charging ISUZU KB P190 2007 Workshop Repair Manual

[x] Cancel search | Manufacturer: ISUZU, Model Year: 2007, Model line: KB P190, Model: ISUZU KB P190 2007Pages: 6020, PDF Size: 70.23 MB

Page 3606 of 6020

Charging System – V6 Page 6D1-1-19

6 Specifications

Ground Polarity...........................................................................................................Negative

Nominal Voltage ............................................................................................................... 1 2 V

Nominal Output............................................................................................................... 12 0 A

Stator Phases .................................................................................................................. ....... 3

Stator W inding Connections ............................................................................................ Delta

Voltage Regulator Setting................................................................................... 14.2 – 14.8 V

Rotor W inding Resistance @ 20 °C ................................................................................. 2.1 V

Slip-ring Outer Diameter ............................................................................................. 22.7 mm

Slip-ring Service Limit ................................................................................................. 22.1 mm

Stator W inding Resistance @ 20 °C ............................................................................ 0.098 Ω

Brush Length New ...................................................................................................... 18.5 mm

Minimum Brush Length................................................................................................. 5.0 mm

Direction of Rotation (viewed from pulley) ................................................................Clockwise

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3607 of 6020

Charging System – V6 Page 6D1-1-20

7 Torque Wrench Specifications

..................................................................................................................... Nm

Generator Mounting Bolts (1, 2, 4) ..............................................................58.0

Generator Mounting Bracket Bolts (1, 3, 4) ......................................40.0 – 60.0

Generator Mounting Bracket Bolts (2) ...........................................................0.0

Battery Harness to G8 – X1 pin A Nut................................................5.0 – 12.0

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3608 of 6020

Charging System – V6 Page 6D1-1-21

8 Special Tools

TOOL NUMBER ILLUSTRATION

DESCRIPTION TOOL

CLASSIFICATION

J35616-A

(KM609)

CONNECTOR TEST ADAPTOR KIT

Used when carrying out electrical

diagnostic circuit checks.

Previously released. Desirable

3588

(J39200)

DIGITAL MULTIMETER

Must have at least 10 M Ω input

impedance and be capable of reading

frequencies.

Previously released. Available

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3646 of 6020

Battery Page 6D1-3–6

2 Safety Precautions

• Battery fluid contains sulphuric acid,

which can cause serious injury. Do not

allow liquid from the battery to contact

eyes or skin. If contact occurs, flush the

area immediately with running water and

contact a physician.

• Lead acid batteries produce explosive

gases. Keep sparks, flames and lighted

cigarettes away from the battery,

especially when the battery is being

charged. Failure to follow this warning

could result in a battery explosion.

• Metal objects that touch a battery terminal

can produce sparks that can cause

serious burns. When working near a

battery, take extra care with metal objects

including tools and items of jewellery,

especially rings and metal watchbands.

Do not allow liquid from the battery to contact

clothing or painted surfaces. If contact occurs,

flush the area immediately with running water.

W hen working with or near the battery, always:

• W ear safety glasses and work gloves.

• Remove items of jewellery such as rings and metal watchbands.

• Ensure the ignition is switched off when connecting or disconnecting battery cables, battery charging equipment or

battery jumper cables. Failing to do so can damage the vehicle electronic components.

• Disconnect the negative battery cable before disconnecting the positive cable from the battery. Inversely, connect

the positive battery cable to the battery before connecting the negative cable. This reduces the possibility of

shorting the battery to ground while working near the positive connections.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3648 of 6020

Battery Page 6D1-3–8

Step Action Yes No

5

Perform the hydrometer test, refer to 3.3 Hydrometer Test.

Is the battery fully charged? Go to Step 6 Fully charge the

battery, refer to 4.2 Battery

Charge

6 Load test the battery, refer to 3.4 Load Test.

Does the battery pass the load test? Battery Serviceable.

