Circuit ISUZU KB P190 2007 Workshop Repair Manual

[x] Cancel search | Manufacturer: ISUZU, Model Year: 2007, Model line: KB P190, Model: ISUZU KB P190 2007Pages: 6020, PDF Size: 70.23 MB

Page 4332 of 6020

7A2-48 TRANSMISSION CONTROL SYSTEM (JR405E)

4Intermittently jump the signal circuit (pin 1 of E-30)

with a test lamp that is connected to a known good

ground while observing the AT Output Speed or

Vehicle Speed parameter with a scan tool.

Does the scan tool indicate any AT output speed or

vehicle speed when the circuit is intermittently

pulled to ground? —

Go to Step 5 Go to Step 8

5 Connect a test lamp between the ignition voltage

feed circuit and the low reference circuit (pins 2 and

3 of E-30).

Does the test lamp illuminate? —

Go to Step 9 Go to Step 7

6 Repair the open circuit or high resistance between

the TCM (15A) fuse and the OSS sensor (pin 2 of

E-30).

Did you complete the repair? —

Go to Step 14 —

7 Repair the open circuit or high resistance on the

low reference circuit between the OSS sensor (pin

3 of E-30) and the engine ground terminal (E-10).

Clean or tighten ground as necessary.

Did you complete the repair? —

Go to Step 14 —

8 1. Test the signal circuit between the TCM (pin

13 of C-95) and the OSS sensor (pin 1 of E-

30) for the following conditions:

• An open circuit

• A short to ground

• A short to the low reference

• A short to battery or ignition voltage

• High resistance

2. Repair the circuit(s) as necessary.

Did you find and correct the condition? —

Go to Step 14 Go to Step 10

9 1. Inspect for an intermittent and for poor

connections at the harness connector of the

OSS sensor (pin 1, 2 and 3 of E-30).

2. Repair the connection(s) as necessary.

Did you find and correct the condition? —

Go to Step 14 Go to Step 11

10 1. Turn OFF the ignition.

2. Disconnect the TCM harness connector.

3. Inspect for an intermittent and for a poor connection at the harness connector of the

TCM (pin 13 of C-95).

4. Repair the connection(s) as necessary.

Did you find and correct the condition? —

Go to Step 14 Go to Step 13

Step

Action Value(s)Yes No

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 4334 of 6020

7A2-50 TRANSMISSION CONTROL SYSTEM (JR405E)

DTC P0727 (Flash Code 13)

Circuit Description

The engine speed signal to the TCM is sent from the

engine control module (ECM) via a signal circuit based

on inputs from the crankshaft position (CKP) sensor

and camshaft position (CMP) sensor. If the TCM

detects no engine speed signal from the ECM during

the vehicle running, this DTC will set.

Condition for Running the DTC • The ignition switch is ON.

• The vehicle speed is more than 40 km/h (24 MPH).

Condition for Setting the DTC • The TCM detects that the engine speed signal pulses from the ECM are not being received for 2

seconds. Action Taken When the DTC Sets

• The TCM blinks the Check Trans lamp when the diagnostic runs and fails.

• The TCM inhibits lock up control.

Condition for Clearing the DTC • The TCM turns OFF the Check Trans lamp when the diagnostic runs and does not fail.

• A current DTC clears when the diagnostic runs and does not fail.

Diagnostic Aids • If an intermittent condition is suspected, refer to Intermittent Conditions in this section.

Schematic Reference: Transmission Controls

Schematics

Connector End View Reference: Transmission

Controls Connector End Views or TCM Connector End

Views

Circuit/ System Testing DTC P0727

Step Action Value(s)Yes No

1 Did you perform the Diagnostic System Check -

Transmission Controls? —

Go to Step 2 Go to Diagnostic

System Check -

Transmission Controls

2 1. Install a scan tool.

