cooling ISUZU KB P190 2007 Workshop Repair Manual

[x] Cancel search | Manufacturer: ISUZU, Model Year: 2007, Model line: KB P190, Model: ISUZU KB P190 2007Pages: 6020, PDF Size: 70.23 MB

Page 3764 of 6020

Automatic Transmission – 4L60E – General Information Page 7C1–4

1.2 7C1 Automatic Transmission – 4L60E –

General Information

This section provides general information about the automatic transmission, including:

• A glossary of terms,

• Transmission identification information,

• Electrical overview of the Transmission Control Module (TCM),

• Some notes that address safe workshop practices,

• Service notes relating to fasteners and consumable items used at various stages throughout this section,

• Special tools required to work on the transmission,

• Fastener torque specifications, and

• Transmission specifications.

For all information relating to the mechanical construction and function of the 4L60E automatic transmission, refer to the

General Motors Powertrain Group Electronically Controlled Automatic Transmission Technician’s Guide.

This guide includes such information as:

• Transmission Cutaway Views,

• Principles of Operation,

• Power Flow,

• Complete Hydraulic Circuits,

• Bushing and Bearing Locations,

• Seal Locations and

• Illustrated Parts List.

NOTE

Specifications quoted in this General Motors

Powertrain Group Electronically Controlled

Automatic Transmission Technician Guide may

not be for the vehicle you are working on. For

correct specifications refer to

7 Transmission Specifications.

Recommendations

When servicing the transmission, all parts should be cleaned and inspected. Individual units should be reassembled

before disassembly of other units to avoid confusion and interchanging of parts.

a Thoroughly clean the transmission exterior before removal of any component.

b Disassembly and reassembly must be made on a clean work bench. Cleanliness is of the utmost importance, the bench tools and parts must be kept clean at all times.

c Before installing screws and other fasteners into aluminium parts, dip screw threads into transmission fluid to prevent galling aluminium threads and to prevent screws from seizing.

d To prevent thread stripping, always use a torque wrench when installing screws or nuts.

e If threads in aluminium parts are stripped or damaged, the parts can be made serviceable by the use of commercially available thread inserts.

f Protective tools must be used when assembling seals to prevent damage. The slightest flaw in the sealing surface of the seal can cause an oil leak.

g Aluminium castings and valve parts are very susceptible to nicks, burrs, etc. and should be handled with care.

h Expand Internal snap rings and compress external snap rings if they are to be re-used to ensure proper seating when reinstalled.

i Do not re-use removed O-rings, gaskets and oil seals.

j Teflon oil seal rings should not be removed unless damaged.

k During assembly of each unit, all internal moving parts must be lubricated with transmission fluid.

Oil Cooler Pipes

Should any transmission fluid cooling pipe suffer accidental damage, a genuine replacement pipe must be fitted. Refer to

the current release of PartFinder™ to determine the correct part number for the particular engine and pipe involved.

Reworking of damaged pipes or hand made replacements are not permitted.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3777 of 6020

Automatic Transmission – 4L60E – General Information Page 7C1–17

7 Transmission Specifications

7.1 General

Type

Hydra-matic 4L60E

Special Features

Electronically controlled shift pattern, feel and torque

Converter clutch operation

Overdrive 4th speed range

Selector Location ..................................................................................Floor mounted console

Gear Ratios Park (P) ....................................................................................................................... ........... –

Reverse (R) .................................................................................................................... ... 2.29

Neutral (N) .............................................................................................................................. –

Drive (D – 4) .................................................................................................................. ...... 0.7

Drive (D – 3) .................................................................................................................. ...... 1.0

Second (2) ......................................................................................................................... 1.63

First (1) ...................................................................................................................... ........ 3.06

Shift Speeds Refer to 7C3 Automatic Transmission – 4L60E – Hydraulic and Mechanical Diagnosis

Oil Pressure

Refer to 7C3 Automatic Transmission – 4L60E – Hydraulic and Mechanical Diagnosis

Torque Converter

Number of Elements .................................................................. 3 plus torque converter clutch

Torque Converter Diameter and End Play

HFV6 ........................................................................................................................... 258 mm

End Play .............................................................................................................. 0.1 – 0.5 mm

Lubricant

Type recommended ................................................................................................ Dexron

® III

Capacity......................... Nominal only. Check when transmission is at operating temperature

Service Refill ............................................................................................................... 4. 8 litres

Total (Dry)................................................................................................................... 8 .8 litres

Fluid Cooling.....................................Transmission fluid to engine coolant in one radiator tank

Clutches and Band 2 – 4 Band:

Type........................................................................................... Composition lined, steel band

Operation: ..................................................................................................................... .. Servo

Adjustment: ................................................................................................ Selective Apply Pin

Pin Size and Identification.