Refer to:

6D1–1 Charging System – V6. Replace the battery,

refer to 4.1

Battery

When all diagnosis and repairs are completed, check the system for correct operation.

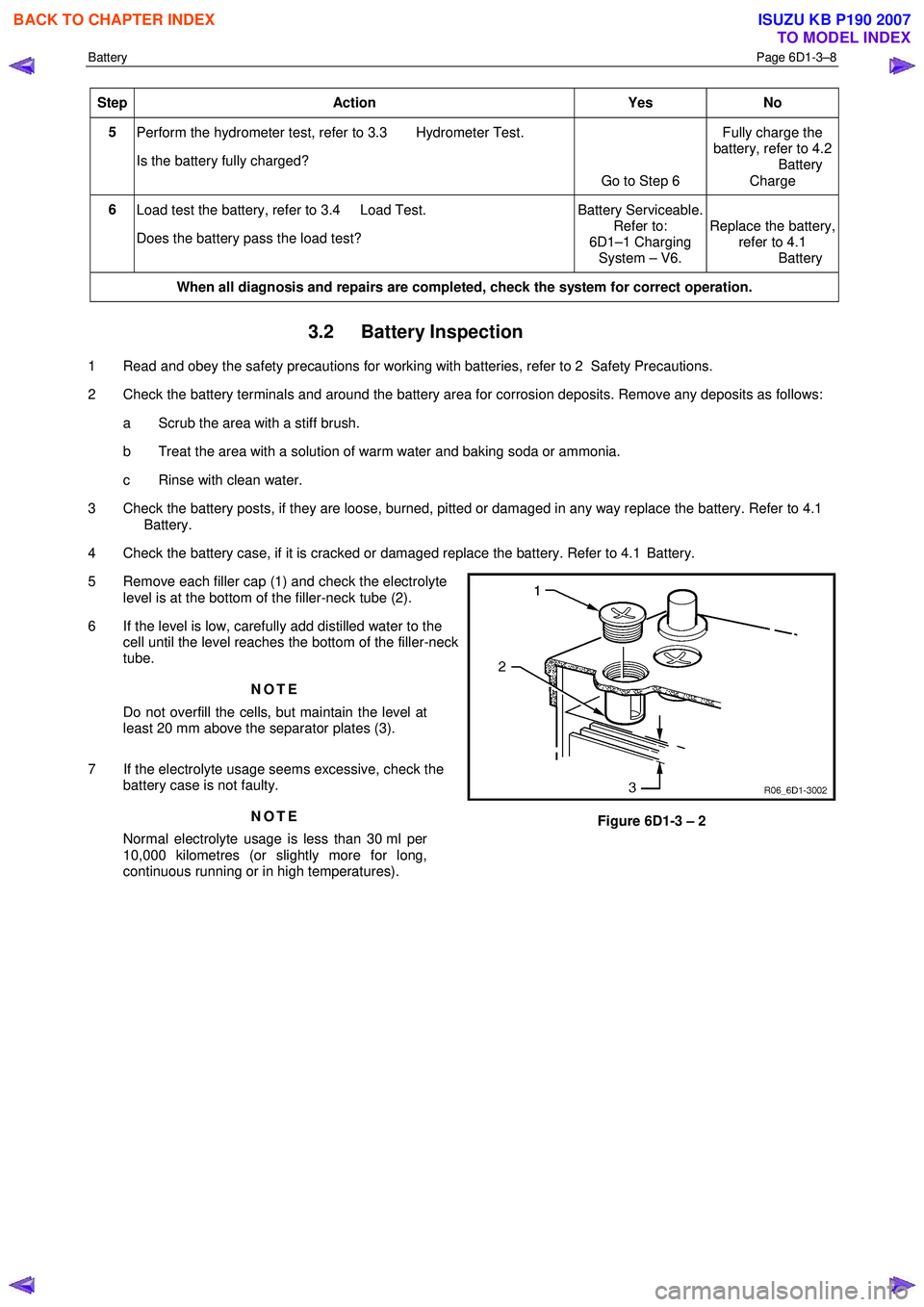

3.2 Battery Inspection

1 Read and obey the safety precautions for working with batteries, refer to 2 Safety Precautions.

2 Check the battery terminals and around the battery area for corrosion deposits. Remove any deposits as follows: a Scrub the area with a stiff brush.

b Treat the area with a solution of warm water and baking soda or ammonia.

c Rinse with clean water.

