fuel type ISUZU KB P190 2007 Workshop Repair Manual

[x] Cancel search | Manufacturer: ISUZU, Model Year: 2007, Model line: KB P190, Model: ISUZU KB P190 2007Pages: 6020, PDF Size: 70.23 MB

Page 2442 of 6020

6E–272 ENGINE DRIVEABILITY AND EMISSIONS

FUEL INJECTOR

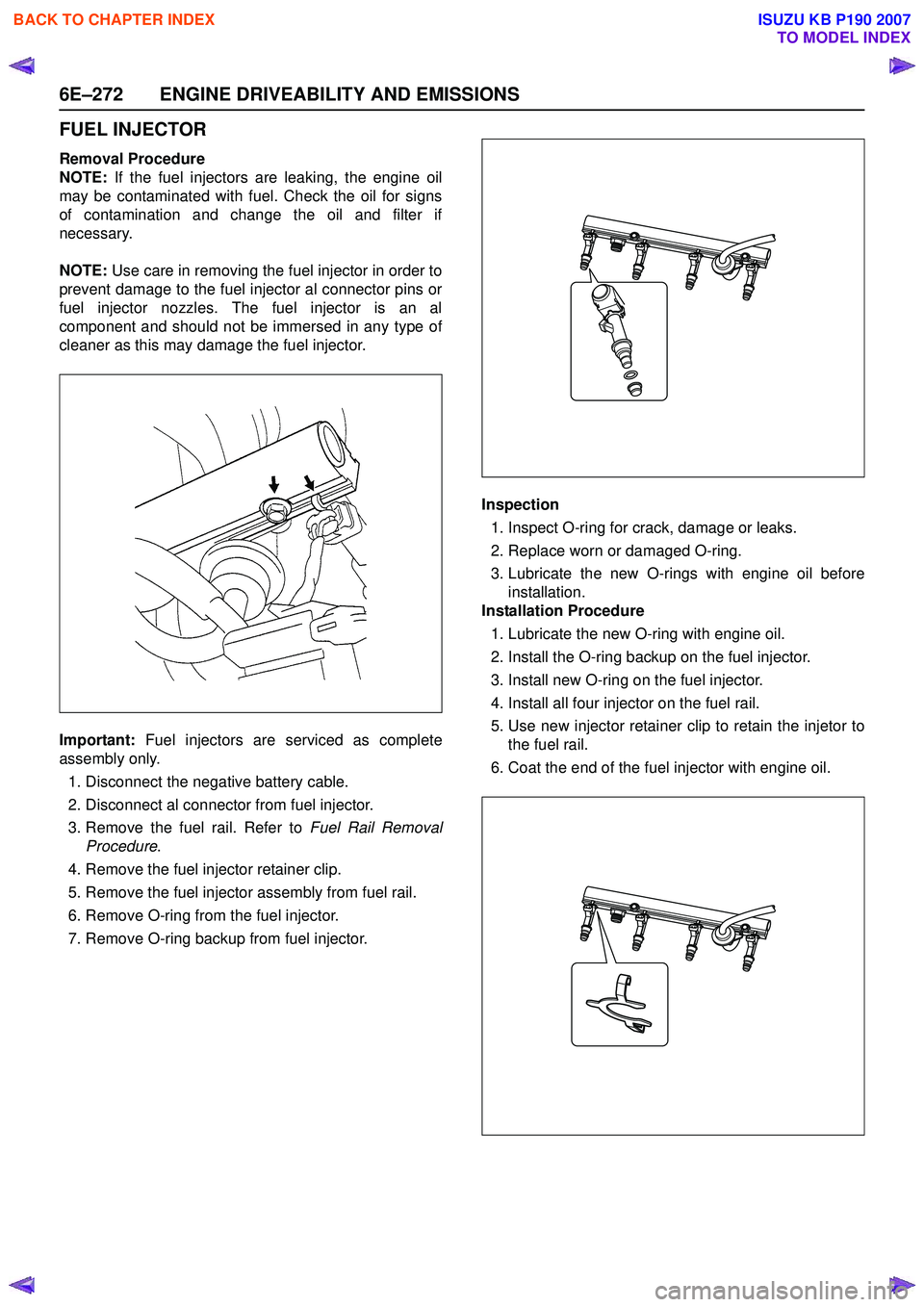

Removal Procedure

NOTE: If the fuel injectors are leaking, the engine oil

may be contaminated with fuel. Check the oil for signs

of contamination and change the oil and filter if

necessary.

NOTE: Use care in removing the fuel injector in order to

prevent damage to the fuel injector al connector pins or

fuel injector nozzles. The fuel injector is an al

component and should not be immersed in any type of

cleaner as this may damage the fuel injector.

Important: Fuel injectors are serviced as complete

assembly only.