2. Turn OFF the ignition for 30 seconds.

3. Start the engine. If the engine does not start, crank over the engine for 10 seconds.

4. Monitor the ENGINE DTC Information with a scan tool.

Is DTC P0335, P0336, P0340 or P0341 set? —

Go to Applicable DTC in engine

control section Go to Step 3

3 Observe the Engine Speed parameter in the

transmission data display with a scan tool.

Does the scan tool indicate correct engine speed? —

Go to Diagnostic

Aids Go to Step 4

4 1. Turn OFF the ignition.

2. Disconnect the engine control module (ECM) harness connector.

3. Turn ON the ignition, with the engine OFF.

4. Intermittently jump the signal circuit (pin 33 of C-58) with a test lamp that is connected to a

known good ground while observing the

Engine Speed parameter with a scan tool.

Does the scan tool indicate any engine speed when

the circuit is intermittently pulled to ground? —

Go to Step 7 Go to Step 5

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 4335 of 6020

TRANSMISSION CONTROL SYSTEM (JR405E) 7A2-51

51. Test the signal circuit between the ECM (33 of

C-58) and the TCM (7 of C-94) for the

following conditions:

• An open circuit

• A short to ground

• A short to battery or ignition voltage

• High resistance

2. Repair the circuit(s) as necessary.

Did you find and correct the condition? —

Go to Step 10 Go to Step 6

6 1. Turn OFF the ignition.

2. Inspect for an intermittent and for a poor connection at the harness connector of the

TCM (pin 7 of C-94).

3. Repair the connection(s) as necessary.

Did you find and correct the condition? —

Go to Step 10 Go to Step 8

7 1. Turn OFF the ignition.

2. Inspect for an intermittent and for a poor connection at the harness connector of the

ECM (pin 33 of C-58).

3. Repair the connection(s) as necessary.

Did you find and correct the condition? —

Go to Step 10 Go to Step 9

8 Important:

Replacement TCM must be

programmed.

Replace the TCM. Refer to TCM Replacement.

Did you complete the replacement? —

Go to Step 10 —

9 Important:

Replacement ECM must be

programmed and learned.

Replace the ECM. Refer to ECM Replacement.

Did you complete the replacement? —

Go to Step 10 —

10 1. Reconnect all previously disconnected

harness connector(s).

2. Clear the DTCs with a scan tool.

3. Turn OFF the ignition for 30 seconds.

4. Start the engine.

5. Observe the Engine Speed parameter with a scan tool.

Does the scan tool indicate correct engine speed? —

Go to Step 11 Go to Step 4

11 Observe the DTC Information with a scan tool.

Are there any DTCs that you have not diagnosed? —

Go to DTC List System OK

Step

Action Value(s)Yes No

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 4336 of 6020

7A2-52 TRANSMISSION CONTROL SYSTEM (JR405E)

