engine ISUZU KB P190 2007 Workshop Repair Manual

[x] Cancel search | Manufacturer: ISUZU, Model Year: 2007, Model line: KB P190, Model: ISUZU KB P190 2007Pages: 6020, PDF Size: 70.23 MB

Page 2955 of 6020

Engine Mechanical – V6 Page 6A1–178

Page 6A1–178

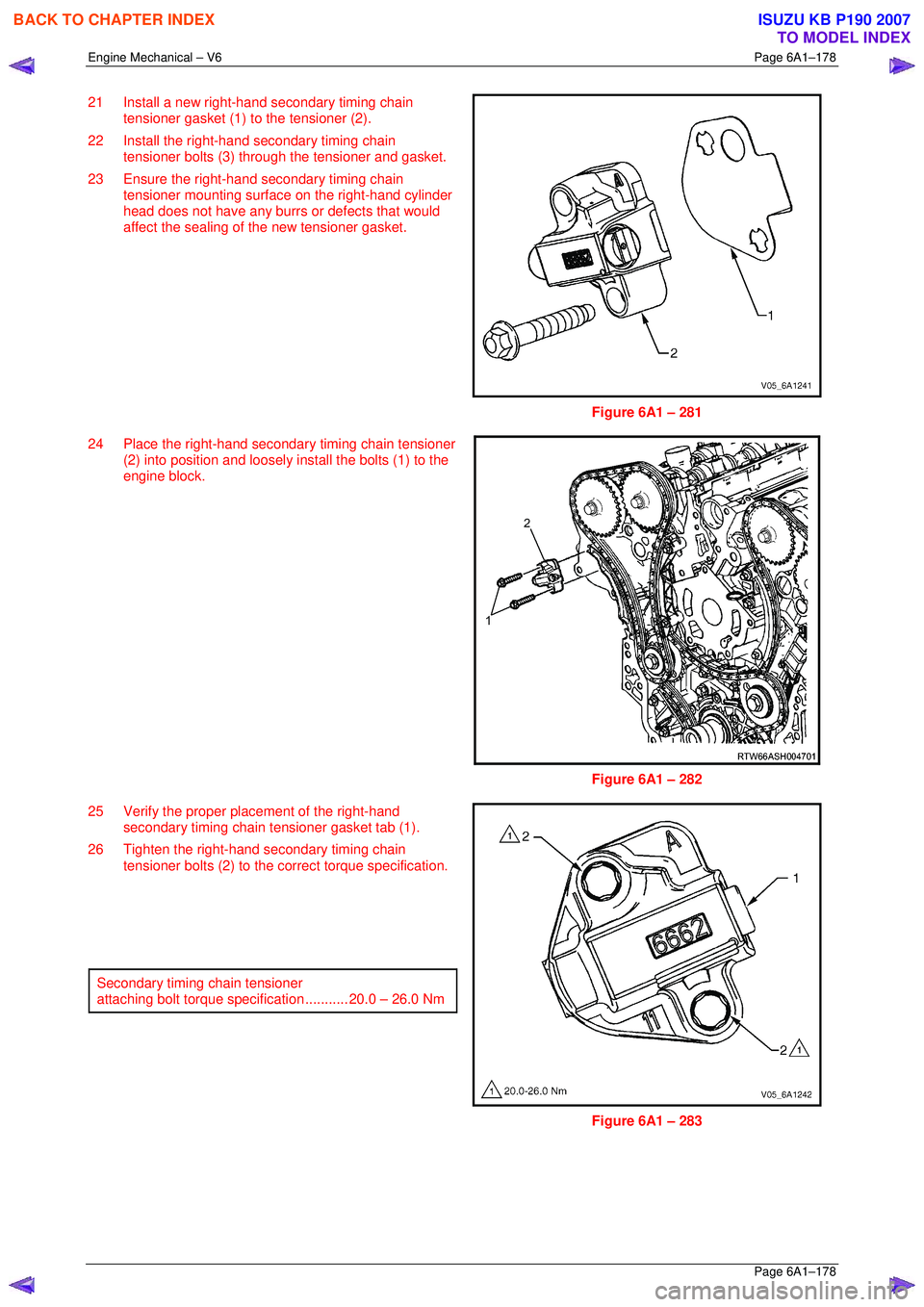

21 Install a new right-hand secondary timing chain

tensioner gasket (1) to the tensioner (2).

22 Install the right-hand secondary timing chain tensioner bolts (3) through the tensioner and gasket.

23 Ensure the right-hand secondary timing chain tensioner mounting surfac e on the right-hand cylinder

head does not have any burrs or defects that would

affect the sealing of the new tensioner gasket.

