brake sensor ISUZU KB P190 2007 Workshop Repair Manual

[x] Cancel search | Manufacturer: ISUZU, Model Year: 2007, Model line: KB P190, Model: ISUZU KB P190 2007Pages: 6020, PDF Size: 70.23 MB

Page 4443 of 6020

TRANSMISSION CONTROL SYSTEM (JR405E) 7A2-159

Based on each transmission fluid pressure (TFP)

switch signal and each speed sensor signal and the

accelerator pedal angle, the duty cycle type shift

solenoid valve adjusts the clutch pressure to match the

engine load and vehicle running conditions. Controlling

the engagement and disengagement of the clutch and

brake pressure is directly and accurately controlled via

TCM, which is different to the conventional accumulator

type. Instead of the conventional system (On/ Off type

shift solenoid valve and shift valve), the combination of

the duty cycle type solenoid valve and the amplifier

(AMP) valve are used to adjust the clutch pressure to

match the engine load and vehicle driving conditions,

based on the signal from the TCM. Also, the TFP

switch provided in the fluid passage of the control valve

transmits to TCM, enabling the engagement and

disengagement control of the clutch and brake to be

directly and finely. When the gear is shifted from the

2nd to 3rd, 3rd to 4th, 4th to 3rd and 3rd to 2nd, the

clutch pressures on the engagement side and

disengagement side are simultaneously controlled. As

a result, engine racing or clutch drag is prevented

which enables a smooth and quick shift response.

Learning Control

Solenoid valve outputs

Low & reverse brake solenoid valve

2-4 brake solenoid valve

High clutch solenoid valve

Low clutch solenoid valve

TCM

Sensor inputs Input shaft speed (ISS) sensor

Output shaft speed (OSS) sensor

Transmission fluid temperature (TFT) sensor

Accelerator pedal position signal (via ECM)

Engine speed signal (via ECM)

Switch inputs

Low & reverse brake transmission fluid

pressure (TFP) switch

2-4 brake transmission fluid pressure (TFP)

switch

High clutch transmission fluid pressure (TFP)

switch

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 4470 of 6020

7A3-16 ON-VEHICLE SERVICE (JR405E)

SOLENOIDS, OIL PRESSURE SWITCH AND OIL TEMPERATURE

SENSOR

244L300003

Legend

1. High clutch oil pressure switch connector

(wire color: Gray)

2. 2-4 brake oil pressure switch connector

(wire color: Brown)

3. Low and reverse brake oil pressure switch connector (wire color: W hite)

4. Low and reverse brake duty solenoid connector

(wire color: Pink and W hite)

5. High clutch duty solenoid connector

(wire color: Green and Gray)

6. Lock-up duty solenoid connector

(wire color: Yellow and Black)

7. 2-4 brake duty solenoid connector

(wire color: Blue and Brown)

8. Low clutch duty solenoid connector

(wire color: Orange and Black)

9. Line pressure solenoid connector

(wire color: Pink)

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 4504 of 6020

UNIT REPAIR (JR405E) 7A4-27

Spring specifications

No. Valve nomenclature Free length

(mm / in) Outside

diameter

(mm / in) Linear

diameter

(mm / in) Number of

coils

14 Pressure relief 49.0 / 1.929 7.6 / 0.299 1.1 / 0.043 17.3

15 Pressure regulator 30.5 / 1.201 14.0 / 0.551 1.4 / 0.055 5.7

16 Low and reverse brake fail (A) 22.0 / 0.866 7.0 / 0.276 0.6 / 0.024 10.0

17 Fail 23.0 / 0.906 11.0 / 0.433 0.5 / 0.020 13.2

18 Low and reverse brake amp 19.5 / 0.768 7.9 / 0.311 0.5 / 0.020 6.9

19 2 – 4 brake fail (A) 24.8 / 0.976 8.5 / 0.335 0.9 / 0.035 7.8

20 Low clutch amp (B) 26.0 / 1.024 11.0 / 0.433 0.5 / 0.020 6.9

21

Torque converter relief More than 47.2

/ 1.858 9.2 / 0.362 1.6 / 0.063 20.2

22 2 – 4 brake solenoid accumulator 31.4 / 1.236 9.8 / 0.386 1.3 / 0.051 9.3

23 High clutch accumulator

51.0 / 2.008 6.5 / 0.256 0.8 / 0.031 23.5

Oil pressure switch

Apply compressed air (390 kPa/4.0 kgf/cm2/57 psi) to the oil

pressure switch to check the oil pressure switch continuity

between the connector and screw.

