charging ISUZU KB P190 2007 Workshop Manual PDF

[x] Cancel search | Manufacturer: ISUZU, Model Year: 2007, Model line: KB P190, Model: ISUZU KB P190 2007Pages: 6020, PDF Size: 70.23 MB

Page 2162 of 6020

6D3-14 STARTING AND CHARGING SYSTEM

7. To remove the pulley, mount an 8mm Allen key in the vice

with the short end upwards, place a 24mm ring spanner on

the puley nut, position the internal hexagon of the roto

r

shaft onto the Allen ken, loosen the nut and remove the

pulley.

Note: the pulley has an integral boss which locks up against

the bearing,

therefore no thrust collar is provided.

8. Removing the rotor assembly. Remove the four retaining screws from the drive end housing, withdraw the roto

r

complete with the bearing.

Note: the rotor must not be pressed from the drive end housing

using a press as the bearing retaining plate and drive end

housing will be damaged or distorted. Parts removed in this

way must be replaced if the integrity of the generator is to be

maintained.

9. Remove the drive end bearing from the rotor shaft using a

chuck type puler, take care not to distort the fan assembl

y

during this process.

10. Remove the slipring end bearing using the same meghod as in 9.

Clean

Thoroughly clean all components except the rotor and stator

with an approved cleaning agent. Ensure that all traced of oil

and dirt are removed. If an abrasive cleaner is used to remove

scale and paint from the housings take care not to abrade the

bearing and mounting spigot surfaces. The rotor and stator

must be cleaned with compressed air only, the use of solvents

could cause damage to the insulating materials.

Inspection

1. Rectifier assembly

The following test equipment is required.

The recitifier assembly is not repairable and must be replaced

if a faulty diode is detected during inspection.

(a)

Adiode tester where the DC output at the test probes does

not exceed 14 volts or in the case of AC testers 12 volts

RMS. This is to ensue that when inspection rectifiers fitted

with zener power diodes the forward and reverse checks

are completer and are not masked by the diode turning on

due to the zener breakdown voltage.

(b) A zenere diode tester with a DC output in excess of 30 volts, the tester should also incorporate internal current

limiting set to 5 Ma. to prevent high currents during

inspection.

(c) Diodes can be destroyed during service due to high temperature and overload, open circuits are usually a result

of excessive voltage.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 2163 of 6020