Figure 6A1 – 281

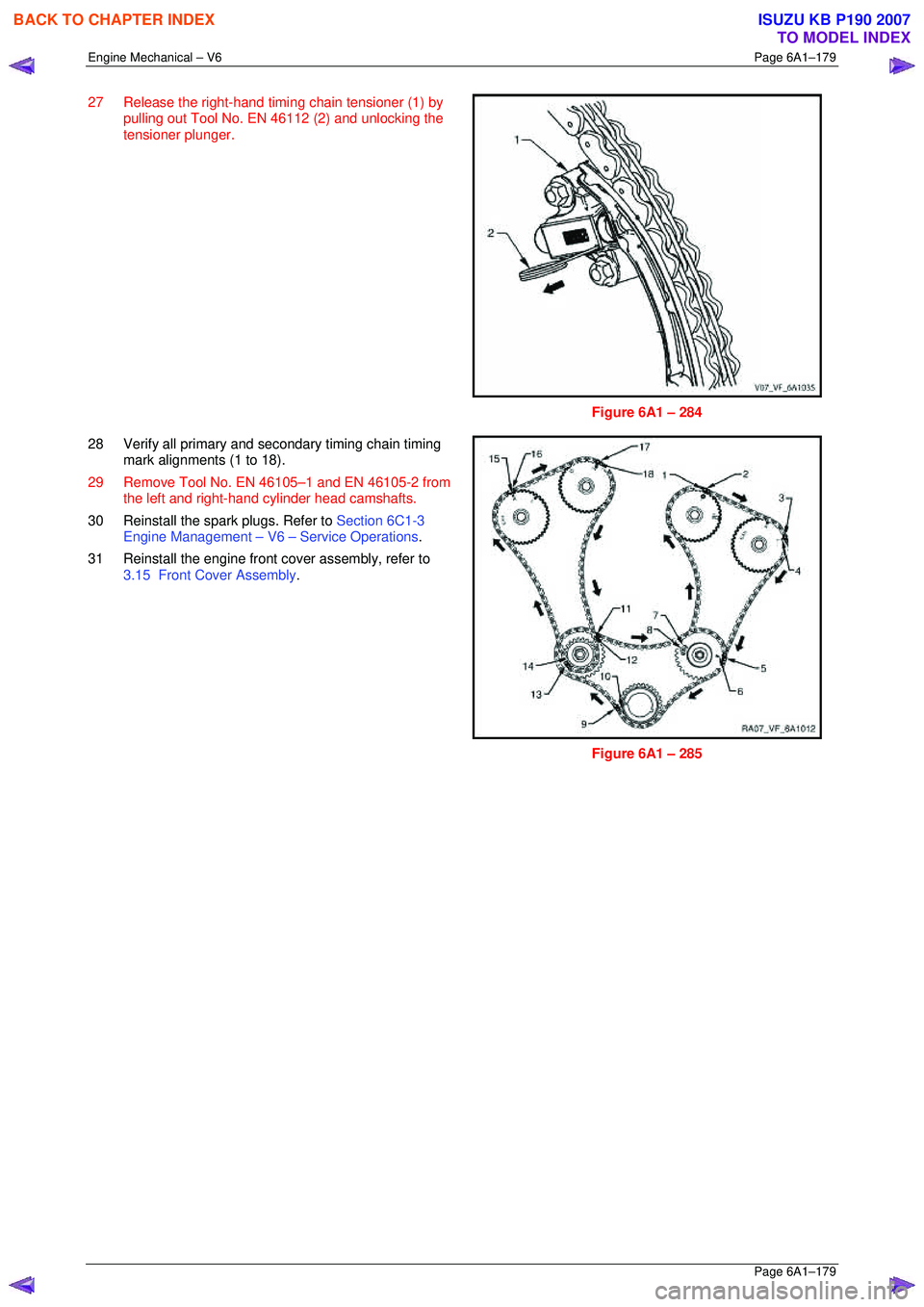

24 Place the right-hand secondar y timing chain tensioner

(2) into position and loosely install the bolts (1) to the

engine block.

Figure 6A1 – 282

25 Verify the proper plac ement of the right-hand

secondary timing chain tensioner gasket tab (1).