244L300011

Oil temperature sensor (harness assembly)

Check the oil temperature sensor resistance between harness

terminals 7 and 6 (ground).

Oil temperature sensor resistance: 2,400 ~

~~

~

2,600 ohms

(20 °

°°

°

C)

Solenoids

Measure the resistance of each solenoid.

Resistance:

Brown connector – 3.0 ∼

∼∼

∼

3.4 ohms (20 °

°°

°

C)

Gray connector – 12.0 ∼

∼∼

∼

13.2 ohms (20 °

°°

°

C)

White connector – 12.2 ∼

∼∼

∼

13.4 ohms (20 °

°°

°

C)

Reassembly steps

• Coat the parts with ATF before installing them.

• Install the control valve to the control valve lower body.

• Install the oil filter to the control valve lower body.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 5303 of 6020

ELECTRICAL-BODY AND CHASSIS 8A-365

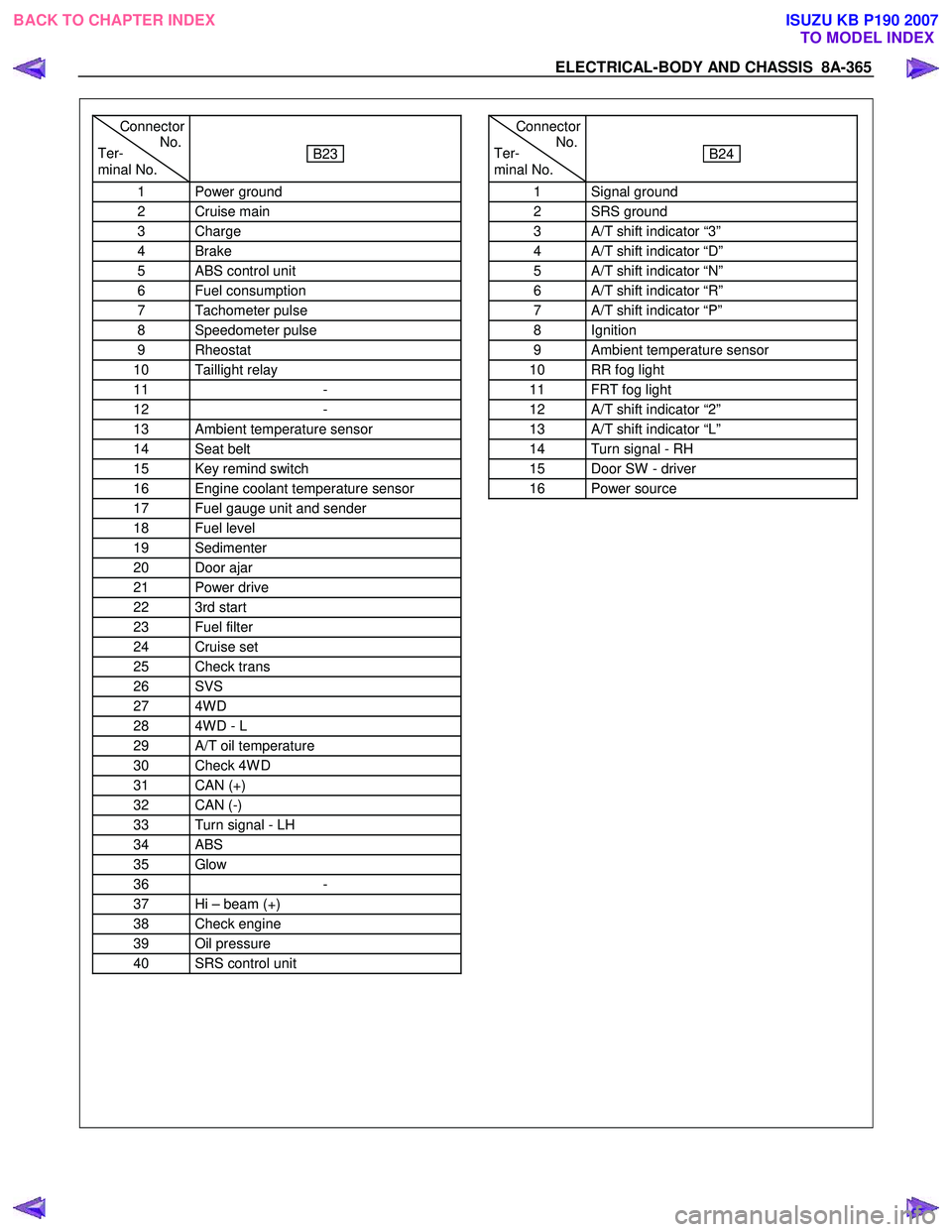

Connector

Ter- No.

minal No.

B23

1 Power ground

2 Cruise main

3 Charge

4 Brake

5 ABS control unit

6 Fuel consumption

7 Tachometer pulse

8 Speedometer pulse

9 Rheostat

10 Taillight relay

11 -

12 -

13 Ambient temperature sensor

14 Seat belt

15 Key remind switch

16 Engine coolant temperature sensor

17 Fuel gauge unit and sender

18 Fuel level

19 Sedimenter

20 Door ajar

21 Power drive

22 3rd start

23 Fuel filter

24 Cruise set

25 Check trans

26 SVS

27 4W D

28 4W D - L

29 A/T oil temperature

30 Check 4W D

31 CAN (+)

32 CAN (-)

33 Turn signal - LH

34 ABS

35 Glow

36 -

37 Hi – beam (+)

38 Check engine

39 Oil pressure

40 SRS control unit

Connector

Ter- No.

minal No.