3 Check the battery posts, if they are loose, burned, pitted or damaged in any way replace the battery. Refer to 4.1 Battery.

4 Check the battery case, if it is cracked or damaged replace the battery. Refer to 4.1 Battery.

5 Remove each filler cap (1) and check the electrolyte level is at the bottom of the filler-neck tube (2).

6 If the level is low, carefully add distilled water to the cell until the level reaches the bottom of the filler-neck

tube.

NOTE

Do not overfill the cells, but maintain the level at

least 20 mm above the separator plates (3).

7 If the electrolyte usage seems excessive, check the battery case is not faulty.

NOTE

Normal electrolyte usage is less than 30 ml per

10,000 kilometres (or slightly more for long,

continuous running or in high temperatures).

Figure 6D1-3 – 2

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3650 of 6020

Battery Page 6D1-3–10

6 Still holding the hydrometer vertically, record the reading.

7 Put the electrolyte back into the cell.

8 Repeat steps 3 to 7 for each cell.

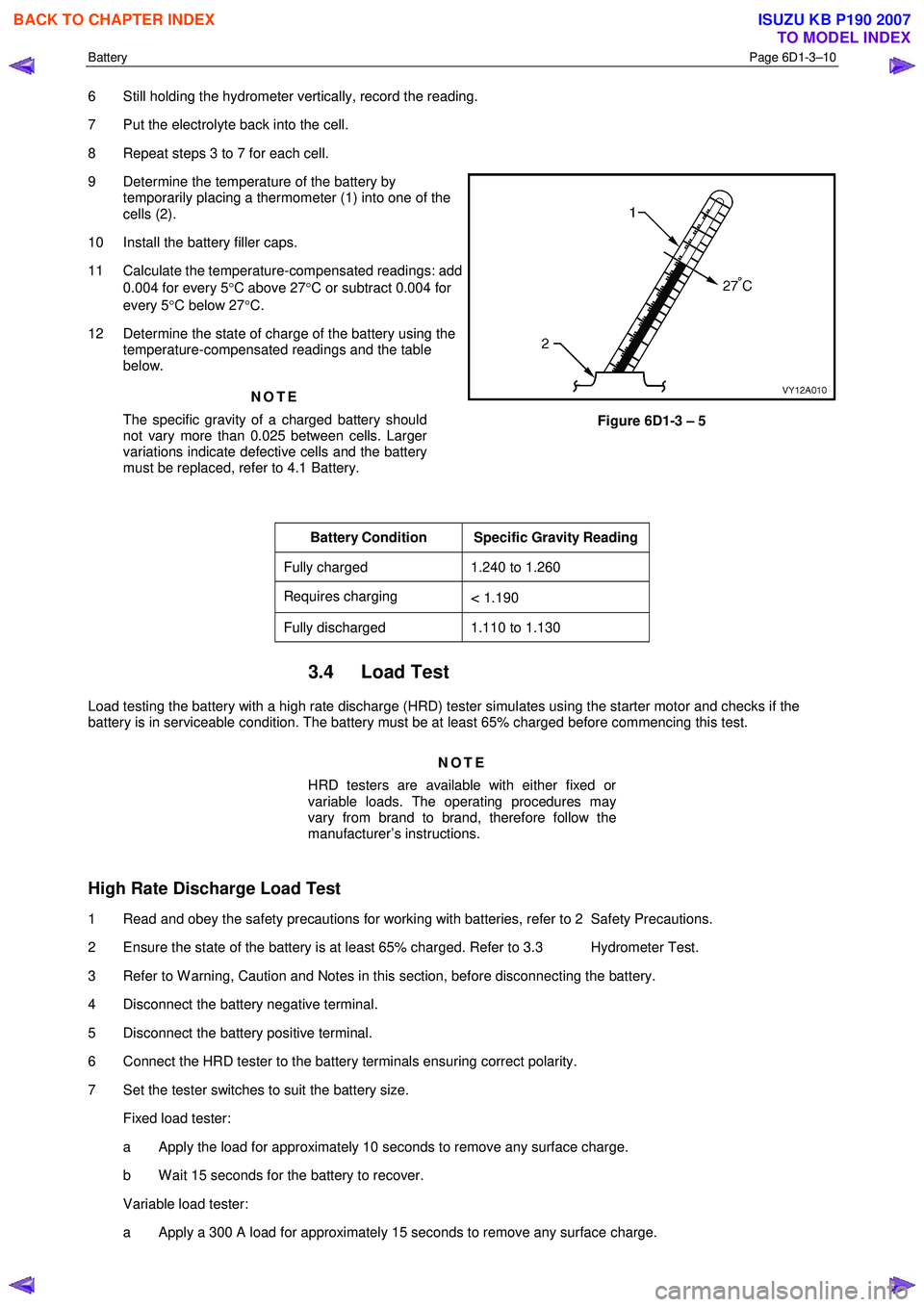

9 Determine the temperature of the battery by temporarily placing a thermometer (1) into one of the

cells (2).

10 Install the battery filler caps.

11 Calculate the temperature-compensated readings: add 0.004 for every 5 °C above 27 °C or subtract 0.004 for

every 5 °C below 27 °C.

12 Determine the state of charge of the battery using the temperature-compensated readings and the table

below.

NOTE

The specific gravity of a charged battery should

