ECU ISUZU KB P190 2007 Workshop Repair Manual

[x] Cancel search | Manufacturer: ISUZU, Model Year: 2007, Model line: KB P190, Model: ISUZU KB P190 2007Pages: 6020, PDF Size: 70.23 MB

Page 3183 of 6020

Engine Cooling – V6 Engine Page 6B1–48

Install

1 Ensure that the coolant inlet pipe and thermostat housing mating surfaces are clean and dry.

2 Install new O-ring to the coolant inlet pipe.

3 Install coolant inlet pipe at the thermostat housing and secure with the attaching bolt. Tighten all bolts to the correct torque specification.

Coolant inlet pipe to thermostat

housing bolt torque specification ..........................23 N.m

4 Raise the front of the vehicle and support on safety stands. Refer to 0A General Information for the location of jacking and support points.

5 Reinstall the coolant inlet pipe to the engine block and secure with the bolt tightened to the correct torque specification.

Coolant inlet pipe to engine block bolt

torque specification .............................................25 N.m

Always wear protective safety glasses when

working with spring type hose clamps. Failure

to do so could result in eye injury.

6 Connect the lower radiator outlet hose and clamp to the coolant inlet pipe connection.

7 Close the radiator drain tap on the lower RHS of the radiator and remove the piece of rubber tubing to the tap outlet.

8 Lower the front of the vehicle.

9 Refill cooling system. Refer to 3.3 Draining and Filling Cooling System in this Section.

10 Check for coolant leaks. Refer to 3.7 Pressure Testing in this Section.

11 Reconnect battery ground lead. Refer to 8A – Electrical Body & Chassis.

3.13 Cooling Fan and Shroud Assembly

Remove

Disconnection of the battery affects certain

vehicle electronic systems. Refer to 1.1

WARNING, CAUTION and NOTES, before

removing the ground lead.

1 Disconnect the battery ground lead. Refer to 8A – Electrical Body & Chassis.

2 Remove the intake duct and mass air flow as an assembly. Refer to 6A1 Engine Mechanical.

3 Remove the coolant recovery hose from the fan shroud retaining clip.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3186 of 6020