B24

1 Signal ground

2 SRS ground

3 A/T shift indicator “3”

4 A/T shift indicator “D”

5 A/T shift indicator “N”

6 A/T shift indicator “R”

7 A/T shift indicator “P”

8 Ignition

9 Ambient temperature sensor

10 RR fog light

11 FRT fog light

12 A/T shift indicator “2”

13 A/T shift indicator “L”

14 Turn signal - RH

15 Door SW - driver

16 Power source

BACK TO CHAPTER INDEX TO MODEL INDEXISUZU KB P190 2007

Page 5304 of 6020

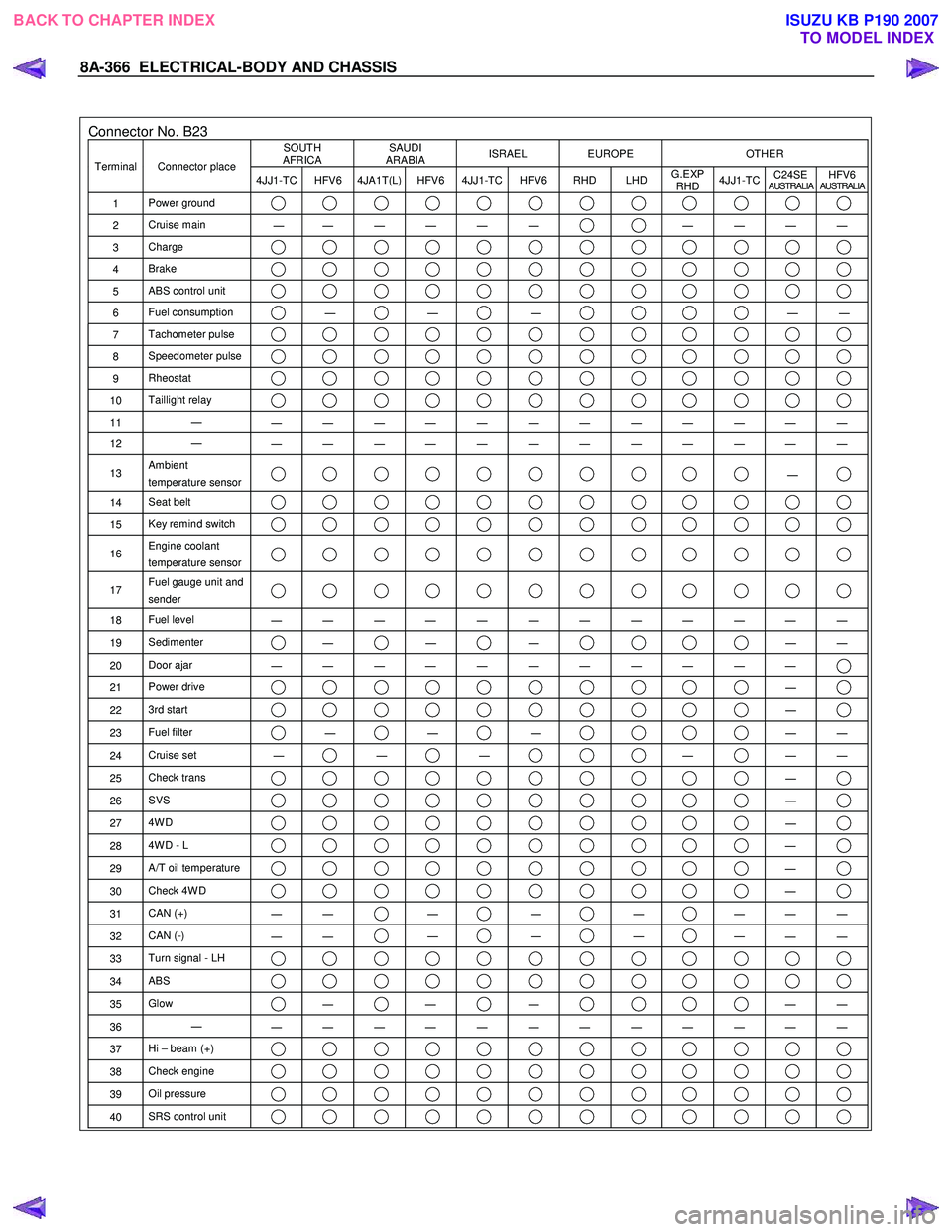

8A-366 ELECTRICAL-BODY AND CHASSIS

Connector No. B23 SOUTH

AFRICA SAUDI

ARABIA ISRAEL EUROPE OTHER

Terminal Connector place

4JJ1-TC HFV6 4JA1T(L) HFV6 4JJ1-TC HFV6 RHD LHD G.EXP

RHD 4JJ1-TC

C24SE

AUSTRALIAHFV6AUSTRALIA

1

Power ground

2 Cruise main

―

― ― ― ― ― ― ― ― ―

3

Charge

4 Brake

5 ABS control unit

6 Fuel consumption ―

―

―

―

―

7 Tachometer pulse

8 Speedometer pulse

9 Rheostat

10 Taillight relay

11 ―

― ― ― ― ― ― ― ― ― ― ― ―

12 ―

― ― ― ― ― ― ― ― ― ― ― ―

13 Ambient

temperature sensor ―

14 Seat belt

15 Key remind switch

16 Engine coolant

temperature sensor

17 Fuel gauge unit and

sender

18 Fuel level

― ― ― ― ― ― ― ― ― ― ― ―

19 Sedimenter ―

―

―

―

―

20 Door ajar

― ― ― ― ― ― ― ― ― ― ―

21 Power drive ―

22 3rd start ―

23 Fuel filter ―

―

―

―

―

24 Cruise set

― ―

―

―

―

―

25 Check trans ―

26 SVS ―

27 4W D ―

28 4W D - L ―

29 A/T oil temperature ―

30 Check 4W D ―

31 CAN (+)

― ― ―

―

―

― ― ―

32

CAN (-)

