” for approximately

three seconds after the ignition switch is returned to the

“ON” position. The warning lamp should remain “OFF”

at all other times.

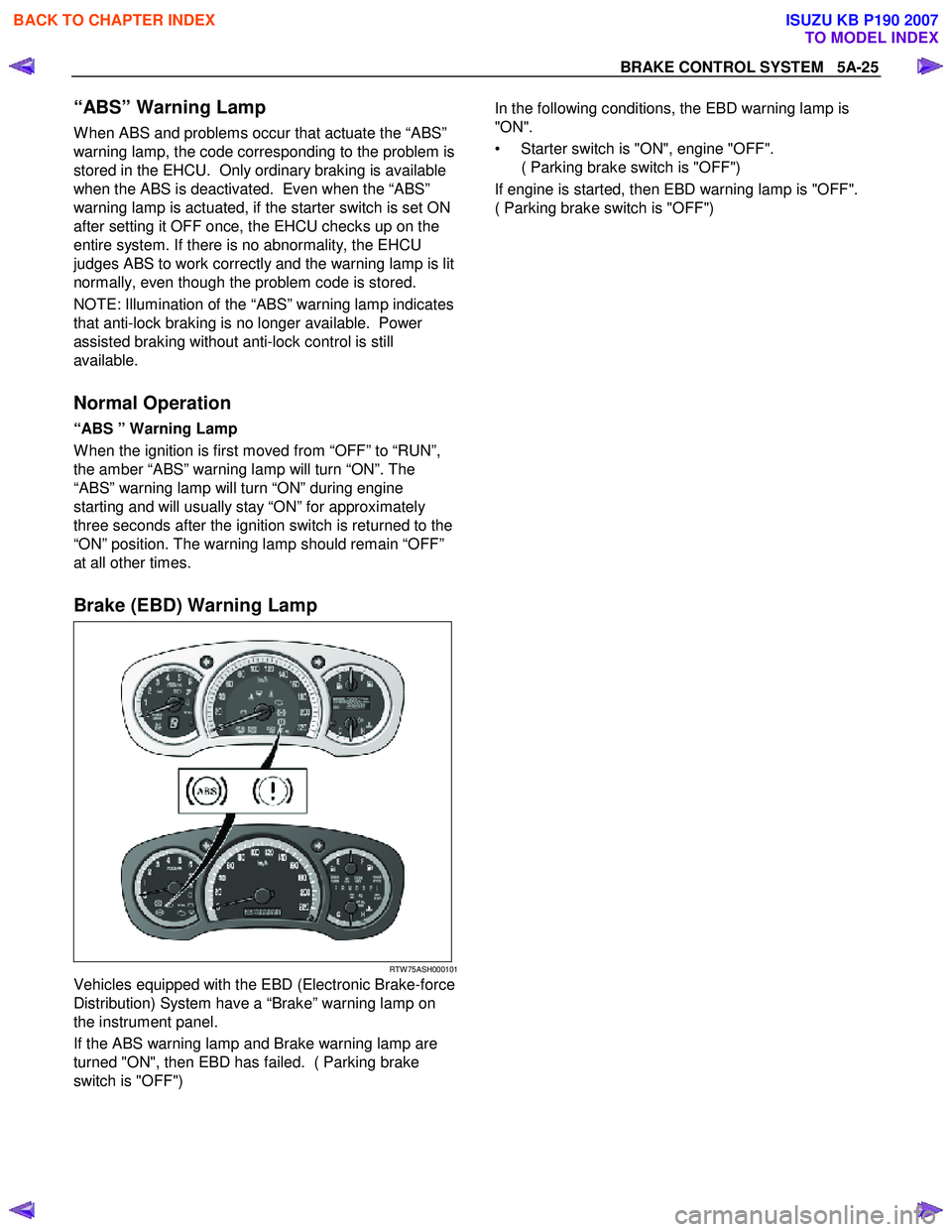

Brake (EBD) Warning Lamp

RTW 75ASH000101

Vehicles equipped with the EBD (Electronic Brake-force

Distribution) System have a “Brake” warning lamp on

the instrument panel.