Engine Cooling – V6 Engine Page 6B1–51

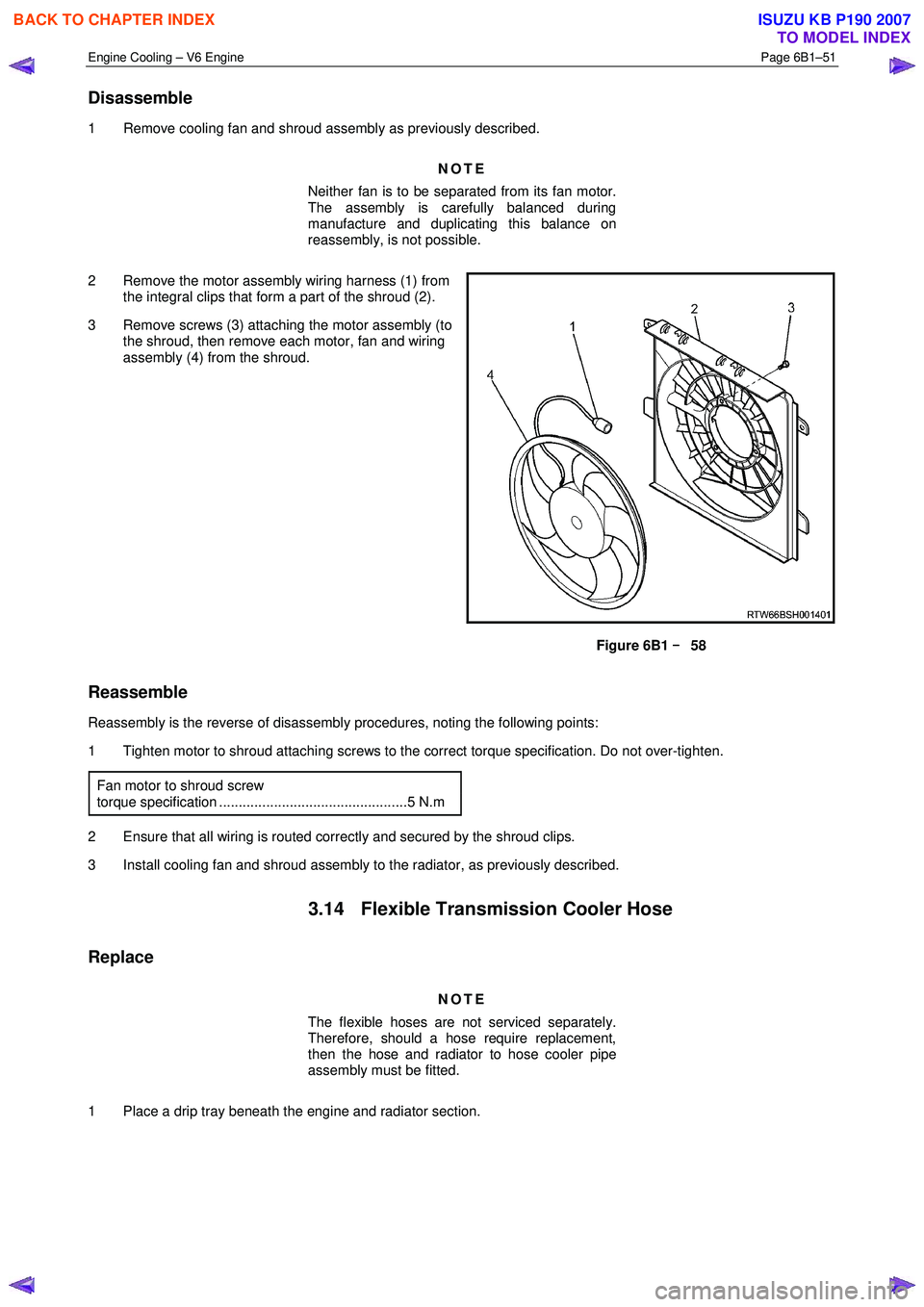

Disassemble

1 Remove cooling fan and shroud assembly as previously described.

NOTE

Neither fan is to be separated from its fan motor.

The assembly is carefully balanced during

manufacture and duplicating this balance on

reassembly, is not possible.

2 Remove the motor assembly wiring harness (1) from the integral clips that form a part of the shroud (2).

3 Remove screws (3) attaching the motor assembly (to the shroud, then remove each motor, fan and wiring

assembly (4) from the shroud.

Figure 6B1 –

––

–

58

Reassemble

Reassembly is the reverse of disassembly procedures, noting the following points:

1 Tighten motor to shroud attaching screws to the correct torque specification. Do not over-tighten.

Fan motor to shroud screw

torque specification ................................................5 N.m

2 Ensure that all wiring is routed correctly and secured by the shroud clips.

3 Install cooling fan and shroud assembly to the radiator, as previously described.

3.14 Flexible Transmission Cooler Hose

Replace

NOTE

The flexible hoses are not serviced separately.

Therefore, should a hose require replacement,

then the hose and radiator to hose cooler pipe

assembly must be fitted.

1 Place a drip tray beneath the engine and radiator section.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3188 of 6020

Engine Cooling – V6 Engine Page 6B1–53

NOTE

Should the spring clip or the O-ring seal in the

quick connect fitting be damaged during the line

removal process, then the complete fitting must

be replaced.