26 Tighten the right-hand secondary timing chain tensioner bolts (2) to the co rrect torque specification.

Secondary timing chain tensioner

attaching bolt torque spec ification ........... 20.0 – 26.0 Nm

Figure 6A1 – 283

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 2956 of 6020

Engine Mechanical – V6 Page 6A1–179

Page 6A1–179

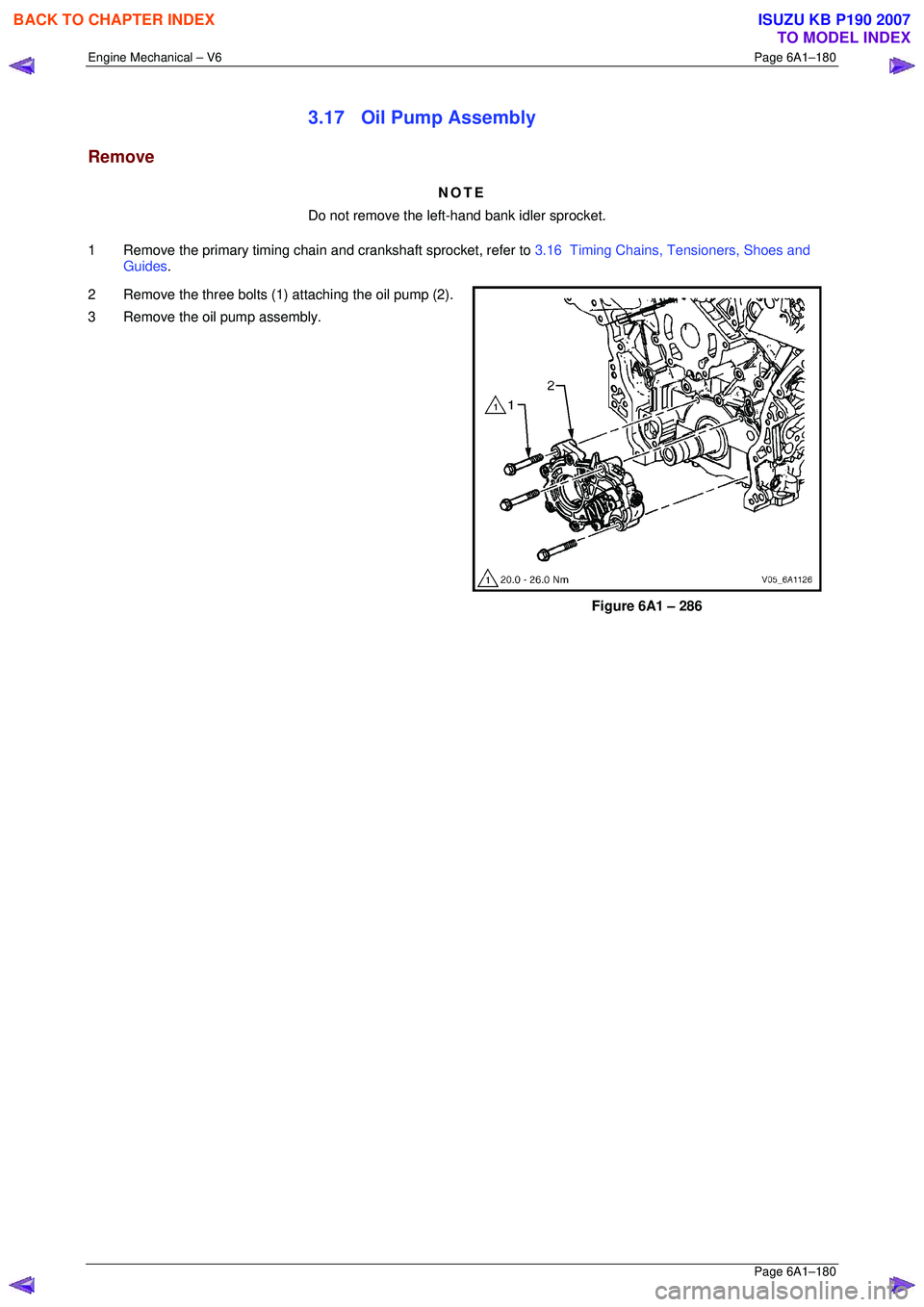

27 Release the right-hand timing chain tensioner (1) by

pulling out Tool No. EN 46112 (2) and unlocking the

tensioner plunger.

Figure 6A1 – 284

28 Verify all primary and secondary timing chain timing mark alignments (1 to 18).

29 Remove Tool No. EN 46105–1 and EN 46105-2 from the left and right-hand cylinder head camshafts.

30 Reinstall the spark plugs. Refer to Section 6C1-3

Engine Management – V6 – Service Operations.