If the ABS warning lamp and Brake warning lamp are

turned "ON", then EBD has failed. ( Parking brake

switch is "OFF")

In the following conditions, the EBD warning lamp is

"ON".

• Starter switch is "ON", engine "OFF". ( Parking brake switch is "OFF")

If engine is started, then EBD warning lamp is "OFF".

( Parking brake switch is "OFF")

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 623 of 6020

5A-30 BRAKE CONTROL SYSTEM

4. Release the brake pedal.

5. Make sure that the front left hold solenoid valve "ON" aimed at by Tech 2 and the wheel locked

position are the same.

If different, check brake pipe, valve line harness wiring

and hydraulic unit. Repair is needed if abnormality is

found.

Front Left Release Valve Test

Purpose: The purpose of this test is to detect brake pipe

and valve line harness wire for incorrect connections and

valve problem.

This test will help you confirm the result of your repai

r

service including the removal/ reinstallation of brake

pipe, valve line harness and valve.

Test conditions: The ignition key is in the "ON" position

with the four wheels lifted up. The brake pedal is stepped

on, released and stepped on again with the parking

brake released.

Test Procedure: 1. Connect Tech 2 with the vehicle, and select "Actuator Test" menus.

2. Select a "Front Left Release Valve Test" menu from the "Actuator Test" menus.

3. Step on the brake pedal.

4. Make sure that the front left release solenoid valve "ON" aimed at by Tech 2 and the wheel released

position are the same.

If different, check brake pipe, valve line harness wiring

and hydraulic unit. Repair is needed if abnormality is

found.

Front Right Hold Valve Test

Purpose: The purpose of this test is to detect brake pipe

and valve line harness wire for incorrect connections and

valve problem.

This test will help you confirm the result of your repai

r

service including the removal/ reinstallation of brake

pipe, valve line harness and valve.

Test conditions: The ignition key is in the "ON" position

with the four wheels lifted up. The brake pedal is stepped

on, released and stepped on again with the parking

brake released.

Test Procedure: 1. Connect Tech 2 with the vehicle, and select "Actuator Test" menus.

2. Select a "Front Right Hold Valve Test" menu from the "Actuator Test" menus.

3. Step on the brake pedal.

4. Release the brake pedal.

5. Make sure that the front right hold solenoid valve "ON" aimed at by Tech 2 and the wheel locked

position are the same.

If different, check brake pipe, valve line harness wiring

and hydraulic unit. Repair is needed if abnormality is

found.

Front Right Release Valve Test

Purpose: The purpose of this test is to detect brake pipe

and valve line harness wire for incorrect connections

and valve problem.

This test will help you confirm the result of your repai

r

service including the removal/ reinstallation of brake

pipe, valve line harness and valve.

Test conditions: The ignition key is in the "ON" position

with the four wheels lifted up. The brake pedal is

stepped on, released and stepped on again with the

parking brake released.

Test Procedure: 1. Connect Tech 2 with the vehicle, and selec

t

"Actuator Test" menus.

2. Select a "Front Right Release Valve Test" menu from the "Actuator Test" menus.

3. Step on the brake pedal.

4. Make sure that the front right release solenoid valve "ON" aimed at by Tech 2 and the wheel released

position are the same.

If different, check brake pipe, valve line harness wiring

and hydraulic unit. Repair is needed if abnormality is

found.

Rear Hold Valve Test

Purpose: The purpose of this test is to detect brake pipe

and valve line harness wire for incorrect connections

and valve problem.

This test will help you confirm the result of your repai

r

service including the removal/ reinstallation of brake

pipe, valve line harness and valve.

Test conditions: The ignition key is in the "ON" position

with the four wheels lifted up. The brake pedal is

stepped on, released and stepped on again with the

parking brake released.

Test Procedure: 1. Connect Tech 2 with the vehicle, and selec

t

"Actuator Test" menus.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 624 of 6020

BRAKE CONTROL SYSTEM 5A-31

2. Select a "Rear Hold Valve Test" menu from the

"Actuator Test" menus.