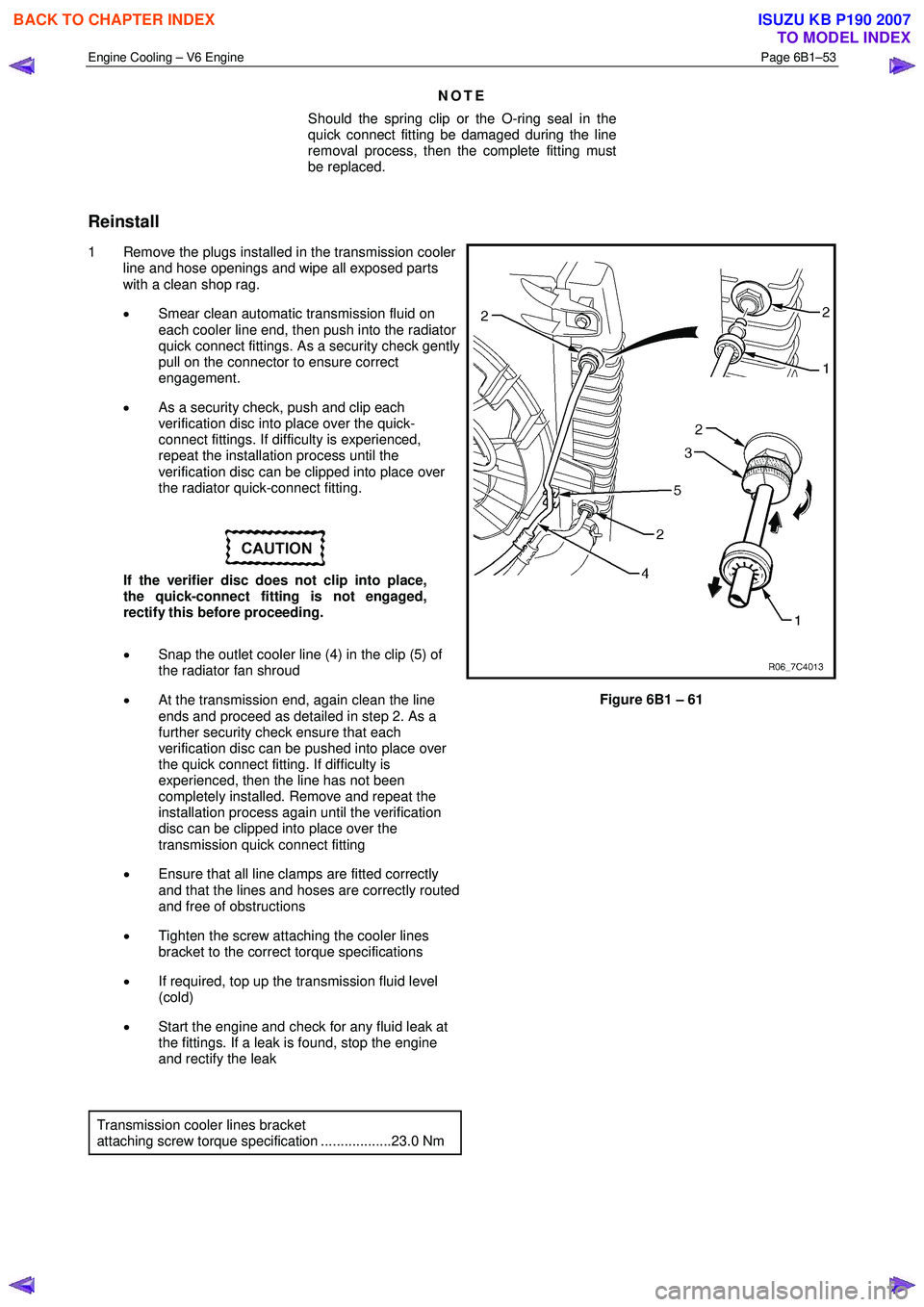

Reinstall

1 Remove the plugs installed in the transmission cooler line and hose openings and wipe all exposed parts

with a clean shop rag.

• Smear clean automatic transmission fluid on

each cooler line end, then push into the radiator

quick connect fittings. As a security check gently

pull on the connector to ensure correct

engagement.

• As a security check, push and clip each

verification disc into place over the quick-

connect fittings. If difficulty is experienced,

repeat the installation process until the

verification disc can be clipped into place over

the radiator quick-connect fitting.

If the verifier disc does not clip into place,

the quick-connect fitting is not engaged,

rectify this before proceeding.

• Snap the outlet cooler line (4) in the clip (5) of

the radiator fan shroud

• At the transmission end, again clean the line

ends and proceed as detailed in step 2. As a

further security check ensure that each

verification disc can be pushed into place over

the quick connect fitting. If difficulty is

experienced, then the line has not been

completely installed. Remove and repeat the

installation process again until the verification

disc can be clipped into place over the

transmission quick connect fitting

• Ensure that all line clamps are fitted correctly

and that the lines and hoses are correctly routed

and free of obstructions

• Tighten the screw attaching the cooler lines

bracket to the correct torque specifications

• If required, top up the transmission fluid level

(cold)

• Start the engine and check for any fluid leak at

the fittings. If a leak is found, stop the engine

and rectify the leak

Figure 6B1 – 61

Transmission cooler lines bracket

attaching screw torque specification ..................23.0 Nm

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3191 of 6020

Engine Cooling – V6 Engine Page 6B1–56

Reinstall

Installation of the radiator is the reverse of removal procedures, noting the following points:

1 Before installing radiator, inspect core to ensure that there is no foreign matter in core fins. Clean out between core fins with compressed air, blowing from rear to front.

2 If the vehicle is fitted with an automatic transmission, remove plugs from the removed cooling pipe ends and the two quick connect fittings.

3 After wiping cooler line ends and smearing clean automatic transmission fluid over each flared line end, push into the quick connect fitting to engage. As a security check, tug on each line to ensure correct engagement.

4 Check the transmission fluid level. Refer to the following references as required:

• 7C4 Automatic Transmission

• 4L60E On-vehicle Servicing

5 Install the following hoses:

a. Lower radiator hose, securing with the hose clamp.

b. Upper radiator hose, securing with the hose clamp.

6 Install the radiator cooling fan and shroud assembly. Refer to 3.13Cooling Fan and Shroud Assembly in this Section. Ensure that electrical connectors and the transmission cooler lines are seated correctly in the integral

retainer clips before install upper radiator shroud.

7 Refill cooling system. Refer to 3.3 Draining and Filling Cooling System in this Section.

8 Check for coolant leaks. Refer to 3.7 Pressure Testing in this Section.

9 Reconnect battery ground lead. Refer to 8A Electrical Body & Chassis.

10 Check cooling fan operation. Refer to 6C1-2 Engine Management Diagnostics. Also check for correct rotational direction of cooling fan.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3209 of 6020