1. Disconnect the negative battery cable.

2. Disconnect al connector from fuel injector.

3. Remove the fuel rail. Refer to Fuel Rail Removal

Procedure .

4. Remove the fuel injector retainer clip.

5. Remove the fuel injector assembly from fuel rail.

6. Remove O-ring from the fuel injector.

7. Remove O-ring backup from fuel injector. Inspection

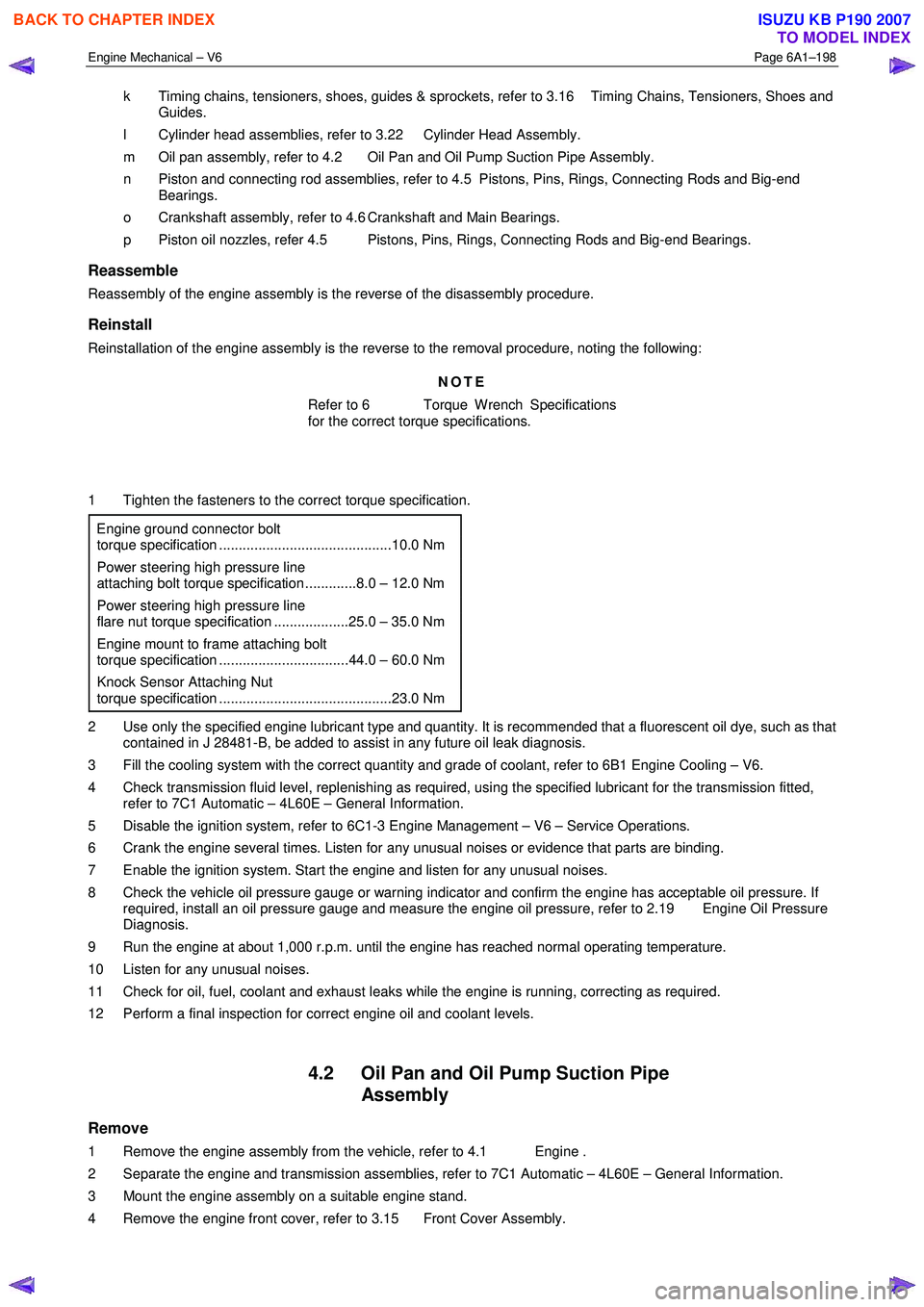

1. Inspect O-ring for crack, damage or leaks.

2. Replace worn or damaged O-ring.

3. Lubricate the new O-rings with engine oil before installation.

Installation Procedure

1. Lubricate the new O-ring with engine oil.

2. Install the O-ring backup on the fuel injector.

3. Install new O-ring on the fuel injector.

4. Install all four injector on the fuel rail.

5. Use new injector retainer clip to retain the injetor to the fuel rail.

6. Coat the end of the fuel injector with engine oil.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 2446 of 6020

6E–276 ENGINE DRIVEABILITY AND EMISSIONS

• Oil in the combustion chamber.