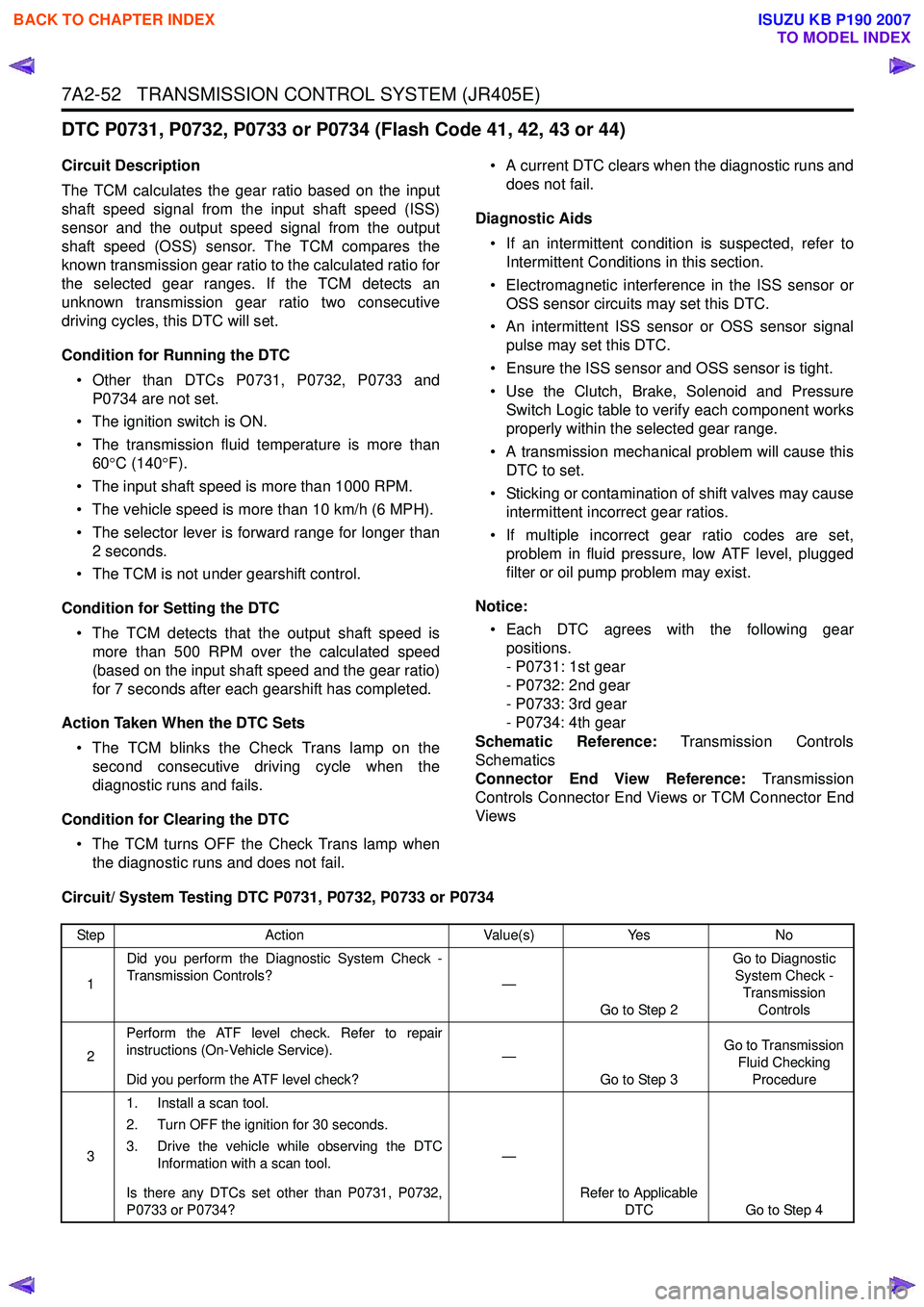

DTC P0731, P0732, P0733 or P0734 (Flash Code 41, 42, 43 or 44)

Circuit Description

The TCM calculates the gear ratio based on the input

shaft speed signal from the input shaft speed (ISS)

sensor and the output speed signal from the output

shaft speed (OSS) sensor. The TCM compares the

known transmission gear ratio to the calculated ratio for

the selected gear ranges. If the TCM detects an

unknown transmission gear ratio two consecutive

driving cycles, this DTC will set.

Condition for Running the DTC • Other than DTCs P0731, P0732, P0733 and P0734 are not set.

• The ignition switch is ON.

• The transmission fluid temperature is more than 60 °C (140 °F).

• The input shaft speed is more than 1000 RPM.

• The vehicle speed is more than 10 km/h (6 MPH).

• The selector lever is forward range for longer than 2 seconds.

• The TCM is not under gearshift control.

Condition for Setting the DTC • The TCM detects that the output shaft speed is more than 500 RPM over the calculated speed

(based on the input shaft speed and the gear ratio)

for 7 seconds after each gearshift has completed.

Action Taken When the DTC Sets • The TCM blinks the Check Trans lamp on the second consecutive driving cycle when the

diagnostic runs and fails.