65.82 – 66.12 mm ...................................................................................................... 1 Groove

67.23 – 67.53 mm ...................................................................................................... 2 Groove

68.64 – 68.94 mm ....................................................................................................No Groove

Reverse Input Clutch Type................................................................................................................Multiple we t disc

Backing plate ........................................................................................................ (1) Select ive

Clutch plate (numbers):

Steel ....................................................................................................................................... 4

Composition............................................................................................................................ 4

Belleville ..................................................................................................................... ............ 1

Backing Plate ........................................................................................................ 1 (Selecti ve)

Backing plate, identification and thickness:

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3821 of 6020

Automatic Transmission – 4L60E – Electrical Diagnosis Page 7C2–35

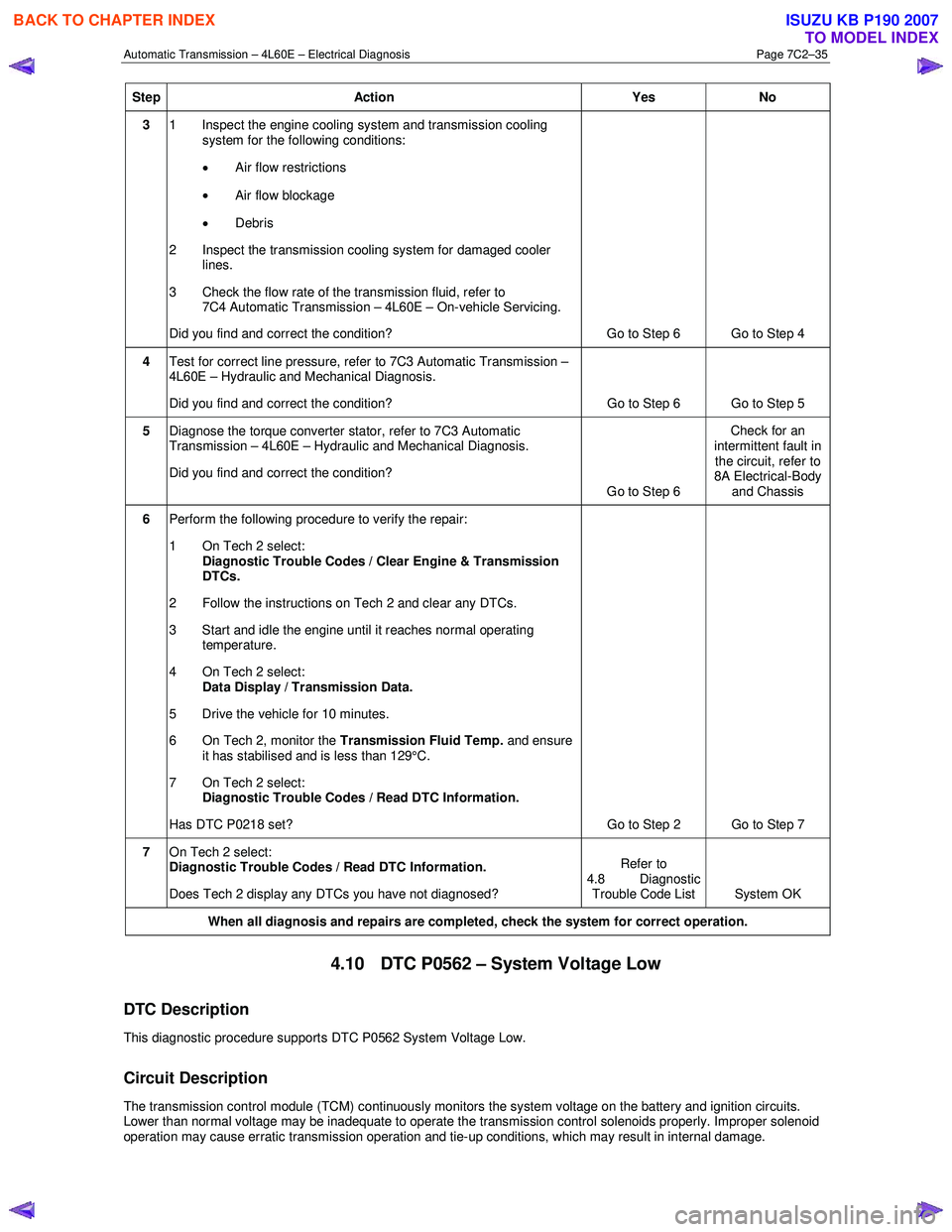

Step Action Yes No

3 1 Inspect the engine cooling system and transmission cooling

system for the following conditions:

• Air flow restrictions

• Air flow blockage

• Debris

2 Inspect the transmission cooling system for damaged cooler lines.

3 Check the flow rate of the transmission fluid, refer to 7C4 Automatic Transmission – 4L60E – On-vehicle Servicing.

Did you find and correct the condition? Go to Step 6 Go to Step 4

4 Test for correct line pressure, refer to 7C3 Automatic Transmission –

4L60E – Hydraulic and Mechanical Diagnosis.

