clock setting ISUZU KB P190 2007 Workshop Repair Manual

[x] Cancel search | Manufacturer: ISUZU, Model Year: 2007, Model line: KB P190, Model: ISUZU KB P190 2007Pages: 6020, PDF Size: 70.23 MB

Page 317 of 6020

3B-56 POWER-ASSISTED STEERING SYSTEM

9. Turn the SRS coil fully counterclockwise, return

about 3 turns and align the neutral mark (1). (with

SRS air bag)

CAUTION: When turning the SRS coil fully

counterclockwise, stop turning if resistance is felt.

Further forced turning may damage to the cable in

the SRS coil.

826RW 014

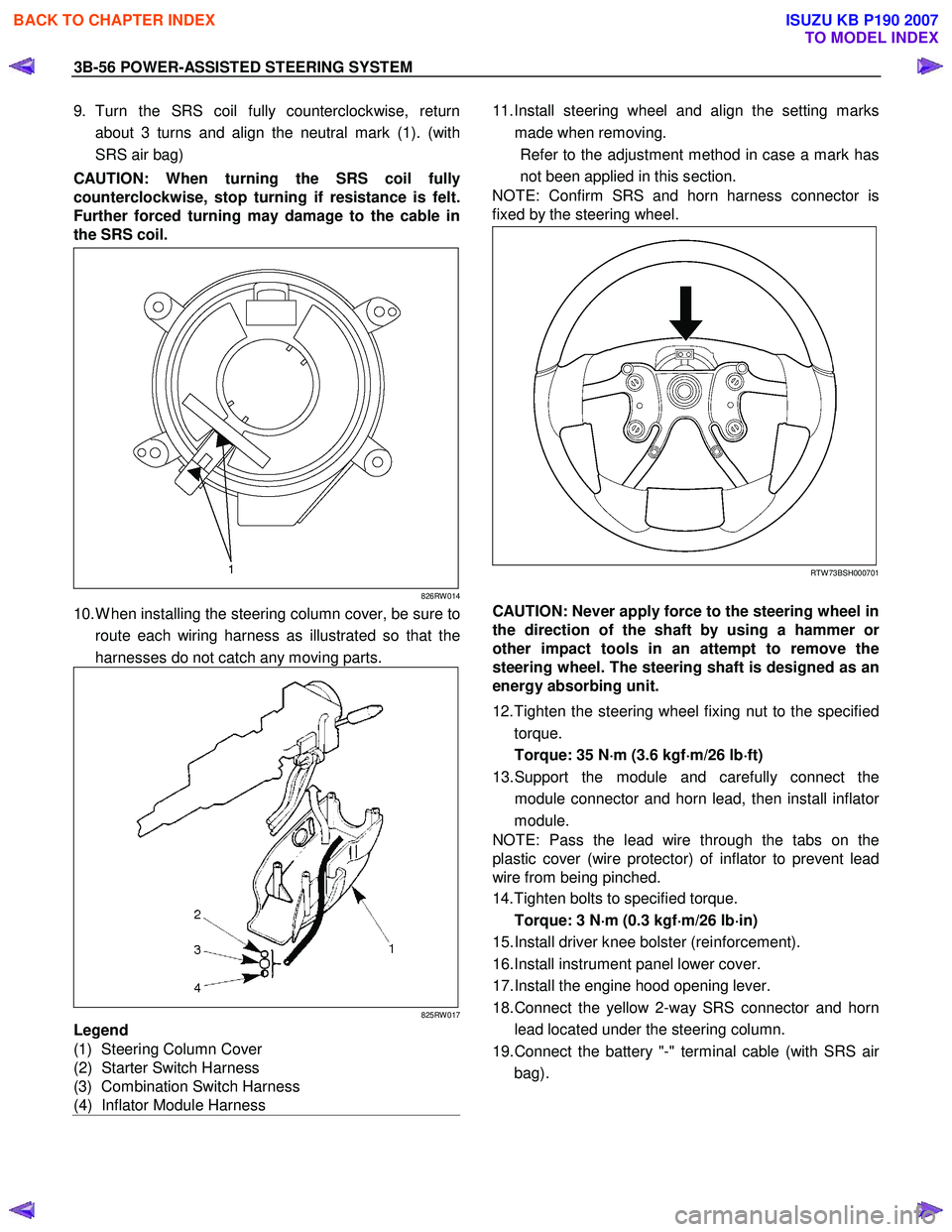

10. W hen installing the steering column cover, be sure to

route each wiring harness as illustrated so that the

harnesses do not catch any moving parts.