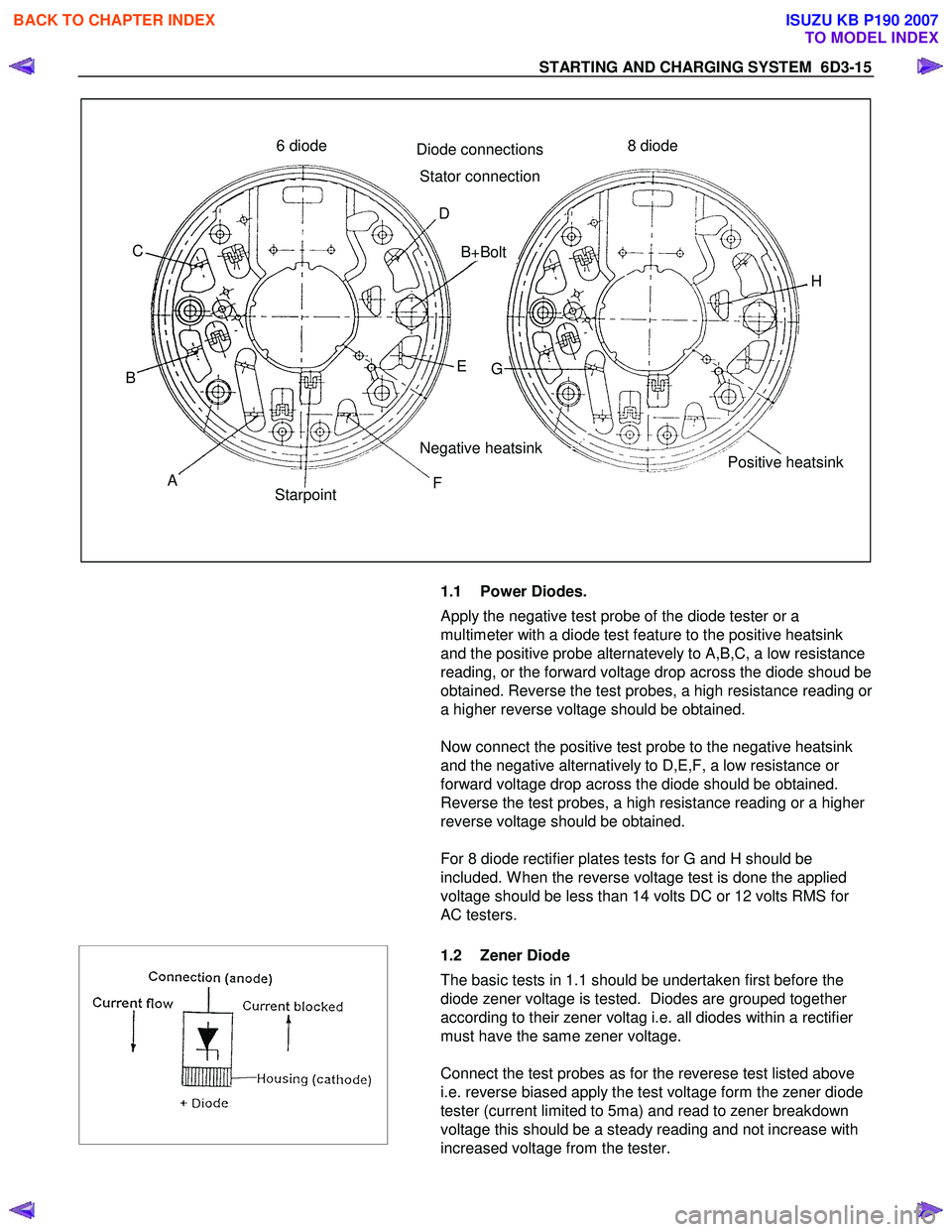

STARTING AND CHARGING SYSTEM 6D3-15

Positive heatsink

8 diode

6 diode

H

G

Negative heatsink

C

B A Starpoint FE

B+Bolt

D

Diode connections

Stator connection

1.1 Power Diodes.

Apply the negative test probe of the diode tester or a

multimeter with a diode test feature to the positive heatsink

and the positive probe alternatevely to A,B,C, a low resistance

reading, or the forward voltage drop across the diode shoud be

obtained. Reverse the test probes, a high resistance reading or

a higher reverse voltage should be obtained.

Now connect the positive test probe to the negative heatsink

and the negative alternatively to D,E,F, a low resistance or

forward voltage drop across the diode should be obtained.

Reverse the test probes, a high resistance reading or a higher

reverse voltage should be obtained.

For 8 diode rectifier plates tests for G and H should be

included. W hen the reverse voltage test is done the applied

voltage should be less than 14 volts DC or 12 volts RMS for

AC testers.

1.2 Zener Diode

The basic tests in 1.1 should be undertaken first before the

diode zener voltage is tested. Diodes are grouped together

according to their zener voltag i.e. all diodes within a rectifier

must have the same zener voltage.

Connect the test probes as for the reverese test listed above

i.e. reverse biased apply the test voltage form the zener diode

tester (current limited to 5ma) and read to zener breakdown

voltage this should be a steady reading and not increase with

increased voltage from the tester.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 2164 of 6020

6D3-16 STARTING AND CHARGING SYSTEM

Readings for Zener diode groups 011 to 042

Zener voltage at

5Ma. Positive

diode Negative

diode Fordward

current Rating

17.8v-19.2v 011 012 25A

18.8v-20.2v 013 014 25A

19.8v-21.2v 015 016 25A

20.8v-22.2v 017 018 25A

21.8v-23.2v 019 020 25A

22.8v-24.2v 021 022 25A

17.8v-19.2v 031 032 35A

18.8v-20.2v 033 034 35A

19.8v-21.2v 035 036 35A

20.8v-22.2v 037 038 35A

21.8v-23.2v 039 040 35A

22.8v-24.2v 041 042 35A

Note: Diode number is stamped on the rear of the diode.

