lock ISUZU KB P190 2007 Workshop Repair Manual

[x] Cancel search | Manufacturer: ISUZU, Model Year: 2007, Model line: KB P190, Model: ISUZU KB P190 2007Pages: 6020, PDF Size: 70.23 MB

Page 732 of 6020

BRAKES 5C-33

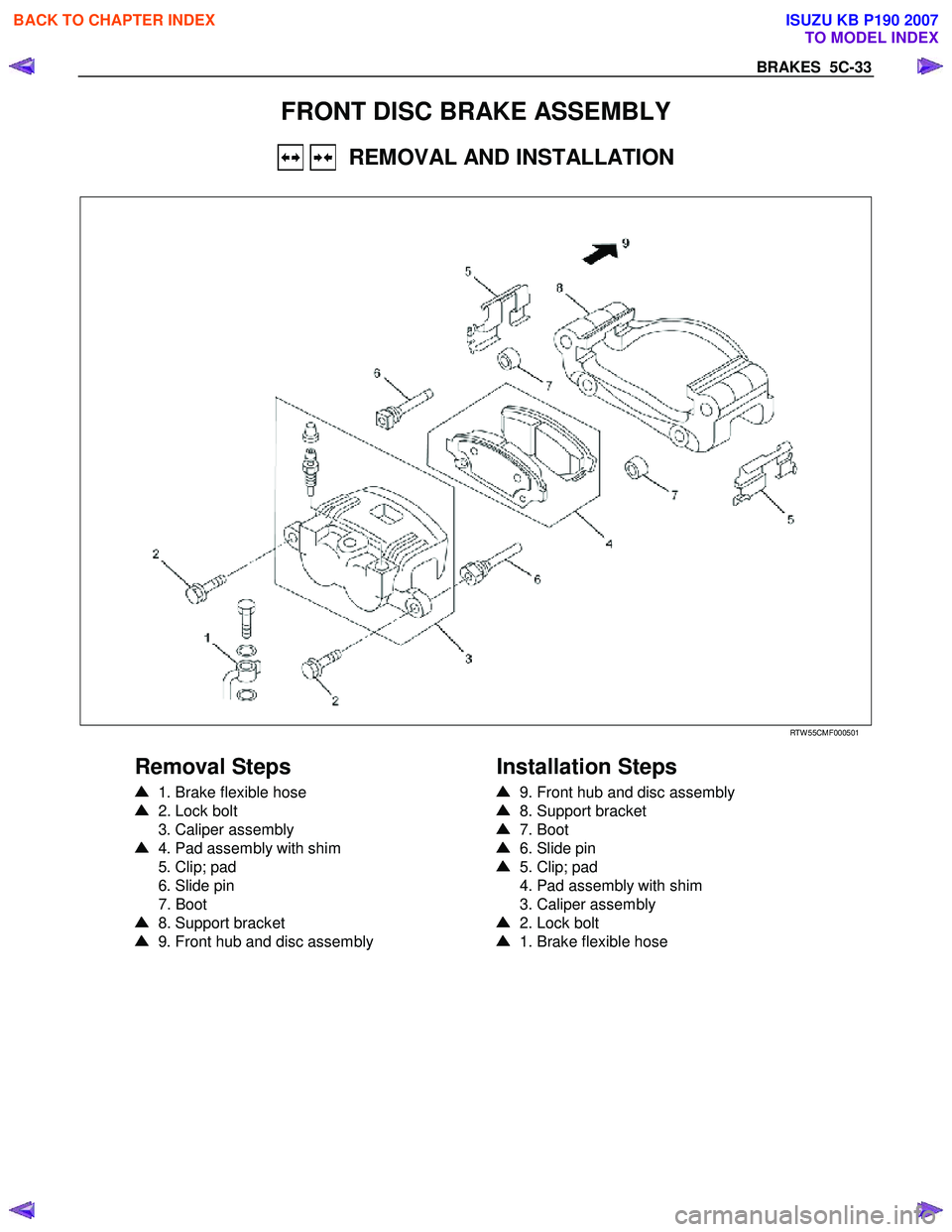

FRONT DISC BRAKE ASSEMBLY

REMOVAL AND INSTALLATION

RTW 55CMF000501

Removal Steps

1. Brake flexible hose

2. Lock bolt

3. Caliper assembly

4. Pad assembly with shim

5. Clip; pad

6. Slide pin

7. Boot

8. Support bracket

9. Front hub and disc assembly

Installation Steps

9. Front hub and disc assembly

8. Support bracket

7. Boot

6. Slide pin

5. Clip; pad

4. Pad assembly with shim

3. Caliper assembly

2. Lock bolt

1. Brake flexible hose

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 733 of 6020

5C-34 BRAKES

RUW 55CSH000101

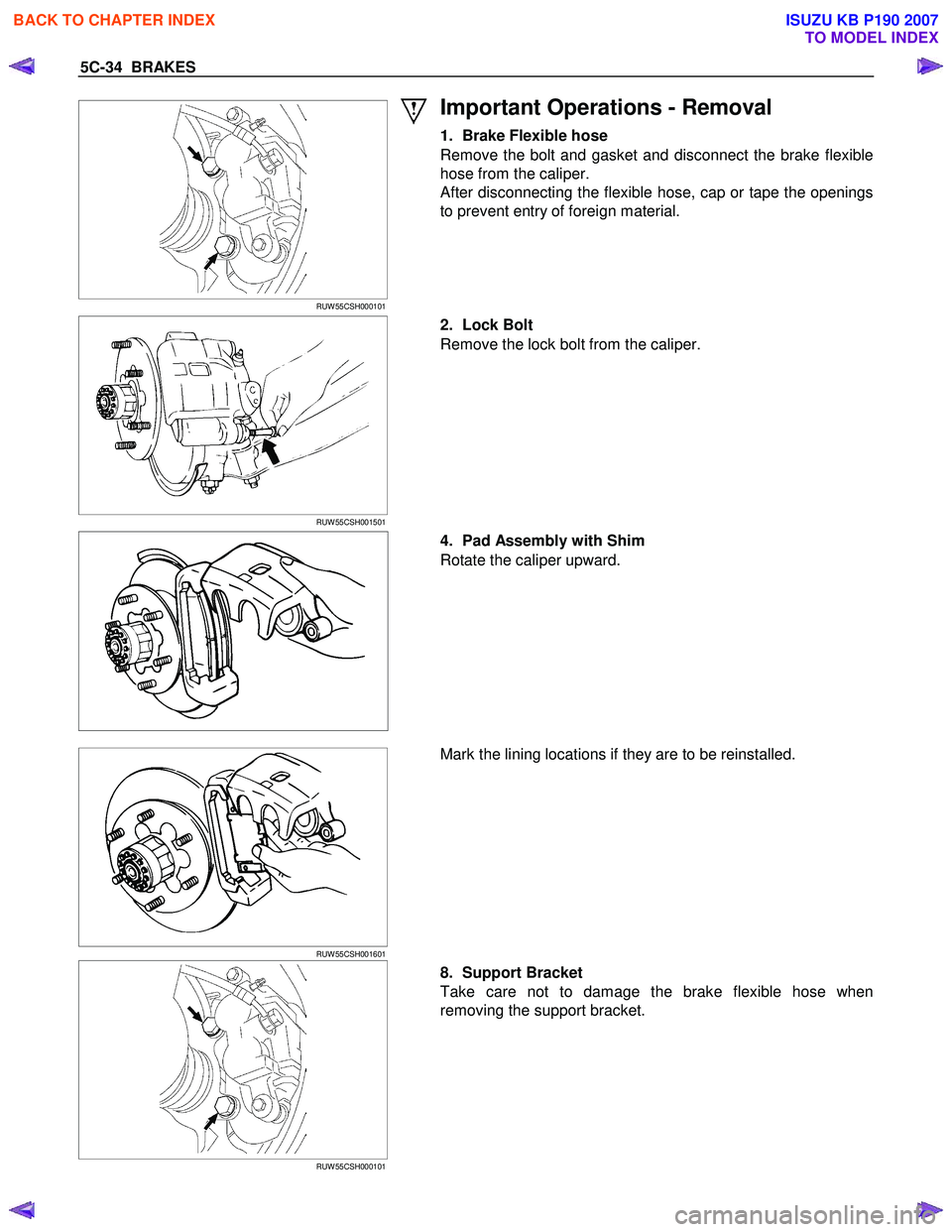

Important Operations - Removal

1. Brake Flexible hose

Remove the bolt and gasket and disconnect the brake flexible

hose from the caliper.

After disconnecting the flexible hose, cap or tape the openings

to prevent entry of foreign material.

RUW 55CSH001501

2. Lock Bolt

Remove the lock bolt from the caliper.

4. Pad Assembly with Shim

Rotate the caliper upward.

RUW 55CSH001601

Mark the lining locations if they are to be reinstalled.

RUW 55CSH000101

8. Support Bracket

Take care not to damage the brake flexible hose when

removing the support bracket.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 734 of 6020

BRAKES 5C-35

9. Front Hub and Disc Assembly

For the removal procedure, refer to Section 4C “FRONT

W HEEL DRIVE”.

Important Operations - Installation

9. Front Hub and Disc Assembly

For the installation procedure, refer to the front hub and disc

reassembly procedure in Section 4C “FRONT W HEEL

DRIVE”.