825RW 017

Legend

(1) Steering Column Cover

(2) Starter Switch Harness

(3) Combination Switch Harness

(4) Inflator Module Harness

11. Install steering wheel and align the setting marks

made when removing. Refer to the adjustment method in case a mark has

not been applied in this section.

NOTE: Confirm SRS and horn harness connector is

fixed by the steering wheel.

RTW 73BSH000701

CAUTION: Never apply force to the steering wheel in

the direction of the shaft by using a hammer o

r

other impact tools in an attempt to remove the

steering wheel. The steering shaft is designed as an

energy absorbing unit.

12. Tighten the steering wheel fixing nut to the specified torque.

Torque: 35 N ⋅

⋅⋅

⋅

m (3.6 kgf ⋅

⋅⋅

⋅

m/26 lb ⋅

⋅⋅

⋅

ft)

13. Support the module and carefully connect the module connector and horn lead, then install inflato

r

module.

NOTE: Pass the lead wire through the tabs on the

plastic cover (wire protector) of inflator to prevent lead

wire from being pinched.

14. Tighten bolts to specified torque.

Torque: 3 N ⋅

⋅⋅

⋅

m (0.3 kgf ⋅

⋅⋅

⋅

m/26 lb ⋅

⋅⋅

⋅

in)

15. Install driver knee bolster (reinforcement).

16. Install instrument panel lower cover.

17. Install the engine hood opening lever.

18. Connect the yellow 2-way SRS connector and horn lead located under the steering column.

19. Connect the battery "-" terminal cable (with SRS ai

r

bag).

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 469 of 6020

REAR AXLE 4B-25

b. Tighten the nut to the specified torque.

Torque:

φ220mm : 2.7 N ⋅m (0.28 kgf ⋅m/24 lb ⋅in)

φ194mm : 2.3 N ⋅m (0.23 kgf ⋅m/20 lb ⋅in)