2. Stator

Inspect the stator insulation resistance to ground with an

insuation tester or a series test lamp up to 110 volts.

The insulation resistance must be greater than 1 megohm.

The winding reisistance is measured between phases using a

low reading ohmmeter designed for this purpose, the values

are given at the rear of this instruction.

3. Rotor

Inspect the rotor for insulation resistance to ground using an

insulation tester or a series test lamp up to 110 volts.

The insulation resistance must be grater than 1 megohm.

Measure the rotor resistance between the sliprings using an

ohmmeter or apply 12 volts across the sliprings and measure

the rotor current flow, then divide 12 by the measured current,

the results is the rotor resistance in ohms. values are given at

the rear of this instruction.

If the sliprings are worn or out of round they must be re-

machined to a minimum diameter or 26.7 mm and should have

a runout not exceeding 0.060mm. If the slipring is below these

limits it must be replaced with a new one.

Warning; extreme care must be exercised when machining

the slipring as it is possible for the turning tool to foul the

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 2165 of 6020

STARTING AND CHARGING SYSTEM 6D3-17

fan.

4. Replacing the brushes (inbuilt regulator)

Check the brushes for length, this is measured from the brush

holder to the end of the brush along it's centre line. Also

inspect for any sideways wear. If worn replace both brushes.

The minimum length is 3.8mm. Inspect the brush springs for

signs of corrosion or loss of tension or uneven tension.

Replacing the brushes, using a soldering iron apply heat to the

soldered joints on the rear of the brush holder of the regulator,

using a small lever prise up the retaining tabs to release the

brush lead and spring. Thread the new brush lead up the

brush holder along with the spring, pull the lead through the

tabs until the brush is protruding 12mm from the holder.

Bend down the tabs and solder the brush lead taking care not

to allow the solder to run up the lead which will reduce

flexibility. Use 60/40 resin cored solder.

5. Ball bearing

Please note the bearings used in this KCA generator are a

high

tolerance type, only fully sealed bearings of the same

specification are to be used as replacements. It is

recommended that the bearings be replaced during the

reconditioning process to restore the unit to original

specification.

6. Regulator

The regulator can only be tested when fitted into an altenator.

Warning: do not reverse"S" and "L" connections or put 12

volt supply to "L" terminal, this connection must not be

used as a supply source other than to supply the

requirements of the warning lamp 2(watts).

Such action will destroy the regulator warning lamp

circuit.

For test voltages refer to Generator output testing section.

See also additional information on regulator function earlier in

this instruction.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 2166 of 6020

6D3-18 STARTING AND CHARGING SYSTEM

Reassembly

Generator

(a) Press new bearing onto slipring end of the rotor taking care to aplly the force to the bearing inner race only, otherwise

the bearing will be noisy and it's life will be shortened.

(b) Fit a new bearing to the drive end housing, fit the bearing plate, and four retaining screws, press the rotor into the

bearing, using a support tool to take the thrust against the

bearing inner.

The support is fitted from the pulley side of the bearing. In this way the thrust is not taken by the drive end housing.

(c) To fit pulley, mount an 8mm Allen key in the vice with the short end upwards, place a 24mm ring spanner on the shaft

nut, position the internal hexagon of the rotor shaft onto the

Allen key, tighten the nut to the required torque(See torque

chart)

(d) Inspect the bearing support ring for signs of damage, if in doubt replace the ring by pressing it into the housing b

y

hand, do not use excessive force.

(e) To refit the rectifier, fit new mica washers to the positive heatsink B+ bolt and retaining screw each washer must

have heatsink compound applied to both surfaces before

fitting.

Fit the three retaining screws to the rectifier then install into slipring end housing. Tighten the B+ bolt to the reuired

torque.

(f) To refit the stator, make sure the spigot surface are clean and free from damage, fit the stator into the slipring end

housing noting the correct lead connection positioning. Fit

the stator leads into the wire loops in the recrifier. Using a

pair of pliers squeeze the loop to retain the stator lead prior

to soldering. Repeat for each lead in turn, solder the leads

into position using 60/40 resin cored solder. Make sure the

leads will be clear of the internal fan when the rotor is

assmebled into the stator.