• The spark plug gap is not set correctly.

If spark plug fouling is excessive, check the fuel and al

system for possible causes of trouble. If fuel and al

system are normal, install spark plugs of a higher heat

range which have the same physical dimensions as the

original equipment spark plugs.

The following symptoms are characteristics of spark

plugs that are running too hot:

• Fuel mixture is too lean.

• Heat range is incorrect.

If vehicle usage does not conform to normal driving

conditions, a more suitable spark plug may be

substituted.

If fuel and al system are normal, in most cases of this

sort, the problem can be corrected by using a colder

type spark plug with the same physical dimensions as

the original equipment spark plug.

3. Check the gaskets for damage and replace if necessary.

4. Measure the spark plug gap. The specification is 1.0 to 1.1mm (0.039 to 0.043").

5. Adjust the spark gap by bending the grounded electrode. Installation

1. Tighten the spark plug to the 25N·m (2.5kgf·m).

2. Push the spark plug cable in until it snaps in.

Installation Procedure 1. Install the spark plug to the cylinder head.

2. Tighten the spark plug with specified tightening torque.

Tightening Torque

• Bolt: 25N·m (2.5kgf·m) 3. Connect the spark plug cable to the spark plug.

4. Connect the negative battery cable.

NOTE: Verify any DTCs (diagnosis Trouble Code) are

not stored after replacement.

Verify proper connection of spark plug cables for each

cylinders.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 2452 of 6020

ENGINE EXHAUST 6F-3

W hen inspecting or replacing exhaust system components,

make sure there is adequate clearance from all points on the

underbody to prevent overheating the floor pan and possible

damage to the passenger compartment insulation and trim

materials.

Check complete exhaust system and nearby body areas and

rear compartment lid for broken, damaged, missing or

mispositioned parts, open seams, holes, loose connections or

other deterioration which could permit exhaust fumes to seep

into the rear compartment or passenger compartment. Dust or

water in the rear compartment may be an indication of a

problem in one of these areas. Any faulty areas should be

corrected immediately.

Hangers

Various types of hangers are used to support exhaust

system(s). These include conventional rubber straps, rubber

rings, and rubber blocks.

The installation of exhaust system supports is very important,

as improperly installed supports can cause annoying vibrations

which can be difficult to diagnose.

Three Way Catalytic Converter (If applicable)

The three way catalytic converter is an emission control device

added to the exhaust system to reduce pollutants from the

exhaust gas stream.

CAUTION: The catalytic converter requires the use of

unleaded fuel only.

Periodic maintenance of the exhaust system is not required. If

the vehicle is raised for other service, it is advisable to check

the condition of the complete exhaust system.

A dual bed monolith catalytic converter is used in combination

with three way catalytic converter.

Catalytic Types:

Three way (Reduction/Oxidation) catalyst

The catalyst coating on the three way (reduction) converter

contains platinum and rhodium which lowers the levels of

nitrous oxide (NOx) as well as hydrocarbons (HC) and carbon

monoxide (Co).

Gasket

The gasket must be replaced whenever a new exhaust pipe,

muffler or catalytic converter is installed.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 2677 of 6020

Engine Mechanical – V6 Page 6A1–198

k Timing chains, tensioners, shoes, guides & sprockets, refer to 3.16 Timing Chains, Tensioners, Shoes and

Guides.

l Cylinder head assemblies, refer to 3.22 Cylinder Head Assembly.

m Oil pan assembly, refer to 4.2 Oil Pan and Oil Pump Suction Pipe Assembly.

n Piston and connecting rod assemblies, refer to 4.5 Pistons, Pins, Rings, Connecting Rods and Big-end Bearings.

o Crankshaft assembly, refer to 4.6 Crankshaft and Main Bearings.

p Piston oil nozzles, refer 4.5 Pistons, Pins, Rings, Connecting Rods and Big-end Bearings.

Reassemble

Reassembly of the engine assembly is the reverse of the disassembly procedure.

Reinstall

Reinstallation of the engine assembly is the reverse to the removal procedure, noting the following:

NOTE

Refer to 6 Torque Wrench Specifications

for the correct torque specifications.

1 Tighten the fasteners to the correct torque specification.

Engine ground connector bolt

torque specification ............................................10.0 Nm

Power steering high pressure line

attaching bolt torque specification .............8.0 – 12.0 Nm

Power steering high pressure line

flare nut torque specification ...................25.0 – 35.0 Nm

Engine mount to frame attaching bolt

torque specification .................................44.0 – 60.0 Nm

Knock Sensor Attaching Nut

torque specification ............................................23.0 Nm

2 Use only the specified engine lubricant type and quantity. It is recommended that a fluorescent oil dye, such as that contained in J 28481-B, be added to assist in any future oil leak diagnosis.