425RW 030

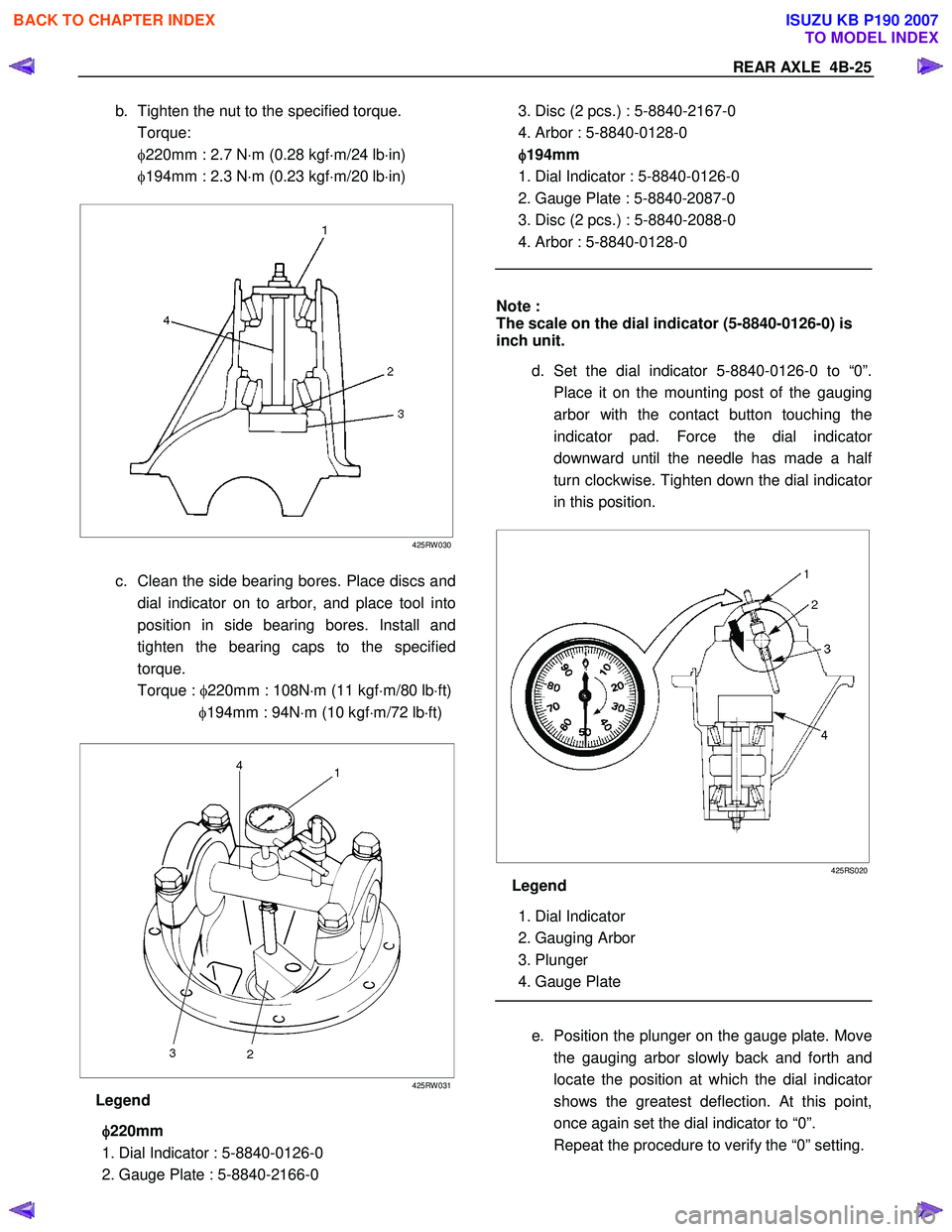

c. Clean the side bearing bores. Place discs and

dial indicator on to arbor, and place tool into

position in side bearing bores. Install and

tighten the bearing caps to the specified

torque.

Torque : φ220mm : 108N ⋅m (11 kgf ⋅m/80 lb ⋅ft)

φ194mm : 94N ⋅m (10 kgf ⋅m/72 lb ⋅ft)

425RW 031

Legend

φ

φφ

φ

220mm

1. Dial Indicator : 5-8840-0126-0

2. Gauge Plate : 5-8840-2166-0

3. Disc (2 pcs.) : 5-8840-2167-0

4. Arbor : 5-8840-0128-0

φ

φφ

φ

194mm

1. Dial Indicator : 5-8840-0126-0

2. Gauge Plate : 5-8840-2087-0

3. Disc (2 pcs.) : 5-8840-2088-0

4. Arbor : 5-8840-0128-0

Note :

The scale on the dial indicator (5-8840-0126-0) is

inch unit.

d. Set the dial indicator 5-8840-0126-0 to “0”.

Place it on the mounting post of the gauging

arbor with the contact button touching the

indicator pad. Force the dial indicato

r

downward until the needle has made a hal

f

turn clockwise. Tighten down the dial indicato

r

in this position.

425RS020

Legend

1. Dial Indicator

2. Gauging Arbor

3. Plunger

4. Gauge Plate

e. Position the plunger on the gauge plate. Move

the gauging arbor slowly back and forth and

locate the position at which the dial indicato

r

shows the greatest deflection. At this point,

once again set the dial indicator to “0”.

Repeat the procedure to verify the “0” setting.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 535 of 6020