31 Reinstall the engine front cover assembly, refer to 3.15 Front Cover Assembly .

Figure 6A1 – 285

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 2957 of 6020

Engine Mechanical – V6 Page 6A1–180

Page 6A1–180

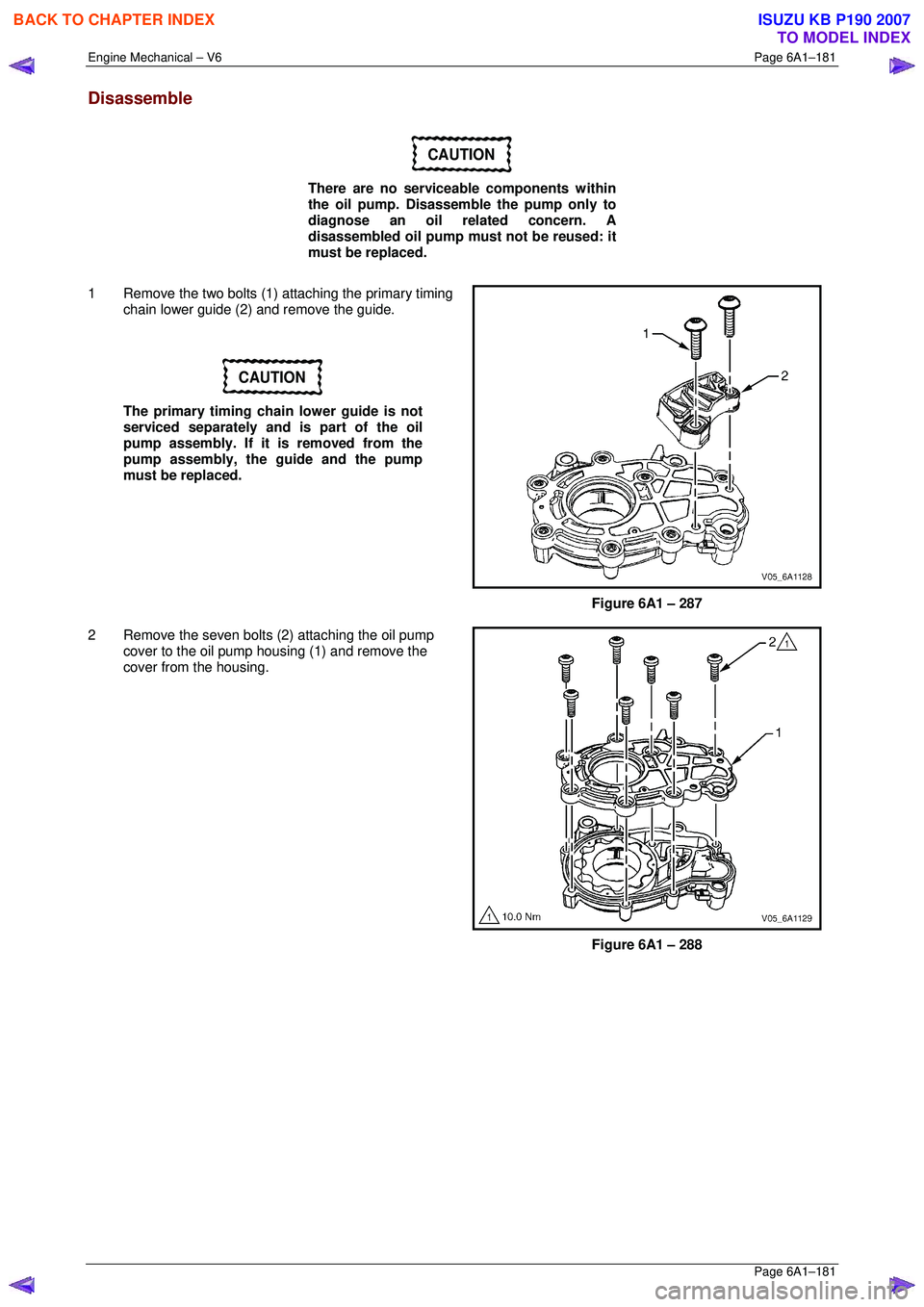

3.17 Oil Pump Assembly

Remove

NOTE

Do not remove the left-hand bank idler sprocket.

1 Remove the primary timing chai n and crankshaft sprocket, refer to 3.16 Timing Chains, Tensioners, Shoes and

Guides .

2 Remove the three bolts (1) attaching the oil pump (2).

3 Remove the oil pump assembly.

Figure 6A1 – 286

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 2958 of 6020

Engine Mechanical – V6 Page 6A1–181

Page 6A1–181

Disassemble

CAUTION

There are no serviceable components within

the oil pump. Disassemble the pump only to

diagnose an oil related concern. A

disassembled oil pump must not be reused: it

must be replaced.

1 Remove the two bolts (1) attaching the primary timing chain lower guide (2) and remove the guide.

CAUTION

The primary timing chain lower guide is not

serviced separately and is part of the oil

pump assembly. If it is removed from the

pump assembly, the guide and the pump

must be replaced.

Figure 6A1 – 287

2 Remove the seven bolts (2) attaching the oil pump cover to the oil pump housing (1) and remove the

cover from the housing.