not vary more than 0.025 between cells. Larger

variations indicate defective cells and the battery

must be replaced, refer to 4.1 Battery.

Figure 6D1-3 – 5

Battery Condition Specific Gravity Reading

Fully charged 1.240 to 1.260

Requires charging < 1.190

Fully discharged 1.110 to 1.130

3.4 Load Test

Load testing the battery with a high rate discharge (HRD) tester simulates using the starter motor and checks if the

battery is in serviceable condition. The battery must be at least 65% charged before commencing this test.

NOTE

HRD testers are available with either fixed or

variable loads. The operating procedures may

vary from brand to brand, therefore follow the

manufacturer’s instructions.

High Rate Discharge Load Test

1 Read and obey the safety precautions for working with batteries, refer to 2 Safety Precautions.

2 Ensure the state of the battery is at least 65% charged. Refer to 3.3 Hydrometer Test.

3 Refer to W arning, Caution and Notes in this section, before disconnecting the battery.

4 Disconnect the battery negative terminal.

5 Disconnect the battery positive terminal.

6 Connect the HRD tester to the battery terminals ensuring correct polarity.

7 Set the tester switches to suit the battery size. Fixed load tester:

a Apply the load for approximately 10 seconds to remove any surface charge.

b W ait 15 seconds for the battery to recover.

Variable load tester:

a Apply a 300 A load for approximately 15 seconds to remove any surface charge.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3655 of 6020