Fuel System – V6 Page 6C – 7

Fuel Flow

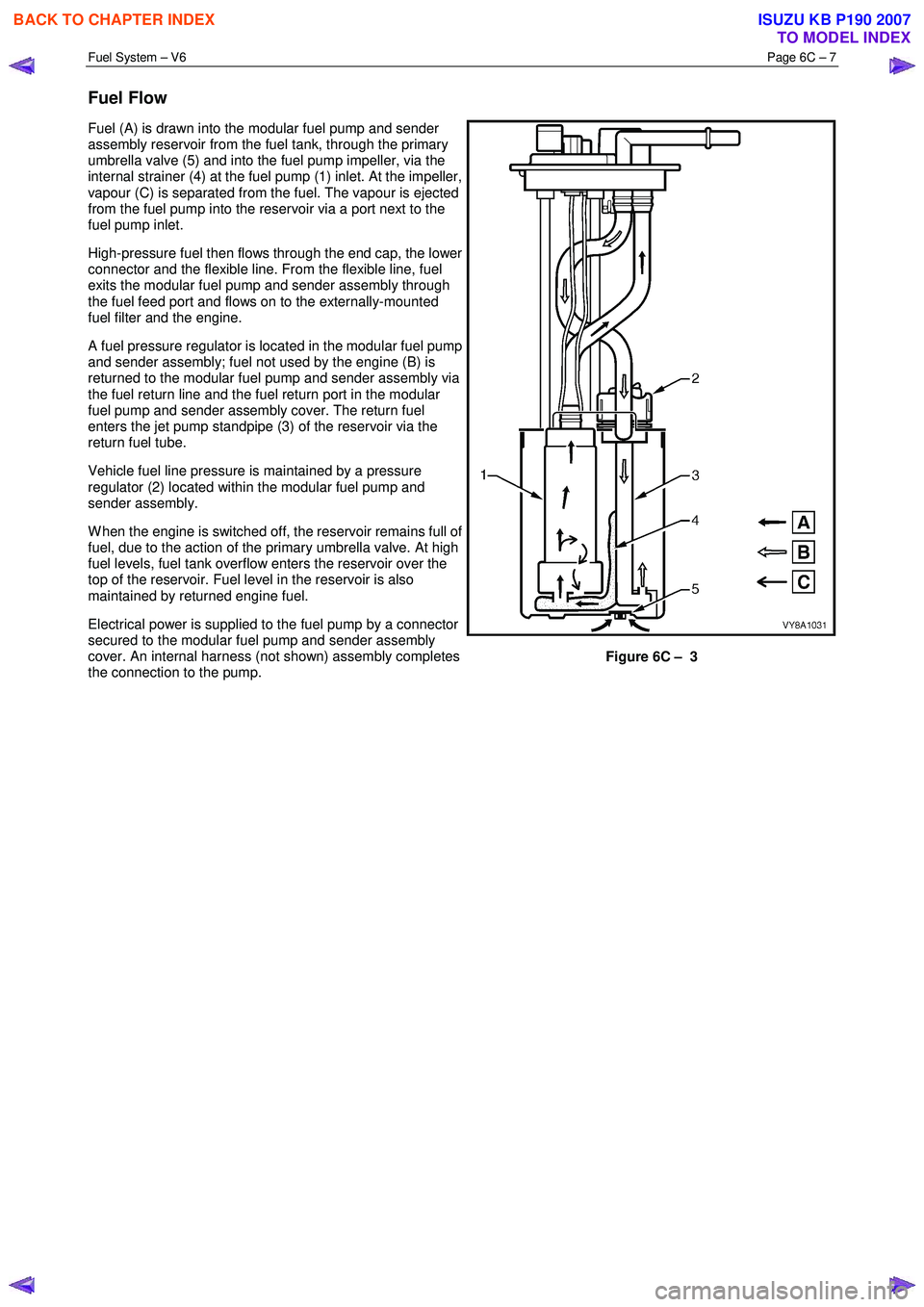

Fuel (A) is drawn into the modular fuel pump and sender

assembly reservoir from the fuel tank, through the primary

umbrella valve (5) and into the fuel pump impeller, via the

internal strainer (4) at the fuel pump (1) inlet. At the impeller,

vapour (C) is separated from the fuel. The vapour is ejected

from the fuel pump into the reservoir via a port next to the

fuel pump inlet.

High-pressure fuel then flows through the end cap, the lower

connector and the flexible line. From the flexible line, fuel

exits the modular fuel pump and sender assembly through

the fuel feed port and flows on to the externally-mounted

fuel filter and the engine.

A fuel pressure regulator is located in the modular fuel pump

and sender assembly; fuel not used by the engine (B) is

returned to the modular fuel pump and sender assembly via

the fuel return line and the fuel return port in the modular

fuel pump and sender assembly cover. The return fuel

enters the jet pump standpipe (3) of the reservoir via the

return fuel tube.

Vehicle fuel line pressure is maintained by a pressure

regulator (2) located within the modular fuel pump and

sender assembly.

W hen the engine is switched off, the reservoir remains full of

fuel, due to the action of the primary umbrella valve. At high

fuel levels, fuel tank overflow enters the reservoir over the

top of the reservoir. Fuel level in the reservoir is also

maintained by returned engine fuel.

Electrical power is supplied to the fuel pump by a connector

secured to the modular fuel pump and sender assembly

cover. An internal harness (not shown) assembly completes

the connection to the pump.