3. Step on the brake pedal.

4. Release the brake pedal.

5. Make sure that the rear hold solenoid valve "ON" aimed at by Tech 2 and the wheel locked position

are the same.

If different, check brake pipe, valve line harness wiring

and hydraulic unit. Repair is needed if abnormality is

found.

Rear Release Valve Test

Purpose: The purpose of this test is to detect brake pipe

and valve line harness wire for incorrect connections and

valve problem.

This test will help you confirm the result of your repai

r

service including the removal/ reinstallation of brake

pipe, valve line harness and valve.

Test conditions: The ignition key is in the "ON" position

with the four wheels lifted up. The brake pedal is stepped

on, released and stepped on again with the parking

brake released.

Test Procedure: 1. Connect Tech 2 with the vehicle, and select "Actuator Test" menus.

2. Select a "Rear Release Valve Test" menu from the "Actuator Test" menus.

3. Step on the brake pedal.

4. Make sure that the rear release solenoid valve "ON" aimed at by Tech 2 and the wheel released position

are the same.

If different, check brake pipe, valve line harness wiring

and hydraulic unit. Repair is needed if abnormality is

found.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 635 of 6020

5A-42 BRAKE CONTROL SYSTEM

Symptom Diagnosis

The symptoms that cannot be indicated by warning

lamp can be divided into the following six categories:

1. ABS works frequently but vehicle does not decelerate.

2. Uneven braking occurs while ABS works.

3. The wheels are locked.

4. Brake pedal feel is abnormal.

5. Braking sound (from EHCU) is heard while not braking.

6. No ABS warning lamp

These are all attributable to problems which cannot be

detected by EHCU self-diagnosis. Use the customer

complaint and a test to determine which symptom is

present.