Condition for Clearing the DTC • The TCM turns OFF the Check Trans lamp when the diagnostic runs and does not fail. • A current DTC clears when the diagnostic runs and

does not fail.

Diagnostic Aids • If an intermittent condition is suspected, refer to Intermittent Conditions in this section.

• Electromagnetic interference in the ISS sensor or OSS sensor circuits may set this DTC.

• An intermittent ISS sensor or OSS sensor signal pulse may set this DTC.

• Ensure the ISS sensor and OSS sensor is tight.

• Use the Clutch, Brake, Solenoid and Pressure Switch Logic table to verify each component works

properly within the selected gear range.

• A transmission mechanical problem will cause this DTC to set.

• Sticking or contamination of shift valves may cause intermittent incorrect gear ratios.

• If multiple incorrect gear ratio codes are set, problem in fluid pressure, low ATF level, plugged

filter or oil pump problem may exist.

Notice: • Each DTC agrees with the following gear positions.

- P0731: 1st gear

- P0732: 2nd gear

- P0733: 3rd gear

- P0734: 4th gear

Schematic Reference: Transmission Controls

Schematics

Connector End View Reference: Transmission

Controls Connector End Views or TCM Connector End

Views

Circuit/ System Testing DTC P0731, P0732, P0733 or P0734

Step Action Value(s)Yes No

1 Did you perform the Diagnostic System Check -

Transmission Controls? —

Go to Step 2 Go to Diagnostic

System Check - Transmission Controls

2 Perform the ATF level check. Refer to repair

instructions (On-Vehicle Service).

Did you perform the ATF level check? —

Go to Step 3 Go to Transmission

Fluid Checking Procedure

3 1. Install a scan tool.