FRONT WHEEL DRIVE 4C1-31

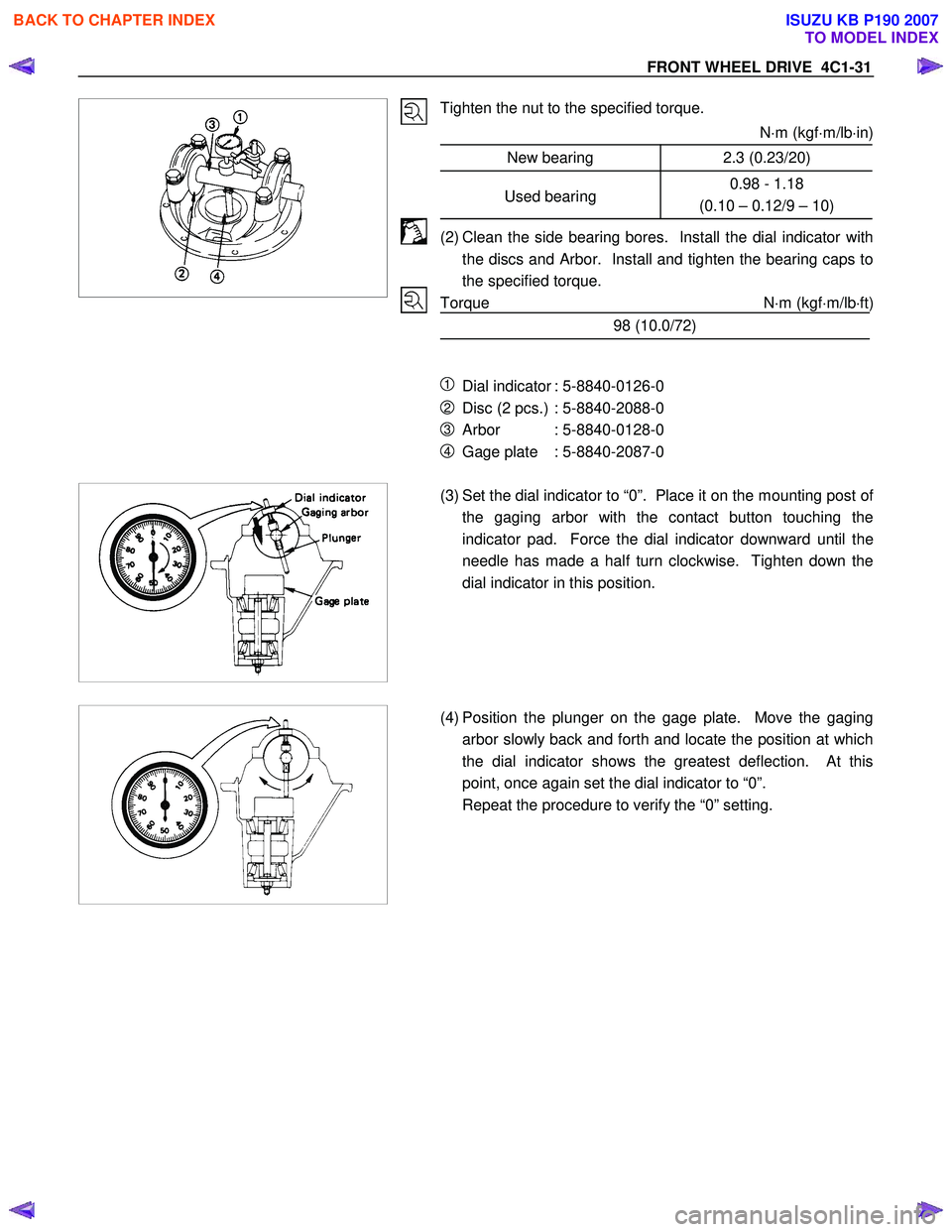

Tighten the nut to the specified torque.

N⋅m (kgf ⋅m/lb ⋅in)

New bearing 2.3 (0.23/20)

Used bearing 0.98 - 1.18

(0.10 – 0.12/9 – 10)

(2) Clean the side bearing bores. Install the dial indicator with the discs and Arbor. Install and tighten the bearing caps to

the specified torque.

Torque N ⋅m (kgf ⋅m/lb ⋅ft)

98 (10.0/72)

1 Dial indicator : 5-8840-0126-0

2 Disc (2 pcs.) : 5-8840-2088-0

3 Arbor : 5-8840-0128-0

4 Gage plate : 5-8840-2087-0

(3) Set the dial indicator to “0”. Place it on the mounting post of

the gaging arbor with the contact button touching the

indicator pad. Force the dial indicator downward until the

needle has made a half turn clockwise. Tighten down the

dial indicator in this position.