Did you find and correct the condition? Go to Step 6 Go to Step 5

5 Diagnose the torque converter stator, refer to 7C3 Automatic

Transmission – 4L60E – Hydraulic and Mechanical Diagnosis.

Did you find and correct the condition? Go to Step 6 Check for an

intermittent fault in the circuit, refer to

8A Electrical-Body

and Chassis

6 Perform the following procedure to verify the repair:

1 On Tech 2 select: Diagnostic Trouble Codes / Clear Engine & Transmission

DTCs.

2 Follow the instructions on Tech 2 and clear any DTCs.

3 Start and idle the engine until it reaches normal operating temperature.

4 On Tech 2 select: Data Display / Transmission Data.

5 Drive the vehicle for 10 minutes.

6 On Tech 2, monitor the Transmission Fluid Temp. and ensure

it has stabilised and is less than 129°C.

7 On Tech 2 select:

Diagnostic Trouble Codes / Read DTC Information.

Has DTC P0218 set? Go to Step 2 Go to Step 7

7 On Tech 2 select:

Diagnostic Trouble Codes / Read DTC Information.

Does Tech 2 display any DTCs you have not diagnosed? Refer to

4.8 Diagnostic Trouble Code List System OK

When all diagnosis and repairs are completed, check the

system for correct operation.

4.10 DTC P0562 – System Voltage Low

DTC Description

This diagnostic procedure supports DTC P0562 System Voltage Low.

Circuit Description

The transmission control module (TCM) continuously monitors the system voltage on the battery and ignition circuits.

Lower than normal voltage may be inadequate to operate the transmission control solenoids properly. Improper solenoid

operation may cause erratic transmission operation and tie-up conditions, which may result in internal damage.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3832 of 6020

Automatic Transmission – 4L60E – Electrical Diagnosis Page 7C2–46

Step Action Yes No

3 Inspect the transmission and related components for the following:

• transmission fluid level,

• transmission fluid cooling system restrictions / blockages,

• debris in the transmission fluid,

• incorrect line pressure,

• torque converter stator operation, and

• transmission overload.

W as a fault found and rectified? Go to Step 10 Check for an

intermittent fault in

the circuit, refer to

8A Electrical-Body and Chassis

4 1 Switch off the ignition.

2 Disconnect connector E-95 from the transmission.

3 Using a multimeter set to measure voltage, probe between harness connector E-95 pin 16 and a known ground.

Does the multimeter display 4.8 – 5.2 V? Go to Step 6 Go to Step 5

5 Test the TFT sensor signal circuit (between connectors E-95 pin 16

and C-96 pin 35) for a high resistance, open circuit, short to ground or

short to voltage fault condition.

Did you find and correct the condition? Go to Step 10 Go to Step 9

6 1 Switch off the ignition.

2 Remove the TCM fuses C-8 and EB-4, refer to 8A Electrical- Body and Chassis.

3 Using a multimeter set to measure resistance, probe between connector E95 pin 15 and a known ground.

Does the multimeter display less than 5 Ω? Go to Step 8 Go to Step 7

7 Using a multimeter, test between E-95 pin 15 and C-96 pin 30 for high

resistance, open circuit, short to ground or short to voltage fault

condition.

W as any fault found and rectified? Go to Step 10 —

8 Replace the TFT sensor, refer to 7C4 Automatic Transmission –

4L60E – On-vehicle Servicing.

NOTE

Check for damaged wiring (short to ground, short to

voltage, high resistance or open circuit) or poor

connections inside the transmission assembly before

replacing the TFT sensor.