2. Turn OFF the ignition for 30 seconds.

3. Drive the vehicle while observing the DTC Information with a scan tool.

Is there any DTCs set other than P0731, P0732,

P0733 or P0734? —

Refer to Applicable DTC Go to Step 4

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 4337 of 6020

TRANSMISSION CONTROL SYSTEM (JR405E) 7A2-53

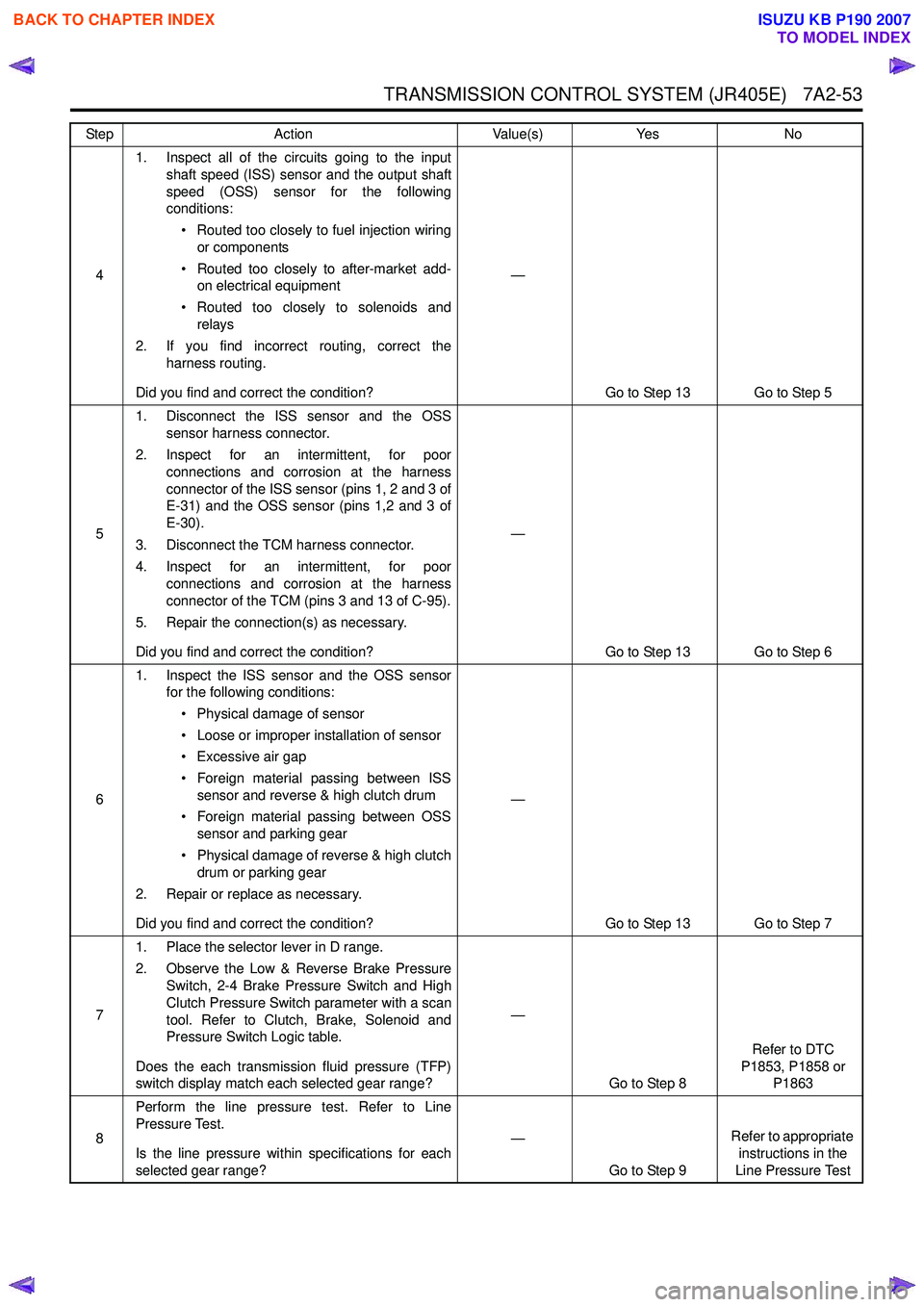

41. Inspect all of the circuits going to the input

shaft speed (ISS) sensor and the output shaft

speed (OSS) sensor for the following

conditions:

• Routed too closely to fuel injection wiring or components

• Routed too closely to after-market add- on electrical equipment

• Routed too closely to solenoids and relays

2. If you find incorrect routing, correct the harness routing.

Did you find and correct the condition? —

Go to Step 13 Go to Step 5

5 1. Disconnect the ISS sensor and the OSS

sensor harness connector.

2. Inspect for an intermittent, for poor connections and corrosion at the harness

connector of the ISS sensor (pins 1, 2 and 3 of

E-31) and the OSS sensor (pins 1,2 and 3 of

E-30).

3. Disconnect the TCM harness connector.

4. Inspect for an intermittent, for poor connections and corrosion at the harness

connector of the TCM (pins 3 and 13 of C-95).

5. Repair the connection(s) as necessary.

Did you find and correct the condition? —

Go to Step 13 Go to Step 6

6 1. Inspect the ISS sensor and the OSS sensor

for the following conditions:

• Physical damage of sensor

• Loose or improper installation of sensor

• Excessive air gap

• Foreign material passing between ISS sensor and reverse & high clutch drum

• Foreign material passing between OSS sensor and parking gear

• Physical damage of reverse & high clutch drum or parking gear

2. Repair or replace as necessary.

Did you find and correct the condition? —

Go to Step 13 Go to Step 7

7 1. Place the selector lever in D range.

2. Observe the Low & Reverse Brake Pressure Switch, 2-4 Brake Pressure Switch and High

Clutch Pressure Switch parameter with a scan

tool. Refer to Clutch, Brake, Solenoid and

Pressure Switch Logic table.