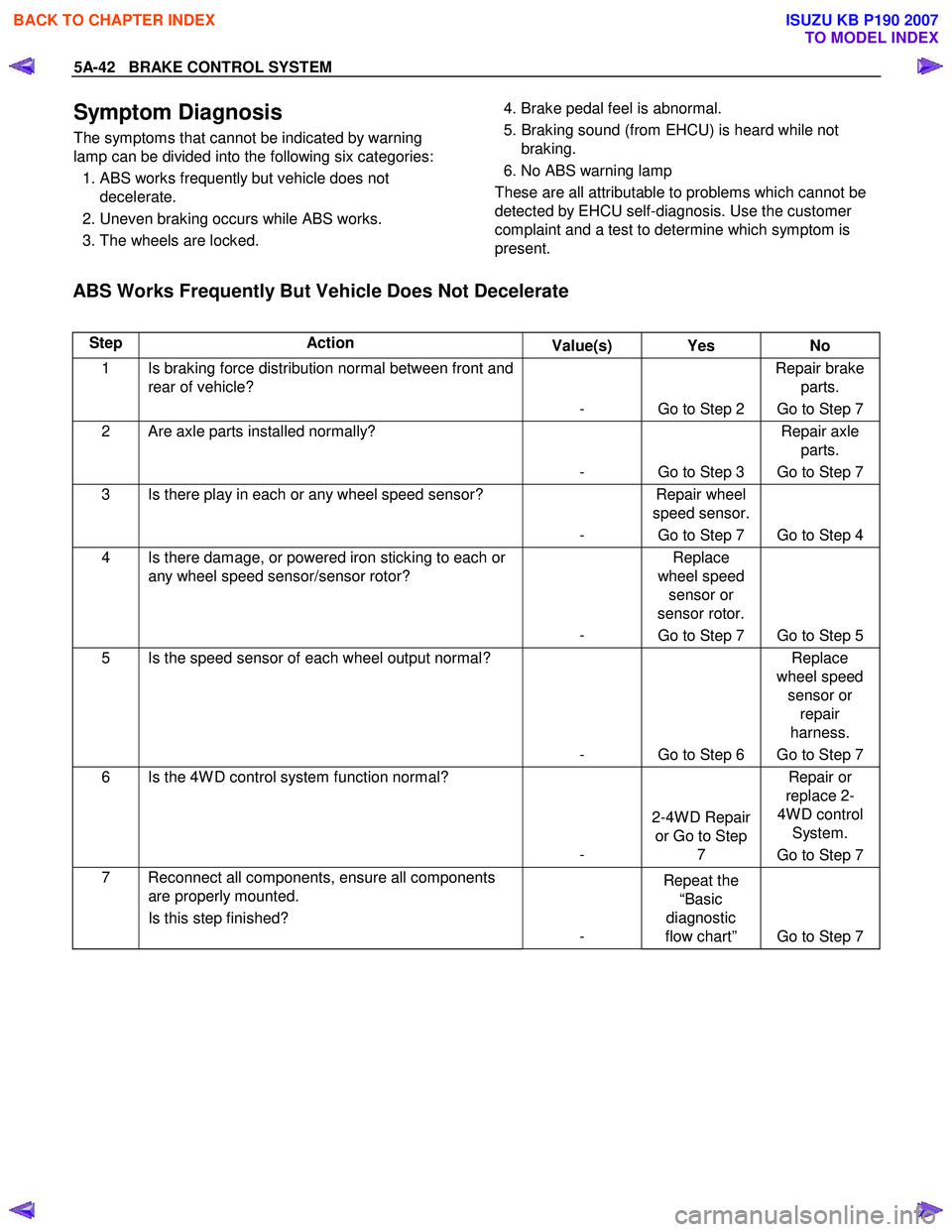

ABS Works Frequently But Vehicle Does Not Decelerate

Step Action Value(s) Yes No

1 Is braking force distribution normal between front and

rear of vehicle?

- Go to Step 2 Repair brake

parts.

Go to Step 7

2 Are axle parts installed normally?

- Go to Step 3 Repair axle

parts.

Go to Step 7

3 Is there play in each or any wheel speed sensor?

- Repair wheel

speed sensor.

Go to Step 7 Go to Step 4

4 Is there damage, or powered iron sticking to each or any wheel speed sensor/sensor rotor?

- Replace

wheel speed sensor or

sensor rotor.

Go to Step 7 Go to Step 5

5 Is the speed sensor of each wheel output normal?

- Go to Step 6 Replace

wheel speed sensor or repair

harness.

Go to Step 7

6 Is the 4W D control system function normal?

- 2-4W D Repair

or Go to Step 7 Repair or

replace 2-

4W D control System.