Figure 6C – 3

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3218 of 6020

Fuel System – V6 Page 6C – 16

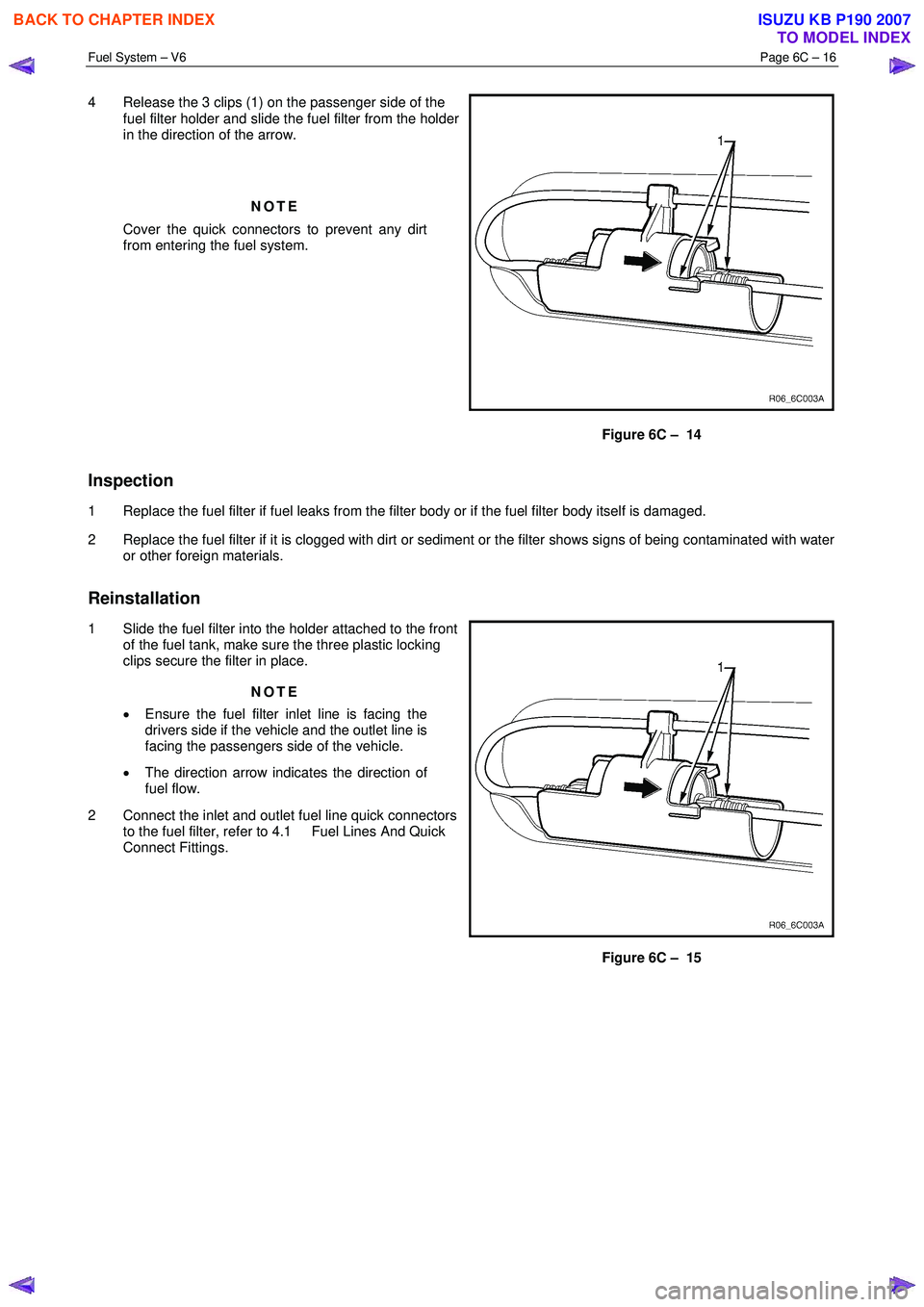

4 Release the 3 clips (1) on the passenger side of the

fuel filter holder and slide the fuel filter from the holder

in the direction of the arrow.

NOTE

Cover the quick connectors to prevent any dirt

from entering the fuel system.

Figure 6C – 14

Inspection

1 Replace the fuel filter if fuel leaks from the filter body or if the fuel filter body itself is damaged.

2 Replace the fuel filter if it is clogged with dirt or sediment or the filter shows signs of being contaminated with water or other foreign materials.

Reinstallation

1 Slide the fuel filter into the holder attached to the front of the fuel tank, make sure the three plastic locking

clips secure the filter in place.

NOTE

• Ensure the fuel filter inlet line is facing the

drivers side if the vehicle and the outlet line is

facing the passengers side of the vehicle.

• The direction arrow indicates the direction of

fuel flow.

2 Connect the inlet and outlet fuel line quick connectors to the fuel filter, refer to 4.1 Fuel Lines And Quick

Connect Fittings.