― ― ―

―

―

― ― ―

33

Turn signal - LH

34 ABS

35 Glow ―

―

―

―

―

36 ―

― ― ― ― ― ― ― ― ― ― ― ―

37 Hi – beam (+)

38 Check engine

39 Oil pressure

40 SRS control unit

BACK TO CHAPTER INDEX

TO MODEL INDEXISUZU KB P190 2007

Page 5307 of 6020

ELECTRICAL-BODY AND CHASSIS 8A-369

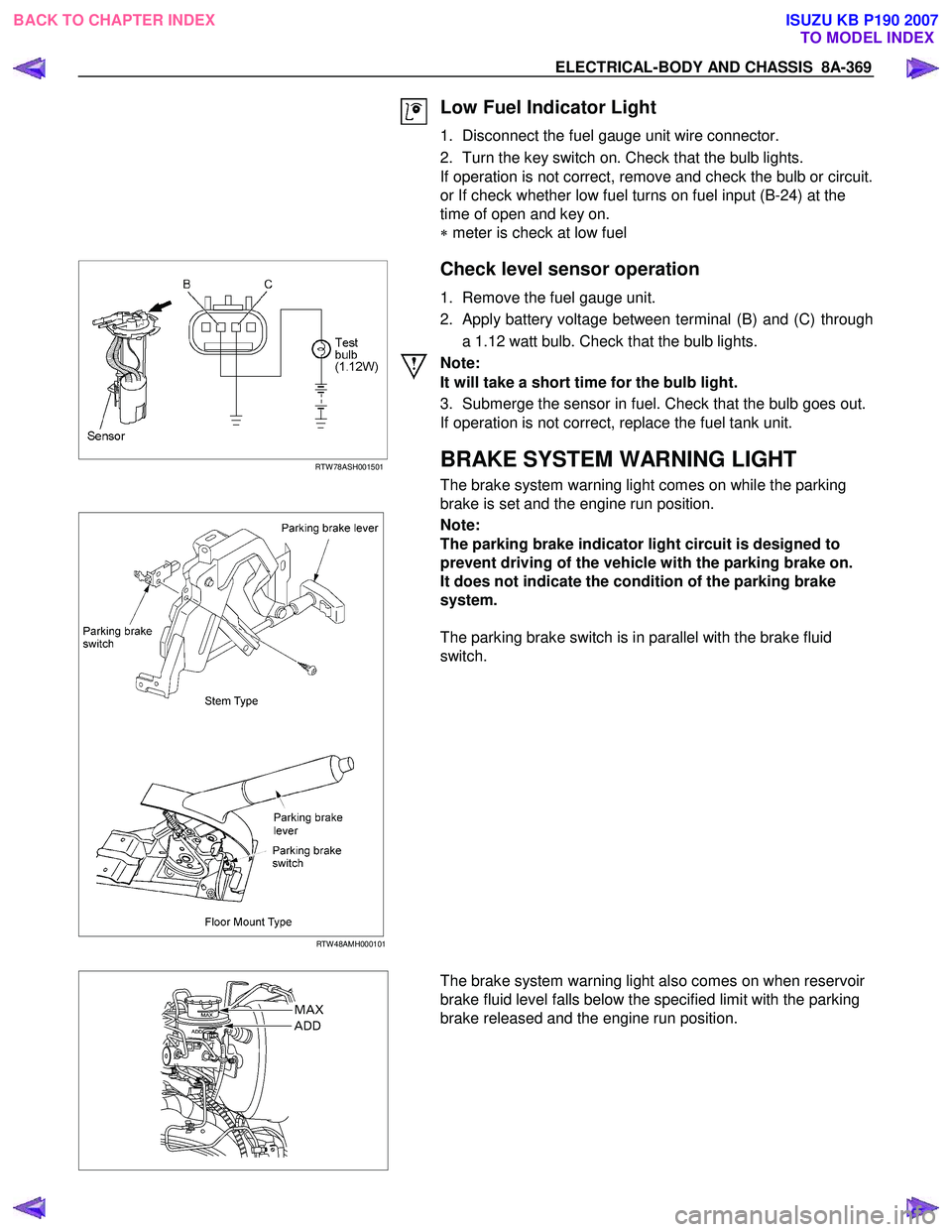

Low Fuel Indicator Light

1. Disconnect the fuel gauge unit wire connector.

2. Turn the key switch on. Check that the bulb lights.

If operation is not correct, remove and check the bulb or circuit.

or If check whether low fuel turns on fuel input (B-24) at the

time of open and key on.

∗ meter is check at low fuel

RTW 78ASH001501

Check level sensor operation

1. Remove the fuel gauge unit.

2. Apply battery voltage between terminal (B) and (C) through a 1.12 watt bulb. Check that the bulb lights.

Note:

It will take a short time for the bulb light.

3. Submerge the sensor in fuel. Check that the bulb goes out.

If operation is not correct, replace the fuel tank unit.