Battery Page 6D1-3–15

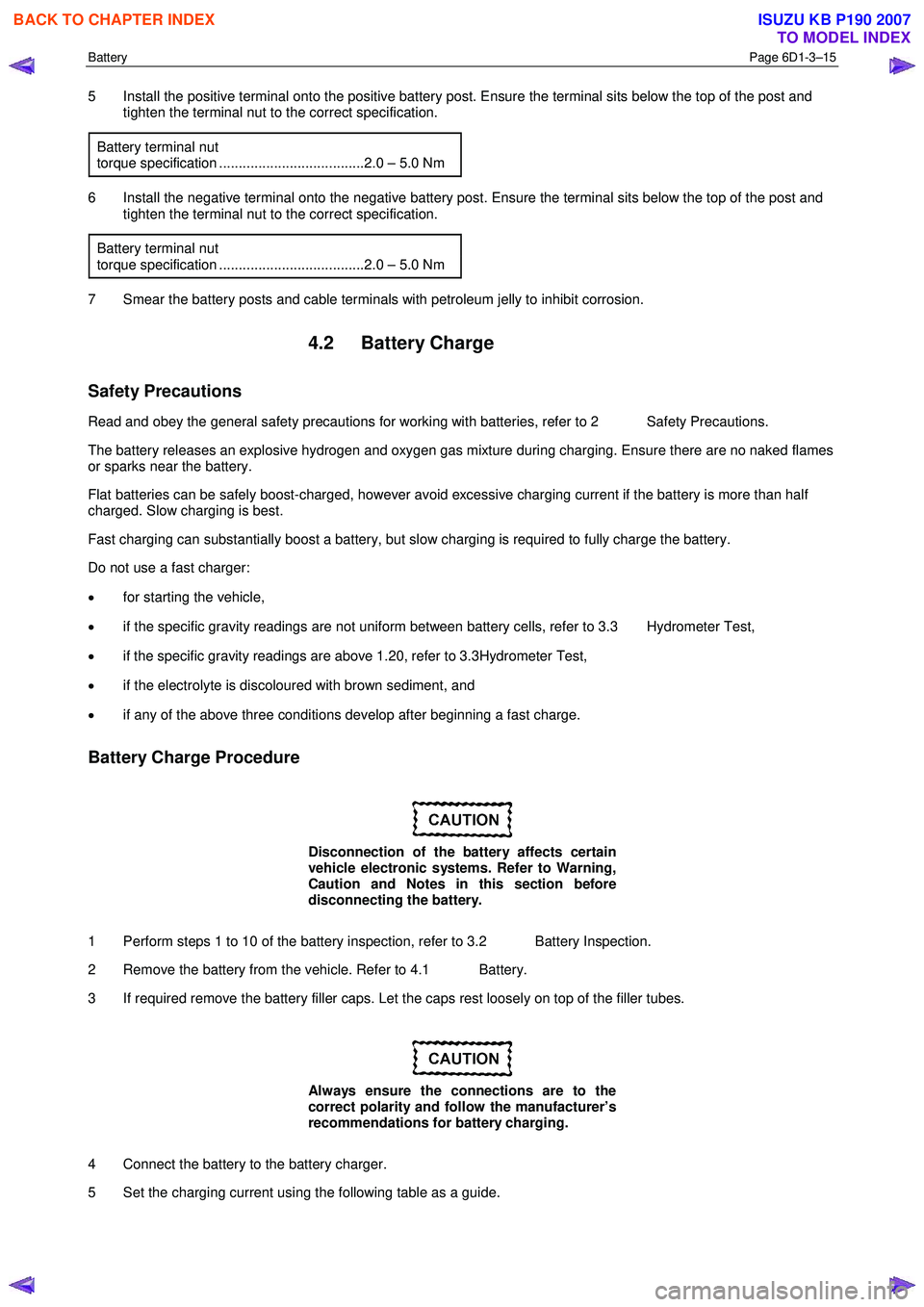

5 Install the positive terminal onto the positive battery post. Ensure the terminal sits below the top of the post and

tighten the terminal nut to the correct specification.

Battery terminal nut

torque specification .....................................2.0 – 5.0 Nm

6 Install the negative terminal onto the negative battery post. Ensure the terminal sits below the top of the post and tighten the terminal nut to the correct specification.