Does the each transmission fluid pressure (TFP)

switch display match each selected gear range? —

Go to Step 8 Refer to DTC

P1853, P1858 or P1863

8 Perform the line pressure test. Refer to Line

Pressure Test.

Is the line pressure within specifications for each

selected gear range? —

Go to Step 9 Refer to appropriate

instructions in the

Line Pressure Test

Step

Action Value(s)Yes No

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 4339 of 6020

TRANSMISSION CONTROL SYSTEM (JR405E) 7A2-55

DTC P0748 (Flash Code 35)

Circuit Description

The pressure control (PC) solenoid valve is installed to

the lower part of the valve body assembly. It controls

the transmission fluid supply to the pressure regulator

spool valve in the valve body. The TCM controls the

solenoid valve by ON/ OFF signal based on the vehicle

running conditions. The TCM turns ON the solenoid

valve when a lower line pressure is required and turns

OFF when a higher line pressure is required. With the

operation of this solenoid valve, the operation and shift

of the hydraulic circuit in the transmission can be

performed smoothly. The PC solenoid valve is

controlled according to the range position, speed

sensor signals, transmission fluid temperature signal

and the accelerator pedal position signal. The TCM

monitors the PC solenoid valve operating status

through the feedback circuit. If the TCM detects an

improper voltage level on the control circuit, this DTC

will set.

Condition for Running the DTC • The ignition switch is ON. Condition for Setting the DTC

• The TCM detects an open circuit or short circuit on the PC solenoid valve control circuit.

Action Taken When the DTC Sets • The TCM blinks the Check Trans lamp when the diagnostic runs and fails.

• The TCM stops PC solenoid valve.

Condition for Clearing the DTC • The TCM turns OFF the Check Trans lamp when the diagnostic runs and does not fail at next

ignition cycle.

• A current DTC clears when the diagnostic runs and does not fail at next ignition cycle.

Diagnostic Aids • If an intermittent condition is suspected, refer to Intermittent Conditions in this section.

Schematic Reference: Transmission Controls

Schematics

Connector End View Reference: Transmission

Controls Connector End Views or TCM Connector End

Views

Circuit/ System Testing DTC P0748

Step Action Value(s)Yes No

1 Did you perform the Diagnostic System Check -

Transmission Controls? —

Go to Step 2 Go to Diagnostic

System Check - Transmission Controls

2 1. Install a scan tool.

2. Perform the Pressure Control (PC) Solenoid control with a scan tool.

3. Command the solenoid valve ON and OFF.

Does the PC solenoid valve click with each

command? —

Go to Diagnostic Aids Go to Step 3

3 1. Turn OFF the ignition.

2. Disconnect the in-line harness connector (E- 54) near the transmission range switch.

3. Connect a test lamp between the control circuit (pin 6 of E-54 female side) and a known

good ground.

4. Turn ON the ignition, with the engine OFF.

5. Perform the PC Solenoid control with a scan tool.

6. Command the solenoid valve ON and OFF.

Does the test lamp turn ON and OFF with each

command? —

Go to Step 8 Go to Step 4

4 Does the test lamp remain illuminated with each

command? —

Go to Step 5 Go to Step 6

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 4340 of 6020

7A2-56 TRANSMISSION CONTROL SYSTEM (JR405E)

51. Test the control circuit between the TCM (pin

23 of C-95) and the in-line harness connector

(pin 6 of E-54 female side) for a short to

battery or ignition voltage.

2. Repair the circuit(s) as necessary.

Did you find and correct the condition? —

Go to Step 12 Go to Step 11

6 1. Test the control circuit between the TCM (pin

23 of C-95) and the in-line harness connector

(pin 6 of E-54 female side) for the following

conditions:

• An open circuit

• A short to ground

• High resistance

2. Repair the circuit(s) as necessary.

Did you find and correct the condition? —

Go to Step 12 Go to Step 7

7 1. Turn OFF the ignition.