(g) Carefully install the rotor into the stator/slipring end housing assembly, noting the alignment of the housings and through

bolt holes. Fit the through bolts making sure the stator is

seated correctly, tighten the through bolts to the correct

torque setting (uneven torque can produce magnetic noise

levels above normal).

(h) Fitting the regulator. Compress the brushes into the brush holder by hand, slip the regulator through the opening in the

rear of the slipring end housing until the brushes come in

contact with the slipring. Press the regulator towards the

slipring until the holes are aligned then fit the retaining

screws and tighten.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 2167 of 6020

STARTING AND CHARGING SYSTEM 6D3-19

Inspection

Generator

Before any in field testing can be undertaken it is important

that the battery's conditions is established and the terminals

are clean and tight.

Check the condition of the generator drive belt and ensure that

it is adjusted in accordance with the engine manufacturer's

recommnedations.

Battery conditions:

Note: This assessment may be difficult with maintenance free

assemblies.

Test the specific gravity of the individual cells the readings

should be within 10 points of each other, it is recommended

that the average SG should be 1.260 or higher.

A load test should be carried out to determine the ability of the

battery to supply and accept current. This is a good indicator

as to the general condition of the battery.

A load equal to the normal starting current should be placed

across the battery, the duration of this load test should not

exceed 10 seconds, during this time the terminal voltage

across the battery should not drop below 9.6 volts. Observe

each cell for signs of excessive gas liberation, usuall an

indication of cell failure.

If the battery test is clear proceed with the Generator tests as

follows.

Care should be taken when making the following connections.

It is recommended that the battery negative terminal be

disconnected before the test meters are connected, and

reconnecting the negative terminal when the meters are

inserted into the circuit under test. The warning lamp in the D+

circuit should not exceed 2 watts.

Regulating voltage test on the vehicle.

Connect a voltmeter to the generator, the positive lead to the

B+ terminal and the nagative lead to the generator casing.

Select the voltage range to suit the system, i.e. 20v for 12 volt

sysytems or 40v for 24 volt systems. Connect an ammeter in

series with the main output cable from the B+ terminal on the

generator, the range selected must be capable of reading the

maximum output from the generator.

Note the voltmeter reading before starting the engine. This

reading should increase when the engine is running indicating

generator output, start the engine and increase the engine

speed until the generator is running at 4000 rpm, switch on

vehicle loads of 5-10 A is indcated on the ammeter, the

voltmeter shoud read 14.0-14.2 v for a 12 volt system, for a 24

volt system the readings should be 5-10 A and 27.7-28.5 volts.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 2168 of 6020