RUW 55CSH000101

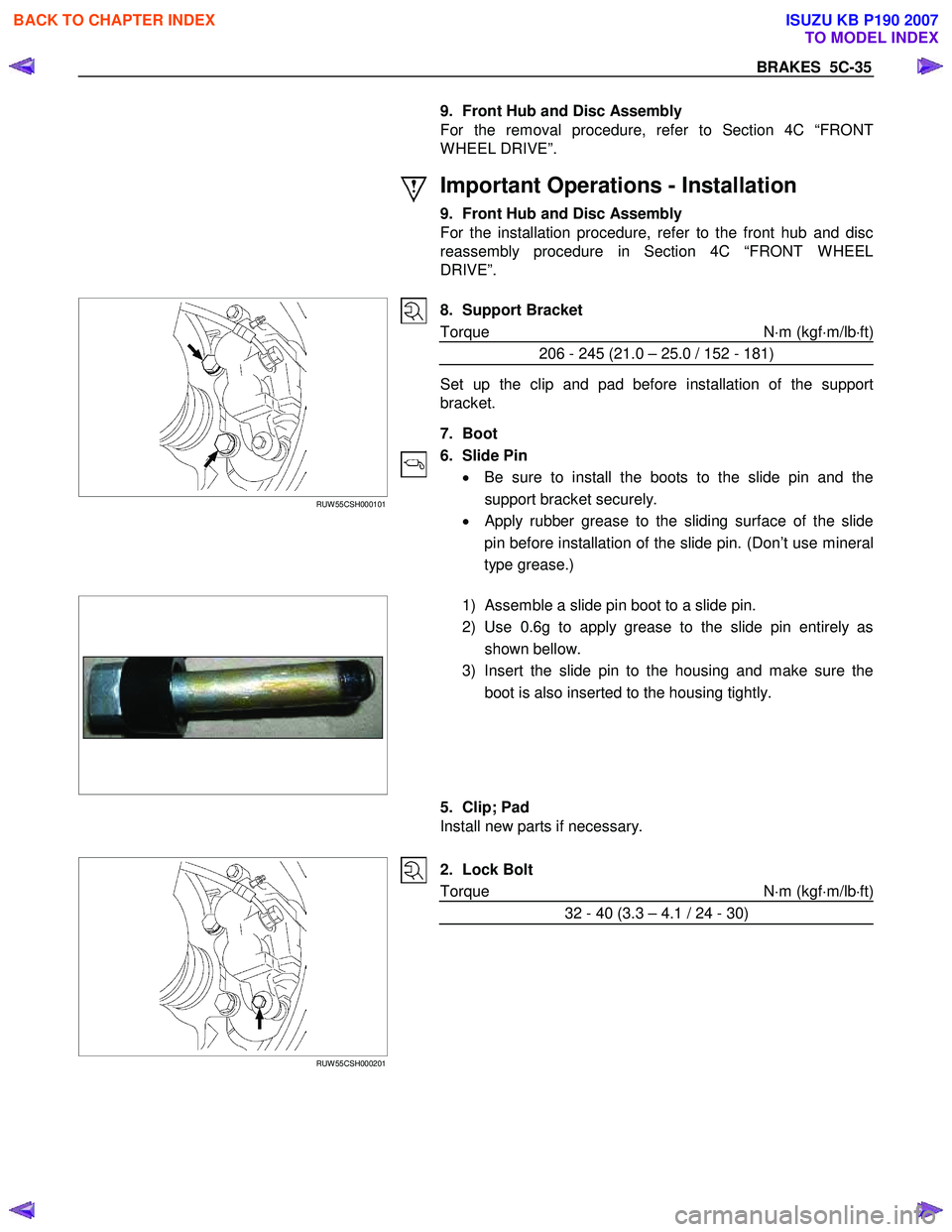

8. Support Bracket

Torque N ⋅m (kgf ⋅m/lb ⋅ft)

206 - 245 (21.0 – 25.0 / 152 - 181)

Set up the clip and pad before installation of the support

bracket.

7. Boot

6. Slide Pin • Be sure to install the boots to the slide pin and the

support bracket securely.

•

Apply rubber grease to the sliding surface of the slide

pin before installation of the slide pin. (Don’t use mineral

type grease.)

1) Assemble a slide pin boot to a slide pin.

2) Use 0.6g to apply grease to the slide pin entirely as shown bellow.

3) Insert the slide pin to the housing and make sure the boot is also inserted to the housing tightly.

5. Clip; Pad

Install new parts if necessary.

RUW 55CSH000201

2. Lock Bolt

Torque N ⋅m (kgf ⋅m/lb ⋅ft)

32 - 40 (3.3 – 4.1 / 24 - 30)