(4) Position the plunger on the gage plate. Move the gaging

arbor slowly back and forth and locate the position at which

the dial indicator shows the greatest deflection. At this

point, once again set the dial indicator to “0”.

Repeat the procedure to verify the “0” setting.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 839 of 6020

6A – 34 ENGINE MECHANICAL

RTW 46ASH000701

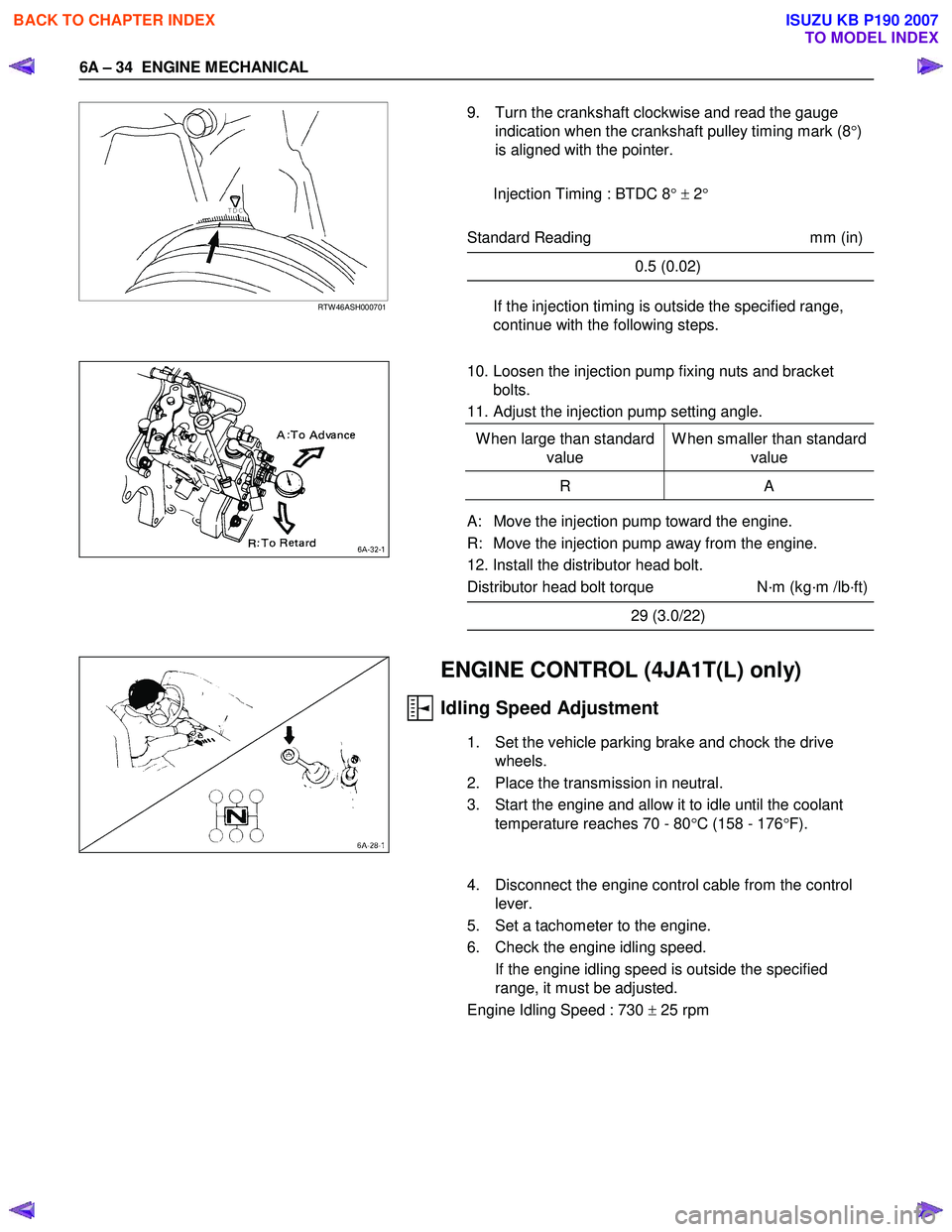

9. Turn the crankshaft clockwise and read the gauge

indication when the crankshaft pulley timing mark (8 °)

is aligned with the pointer.