Figure 6A1 – 288

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 2959 of 6020

Engine Mechanical – V6 Page 6A1–182

Page 6A1–182

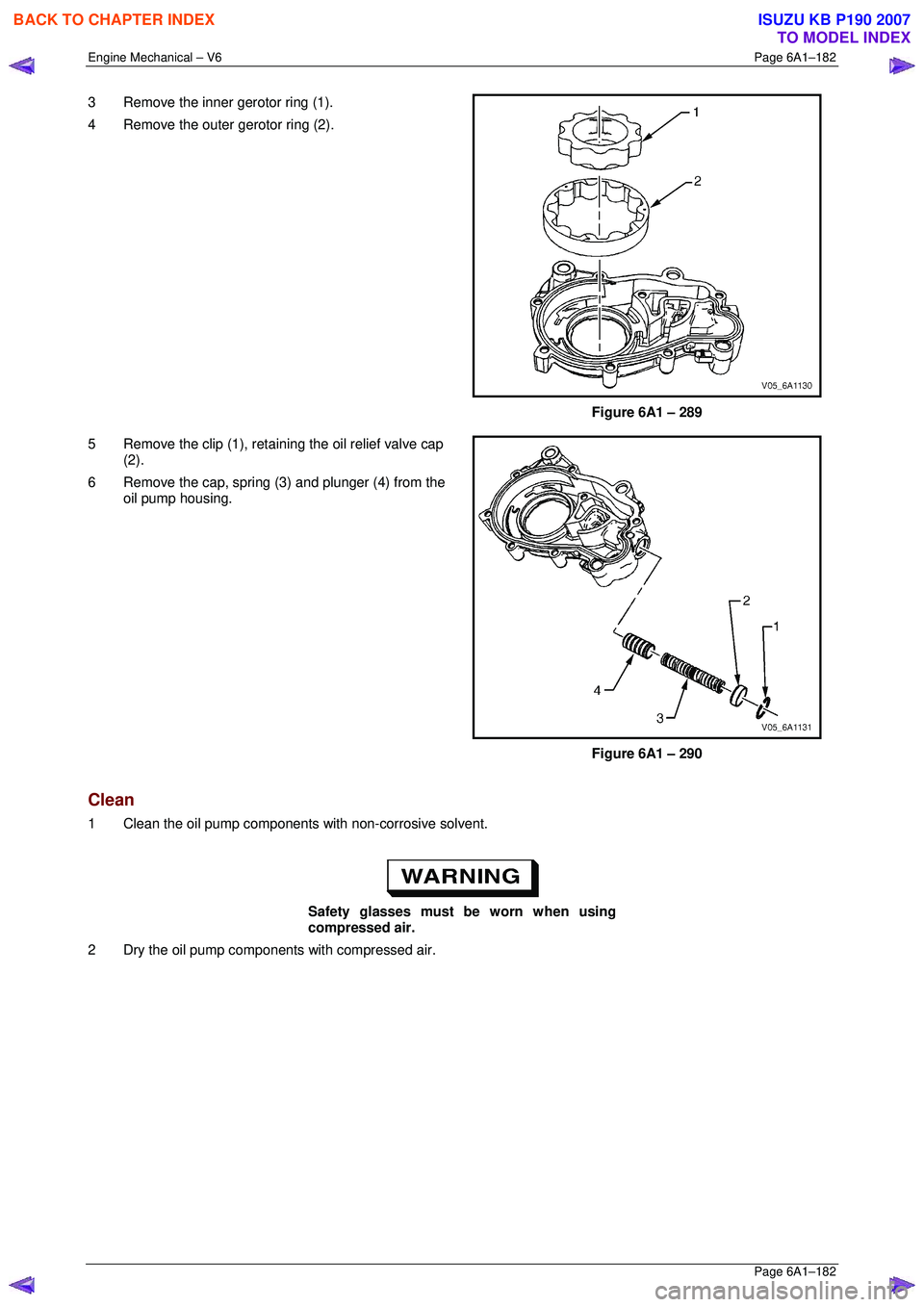

3 Remove the inner gerotor ring (1).

4 Remove the outer gerotor ring (2).

Figure 6A1 – 289

5 Remove the clip (1), retaining the oil relief valve cap (2).

6 Remove the cap, spring (3) and plunger (4) from the oil pump housing.

Figure 6A1 – 290

Clean

1 Clean the oil pump components with non-corrosive solvent.

Safety glasses must be worn when using

compressed air.