Battery terminal nut

torque specification .....................................2.0 – 5.0 Nm

7 Smear the battery posts and cable terminals with petroleum jelly to inhibit corrosion.

4.2 Battery Charge

Safety Precautions

Read and obey the general safety precautions for working with batteries, refer to 2 Safety Precautions.

The battery releases an explosive hydrogen and oxygen gas mixture during charging. Ensure there are no naked flames

or sparks near the battery.

Flat batteries can be safely boost-charged, however avoid excessive charging current if the battery is more than half

charged. Slow charging is best.

Fast charging can substantially boost a battery, but slow charging is required to fully charge the battery.

Do not use a fast charger:

• for starting the vehicle,

• if the specific gravity readings are not uniform between battery cells, refer to 3.3 Hydrometer Test,

• if the specific gravity readings are above 1.20, refer to 3.3Hydrometer Test,

• if the electrolyte is discoloured with brown sediment, and

• if any of the above three conditions develop after beginning a fast charge.

Battery Charge Procedure

Disconnection of the battery affects certain

vehicle electronic systems. Refer to Warning,

Caution and Notes in this section before

disconnecting the battery.

1 Perform steps 1 to 10 of the battery inspection, refer to 3.2 Battery Inspection.

2 Remove the battery from the vehicle. Refer to 4.1 Battery.

3 If required remove the battery filler caps. Let the caps rest loosely on top of the filler tubes.

Always ensure the connections are to the

correct polarity and follow the manufacturer’s

recommendations for battery charging.

4 Connect the battery to the battery charger.

5 Set the charging current using the following table as a guide.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3656 of 6020