Go to Step 7

7 Reconnect all components, ensure all components are properly mounted.

Is this step finished? - Repeat the

“Basic

diagnostic

flow chart” Go to Step 7

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 636 of 6020

BRAKE CONTROL SYSTEM 5A-43

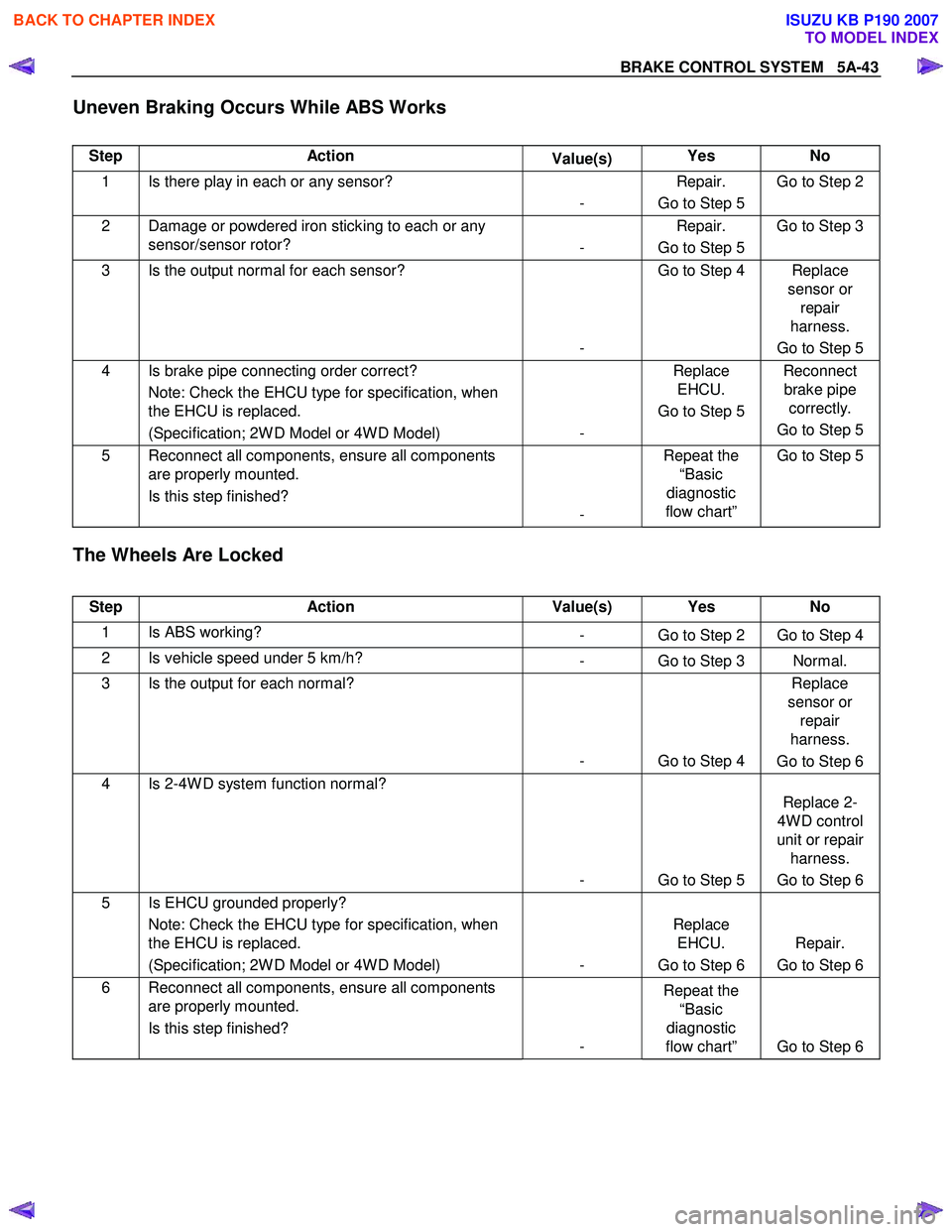

Uneven Braking Occurs While ABS Works

Step Action Value(s) Yes No

1 Is there play in each or any sensor?

- Repair.

Go to Step 5 Go to Step 2

2 Damage or powdered iron sticking to each or any

sensor/sensor rotor? - Repair.

Go to Step 5 Go to Step 3

3 Is the output normal for each sensor?

- Go to Step 4 Replace

sensor or repair

harness.

Go to Step 5

4 Is brake pipe connecting order correct? Note: Check the EHCU type for specification, when

the EHCU is replaced.

(Specification; 2W D Model or 4W D Model) - Replace

EHCU.

Go to Step 5 Reconnect

brake pipe correctly.

Go to Step 5

5 Reconnect all components, ensure all components are properly mounted.

Is this step finished? - Repeat the

“Basic

diagnostic

flow chart” Go to Step 5

The Wheels Are Locked

Step Action Value(s) Yes No

1 Is ABS working?

- Go to Step 2 Go to Step 4

2 Is vehicle speed under 5 km/h? - Go to Step 3 Normal.

3 Is the output for each normal?

- Go to Step 4 Replace

sensor or repair

harness.

Go to Step 6

4 Is 2-4W D system function normal?

- Go to Step 5 Replace 2-

4W D control

unit or repair harness.

Go to Step 6

5 Is EHCU grounded properly? Note: Check the EHCU type for specification, when

the EHCU is replaced.

(Specification; 2W D Model or 4W D Model) - Replace

EHCU.

Go to Step 6 Repair.