2 Dry the oil pump components with compressed air.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 2960 of 6020

Engine Mechanical – V6 Page 6A1–183

Page 6A1–183

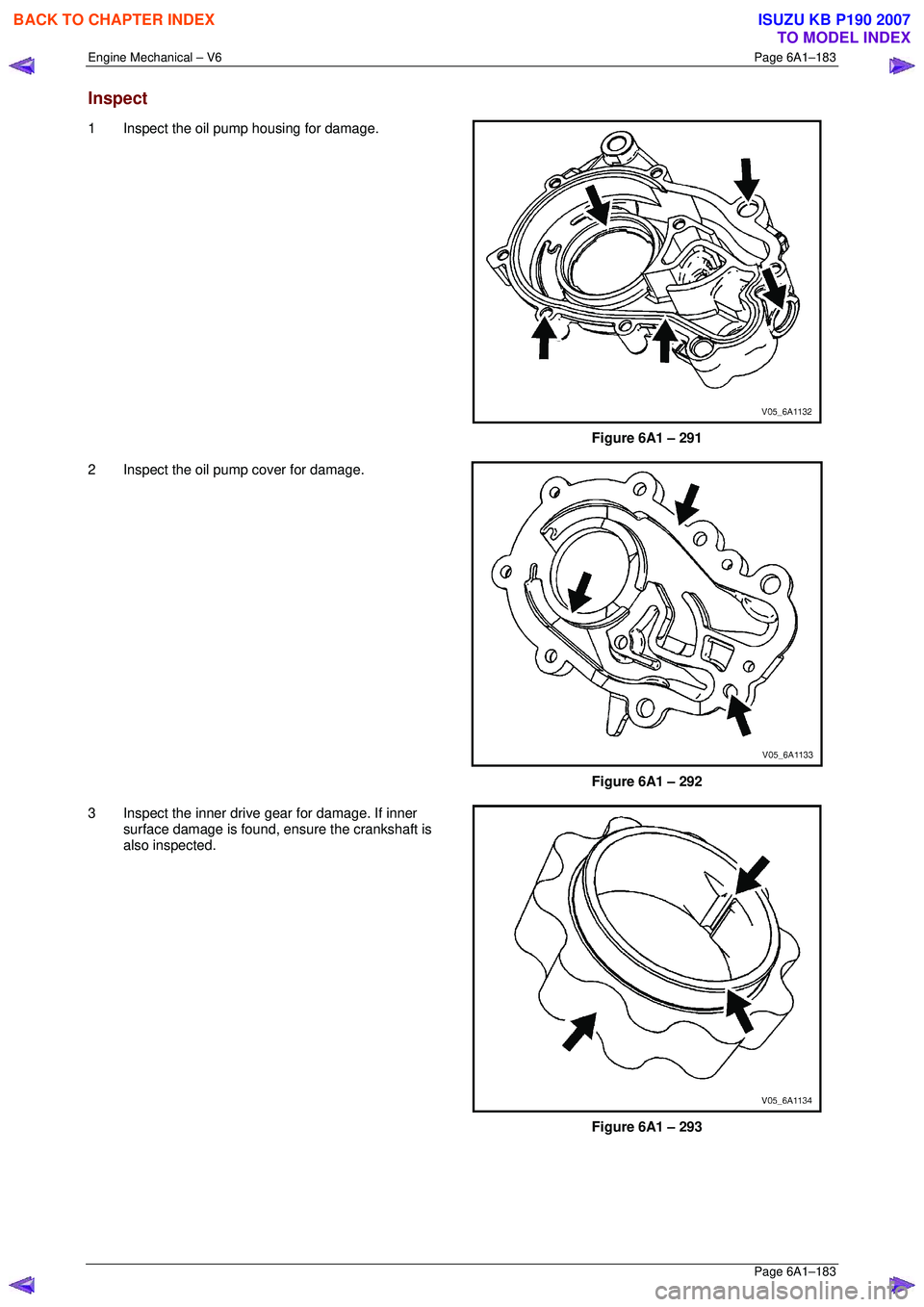

Inspect

1 Inspect the oil pump housing for damage.

Figure 6A1 – 291

2 Inspect the oil pump cover for damage.

Figure 6A1 – 292

3 Inspect the inner drive gear for damage. If inner surface damage is found, ens ure the crankshaft is

also inspected.

Figure 6A1 – 293

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 2961 of 6020

Engine Mechanical – V6 Page 6A1–184

Page 6A1–184

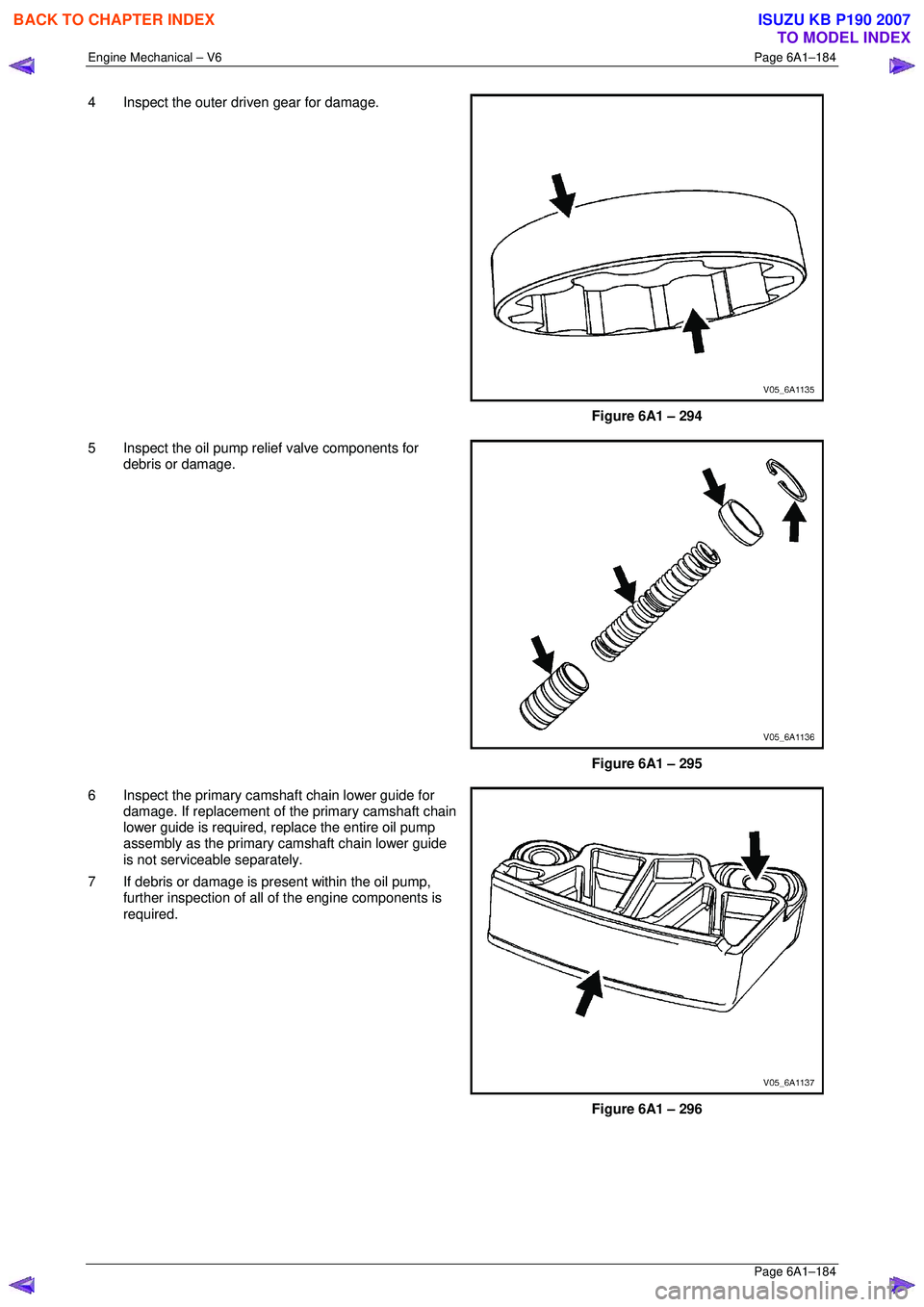

4 Inspect the outer driven gear for damage.

Figure 6A1 – 294

5 Inspect the oil pump relief valve components for debris or damage.

Figure 6A1 – 295

6 Inspect the primary camshaft chain lower guide for damage. If replacement of t he primary camshaft chain

lower guide is required, r eplace the entire oil pump

assembly as the primary camshaft chain lower guide

is not serviceable separately.