Battery Page 6D1-3–16

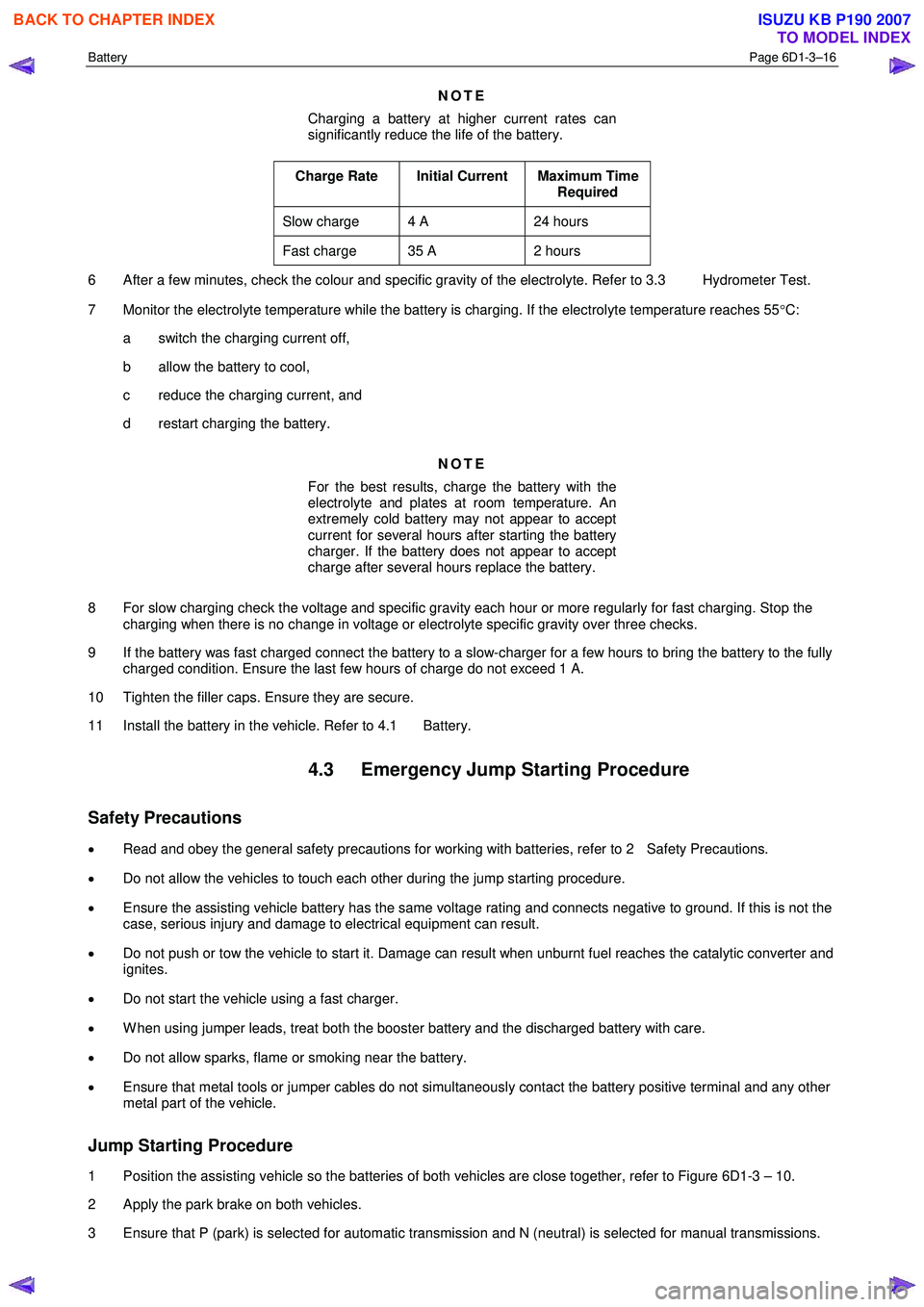

NOTE

Charging a battery at higher current rates can

significantly reduce the life of the battery.

Charge Rate Initial Current Maximum Time Required

Slow charge 4 A 24 hours

Fast charge 35 A 2 hours

6 After a few minutes, check the colour and specific gravity of the electrolyte. Refer to 3.3 Hydrometer Test.

7 Monitor the electrolyte temperature while the battery is charging. If the electrolyte temperature reaches 55 °C:

a switch the charging current off,

b allow the battery to cool,

c reduce the charging current, and

d restart charging the battery.

NOTE

For the best results, charge the battery with the

electrolyte and plates at room temperature. An

extremely cold battery may not appear to accept

current for several hours after starting the battery

charger. If the battery does not appear to accept

charge after several hours replace the battery.

8 For slow charging check the voltage and specific gravity each hour or more regularly for fast charging. Stop the charging when there is no change in voltage or electrolyte specific gravity over three checks.

9 If the battery was fast charged connect the battery to a slow-charger for a few hours to bring the battery to the fully charged condition. Ensure the last few hours of charge do not exceed 1 A.

10 Tighten the filler caps. Ensure they are secure.

11 Install the battery in the vehicle. Refer to 4.1 Battery.

4.3 Emergency Jump Starting Procedure

Safety Precautions

• Read and obey the general safety precautions for working with batteries, refer to 2 Safety Precautions.

• Do not allow the vehicles to touch each other during the jump starting procedure.

• Ensure the assisting vehicle battery has the same voltage rating and connects negative to ground. If this is not the

case, serious injury and damage to electrical equipment can result.

• Do not push or tow the vehicle to start it. Damage can result when unburnt fuel reaches the catalytic converter and

ignites.

• Do not start the vehicle using a fast charger.

• W hen using jumper leads, treat both the booster battery and the discharged battery with care.

• Do not allow sparks, flame or smoking near the battery.

• Ensure that metal tools or jumper cables do not simultaneously contact the battery positive terminal and any other

metal part of the vehicle.