3 Fill the cooling system with the correct quantity and grade of coolant, refer to 6B1 Engine Cooling – V6.

4 Check transmission fluid level, replenishing as required, using the specified lubricant for the transmission fitted, refer to 7C1 Automatic – 4L60E – General Information.

5 Disable the ignition system, refer to 6C1-3 Engine Management – V6 – Service Operations.

6 Crank the engine several times. Listen for any unusual noises or evidence that parts are binding.

7 Enable the ignition system. Start the engine and listen for any unusual noises.

8 Check the vehicle oil pressure gauge or warning indicator and confirm the engine has acceptable oil pressure. If required, install an oil pressure gauge and measure the engine oil pressure, refer to 2.19 Engine Oil Pressure

Diagnosis.

9 Run the engine at about 1,000 r.p.m. until the engine has reached normal operating temperature.

10 Listen for any unusual noises.

11 Check for oil, fuel, coolant and exhaust leaks while the engine is running, correcting as required.

12 Perform a final inspection for correct engine oil and coolant levels.

4.2 Oil Pan and Oil Pump Suction Pipe Assembly

Remove

1 Remove the engine assembly from the vehicle, refer to 4.1 Engine .

2 Separate the engine and transmission assemblies, refer to 7C1 Automatic – 4L60E – General Information.

3 Mount the engine assembly on a suitable engine stand.

4 Remove the engine front cover, refer to 3.15 Front Cover Assembly.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3030 of 6020

Engine Mechanical – V6 Page 6A1–253

Page 6A1–253

k Timing chains, tensioners, shoes, guides & sprockets, refer to 3.16 Timing Chains, Tensioners, Shoes and

Guides .

l Cylinder head assemblies, refer to 3.22 Cylinder Head Assembly.

m Oil pan assembly, refer to 4.2 Oil Pan and Oil Pump Suction Pipe Assembly .

n Piston and connecting rod assemblies, refer to 4.5 Pistons, Pins, Rings, Connecting Rods and Big-end

Bearings .

o Crankshaft assembly, refer to 4.6 Crankshaft and Main Bearings.

p Piston oil nozzles, refer 4.5 Pistons, Pins, Rings, Connecting Rods and Big-end Bearings .

Reassemble

Reassembly of the engine assembly is the reverse of the disassembly procedure.

Reinstall

Reinstallation of the engine assembly is the revers e to the removal procedure, noting the following:

NOTE

Refer to 6 Torque Wrench Specifications for the

correct torque specifications.

1 Tighten the fasteners to the co rrect torque specification.

Engine ground connector bolt

torque specificat ion ............................................ 10.0 Nm

Power steering high pressure line

attaching bolt torque specification ............. 8.0 – 12.0 Nm

Power steering high pressure line

flare nut torque specif ication ................... 25. 0 – 35.0 Nm

Engine mount to frame attaching bolt

torque specification ................................. 44. 0 – 60.0 Nm

Knock Sensor Attaching Nut

torque specification ............................................ 23.0 Nm

2 Use only the specified engine lubricant type and quantity. It is recommended that a fluorescent oil dye, such as that

contained in J 28481-B, be added to assist in any future oil leak diagnosis.

3 Fill the cooling system with the corre ct quantity and grade of coolant, refer to Section 6B1 Engine Cooling – V6.

4 Check transmission fluid level, replenishing as required, using the specified lubricant for the transmission fitted,

refer to Section 7C1 Automatic – 4L60E – General Information .

5 Disable the ignition system, refer to Section 6C1-3 Engine Management – V6 – Service Operations.

6 Crank the engine several times. Listen for any unusual noises or evidence that parts are binding.

7 Enable the ignition system. Start t he engine and listen for any unusual noises.

8 Check the vehicle oil pressure gauge or warning indica tor and confirm the engine has acceptable oil pressure. If

required, install an oil pressure gauge and m easure the engine oil pressure, refer to 2.19 Engine Oil Pressure

Diagnosis .

9 Run the engine at about 1,000 r. p.m. until the engine has reached normal operating temperature.

10 Listen for any unusual noises.

11 Check for oil, fuel, coolant and exhaust leaks wh ile the engine is running, correcting as required.

12 Perform a final inspection for correct engine oil and coolant levels.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3205 of 6020

Fuel System – V6 Page 6C – 3

1 General Information

Description

Fuel is injected into the engine by separate fuel injectors that are mounted in the intake manifold (common chamber).

Fuel is supplied to the injectors under pressure from the fuel tank through the fuel lines and the fuel rail, which is

attached to the top of the common chamber.

