fuel type ISUZU KB P190 2007 Workshop Repair Manual

[x] Cancel search | Manufacturer: ISUZU, Model Year: 2007, Model line: KB P190, Model: ISUZU KB P190 2007Pages: 6020, PDF Size: 70.23 MB

Page 3582 of 6020

Engine Management – V6 – Service Operations Page 6C1-3–58

Engine Oil Level and Temperature Sensor

Level sensor type ....................................... Magnetic reed switch

Temperature sensor type .......................... Negative temperature

................................................................... coefficient thermistor

Engine Oil Temperature Vs Resistance

Temperature °C Resistance – Ohms ( Ω)

0 7570 – 8000

20 2351 – 2649

30 2225 – 2375

40 1118 – 1231

50 1050 – 1150

80 380 – 470

100 270 – 290

Evaporative Emission (EVAP) Canister Purge Valve

Type .............................................................................. Solenoid

Resistance @ 20°C...................................................... 24 – 28 Ω

Operating voltage................................................... 12.0 – 16.0 V

Engine Firing Order ..................................................................... 1, 2, 3, 4, 5, 6

Fuel Injector

Type .............................................................................. Solenoid

Fuel Injector Resistance @ 20°C ........................... 11.4 – 12.6 Ω

Heated Oxygen Sensor (HO2S) – Four wire

Type ...................................................... Four wire, planar sensor

Operating range (greater than 360°C) .................. 10 – 1000 mV

Closed loop operating range ................................. 300 – 600 mV

Heater resistance @ 20°C ....................................... 8.0 – 10.0 Ω

Heated Oxygen Sensor (HO2S) – Six W ire

Type ....................................... Six wire, wide band planar sensor

Heater resistance @ 20°C ....................................... 8.0 – 10.0 Ω

Intake Air Temperature (IAT) Sensor

Type .......................................................... Negative temperature

.................................................................. Coefficient thermistor

Intake Air Temperature Vs Resistance

Temperature °C Resistance – Ohms ( Ω)

-40 35140 – 43760

-20 12660 – 15120

-10 7943 – 9307

0 5119 – 5892

20 2290 – 2551

25 1900 –2100

40 1096 –1238

60 565 – 654

80 312 – 370

100 184 – 222

120 114 –141

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3863 of 6020

Automatic Transmission – 4L60E – Electrical Diagnosis Page 7C2–77

Step Action Yes No

When all diagnosis and repairs are completed, check the system for correct operation.

4.25 DTC P0788 – 3-2 Shift Solenoid Control

Circuit High Voltage

DTC Description

This diagnostic procedure supports DTC P0788 3-2 Shift Solenoid (SS) Control Circuit High Voltage.

Circuit Description

The 3-2 shift solenoid (SS) valve is a normally-closed, 3-port, on/off device that controls the 3-2 downshift. The solenoid

attaches to the control valve body within the transmission. The solenoid receives ignition voltage through the ignition 1

circuit. The transmission control module (TCM) controls the solenoid by providing a ground path on the 3-2 shift solenoid

valve control circuit. During a 3-2 downshift, the 2-4 band applies as the 3-4 clutch releases. The TCM varies the timing

between the 3-4 clutch release and the 2-4 band apply depending on the vehicle speed and the throttle position.

When the TCM detects a continuous short to voltage in the 3-2 shift solenoid valve control circuit, then DTC P0788 sets.

DTC P0788 is a type A DTC.

Refer to 2 W iring Diagrams and Connector Chart to aid in diagnosis.

Conditions for Running the DTC

• The system voltage is 10 – 18 V.

• The engine speed is 450 r.p.m. for 5 seconds.

• The engine is not in fuel cut off.

Conditions for Setting the DTC

DTC P0788 sets if the TCM commands the solenoid on and the voltage feedback remains high, battery voltage.

Action Taken When the DTC Sets

• The TCM requests the ECM to illuminate the MIL during the second consecutive trip in which the Conditions for

Setting the DTC are met.