Jump Starting Procedure

1 Position the assisting vehicle so the batteries of both vehicles are close together, refer to Figure 6D1-3 – 10.

2 Apply the park brake on both vehicles.

3 Ensure that P (park) is selected for automatic transmission and N (neutral) is selected for manual transmissions.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3732 of 6020

Powertrain Interface Module – V6 Page 6E1–71

11 Service Operations

11.1 Safety and Precautionary Measures

The following safety and precautionary

measures must be followed when servicing

and diagnosing the powertrain interface

module (PIM) System. Otherwise, personal

injury and / or improper braking system

operation may occur:

• W hen using electric welding equipment, disconnect the wiring harness connector from the PIM.

• Never disconnect or reconnect the PIM wiring harness connector when the ignition is switched ON.

• Do not touch the PIM connector pins or soldered components on the PIM circuit board to prevent possible

Electrostatic Discharge damage.

• To avoid wiring connector terminal damage, always use suitable wiring harness test leads (such as those in Tool

No, J35616) when performing tests on the PIM wiring connector.

• The PIM is extremely sensitive to Electro Magnetic Interference (EMI). Ensure the PIM wiring harness is routed

correctly and securely fitted to mounting clips when performing service procedures.

• Due to the sensitive nature of the PIM circuitry, specific wiring repair procedures have been developed. These

procedures and instructions are detailed in 8A Electrical - Body and Chassis and are the only recommended and

approved wiring repair methods.

• Ensure that all wiring harness connectors are seated correctly.

• Never disconnect the battery from the vehicle electrical system while the engine is running.

• Always disconnect the battery from the vehicle electrical system before charging.

• Do not use a fast charger for starting the vehicle.

• Ensure the battery cable terminals are secure.

• Before installing a new PIM, ensure the correct type is fitted. Always refer to the latest spare parts information.

11.2 Powertrain Interface Module

Do not touch the powertrain interface module

pins as Electrostatic Discharge (ESD) damage

may result. For further information on ESD,

refer to 1.2 Warning Caution and Notes.

When replacing the PIM, the PIM must be

reset prior to removal. Failure to perform this

procedure will result in the inability to:

• Test the PIM for warranty purposes.

• Install the PIM into other vehicles.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3813 of 6020

Automatic Transmission – 4L60E – Electrical Diagnosis Page 7C2–27

4 Diagnostics

4.1 Introduction

The transmission diagnostic procedure is organised in a logical structure that begins with the diagnostic system check

and as such must always be used as the starting point. The diagnostic system check directs the technician to the logical

steps necessary to diagnose a transmission driveability fault condition.

4.2 Basic Knowledge Required

A lack of basic understanding regarding

electronics, electrical wiring circuits and use

of electrical circuit testing tools when

performing any diagnostic procedure, could

result in incorrect diagnostic results or

damage to system components.

Understanding of the following is required to perform any of the diagnostic procedures detailed in this Service

Information:

• Basic electronics,

• Electrical wiring circuits,

• Electrical circuits testing, and

• Correct use of basic system diagnostic tools.

4.3 Diagnostic Precautions

When tests are required on connector

terminals, use the adapters in connector

adaptor kit J35616-C to prevent damage to

terminals.

The following precautions must be observed when performing all diagnostic procedures. Otherwise, incorrect diagnostic

results or damage to system components will occur:

1 Disconnection of the battery affects certain vehicle electronic systems.

2 Disconnect the battery negative lead when performing the following procedures:

• Disconnecting the electronic control module wiring harness connector/s or

• Charging the battery.

3 Disconnect the battery terminal ground lead and the electronic control module wiring harness connector before attempting any electric arc welding on the vehicle.

4 Do not start the engine if the battery terminal is not properly secured to the battery.

5 Do not disconnect or reconnect any of the following while the ignition is switched on or when the engine is running:

• Any electronic control module or system component electrical wiring connector, or

• Battery terminal leads.

6 Ensure that the correct procedure for disconnecting and connecting system electrical wiring harness connectors is always followed. For information on the correct procedure for disconnecting and connecting specific wiring

connectors, refer to 8A Electrical-Body and Chassis.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007