Figure 6C – 15

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3222 of 6020

Fuel System – V6 Page 6C – 20

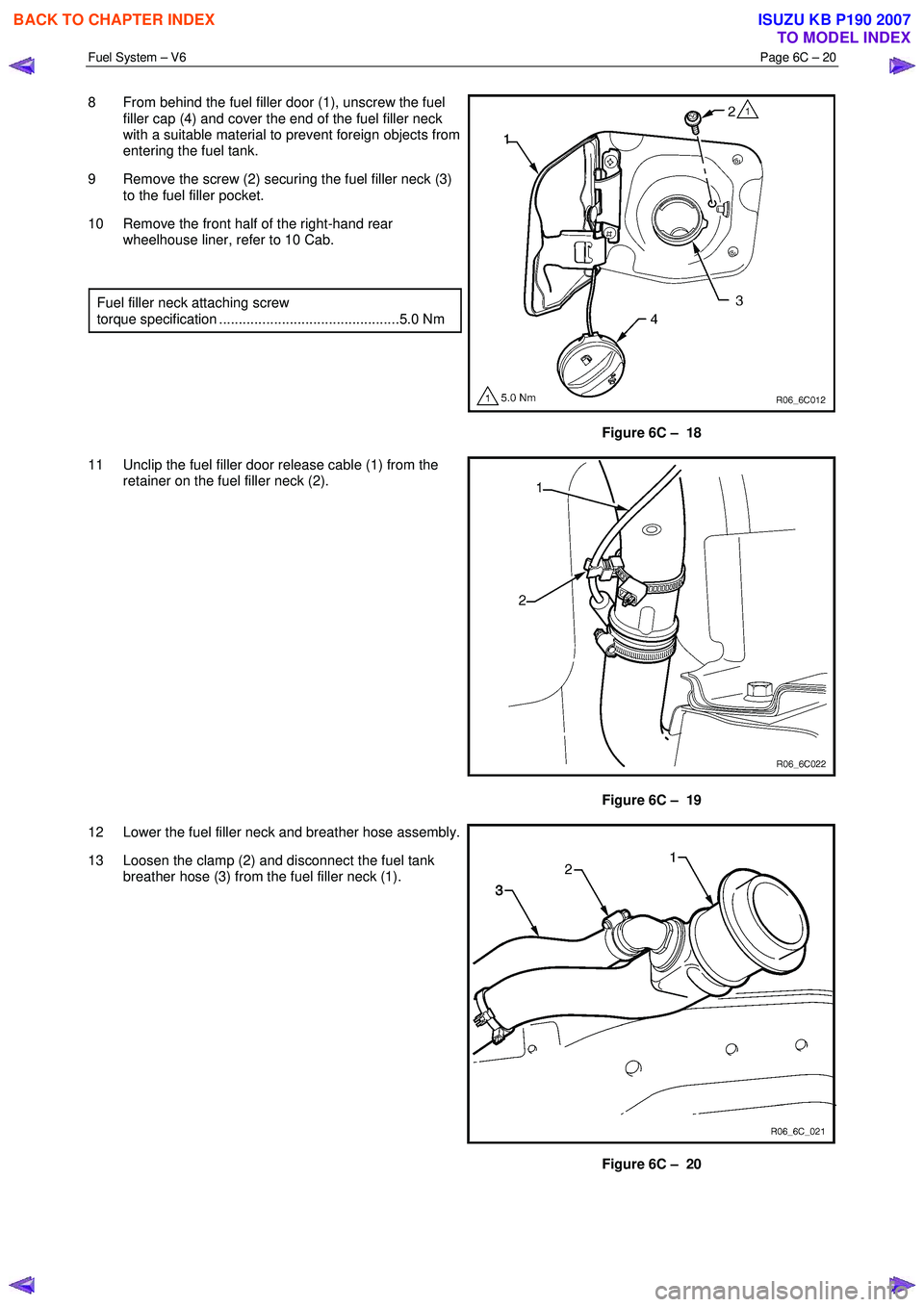

8 From behind the fuel filler door (1), unscrew the fuel

filler cap (4) and cover the end of the fuel filler neck

with a suitable material to prevent foreign objects from

entering the fuel tank.