• The TCM commands maximum line pressure.

• The TCM freezes transmission adaptive functions.

• The TCM commands 3rd gear.

• The TCM inhibits TCC engagement.

• At the time of the first failure, the TCM records the operating conditions when the conditions for setting the DTC are

met. The TCM stores this information as a Failure Record.

• At the time of the second failure, the ECM records the operating conditions when the conditions for setting the DTC

are met. The ECM stores this information as a Freeze Frame.

• The TCM stores DTC P0788 in TCM history during the second consecutive trip in which the conditions for setting

the DTC are met.

Conditions for Clearing the DTC

• The ECM turns off the MIL after the fourth consecutive drive trip in which the TCM does not send a MIL illumination

request.

• Tech 2 can clear the DTC.

• The TCM clears the DTC from TCM history if the vehicle completes 40 warm-up cycles without a non-emission

related diagnostic fault occurring.

• The TCM cancels the DTC default actions when the ignition is off long enough to power down the TCM.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 4117 of 6020

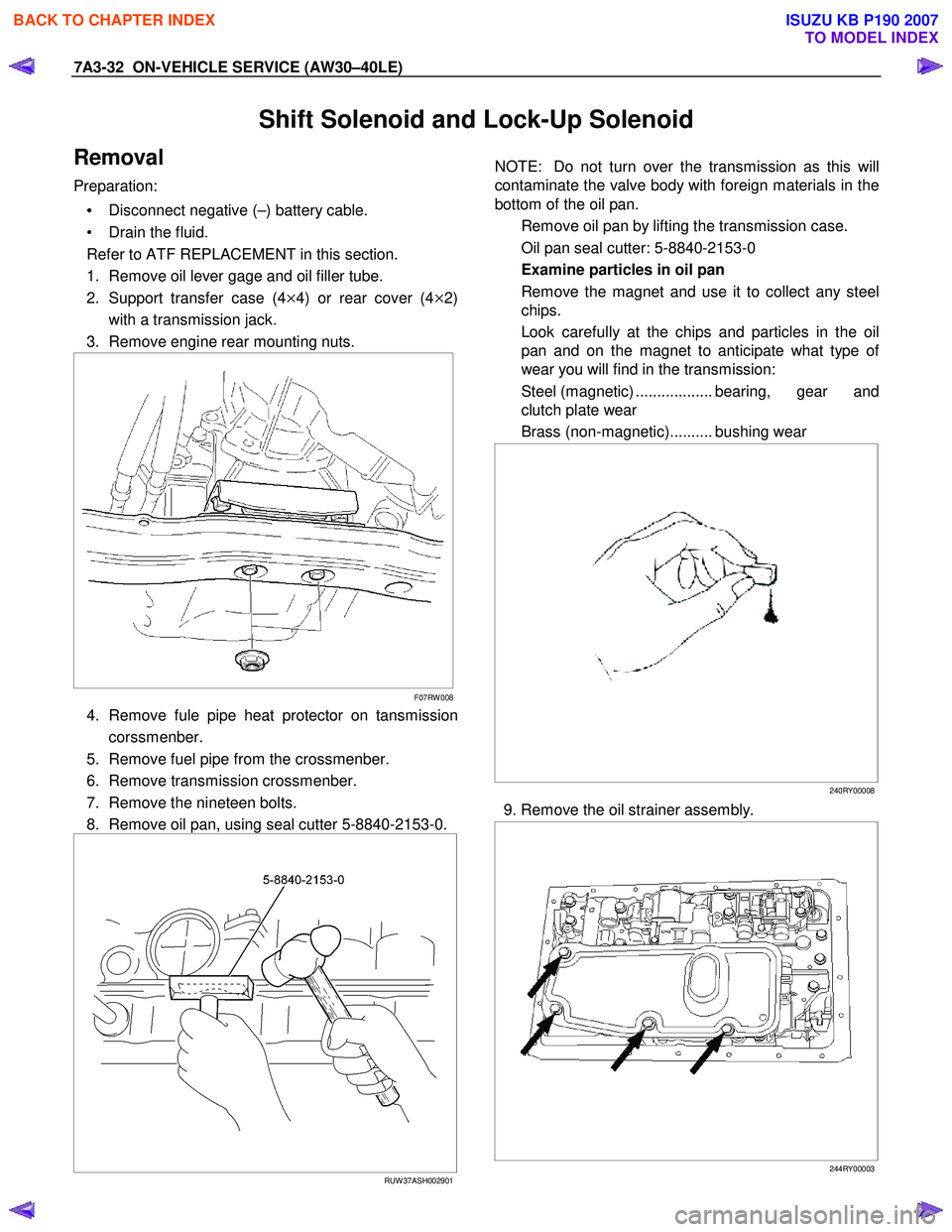

7A3-32 ON-VEHICLE SERVICE (AW30–40LE)

Shift Solenoid and Lock-Up Solenoid

Removal

Preparation:

• Disconnect negative (–) battery cable.

• Drain the fluid.

Refer to ATF REPLACEMENT in this section.

1. Remove oil lever gage and oil filler tube.

2. Support transfer case (4

×4) or rear cover (4×2)

with a transmission jack.

3. Remove engine rear mounting nuts.

F07RW 008

4. Remove fule pipe heat protector on tansmission

corssmenber.

5. Remove fuel pipe from the crossmenber.

6. Remove transmission crossmenber.

7. Remove the nineteen bolts.

8. Remove oil pan, using seal cutter 5-8840-2153-0.

RUW 37ASH002901

NOTE: Do not turn over the transmission as this will

contaminate the valve body with foreign materials in the

bottom of the oil pan.

Remove oil pan by lifting the transmission case.

Oil pan seal cutter: 5-8840-2153-0

Examine particles in oil pan

Remove the magnet and use it to collect any steel

chips.

Look carefully at the chips and particles in the oil

pan and on the magnet to anticipate what type o

f

wear you will find in the transmission:

Steel (magnetic) .................. bearing, gear and

clutch plate wear

Brass (non-magnetic).......... bushing wear

240RY00008

9. Remove the oil strainer assembly.

244RY00003

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 5759 of 6020

CAB 10-1

SECTION 10

CAB

TABLE OF CONTENTS

PAGE

Windshield ..................................................................................................................... .... 10- 2