A fuel pressure control valve is installed on the fuel rail to maintain fuel line pressure across the injectors under all

operating conditions. Fuel pressure is maintained by controlling the amount of fuel that is supplied from the fuel tank,

based on the demand of the engine via the engine control module (ECM).

Two interchangeable “O” rings are used on the fuel injector and must be replaced when the injectors are removed.

The Multiport Fuel Injection system utilizes an injection system where the injectors turn on at every crankshaft revolution.

The ECM controls the injector on time so that the correct amount of fuel is metered depending on driving conditions.

The V6 engine is designed to use only unleaded petrol.

Unleaded petrol must be used for correct emission control system operation and its use will also minimize spark plug

fouling and extend engine oil life.

Using leaded petrol can damage the emission control system and could void the vehicle warranty. All vehicles are

equipped with an Evaporative Emission Control System. The purpose of the system is to minimize the escape of fuel

vapours into the atmosphere.

Service Precautions

• Use extreme care when working on the fuel system and follow all safety precautions.

• W hen working on the fuel system, disconnect the battery ground cable except for tests where battery voltage is

required.

• Always keep a dry chemical (class B) fire extinguisher near the work area.

• Relace all fuel lines and fittings with the same type of line and fitting as those removed.

• Clean and inspect “O” rings carefully and replace if required.

• Always depressurize the fuel lines before servicing any fuel system components.

• Do not attempt any repairs on the fuel system until, all warnings and instructions, relating to that repair have been

read and ensure all notices and cautions are adhered to.

• Do not allow any naked frames or sparks near the work area when working on the fuel system.

• If draining of the fuel system is required, this should be done in a well ventilated area.

• Protect the fuel lines and associated parts from thermal damage, spattering when welding.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3234 of 6020