2. Disconnect the TCM harness connector.

3. Inspect for an intermittent and for a poor connection at the harness connector of the

TCM (pin 23 of C-95).

4. Repair the connection(s) as necessary.

Did you find and correct the condition? —

Go to Step 12 Go to Step 11

8 1. Inspect for an intermittent and for a poor

connection at the in-line harness connector

(pin 6 of E-54).

2. Repair the connection(s) as necessary.

Did you find and correct the condition? —

Go to Step 12 Go to Step 9

9 1. Remove the transmission oil pan. Refer to

repair instructions (On-Vehicle Service).

2. Inspect the PC solenoid valve for the following conditions:

• Physical damage of solenoid valve

• Loose or improper installation of solenoid valve

3. Inspect for an intermittent and for a poor connection at the in-line harness connector.

4. Test the control circuit between the PC solenoid valve and the in-line harness

connector (pin 6 of E-54 male side) for the

following conditions:

• An open circuit

• A short to ground

• A short to the other solenoid valve circuit

• High resistance

5. Repair the connection(s) or circuit(s) as necessary.

Did you find and correct the condition? —

Go to Step 12 Go to Step 10

10 Replace the PC solenoid valve. Refer to repair

instructions (On-Vehicle Service).

Did you complete the replacement? —

Go to Step 12 —

Step

Action Value(s)Yes No

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 4342 of 6020

7A2-58 TRANSMISSION CONTROL SYSTEM (JR405E)

DTC P0753 (Flash Code 31)

Circuit Description

The low & reverse brake solenoid valve controls fluid

acting on spool valves in the low & reverse brake

hydraulic circuits, which then controls low & reverse

brake apply and release. The solenoid valve is installed

to the lower part of the valve body assembly. The TCM

controls the solenoid valve by a duty cycle (pulse width

modulation [PWM]) signal based on the commanded

gear position. The solenoid valve provides a smooth

gearshift by operating on a duty cycle percentage of

ON time. The TCM monitors the low & reverse brake

solenoid valve operating status through the feedback

circuit. If the TCM detects an improper voltage level on

the control circuit, this DTC will set.

Condition for Running the DTC • The ignition switch is ON.

Condition for Setting the DTC • The TCM detects an open circuit or short circuit on the low & reverse brake solenoid valve control

circuit.

Action Taken When the DTC Sets • The TCM blinks the Check Trans lamp when the diagnostic runs and fails.

During the vehicle running;

• The TCM holds the last gear position when the diagnostic runs and fails. • The TCM stops low & reverse brake solenoid

valve.

• The TCM inhibits lock up control.

After the vehicle stopped;

• The TCM stops all shift solenoid valves and fixes to the 3rd gear. If a fail-safe valve problem is

detected, the shift solenoid valves are not stopped

but gear is fixed to the 3rd gear.

• The TCM stops PC solenoid valve.

Condition for Clearing the DTC • The TCM turns OFF the Check Trans lamp when the diagnostic runs and does not fail at next

ignition cycle.

• A current DTC clears when the diagnostic runs and does not fail at next ignition cycle.

Diagnostic Aids • If an intermittent condition is suspected, refer to Intermittent Conditions in this section.

• Use the Clutch, Brake, Solenoid and Pressure Switch Logic table to verify each component works

properly within the selected gear range.

Schematic Reference: Transmission Controls

Schematics

Connector End View Reference: Transmission

Controls Connector End Views or TCM Connector End

Views

Circuit/ System Testing DTC P0753

Step Action Value(s)Yes No

1 Did you perform the Diagnostic System Check -

Transmission Controls? —

Go to Step 2 Go to Diagnostic

System Check - Transmission Controls

2 1. Install a scan tool.

2. Turn OFF the ignition for 30 seconds.

3. Lift the driving wheels or drive the vehicle while observing the DTC Information with a

scan tool.

Is DTC P1875 also set? —

Go to DTC P1875 Go to Step 3

3 1. Park the vehicle.