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 736 of 6020

BRAKES 5C-37

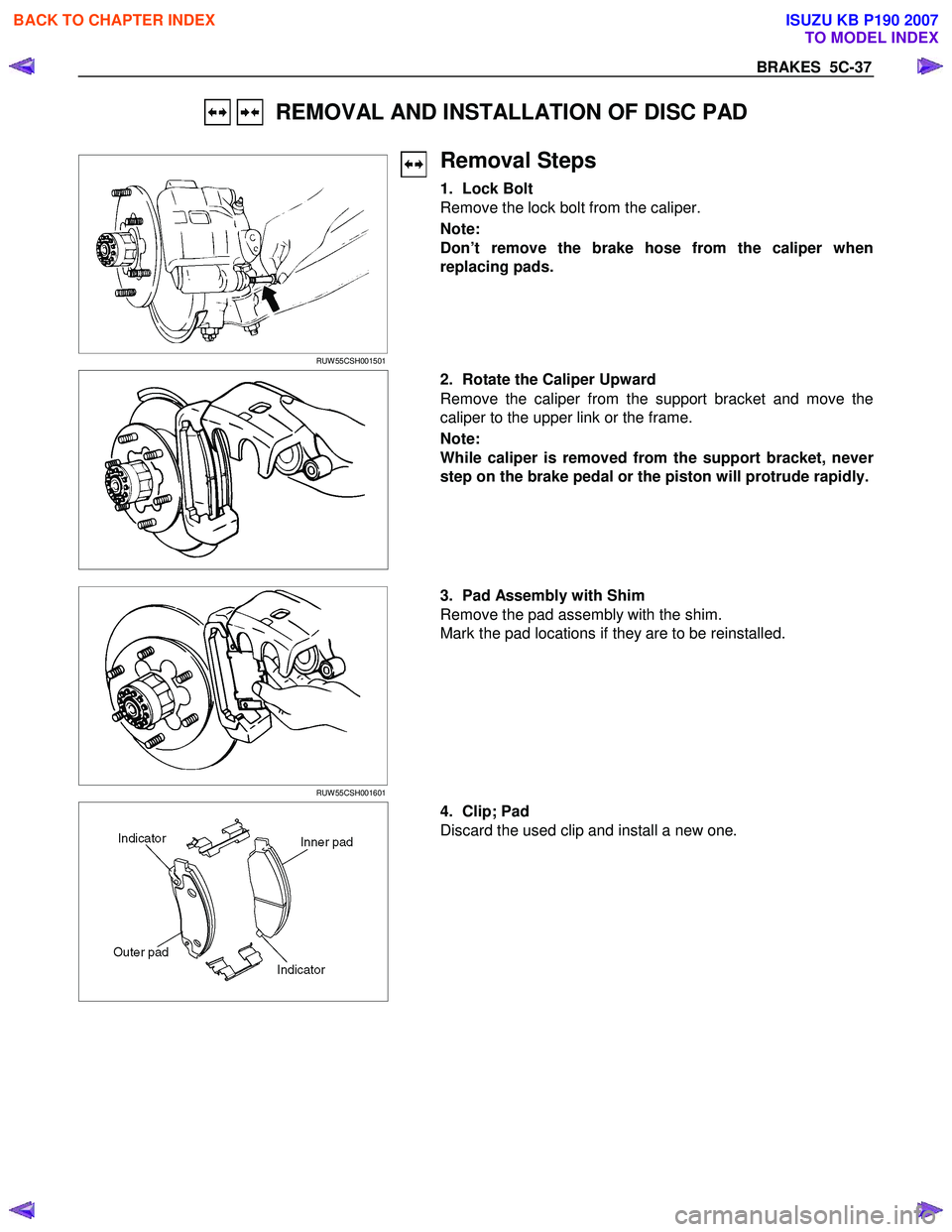

REMOVAL AND INSTALLATION OF DISC PAD

RUW 55CSH001501

Removal Steps

1. Lock Bolt

Remove the lock bolt from the caliper.

Note:

Don’t remove the brake hose from the caliper when

replacing pads.

2. Rotate the Caliper Upward

Remove the caliper from the support bracket and move the

caliper to the upper link or the frame.

Note:

While caliper is removed from the support bracket, neve

r

step on the brake pedal or the piston will protrude rapidly.

RUW 55CSH001601

3. Pad Assembly with Shim

Remove the pad assembly with the shim.

Mark the pad locations if they are to be reinstalled.

4. Clip; Pad

Discard the used clip and install a new one.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 737 of 6020