Go to Step 6

6 Reconnect all components, ensure all components are properly mounted.

Is this step finished? - Repeat the

“Basic

diagnostic

flow chart” Go to Step 6

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 680 of 6020

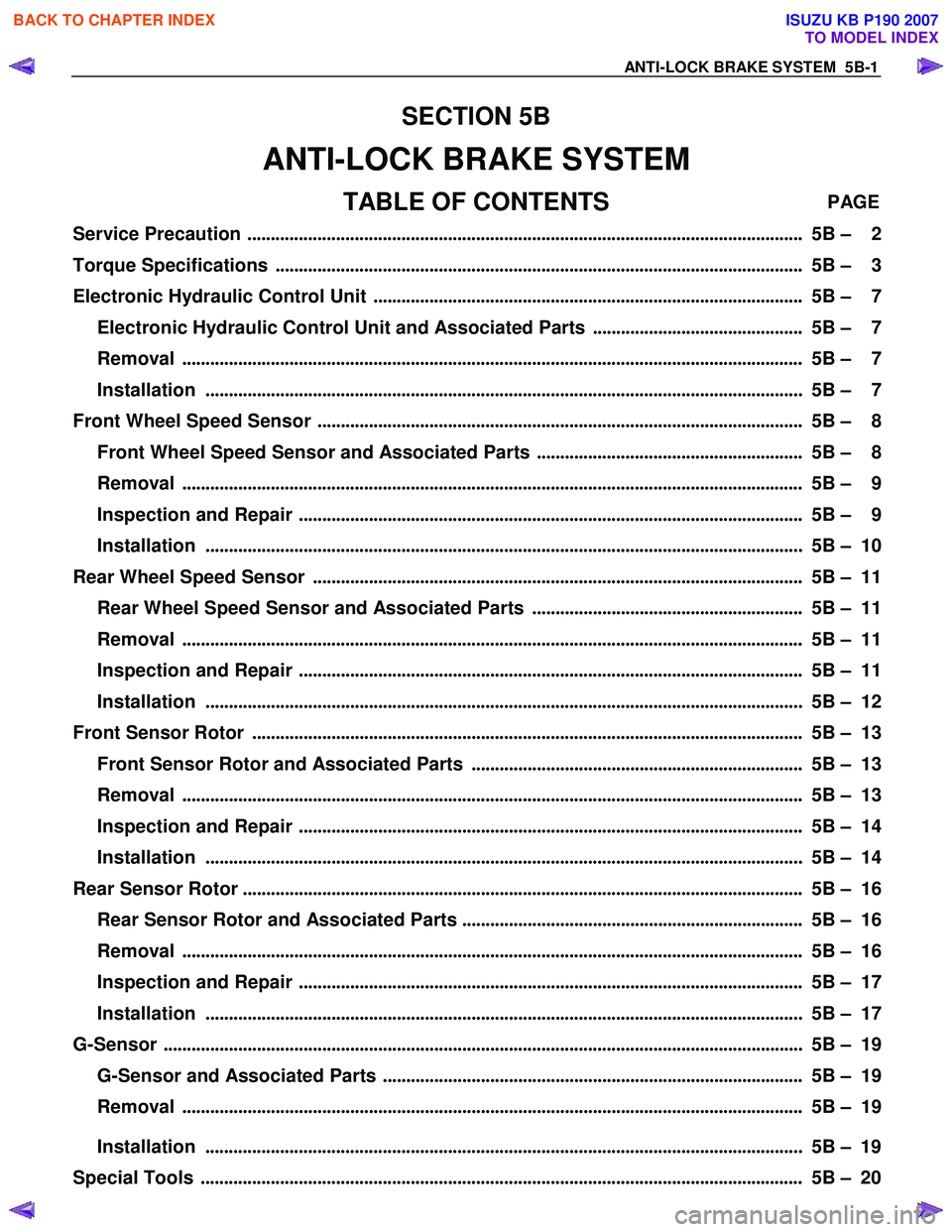

ANTI-LOCK BRAKE SYSTEM 5B-1

SECTION 5B

ANTI-LOCK BRAKE SYSTEM

TABLE OF CONTENTS PAGE

Ser vice Precau tion ....................................................................................................................... 5B – 2

Torque Specifications ................................................................................................................. 5B – 3

Electronic Hydraulic Control Unit ............................................................................................ 5B – 7

Electronic Hydraulic Control Unit and Associated Parts ............................................. 5B – 7