Rear Window Assembly .................................................................................................... 10- 6

Front Door Assembly ........................................................................................................ 10- 9

Rear Door Assembly (Crew Cab) ..................................................................................... 10- 19

Instrument Panel ............................................................................................................... 10- 27

Floor Console .................................................................................................................. .. 10- 35

Console Box (Without Floor Console) ............................................................................. 10- 39

Headlining ..................................................................................................................... ..... 10- 40

Interior Trim Panels ........................................................................................................... 10- 45

Fuel Filler Lid Opener Lever/Cable .................................................................................. 10- 56

Quarter Glass (Extend Cab).............................................................................................. 10- 71

Font Seat ...................................................................................................................... ...... 10- 72

Rear Seat (Crew Cab) ........................................................................................................ 10- 74

Jump Seat (Extend Cab) ................................................................................................... 10- 75

Front Seat Belt ................................................................................................................ ... 10- 76

Rear Seat Belt (Crew Cab) ................................................................................................ 10- 80

Rear Seat Belt (Extend Cab) ............................................................................................. 10- 84

Front Wheel Extension (A type) ....................................................................................... 10- 87

Front Wheel Extension (B type) ....................................................................................... 10- 88

Rear Wheel Extension (A type)......................................................................................... 10- 89

Rear Wheel Extension (B type)......................................................................................... 10- 90

Tail Gate Assembly ........................................................................................................... 10 - 91

TO MODEL INDEX

BACK TO MAIN INDEX

ISUZU KB P190 2007