5C-38 BRAKES

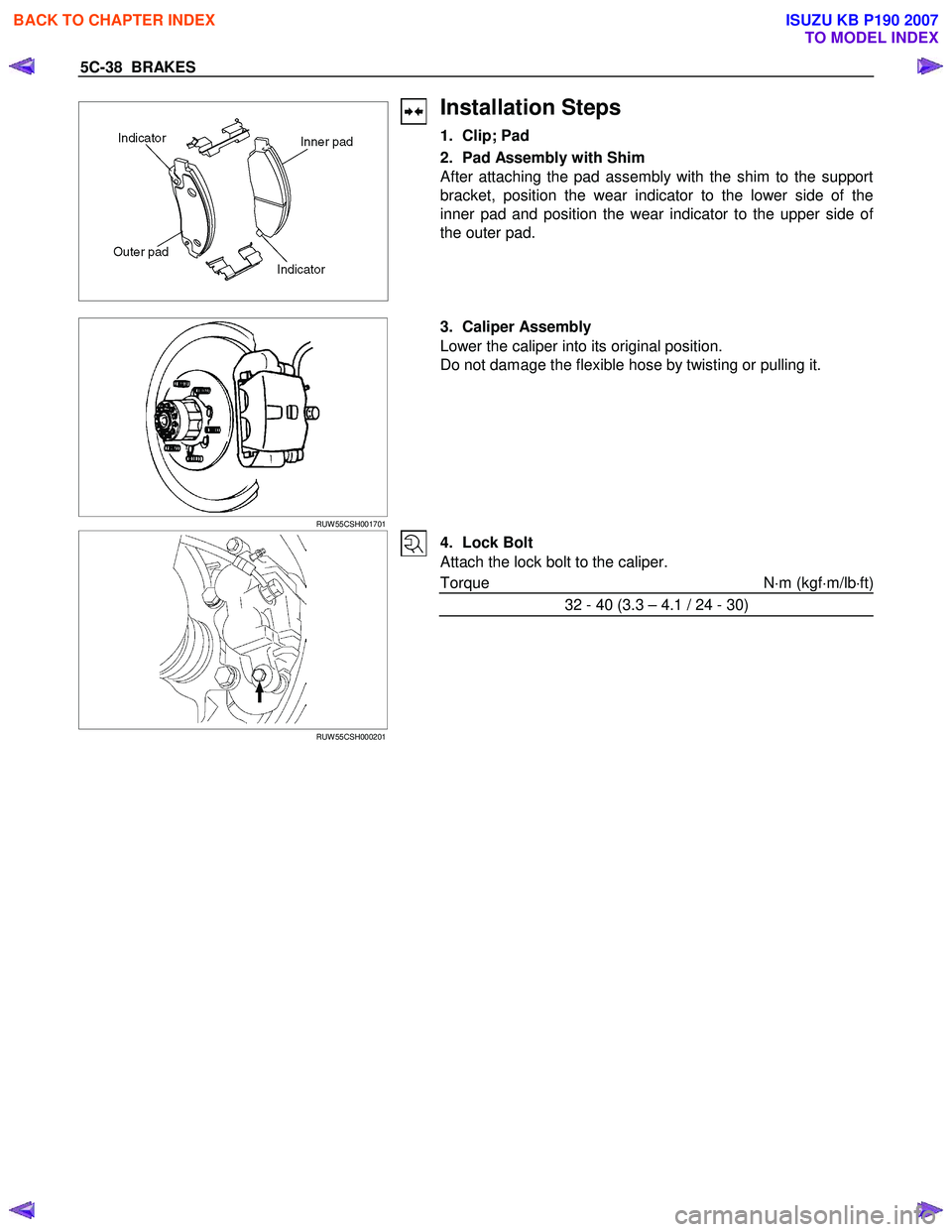

Installation Steps

1. Clip; Pad

2. Pad Assembly with Shim

After attaching the pad assembly with the shim to the support

bracket, position the wear indicator to the lower side of the

inner pad and position the wear indicator to the upper side o

f

the outer pad.

RUW 55CSH001701

3. Caliper Assembly

Lower the caliper into its original position.

Do not damage the flexible hose by twisting or pulling it.

RUW 55CSH000201

4. Lock Bolt

Attach the lock bolt to the caliper.

Torque N ⋅m (kgf ⋅m/lb ⋅ft)

32 - 40 (3.3 – 4.1 / 24 - 30)