2. Turn ON the ignition, with the engine OFF.

3. Perform the Low & Reverse Brake Solenoid control with a scan tool.

4. Command the solenoid valve ON and OFF.

Does the low & reverse brake solenoid valve click

with each command? —

Go to Diagnostic Aids Go to Step 4

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 4343 of 6020

TRANSMISSION CONTROL SYSTEM (JR405E) 7A2-59

41. Turn OFF the ignition.

2. Disconnect the in-line harness connector (E- 54) near the transmission range switch.

3. Connect a test lamp between the control circuit (pin 5 of E-54 female side) and a known

good ground.

4. Turn ON the ignition, with the engine OFF.

5. Perform the Low & Reverse Brake Solenoid control with a scan tool.

6. Command the solenoid valve ON and OFF.

Does the test lamp turn ON and OFF with each

command? —

Go to Step 9 Go to Step 5

5 Does the test lamp remain illuminated with each

command? —

Go to Step 6 Go to Step 7

6 1. Test the control circuit between the TCM (pin 6

of C-95) and the in-line harness connector (pin

5 of E-54 female side) for a short to battery or

ignition voltage.

2. Repair the circuit(s) as necessary.

Did you find and correct the condition? —

Go to Step 13 Go to Step 12

7 1. Test the control circuit between the TCM (pin 6

of C-95) and the in-line harness connector (pin

5 of E-54 female side) for the following

conditions:

• An open circuit

• A short to ground

• High resistance

2. Repair the circuit(s) as necessary.

Did you find and correct the condition? —

Go to Step 13 Go to Step 8

8 1. Turn OFF the ignition.

2. Disconnect the TCM harness connector.

3. Inspect for an intermittent and for a poor connection at the harness connector of the

TCM (pin 6 of C-95).

4. Repair the connection(s) as necessary.

Did you find and correct the condition? —

Go to Step 13 Go to Step 12

9 1. Inspect for an intermittent and for a poor

connection at the in-line harness connector

(pin 5 of E-54).

2. Repair the connection(s) as necessary.

Did you find and correct the condition? —

Go to Step 13 Go to Step 10

Step

Action Value(s)Yes No

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 4344 of 6020

7A2-60 TRANSMISSION CONTROL SYSTEM (JR405E)

101. Remove the transmission oil pan. Refer to

repair instructions (On-Vehicle Service).

2. Inspect the low & reverse brake solenoid valve for the following conditions:

• Physical damage of solenoid valve

• Loose or improper installation of solenoid valve

3. Inspect for an intermittent and for a poor connection at the harness connector of the

low & reverse brake solenoid valve or in-line

harness connector.

4. Inspect for an intermittent and for a poor connection of ground wire.

5. Test the control circuit between the low & reverse brake solenoid valve and the in-line

harness connector (pin 5 of E-54 male side)

for the following conditions:

• An open circuit

• A short to ground

• A short to the other solenoid valve circuit

• High resistance

6. Repair the connection(s) or circuit(s) as necessary.

Did you find and correct the condition? —

Go to Step 13 Go to Step 11

11 Replace the low & reverse brake solenoid valve.

Refer to repair instructions (On-Vehicle Service).

Did you complete the replacement? —

Go to Step 13 —

12 Important:

Replacement TCM must be

programmed.

Replace the TCM. Refer to TCM Replacement.

Did you complete the replacement? —

Go to Step 13 —

13 1. Reconnect all previously disconnected

components or harness connector(s).

2. Clear the DTCs with a scan tool.

3. Turn OFF the ignition for 30 seconds.

4. Start the engine.

5. Lift the driving wheels or drive the vehicle while observing the DTC Information with a

scan tool.

Did the DTC fail this ignition? —

Go to Step 4 Go to Step 14

14 Observe the DTC Information with a scan tool.

Are there any DTCs that you have not diagnosed? —

Go to DTC List System OK

Step

Action Value(s)Yes No

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007