Fuel System – V6 Page 6C – 32

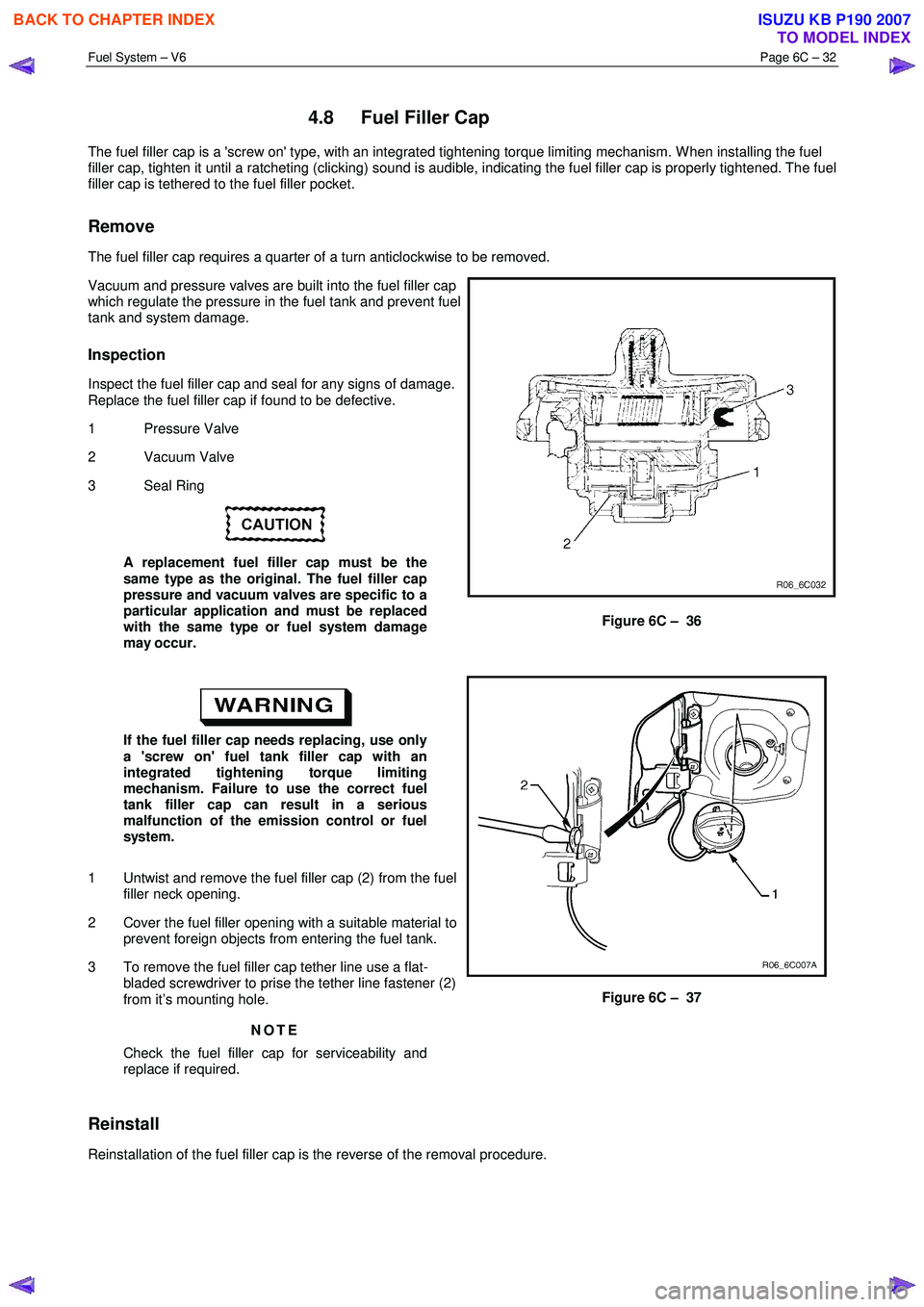

4.8 Fuel Filler Cap

The fuel filler cap is a 'screw on' type, with an integrated tightening torque limiting mechanism. W hen installing the fuel

filler cap, tighten it until a ratcheting (clicking) sound is audible, indicating the fuel filler cap is properly tightened. Th e fuel

filler cap is tethered to the fuel filler pocket.

Remove

The fuel filler cap requires a quarter of a turn anticlockwise to be removed.

Vacuum and pressure valves are built into the fuel filler cap

which regulate the pressure in the fuel tank and prevent fuel

tank and system damage.

Inspection

Inspect the fuel filler cap and seal for any signs of damage.

Replace the fuel filler cap if found to be defective.

1 Pressure Valve

2 Vacuum Valve

3 Seal Ring

A replacement fuel filler cap must be the

same type as the original. The fuel filler cap

pressure and vacuum valves are specific to a

particular application and must be replaced

with the same type or fuel system damage

may occur.

Figure 6C – 36

If the fuel filler cap needs replacing, use only

a 'screw on' fuel tank filler cap with an

integrated tightening torque limiting

mechanism. Failure to use the correct fuel

tank filler cap can result in a serious

malfunction of the emission control or fuel

system.

1 Untwist and remove the fuel filler cap (2) from the fuel filler neck opening.

2 Cover the fuel filler opening with a suitable material to prevent foreign objects from entering the fuel tank.

3 To remove the fuel filler cap tether line use a flat- bladed screwdriver to prise the tether line fastener (2)

from it’s mounting hole.

NOTE

Check the fuel filler cap for serviceability and

replace if required.

Figure 6C – 37

Reinstall

Reinstallation of the fuel filler cap is the reverse of the removal procedure.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3240 of 6020

Fuel System – V6 Page 6C – 38

5 Specifications

Fuel Tank Capacity:

............................................................................................................................... ...... 76 litres

Fuel Tank Material:

.......................................................................... 'W '-type high-density multi-layer polyethylene

Fuel Filler Location:

................................................................................................. Attached to the left side of t ray

Fuel Pump Type:

............................................................................................................................ Sin gle turbine

Pressure Regulator Location:

............................................................................................................................... . Engine bay

Fuel Pump Location:

............................................................................................................................... . In fuel tank

Fuel Pump Regulated Pressure:

............................................................................................................. approx. 410 kPa at idle

Minimum Fuel Pump Flow Capacity (at Regulated Pressure):

............................................................................................................ 2.95 L/min @ 13.5 v olts

Fuel Pump Current Draw (Steady State at Regulated Pressure):

................................................................................................................ 11.0 Amps maxim um