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 738 of 6020

BRAKES 5C-39

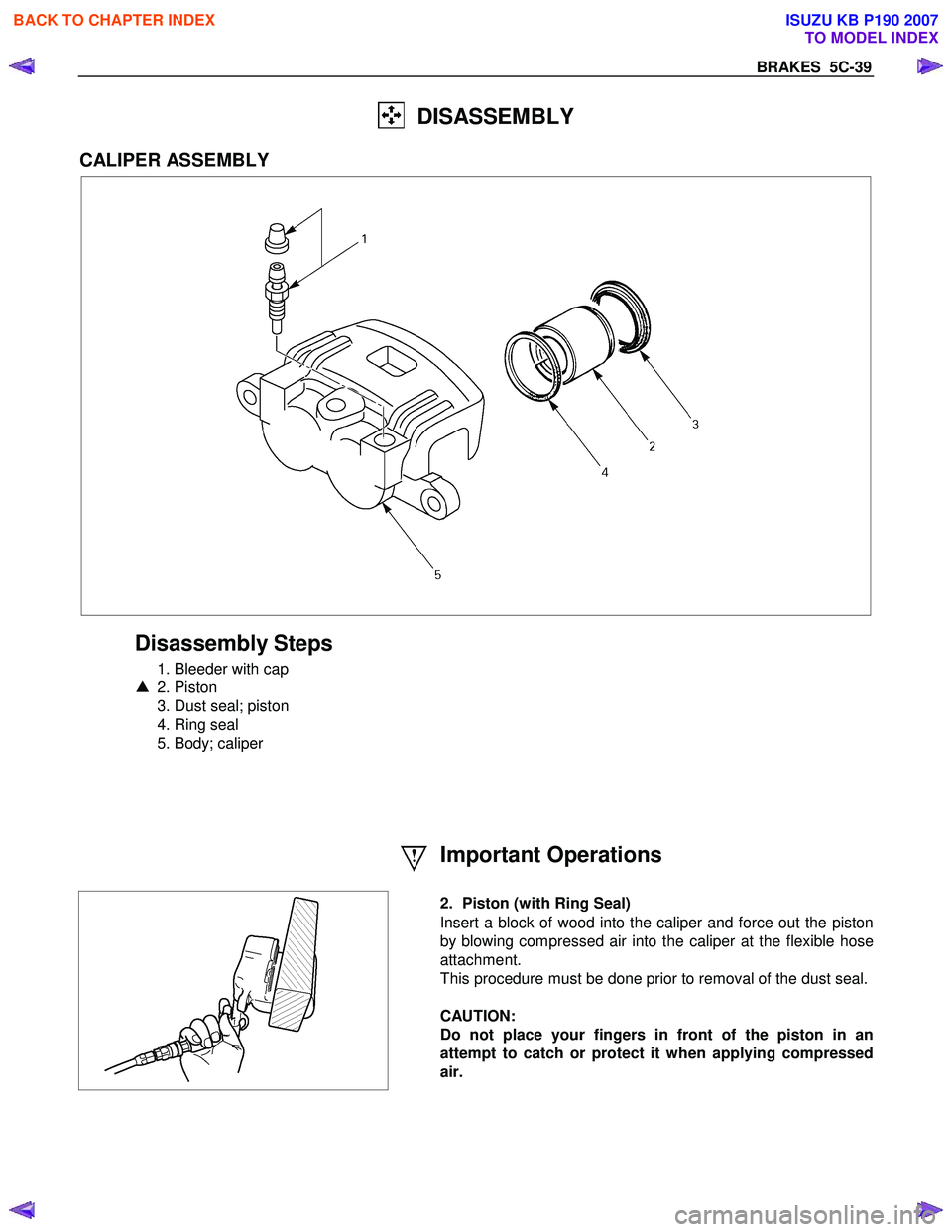

DISASSEMBLY

CALIPER ASSEMBLY

Disassembly Steps

1. Bleeder with cap

▲ 2. Piston

3. Dust seal; piston

4. Ring seal

5. Body; caliper

Important Operations

2. Piston (with Ring Seal)

Insert a block of wood into the caliper and force out the piston

by blowing compressed air into the caliper at the flexible hose

attachment.

This procedure must be done prior to removal of the dust seal.

CAUTION:

Do not place your fingers in front of the piston in an

attempt to catch or protect it when applying compressed

air.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 739 of 6020

5C-40 BRAKES

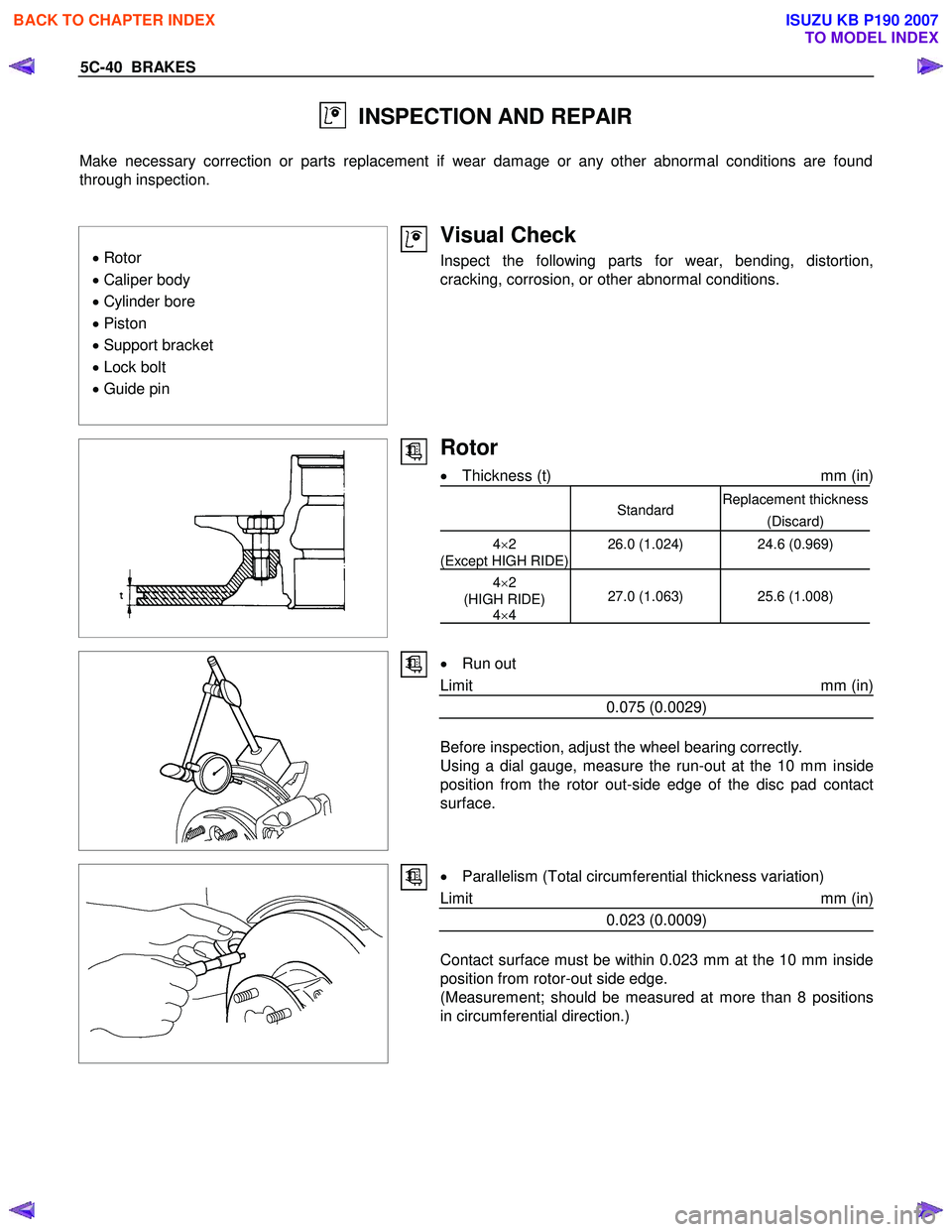

INSPECTION AND REPAIR

Make necessary correction or parts replacement if wear damage or any other abnormal conditions are found

through inspection.