9 Remove the screw (2) securing the fuel filler neck (3) to the fuel filler pocket.

10 Remove the front half of the right-hand rear wheelhouse liner, refer to 10 Cab.

Fuel filler neck attaching screw

torque specification ..............................................5.0 Nm

Figure 6C – 18

11 Unclip the fuel filler door release cable (1) from the retainer on the fuel filler neck (2).

Figure 6C – 19

12 Lower the fuel filler neck and breather hose assembly.

13 Loosen the clamp (2) and disconnect the fuel tank breather hose (3) from the fuel filler neck (1).

Figure 6C – 20

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3223 of 6020

Fuel System – V6 Page 6C – 21

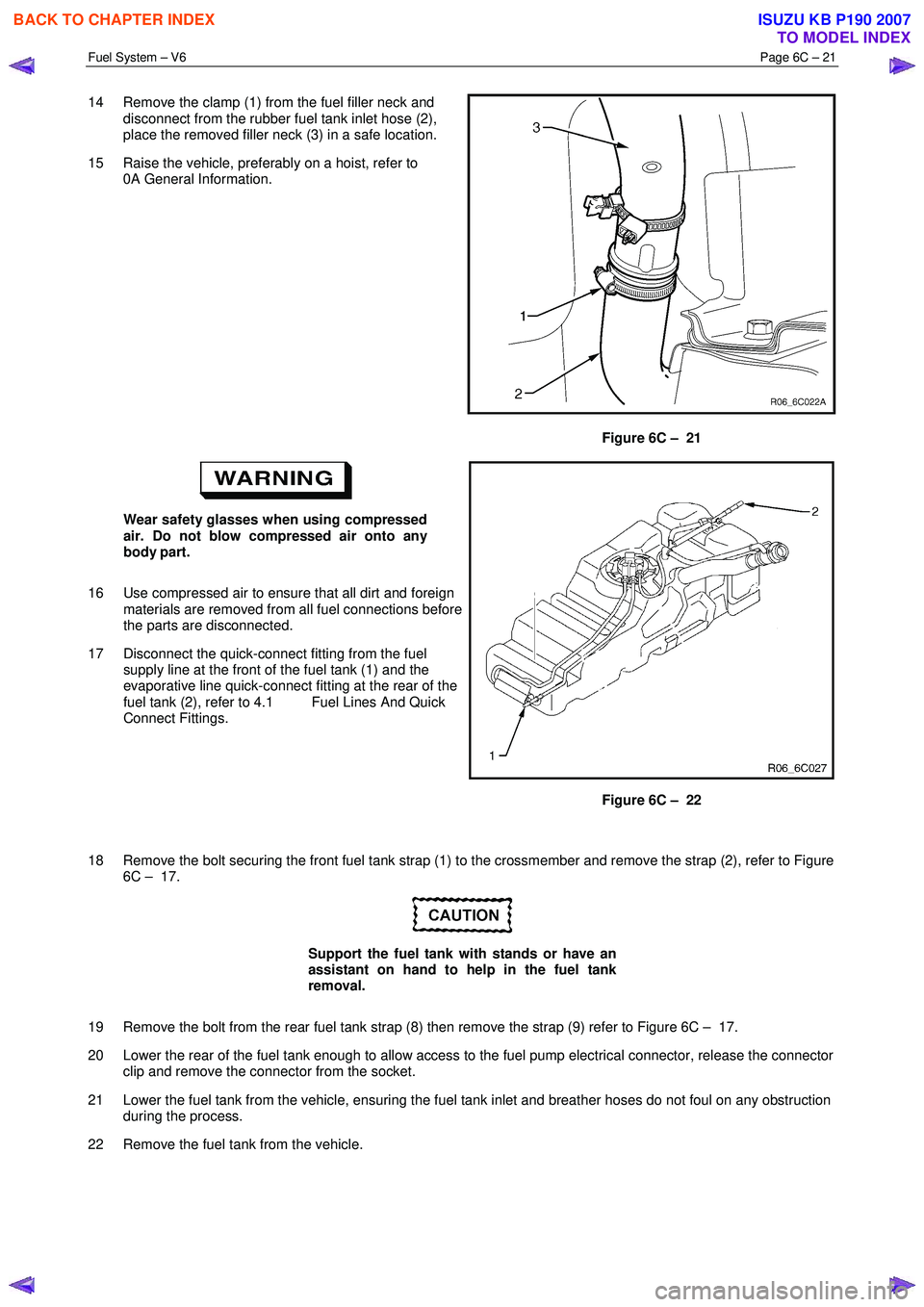

14 Remove the clamp (1) from the fuel filler neck and

disconnect from the rubber fuel tank inlet hose (2),

place the removed filler neck (3) in a safe location.

15 Raise the vehicle, preferably on a hoist, refer to 0A General Information.

Figure 6C – 21

Wear safety glasses when using compressed

air. Do not blow compressed air onto any

body part.

16 Use compressed air to ensure that all dirt and foreign materials are removed from all fuel connections before

the parts are disconnected.

17 Disconnect the quick-connect fitting from the fuel supply line at the front of the fuel tank (1) and the

evaporative line quick-connect fitting at the rear of the

fuel tank (2), refer to 4.1 Fuel Lines And Quick

Connect Fittings.

Figure 6C – 22

18 Remove the bolt securing the front fuel tank strap (1) to the crossmember and remove the strap (2), refer to Figure 6C – 17.

Support the fuel tank with stands or have an

assistant on hand to help in the fuel tank

removal.

19 Remove the bolt from the rear fuel tank strap (8) then remove the strap (9) refer to Figure 6C – 17.

20 Lower the rear of the fuel tank enough to allow access to the fuel pump electrical connector, release the connector clip and remove the connector from the socket.

21 Lower the fuel tank from the vehicle, ensuring the fuel tank inlet and breather hoses do not foul on any obstruction during the process.

22 Remove the fuel tank from the vehicle.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3224 of 6020

Fuel System – V6 Page 6C – 22

Reinstall

Reinstallation of the fuel tank is the reverse of the removal procedure, noting the following:

1 Lift the fuel tank into position reinserting the fuel tank inlet and breather hoses into the body opening. Raise the fuel tank into place and rest the front of the tank on the crossmember.

2 Replace the fuel pump electrical connector, be sure to engage the locking tab.

3 Fit the fuel tank mounting straps in the following order, refer to Figure 6C – 17, a Loosely reattach the rear fuel tank mounting strap and bolt (8 & 9), refer to Figure 6C – 17.

b Loosely attach the front mounting strap and bolt (1 & 2), refer to Figure 6C – 17.

c Ensure that the fuel tank is located in the correct position then,

d Tighten the rear mounting strap bolt (8), Figure 6C – 17.

e Tighten the front mounting strap bolt (1), Figure 6C – 17.

4 Tighten all fuel tank mounting strap bolts to the correct torque specification.

Fuel tank mounting strap bolts

torque specification ............................................68.0 Nm

Install the fuel filter with the flow arrow on its

body pointing in the same direction as the

fuel flow to the front of the vehicle.

5 Install the disconnected quick-connect fittings to the fuel supply line at the front of the fuel tank and the evaporative line quick-connect fitting at the rear of the fuel tank. Refer to 4.1 Fuel Lines And Quick Connect Fittings, for the

correct component routeing.

6 Lower the vehicle to a comfortable working height and reinstall the clamp (1) to the fuel filler neck and reconnect the rubber fuel tank inlet hose (2) and tighten the clamp, refer to Figure 6C – 21.

7 Reinstall the fuel tank breather hose (3) to the fuel filler neck (1) and tighten the clamp (2), refer to Figure 6C – 20.

8 Clip the fuel filler door release cable (1) to the retainer on the fuel filler neck (2), refer to Figure 6C – 19.

9 Locate the fuel filler neck (3) to the filler pocket and attach with the securing screw (2), remove the cover material from the fuel filler neck inlet and refit the fuel filler cap (4), refer to Figure 6C – 18.