7 If debris or damage is pres ent within the oil pump,

further inspection of all of the engine components is

required.

Figure 6A1 – 296

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 2962 of 6020

Engine Mechanical – V6 Page 6A1–185

Page 6A1–185

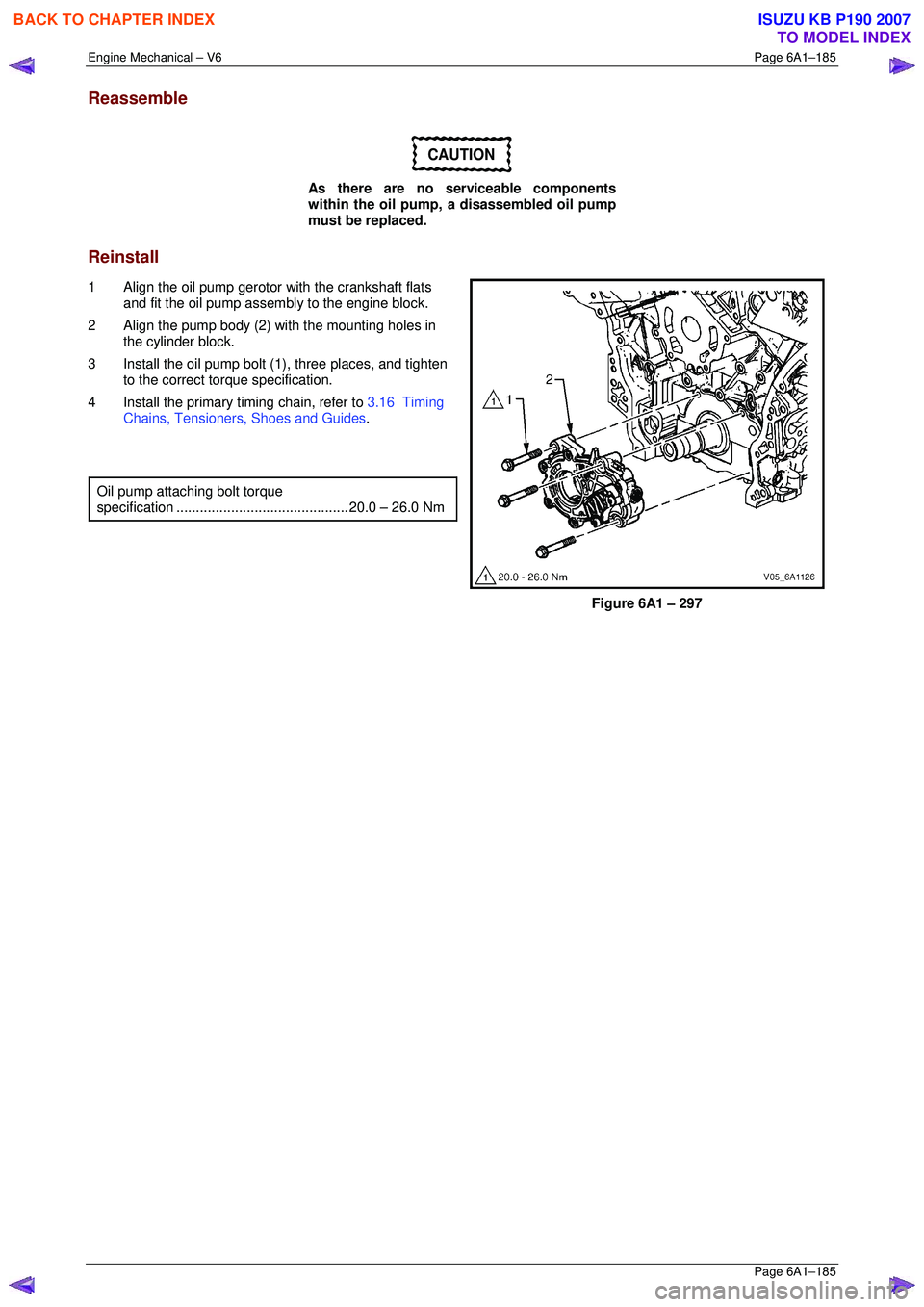

Reassemble

CAUTION

As there are no serviceable components

within the oil pump, a disassembled oil pump

must be replaced.

Reinstall

1 Align the oil pump gerotor with the crankshaft flats

and fit the oil pump assembly to the engine block.

2 Align the pump body (2) with the mounting holes in the cylinder block.

3 Install the oil pump bolt (1), three places, and tighten to the correct torque specification.

4 Install the primary timing chain, refer to 3.16 Timing

Chains, Tensioners, Shoes and Guides .

Oil pump attaching bolt torque

specificat ion ............................................ 20.0 – 26.0 Nm

Figure 6A1 – 297

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 2963 of 6020

Engine Mechanical – V6 Page 6A1–186

Page 6A1–186

3.18 Camshaft Sprocket – Excluding MY06

Update

CAUTION

Setting the camshaft timing is required

whenever the camshaft drive system is

disturbed to ensure the relationship between

any chain and sprocket is not lost. Even when

only one sprocket is involved, multiple

crankshaft rotations will not produce

conditions where correct timing can be

confirmed.