6D3-20 STARTING AND CHARGING SYSTEM

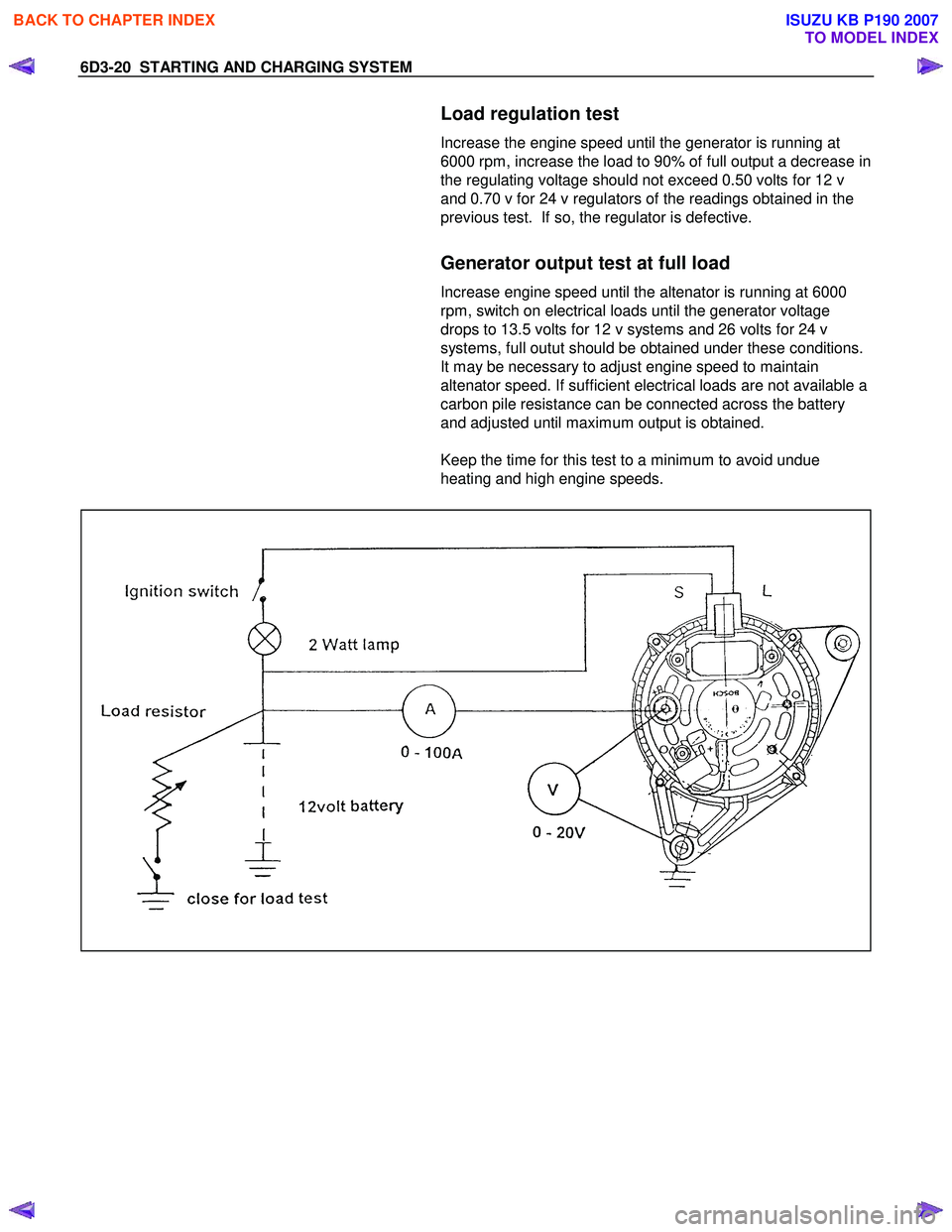

Load regulation test

Increase the engine speed until the generator is running at

6000 rpm, increase the load to 90% of full output a decrease in

the regulating voltage should not exceed 0.50 volts for 12 v

and 0.70 v for 24 v regulators of the readings obtained in the

previous test. If so, the regulator is defective.

Generator output test at full load

Increase engine speed until the altenator is running at 6000

rpm, switch on electrical loads until the generator voltage

drops to 13.5 volts for 12 v systems and 26 volts for 24 v

systems, full outut should be obtained under these conditions.

It may be necessary to adjust engine speed to maintain

altenator speed. If sufficient electrical loads are not available a

carbon pile resistance can be connected across the battery

and adjusted until maximum output is obtained.

Keep the time for this test to a minimum to avoid undue

heating and high engine speeds.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 2169 of 6020

STARTING AND CHARGING SYSTEM 6D3-21

Technical Data

(mm)

Brush wear - Minimum Length 3.8

Sliprings - Minimum Diameter 26.7

Sliprings - Trueness <0.06

Pole claws - Trueness <0.05(93.25 ±0.05)

Torque N.m(kgf⋅m)

Pulley retaining nut 54-68(5.5-6.9)

Capacitor retaining screw 2.7-3.8(0.3-0.4)

Capacitor whiz nut 1.5-2.2(0.1-0.2)

B+ terminal nut M8 7.5-8.5(0.8-0.9)

B+ terminal rectifier nut 6.0-7.5(0.6-0.8)

Regulator retaining screw 1.6-2.3(0.1-0.2)

Rectifier retaining screw 1.6-2.3(0.1-0.2)

Bearing retaining plate screw 2.1-3.0(0.2-0.3)

Through bolt 3.8-5.5(0.4-0.6)

W inding resistance(between phases) (Ω )