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3242 of 6020

Fuel System – V6 Page 6C – 40

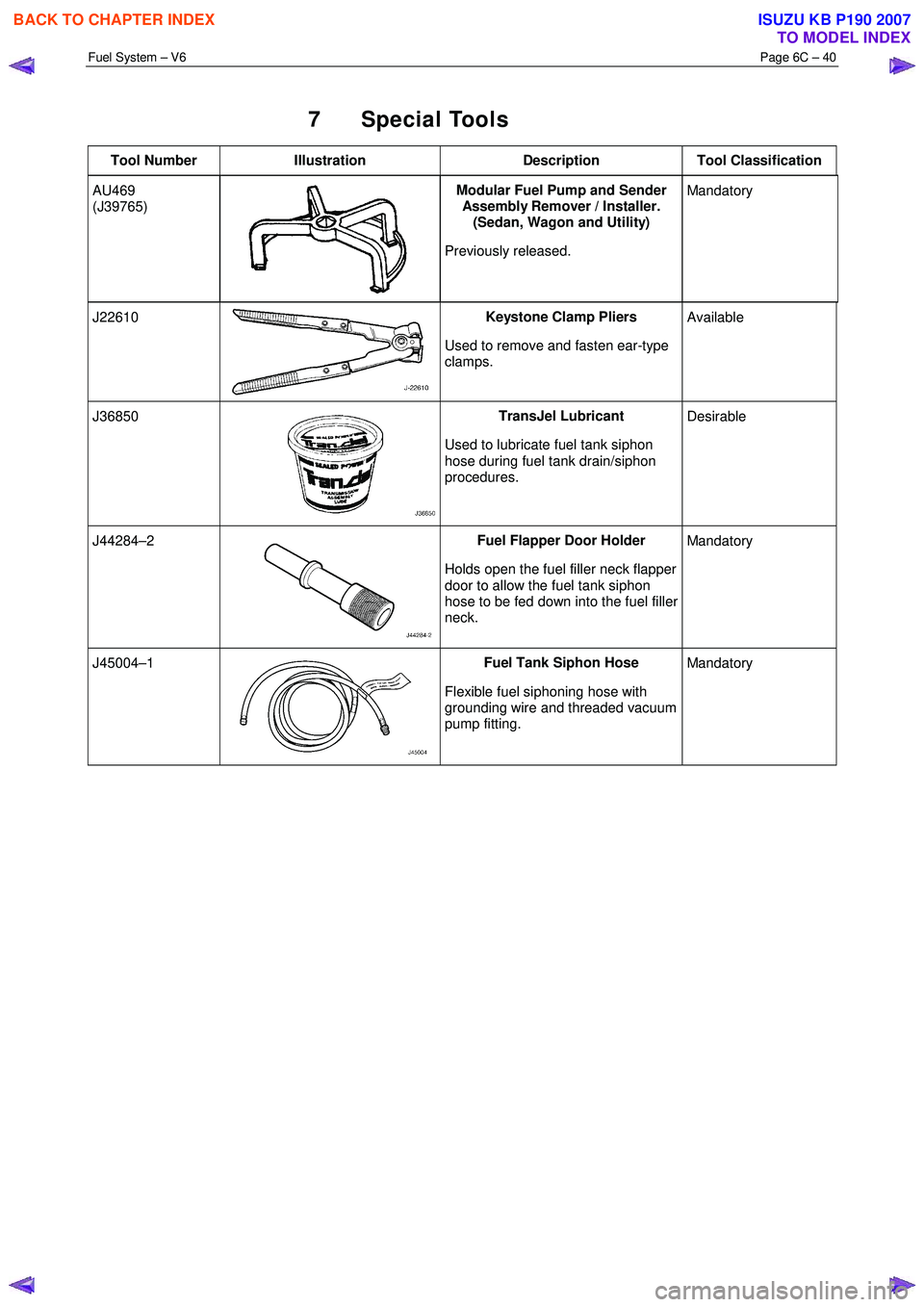

7 Special Tools

Tool Number Illustration Description Tool Classification

AU469

(J39765)

Modular Fuel Pump and Sender

Assembly Remover / Installer.

(Sedan, Wagon and Utility)