Removal ..................................................................................................................................... 5B – 7

Installation ............................................................................................................................... . 5B – 7

Front Wheel Speed Sensor ........................................................................................................ 5B – 8

Front Wheel Speed Sensor and Associated Parts ......................................................... 5B – 8

Removal ..................................................................................................................................... 5B – 9

Inspection and Repair ............................................................................................................ 5B – 9

Installation ............................................................................................................................... . 5B – 10

Rear Wheel Speed Sensor ......................................................................................................... 5B – 11

Rear Wheel Speed Sensor and Associated Parts .......................................................... 5B – 11

Removal ..................................................................................................................................... 5B – 11

Inspection and Repair ............................................................................................................ 5B – 11

Installation ............................................................................................................................... . 5B – 12

Front Sensor Rotor ...................................................................................................................... 5B – 13

Front Sensor Rotor and Associated Parts ....................................................................... 5B – 13

Removal ..................................................................................................................................... 5B – 13

Inspection and Repair ............................................................................................................ 5B – 14

Installation ............................................................................................................................... . 5B – 14

Rear Sensor Rotor ........................................................................................................................ 5B – 16

Rear Sensor Rotor and Associated Parts ......................................................................... 5B – 16

Removal ..................................................................................................................................... 5B – 16

Inspection and Repair ............................................................................................................ 5B – 17

Installation ............................................................................................................................... . 5B – 17

G-Sensor .............................................................................................................................. ........... 5B – 19

G-Sensor and Associated Parts .......................................................................................... 5B – 19

Removal ..................................................................................................................................... 5B – 19

Installation ............................................................................................................................... . 5B – 19

Special Tools ................................................................................................................................. 5B – 20

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 681 of 6020

5B-2 ANTI-LOCK BRAKE SYSTEM

Service Precaution

WARNING: THIS VEHICLE HAS A SUPPLEMENTAL

RESTRAINT SYSTEM (SRS). REFER TO THE SRS

COMPONENT AND WIRING LOCATION VIEW IN

ORDER TO DETERMINE WHETHER YOU ARE

PERFORMING SERVICE ON OR NEAR THE SRS

COMPONENTS OR THE SRS WIRING. WHEN YOU

ARE PERFORMING SERVICE ON OR NEAR THE

SRS COMPONENTS OR THE SRS WIRING, REFER

TO THE SRS SERVICE INFORMATION. FAILURE TO

FOLLOW WARNINGS COULD RESULT IN POSSIBLE

AIR BAG DEPLOYMENT, PERSONAL INJURY, OR

OTHERWISE UNNECESSARY SRS SYSTEM

REPAIRS.

CAUTION: Always use the correct fastener in the

proper location. When you replace a fastener, use

ONLY the exact part number for that application.

ISUZU/GM will call out those fasteners that require a

replacement after removal. ISUZU/GM will also call

out the fasteners that require thread lockers o

r

thread sealant. UNLESS OTHERWISE SPECIFIED,

do not use supplemental coatings (paints, greases,

or other corrosion inhibitors) on threaded fasteners

or fastener joint interfaces. Generally, such coatings

adversely affect the fastener torque and the joint

clamping force, and may damage the fastener.

When you install fasteners, use the correct

tightening sequence and specifications. Following

these instructions can help you avoid damage to

parts and systems.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 682 of 6020

ANTI-LOCK BRAKE SYSTEM 5B-3

Torque Specifications

Electronic Hydraulic Control Unit N⋅m (kgf ⋅m/lb ⋅ft)

RTW 75BMF000401

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 683 of 6020

5B-4 ANTI-LOCK BRAKE SYSTEM

4×

××

×

2 (Except High Ride Suspension) Front Wheel Speed Sensor N⋅m (kgf ⋅m/lb ⋅ft)

RTW 55ALF000301

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 684 of 6020

ANTI-LOCK BRAKE SYSTEM 5B-5

4×

××

×

2 High Ride Suspension, 4 ×

××

×

4 Front Wheel Speed Sensor N⋅m (kgf ⋅m/lb ⋅ft)

RTW 55ALF000101

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007