Injection Timing : BTDC 8 ° ± 2 °

Standard Reading mm (in)

0.5 (0.02)

If the injection timing is outside the specified range,

continue with the following steps.

10. Loosen the injection pump fixing nuts and bracket bolts.

11. Adjust the injection pump setting angle.

W hen large than standard value W hen smaller than standard

value

R A

A: Move the injection pump toward the engine.

R: Move the injection pump away from the engine.

12. Install the distributor head bolt.

Distributor head bolt torque N·m (kg·m /lb·ft)

29 (3.0/22)

ENGINE CONTROL (4JA1T(L) only)

Idling Speed Adjustment

1. Set the vehicle parking brake and chock the drive wheels.

2. Place the transmission in neutral.

3. Start the engine and allow it to idle until the coolant temperature reaches 70 - 80 °C (158 - 176 °F).

4. Disconnect the engine control cable from the control lever.

5. Set a tachometer to the engine.

6. Check the engine idling speed. If the engine idling speed is outside the specified

range, it must be adjusted.

Engine Idling Speed : 730 ± 25 rpm

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 915 of 6020

6A – 110 ENGINE MECHANICAL

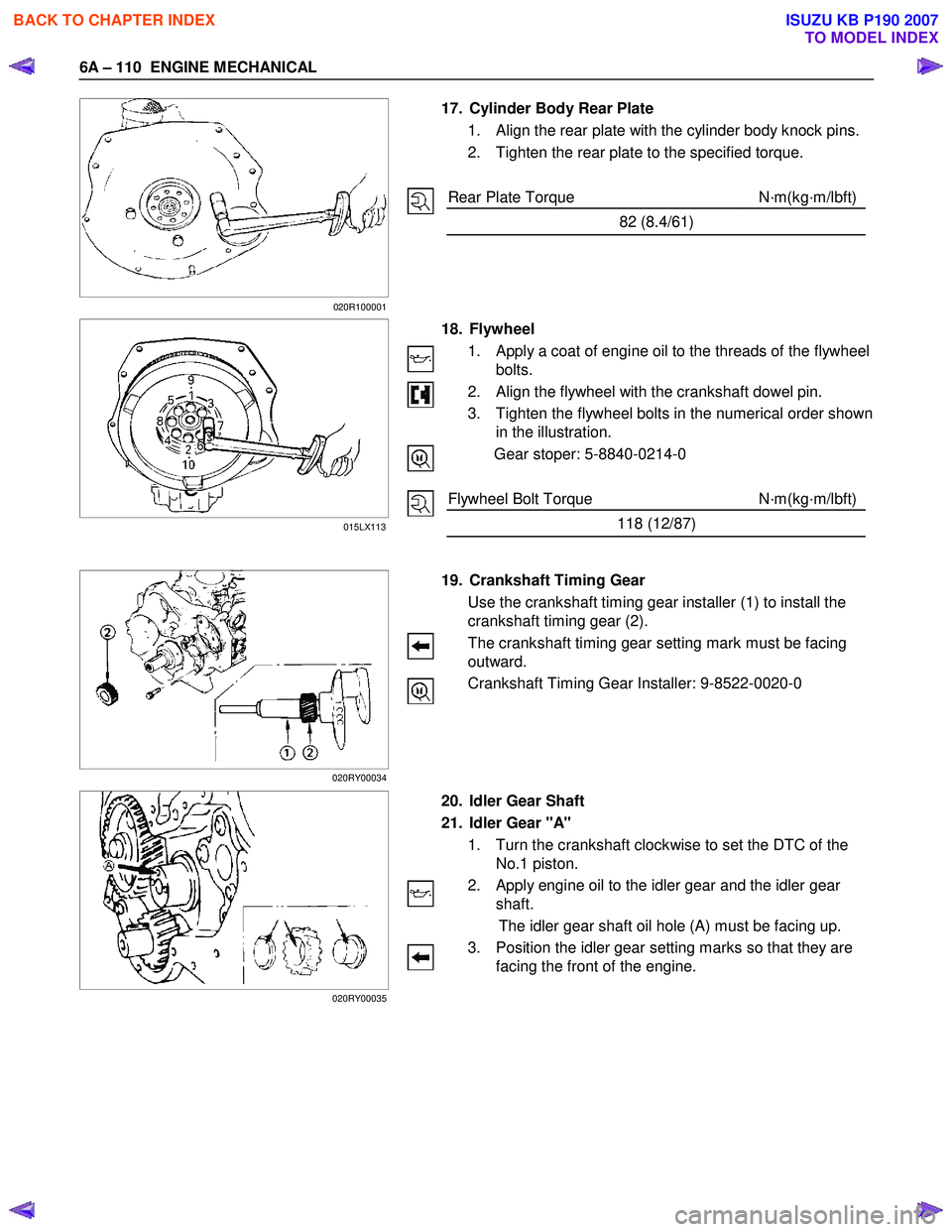

17. Cylinder Body Rear Plate

1. Align the rear plate with the cylinder body knock pins.

2. Tighten the rear plate to the specified torque.

Rear Plate Torque N·m(kg·m/lbft)

82 (8.4/61)

18. Flywheel

1. Apply a coat of engine oil to the threads of the flywheel bolts.

2. Align the flywheel with the crankshaft dowel pin.

3. Tighten the flywheel bolts in the numerical order shown in the illustration.

Gear stoper: 5-8840-0214-0

Flywheel Bolt Torque N·m(kg·m/lbft)

118 (12/87)

19. Crankshaft Timing Gear

Use the crankshaft timing gear installer (1) to install the

crankshaft timing gear (2).

The crankshaft timing gear setting mark must be facing

outward.

Crankshaft Timing Gear Installer: 9-8522-0020-0

20. Idler Gear Shaft

21. Idler Gear "A"

1. Turn the crankshaft clockwise to set the DTC of the No.1 piston.

2. Apply engine oil to the idler gear and the idler gear shaft.

The idler gear shaft oil hole (A) must be facing up.

3. Position the idler gear setting marks so that they are facing the front of the engine.

015LX113

020R100001

020RY00034

020RY00035

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3606 of 6020

Charging System – V6 Page 6D1-1-19

6 Specifications

Ground Polarity...........................................................................................................Negative

Nominal Voltage ............................................................................................................... 1 2 V

Nominal Output............................................................................................................... 12 0 A

Stator Phases .................................................................................................................. ....... 3

Stator W inding Connections ............................................................................................ Delta

Voltage Regulator Setting................................................................................... 14.2 – 14.8 V

Rotor W inding Resistance @ 20 °C ................................................................................. 2.1 V

Slip-ring Outer Diameter ............................................................................................. 22.7 mm

Slip-ring Service Limit ................................................................................................. 22.1 mm

Stator W inding Resistance @ 20 °C ............................................................................ 0.098 Ω

Brush Length New ...................................................................................................... 18.5 mm

Minimum Brush Length................................................................................................. 5.0 mm

Direction of Rotation (viewed from pulley) ................................................................Clockwise