Previously released. Mandatory

J22610 Keystone Clamp Pliers

Used to remove and fasten ear-type

clamps. Available

J36850 TransJel Lubricant

Used to lubricate fuel tank siphon

hose during fuel tank drain/siphon

procedures. Desirable

J44284–2 Fuel Flapper Door Holder

Holds open the fuel filler neck flapper

door to allow the fuel tank siphon

hose to be fed down into the fuel filler

neck. Mandatory

J45004–1 Fuel Tank Siphon Hose

Flexible fuel siphoning hose with

grounding wire and threaded vacuum

pump fitting. Mandatory

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3269 of 6020

Engine Management – V6 – General Information Page 6C1-1–27

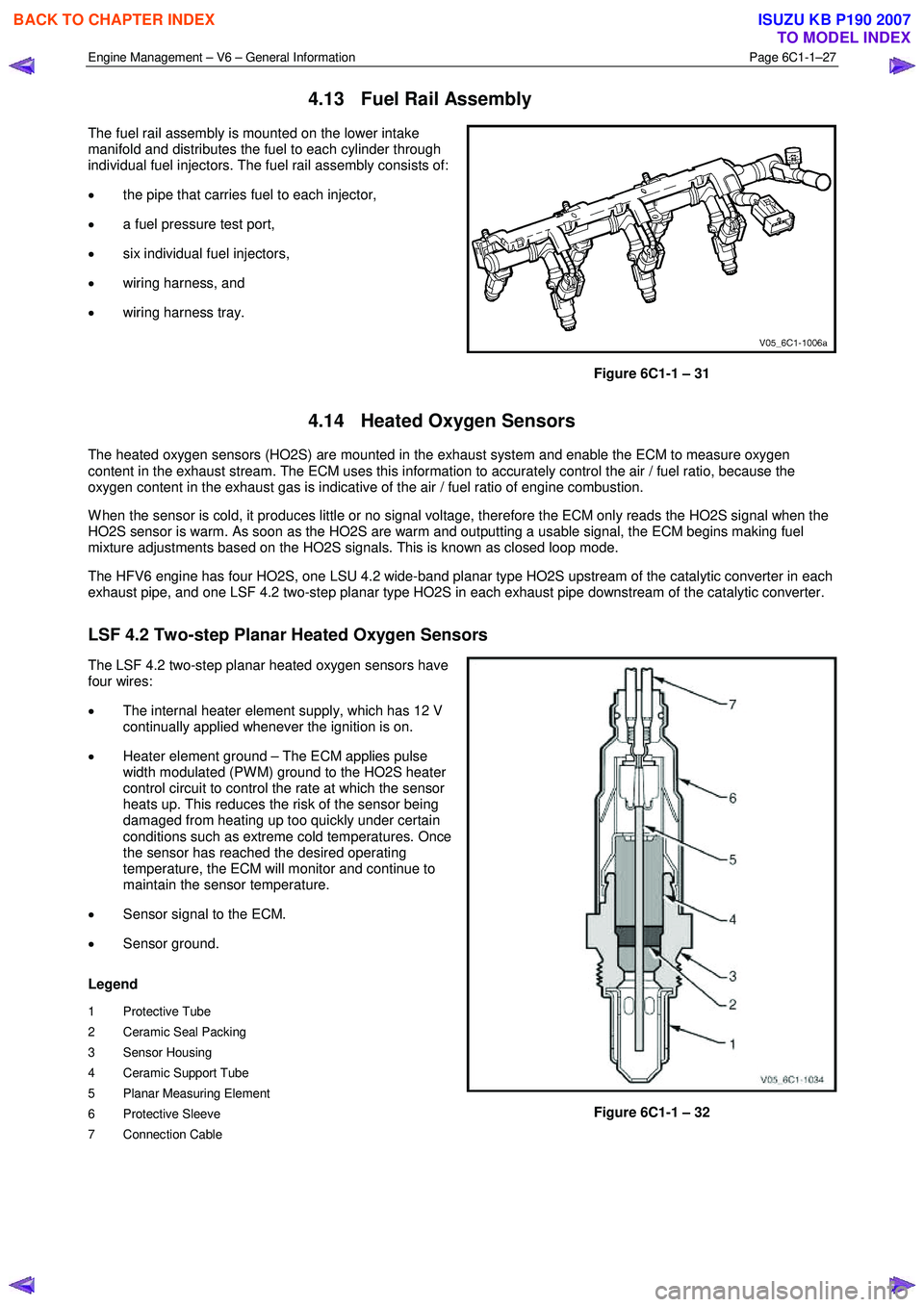

4.13 Fuel Rail Assembly

The fuel rail assembly is mounted on the lower intake

manifold and distributes the fuel to each cylinder through

individual fuel injectors. The fuel rail assembly consists of:

• the pipe that carries fuel to each injector,

• a fuel pressure test port,

• six individual fuel injectors,

• wiring harness, and

• wiring harness tray.

Figure 6C1-1 – 31

4.14 Heated Oxygen Sensors

The heated oxygen sensors (HO2S) are mounted in the exhaust system and enable the ECM to measure oxygen

content in the exhaust stream. The ECM uses this information to accurately control the air / fuel ratio, because the

oxygen content in the exhaust gas is indicative of the air / fuel ratio of engine combustion.

W hen the sensor is cold, it produces little or no signal voltage, therefore the ECM only reads the HO2S signal when the

HO2S sensor is warm. As soon as the HO2S are warm and outputting a usable signal, the ECM begins making fuel

mixture adjustments based on the HO2S signals. This is known as closed loop mode.

The HFV6 engine has four HO2S, one LSU 4.2 wide-band planar type HO2S upstream of the catalytic converter in each

exhaust pipe, and one LSF 4.2 two-step planar type HO2S in each exhaust pipe downstream of the catalytic converter.

LSF 4.2 Two-step Planar Heated Oxygen Sensors

The LSF 4.2 two-step planar heated oxygen sensors have

four wires:

• The internal heater element supply, which has 12 V

continually applied whenever the ignition is on.

• Heater element ground – The ECM applies pulse

width modulated (PW M) ground to the HO2S heater

control circuit to control the rate at which the sensor

heats up. This reduces the risk of the sensor being

damaged from heating up too quickly under certain

conditions such as extreme cold temperatures. Once

the sensor has reached the desired operating

temperature, the ECM will monitor and continue to

maintain the sensor temperature.

• Sensor signal to the ECM.

• Sensor ground.

Legend

1 Protective Tube

2 Ceramic Seal Packing

3 Sensor Housing

4 Ceramic Support Tube

5 Planar Measuring Element

6 Protective Sleeve

7 Connection Cable

Figure 6C1-1 – 32

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007