Stator Rotor

70 Amp generator 0.086+10% 2.6 ±0.13

85 Amp generator 0.058+10% 2.6 ±0.13

90 Amp generator 0.056+10% 2.6 ±0.13

W arning lamp fault indication

Fault running Generator not

running Ignition ON Generator

Iginiton ON

Generator out cable

O/C ON

ON

Battery "S" cable O/C ONON

Battery overcharged ONON

Positive diode short OFFON

Negative diode short ONON

Positive diode open ONOFF

Negative diode open ONOFF

Phase voltage sensing ONON

cable open circuit

Power transistor

shorted ON

ON

W arnign lamp driver

O/C OFF

OFF

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 2170 of 6020

6D3-22 STARTING AND CHARGING SYSTEM

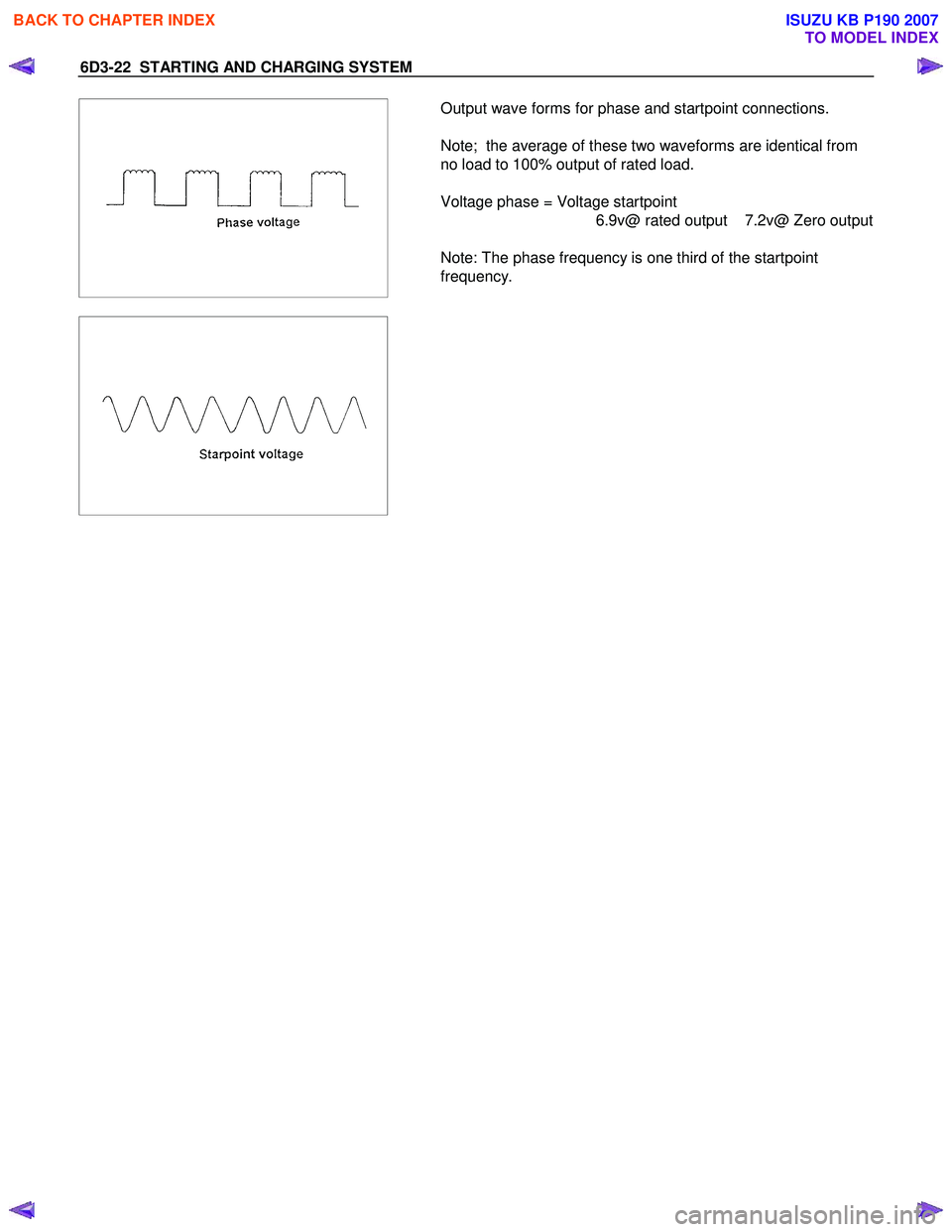

Output wave forms for phase and startpoint connections.