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 4431 of 6020

TRANSMISSION CONTROL SYSTEM (JR405E) 7A2-147

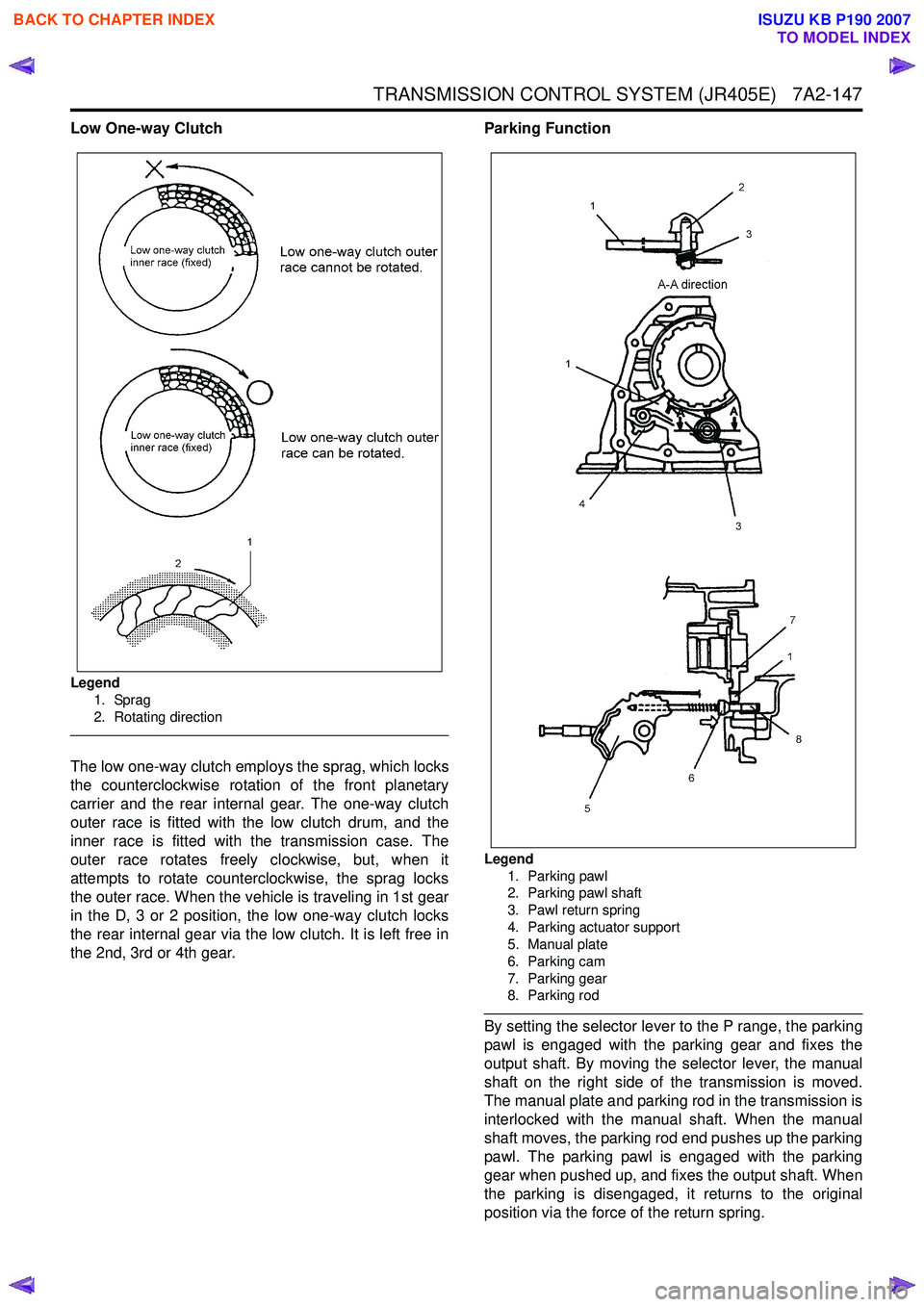

Low One-way Clutch

Legend1. Sprag

2. Rotating direction

The low one-way clutch employs the sprag, which locks

the counterclockwise rotation of the front planetary

carrier and the rear internal gear. The one-way clutch

outer race is fitted with the low clutch drum, and the

inner race is fitted with the transmission case. The

outer race rotates freely clockwise, but, when it

attempts to rotate counterclockwise, the sprag locks

the outer race. When the vehicle is traveling in 1st gear

in the D, 3 or 2 position, the low one-way clutch locks

the rear internal gear via the low clutch. It is left free in

the 2nd, 3rd or 4th gear. Parking Function

Legend

1. Parking pawl

2. Parking pawl shaft

3. Pawl return spring

4. Parking actuator support

5. Manual plate

6. Parking cam

7. Parking gear

8. Parking rod

By setting the selector lever to the P range, the parking

pawl is engaged with the parking gear and fixes the

output shaft. By moving the selector lever, the manual

shaft on the right side of the transmission is moved.

The manual plate and parking rod in the transmission is

interlocked with the manual shaft. When the manual

shaft moves, the parking rod end pushes up the parking

pawl. The parking pawl is engaged with the parking

gear when pushed up, and fixes the output shaft. When

the parking is disengaged, it returns to the original

position via the force of the return spring.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007