• Rotor

• Caliper body

• Cylinder bore

• Piston

• Support bracket

• Lock bolt

• Guide pin

Visual Check

Inspect the following parts for wear, bending, distortion,

cracking, corrosion, or other abnormal conditions.

Rotor

• Thickness (t) mm (in)

StandardReplacement thickness

(Discard)

4×2

(Except HIGH RIDE) 26.0 (1.024)

24.6 (0.969)

4×2

(HIGH RIDE) 4×4 27.0 (1.063) 25.6 (1.008)

•

Run out

Limit mm (in)

0.075 (0.0029)

Before inspection, adjust the wheel bearing correctly.

Using a dial gauge, measure the run-out at the 10 mm inside

position from the rotor out-side edge of the disc pad contact

surface.

•

Parallelism (Total circumferential thickness variation)

Limit mm (in)

0.023 (0.0009)

Contact surface must be within 0.023 mm at the 10 mm inside

position from rotor-out side edge.

(Measurement; should be measured at more than 8 positions

in circumferential direction.)

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 742 of 6020

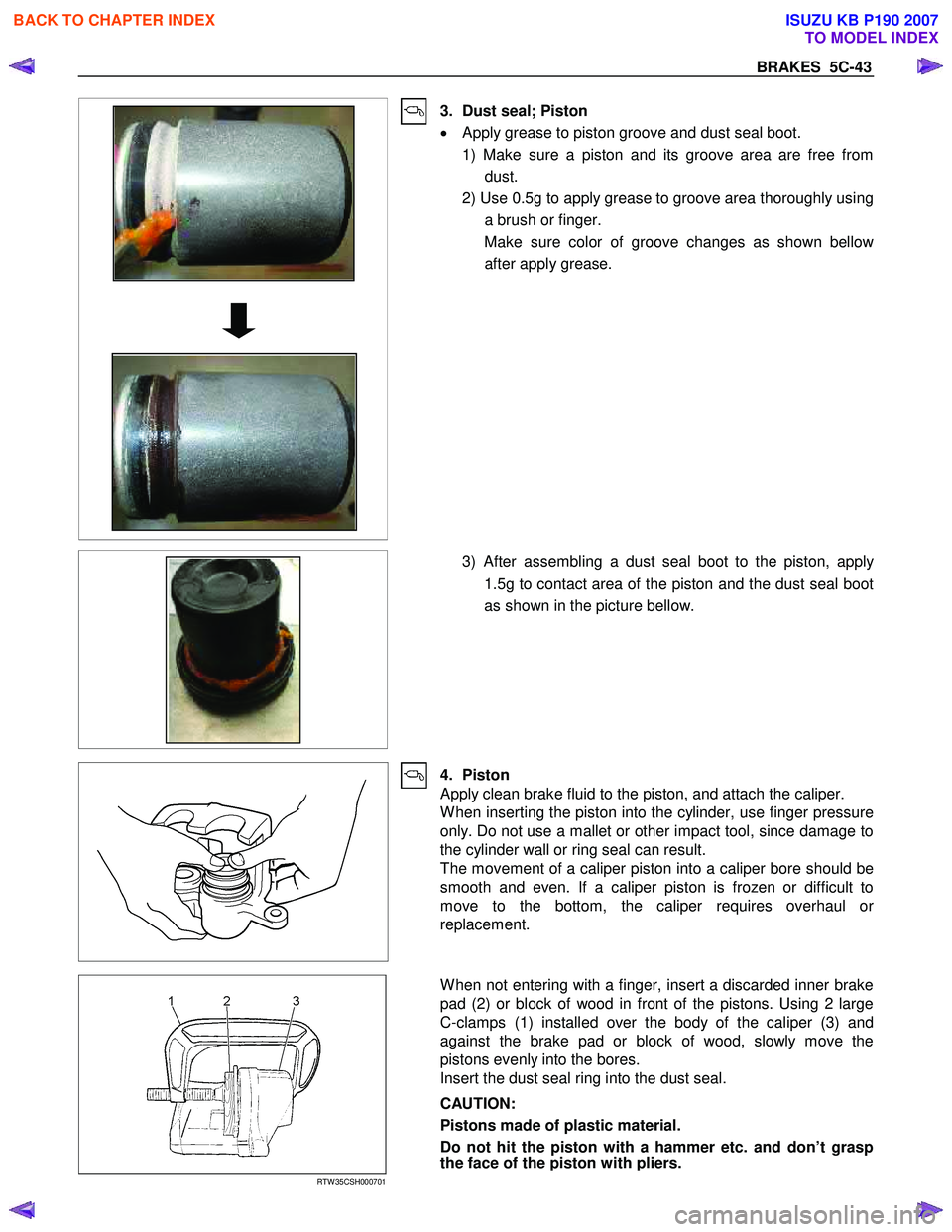

BRAKES 5C-43

3. Dust seal; Piston

• Apply grease to piston groove and dust seal boot.

1) Make sure a piston and its groove area are free from dust.