Note; the average of these two waveforms are identical from

no load to 100% output of rated load.

Voltage phase = Voltage startpoint 6.9v@ rated output 7.2v@ Zero output

Note: The phase frequency is one third of the startpoint

frequency.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 2237 of 6020

ENGINE DRIVEABILITY AND EMISSIONS 6E–67

GENERAL SERVICE INFORMATION

Aftermarket Electrical and Vacuum

Equipment

Aftermarket (add-on) electrical and vacuum equipment

is defined as any equipment which connects to the

vehicle's electrical or vacuum systems that is installed

on a vehicle after it leaves the factory. No allowances

have been made in the vehicle design for this type of

equipment.

NOTE: No add-on vacuum equipment should be added

to this vehicle.

NOTE: Add-on electrical equipment must only be

connected to the vehicle's electrical system at the

battery (power and ground).

Add-on electrical equipment, even when installed to

these guidelines, may still cause the electric system to

malfunction. This may also include equipment not

connected to the vehicle electrical system such as

portable telephones and radios. Therefore, the first step

in diagnosing any electric problem is to eliminate all

aftermarket electrical equipment from the vehicle. After

this is done, if the problem still exists, it may be

diagnosed in the normal manner.

Electrostatic Discharge Damage

Electronic components used in the ECM are often

designed to carry very low voltage. Electronic

components are susceptible to damage caused by

electrostatic discharge. Less than 100 volts of static

electricity can cause damage to some electronic

components. By comparison, it takes as much as 4000

volts for a person to feel even the zap of a static

discharge.

There are several ways for a person to become

statically charged. The most common methods of

charging are by friction and induction.

• An example of charging by friction is a person sliding across a vehicle seat.

• Charge by induction occurs when a person with well- insulated shoes stands near a highly charged object

and momentarily touches ground. Charges of the

same polarity are drained off leaving the person

highly charged with the opposite polarity. Static

charges can cause damage, therefore it is important

to use care when handling and testing electronic

components. Non-OEM Parts

All of the OBD diagnostics have been calibrated to run

with OEM parts. Accordingly, if commercially sold

sensor or switch is installed, it makes a wrong diagnosis

and turns on the check engine lamp.

Aftermarket electronics, such as cellular phones,

stereos, and anti-theft devices, may radiate EMI into the

control system if they are improperly installed. This may

cause a false sensor reading and turn on the check

engine lamp.

Poor Vehicle Maintenance

The sensitivity of OBD diagnostics will cause the check

engine lamp to turn on if the vehicle is not maintained

properly. Restricted oil filters, fuel filters, and crankcase

deposits due to lack of oil changes or improper oil

viscosity can trigger actual vehicle faults that were not

previously monitored prior to OBD. Poor vehicle

maintenance can not be classified as a “non-vehicle

fault”, but with the sensitivity of OBD diagnostics,

vehicle maintenance schedules must be more closely

followed.

Related System Faults

Many of the OBD system diagnostics will not run if the

ECM detects a fault on a related system or component.

Visual/Physical Engine Compartment

Inspection

Perform a careful visual and physical engine

compartment inspection when performing any

diagnostic procedure or diagnosing the cause of an

emission test failure. This can often lead to repairing a

problem without further steps. Use the following

guidelines when performing a visual/physical

inspection:

• Inspect all vacuum hoses for punches, cuts, disconnects, and correct routing.

• Inspect hoses that are difficult to see behind other components.

• Inspect all wires in the engine compartment for proper connections, burned or chafed spots, pinched

wires, contact with sharp edges or contact with hot

exhaust manifolds or pipes.

Basic Knowledge of Tools Required

NOTE: Lack of basic knowledge of this powertrain

when performing diagnostic procedures could result in

an incorrect diagnosis or damage to powertrain

components. Do not attempt to diagnose a powertrain

problem without this basic knowledge.

A basic understanding of hand tools is necessary to

effectively use this section of the Service Manual.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007