If required, follow the Left-hand Secondary

Camshaft Chain Components reinstallation

procedure to reset the camshaft timing.

Remove

Right-hand Side

1 Remove the right-hand ca mshaft cover, refer to 3.12 Camshaft Cover.

2 Remove the camshaft position sensors, refer to Section 6C1-3 Engine Management – Service Operations.

3 Remove the camshaft position actuator solenoids, refer to Section 6C1-3 Engine Management – V6 – Service

Operations .

4 Remove the crankshaft bal ancer assembly, refer to 3.13 Crankshaft Balancer Assembly .

5 Install the crankshaft rotation socket Tool No. EN-46111 onto the crankshaft.

6 Rotate the crankshaft until the camshafts are in a neutral low tension position. The camshaft flats will be

parallel with the camshaft cover rail (1).

Figure 6A1 – 298

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 2964 of 6020

Engine Mechanical – V6 Page 6A1–187

Page 6A1–187

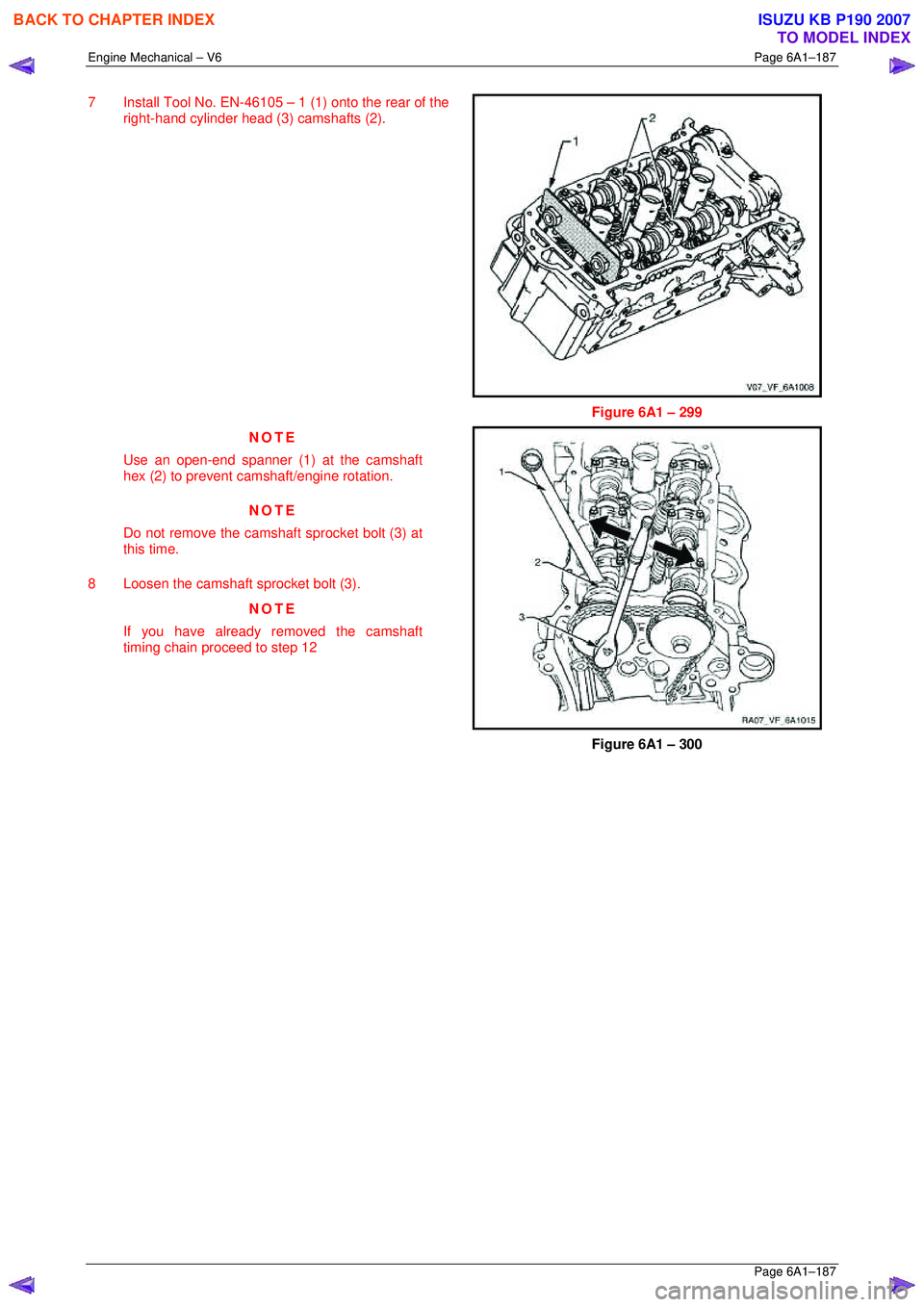

7 Install Tool No. EN-46105 – 1 (1) onto the rear of the

right-hand cylinder head (3) camshafts (2).

Figure 6A1 – 299

NOTE

Use an open-end spanner (1) at the camshaft

hex (2) to prevent camshaft/engine rotation.

NOTE

Do not remove the cams haft sprocket bolt (3) at

this time.

8 Loosen the camshaft sprocket bolt (3). NOTE

If you have already removed the camshaft

timing chain proceed to step 12

Figure 6A1 – 300

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007