10 Reinstall the front half of the right-hand rear wheelhouse liner, refer to 10 Cab.

11 Before starting the vehicle, perform a fuel system leak test, refer to 3.3 Fuel Leak Test.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3231 of 6020

Fuel System – V6 Page 6C – 29

6 Block the canister vent port (1) and the canister purge port (2). Apply low-pressure compressed air

(20–35 kPa) to the tank vent port (3). If any air leaks from the canister (that is, around the ports or seams), replace

the canister.

NOTE

In dusty areas, an alternative is to block the

canister purge port (2). Blow air through the

canister vent (1) port and check that air is

expelled through the tank vent port (3).

Reinstall

Reinstallation of the evaporative emission control canister is the reverse of the removal procedure.

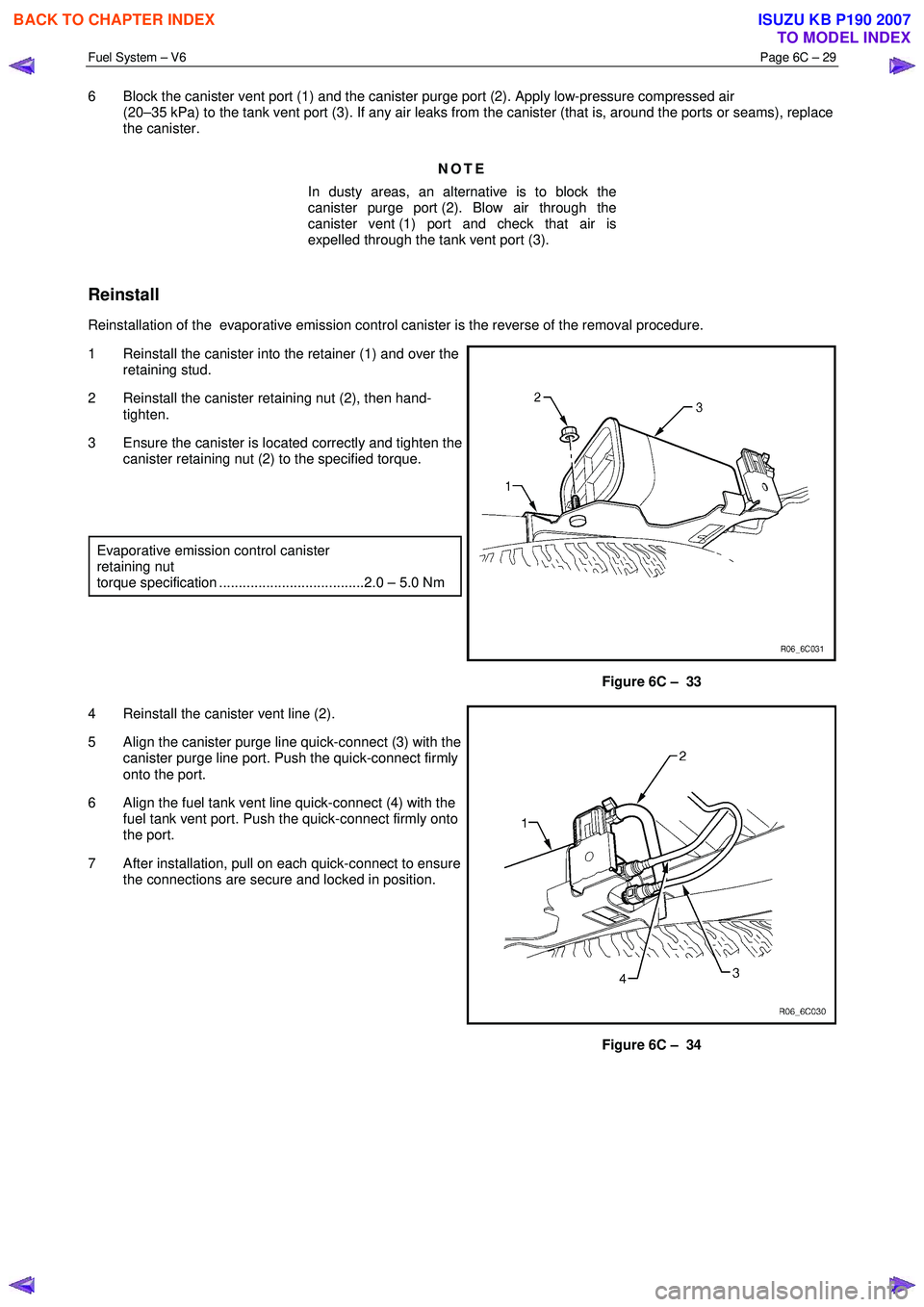

1 Reinstall the canister into the retainer (1) and over the retaining stud.

2 Reinstall the canister retaining nut (2), then hand- tighten.

3 Ensure the canister is located correctly and tighten the canister retaining nut (2) to the specified torque.

Evaporative emission control canister

retaining nut

torque specification .....................................2.0 – 5.0 Nm

Figure 6C – 33

4 Reinstall the canister vent line (2).

5 Align the canister purge line quick-connect (3) with the canister purge line port. Push the quick-connect firmly

onto the port.

6 Align the fuel tank vent line quick-connect (4) with the fuel tank vent port. Push the quick-connect firmly onto

the port.

7 After installation, pull on each quick-connect to ensure the connections are secure and locked in position.

Figure 6C – 34

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007