BRAKE SYSTEM WARNING LIGHT

The brake system warning light comes on while the parking

brake is set and the engine run position.

RTW 48AMH000101

Note:

The parking brake indicator light circuit is designed to

prevent driving of the vehicle with the parking brake on.

It does not indicate the condition of the parking brake

system.

The parking brake switch is in parallel with the brake fluid

switch.

The brake system warning light also comes on when reservoir

brake fluid level falls below the specified limit with the parking

brake released and the engine run position.

BACK TO CHAPTER INDEX TO MODEL INDEXISUZU KB P190 2007

Page 5550 of 6020

8A-612 ELECTRICAL-BODY AND CHASSIS

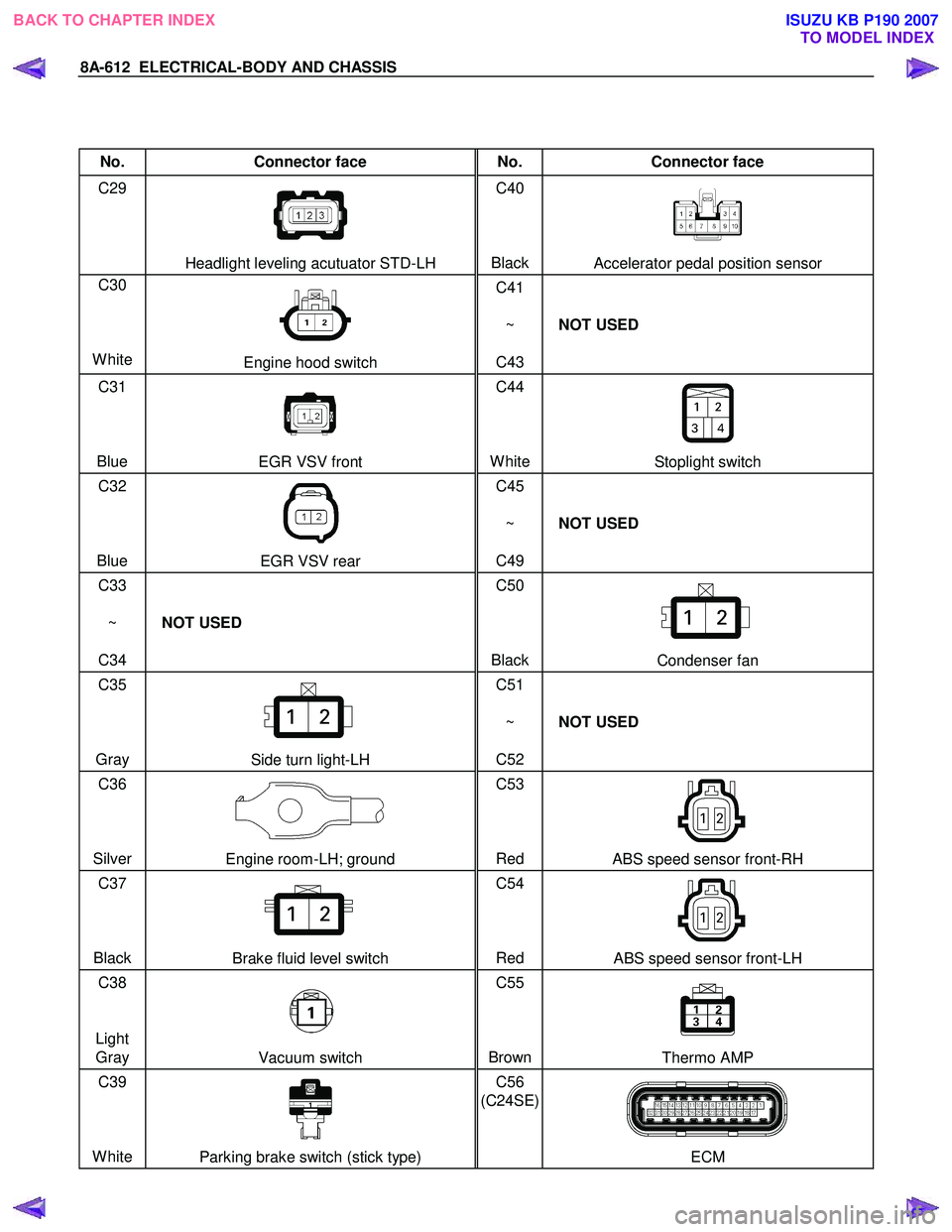

No. Connector face No. Connector face

C29

Headlight leveling acutuator STD-LH C40

BlackAccelerator pedal position sensor

C30

White

Engine hood switch C41

~

C43 NOT USED

C31

Blue

EGR VSV front C44

WhiteStoplight switch

C32

Blue

EGR VSV rear C45

~

C49 NOT USED

C33

~

C34 NOT USED C50

Black

Condenser fan

C35

Gray

Side turn light-LH C51

~

C52 NOT USED

C36

Silver

Engine room-LH; ground C53

Red ABS speed sensor front-RH

C37

Black

Brake fluid level switch C54

Red ABS speed sensor front-LH

C38

Light Gray

Vacuum switch C55

BrownThermo AMP

C39

White

Parking brake switch (stick type) C56

(C24SE)

ECM

BACK TO CHAPTER INDEX TO MODEL INDEXISUZU KB P190 2007

Page 5584 of 6020

Cruise Control – HFV6 Page 8C–6

The stop lamp switch contacts are normally open with the brake pedal at rest and close when the brake pedal is pressed

turning on the vehicles brake lamps. These switch contacts also double as the cruise cancel signal for the cruise control

operation.

The cruise control initial brake apply signal function switch contacts are normally closed with the brake pedal at rest and

open when the brake pedal is pressed. This switch function is a safety requirement of the vehicle as it ensures that the

cruise control cannot be activated without the brake pedal first being pressed.

Powertrain Interface Module

The Powertrain Interface Module (PIM) is located on the driver’s side, kick trim panel. The purpose of the PIM is to act as

an interface between the drivetrain serial data bus (GMLAN protocol) and the body side data bus (UART Bus protocol).

All inputs from the cruise control switch assembly are directly wired to the PIM. The PIM then takes these inputs,