2) Use 0.5g to apply grease to groove area thoroughly using a brush or finger.

Make sure color of groove changes as shown bello

w

after apply grease.

3) After assembling a dust seal boot to the piston, apply

1.5g to contact area of the piston and the dust seal boot

as shown in the picture bellow.

4. Piston

Apply clean brake fluid to the piston, and attach the caliper.

W hen inserting the piston into the cylinder, use finger pressure

only. Do not use a mallet or other impact tool, since damage to

the cylinder wall or ring seal can result.

The movement of a caliper piston into a caliper bore should be

smooth and even. If a caliper piston is frozen or difficult to

move to the bottom, the caliper requires overhaul o

r

replacement.

RTW 35CSH000701

W hen not entering with a finger, insert a discarded inner brake

pad (2) or block of wood in front of the pistons. Using 2 large

C-clamps (1) installed over the body of the caliper (3) and

against the brake pad or block of wood, slowly move the

pistons evenly into the bores.

Insert the dust seal ring into the dust seal.

CAUTION:

Pistons made of plastic material.

Do not hit the piston with a hammer etc. and don’t grasp

the face of the piston with pliers.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 760 of 6020

BRAKES 5C-61

RTW 75CSH002701

Important Operation-Removal

1. Brake pipe

W hen hurdling, be careful not to spill brake fluid over the

painted surfaces, as damage to the paint finish will result.

2. Master Cylinder Fixing Nut

3. Bracket

4. Master Cylinder Assembly

NOTE:

W hen removing the master cylinder from the vacuum booster,

be sure to get rid of the internal negative pressure of the

vacuum booster (by, for instance, disconnecting the vacuum

hose) in advance.

If any negative pressure remains in the vacuum booster, the

piston may possibly come out when the master cylinder is

being removed, letting the brake fluid run out.

W hile removing the master cylinder, do not hold the piston as it

can be easily pulled out.

Inspection and Repair

Vacuum Hose (The built in check valve)

360R300002

1) Inspect the check valve, which is installed inside the

vacuum hose.

2) Blow air into the hose from the booster side as shown in the illustration. The air should pass freely through the

hose.

3) Blow air into the hose from the engine side. The check valve should close to block the passage of air.

The vacuum hose and built-in check valve must be

replaced as a set if either is found to be defective.

Important Operation-Installation

10. Vacuum Booster Assembly

Note:

•

Adjustment of push rod of vacuum booster is not carried

out. W hen vacuum booster is damaged it exchanges for a

new article. (Push rod is adjusted)

• Measurement of primary piston position by the side o

f

master cylinder is unnecessary.

9. Spacer

8. Gasket

7. Vacuum Booster Fixing Nut

6. Snap Pin

Install the vacuum booster assembly to the dash panel and

pedal mounting bracket.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 771 of 6020

PARKING BRAKE SYSTEM 5D-1

Service Precaution

Service Precaution

WARNING: THIS VEHICLE HAS A SUPPLEMENTAL

RESTRAINT SYSTEM (SRS). REFER TO THE SRS

COMPONENT AND WIRING LOCATION VIEW IN

ORDER TO DETERMINE WHETHER YOU ARE

PERFORMING SERVICE ON OR NEAR THE SRS

COMPONENTS OR THE SRS WIRING. WHEN YOU

ARE PERFORMING SERVICE ON OR NEAR THE

SRS COMPONENTS OR THE SRS WIRING, REFER

TO THE SRS SERVICE INFORMATION. FAILURE TO

FOLLOW WARNINGS COULD RESULT IN

POSSIBLE AIR BAG DEPLOYMENT, PERSONAL

INJURY, OR OTHERWISE UNNECESSARY SRS

SYSTEM REPAIRS.

CAUTION: Always use the correct fastener in the

proper location. When you replace a fastener, use

ONLY the exact part number for that application.

ISUZU/GM will call out those fasteners that require

a replacement after removal. ISUZU/GM will also

call out the fasteners that require thread lockers o

r

thread sealant. UNLESS OTHERWISE SPECIFIED,

do not use supplemental coatings (paints, greases,

or other corrosion inhibitors) on threaded fasteners

or fastener joint interfaces. Generally, such

coatings adversely affect the fastener torque and

the joint clamping force, and may damage the

fastener. When you install fasteners, use the

correct tightening sequence and specifications.

Following these instructions can help you avoid

damage to parts and systems.

General Description

Pulling up the parking brake lever by hand will set the

parking brake. By means of a ratchet type lock, the

lever can be held in that position until it is released. The

position of the lever is transmitted through cable/leve

r

systems to the rear wheels. These parts are designed

to obtain sufficient braking force even when parking on

slopes. W hen the parking brake is set, or when the

ignition SW is in the “ON” position, the brake warning

light illuminates. The rear wheel parking brake is a

leading-trailing brake (mechanical inside expansion

type) built in the rear drum brake. Parking brake

adjustment is made through the adjusting hole (bored

through back plate). Parking brake lever stroke should

be adjusted to 8 −14 notches with 294N (30 kg / 66 lb)

(bench seat) or 6 −9 notches with 294N (30 kg / 66 lb)

(bucket seat). Refer to “Parking Brake Adjustment” in

this section.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007