converts them to GMLAN protocol and sends the messages via the data bus to the engine control module (ECM). The

PIM also receives signals for the cruise control system from the ECM. When the ECM activates cruise control, it sends a

signal through the PIM (which converts it from GMLAN to UART protocol) to display the various cruise control messages

on the instrument cluster assembly.

For further information on the operation of the PIM, refer to 6E1 Powertrain Interface Module – V6.

Engine Control Module

The Engine Control Module (ECM) is mounted on the front of the engine. The role of the ECM is to receive all the inputs

from various sensors (vehicle speed (VSS) etc.) and switches to manage the engine. W hen a request is sent from the

cruise control switch assembly via the PIM to the ECM, the ECM will activate cruise control providing given parameters

are satisfied. Once the cruise is set, the ECM monitors the vehicle speed and controls the throttle actuator assembly thus

controlling the speed of the vehicle.

For further information on the operation of the ECM, refer to 6C1-1 Engine Management – V6 – General Information.

Throttle Actuator Control (TAC) Assembly

The throttle actuator control assembly is located on the front of the inlet manifold. The throttle actuator control assembly

receives signals from the ECM and controls the angle of the throttle plate. Refer to 6C1-1 Engine Management – V6 –

General Information for further information.

1.3 System Operation

Preliminary Information

Enabled and Disabled

The cruise control is enabled / disabled by pressing the cruise control ON–OFF switch mounted on the lower right hand

side of the dash panel. When cruise control is enabled, the cruise control ON–OFF switch illuminates and the cruise

control is ready for a speed to be set (cruise control activated). W hen the cruise control is disabled, the cruise control

cannot be activated.

Cruise Enabled

1 The cruise control ON–OFF switch (1) supplies 12 Volts to the Powertrain Interface Module (PIM) when it

is pressed.

2 The cruise control ON–OFF switch lamp (2) turns on.

Cruise Disabled

1 W hen cruise control ON–OFF switch (1) is pressed again, power is removed from the PIM disabling the

cruise control.

2 The cruise control ON–OFF switch lamp (2) turns off.

Figure 8C – 4

BACK TO CHAPTER INDEX TO MODEL INDEXISUZU KB P190 2007