Was the repair complete? Go to Step 10 —

9 Replace the TCM, refer to 7C4 Automatic Transmission – 4L60E –

On-vehicle Servicing

Was the repair completed? Go to Step 10

—

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 4243 of 6020

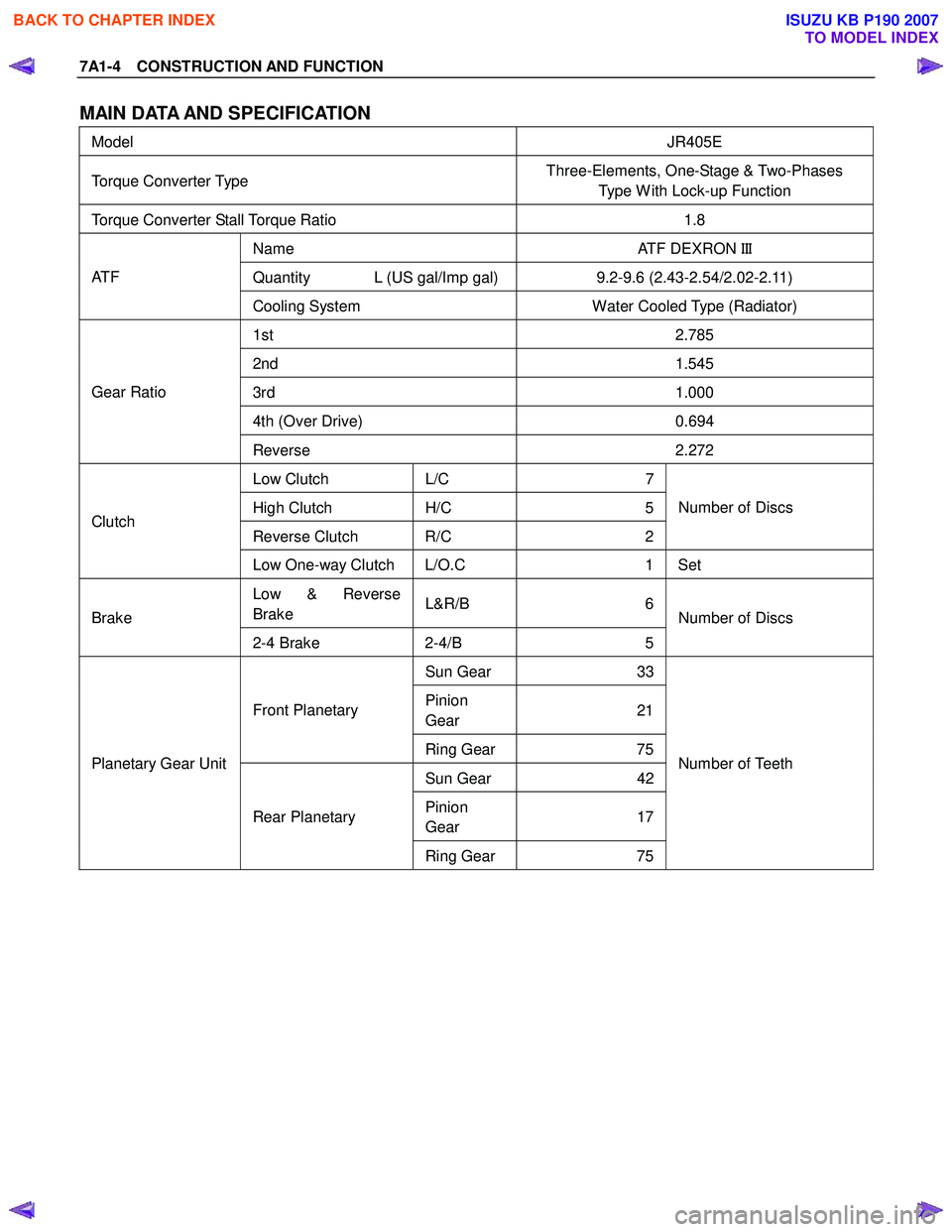

7A1-4 CONSTRUCTION AND FUNCTION

MAIN DATA AND SPECIFICATION

Model JR405E

Torque Converter Type Three-Elements, One-Stage & Two-Phases

Type W ith Lock-up Function

Torque Converter Stall Torque Ratio 1.8

Name ATF DEXRON III

Quantity L (US gal/Imp gal) 9.2-9.6 (2.43-2.54/2.02-2.11) AT F

Cooling System Water Cooled Type (Radiator)

1st 2.785

2nd 1.545

3rd 1.000

4th (Over Drive) 0.694

Gear Ratio

Reverse 2.272

Low Clutch L/C 7

High Clutch H/C 5

Reverse Clutch R/C 2Number of Discs Clutch

Low One-way Clutch L/O.C 1 Set

Low & Reverse

Brake L&R/B 6

Brake

2-4 Brake 2-4/B 5 Number of Discs

Sun Gear

33

Pinion

Gear 21Front Planetary

Ring Gear 75

Sun Gear 42

Pinion

Gear 17

Planetary Gear Unit

Rear Planetary Ring Gear 75 Number of Teeth

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 4286 of 6020

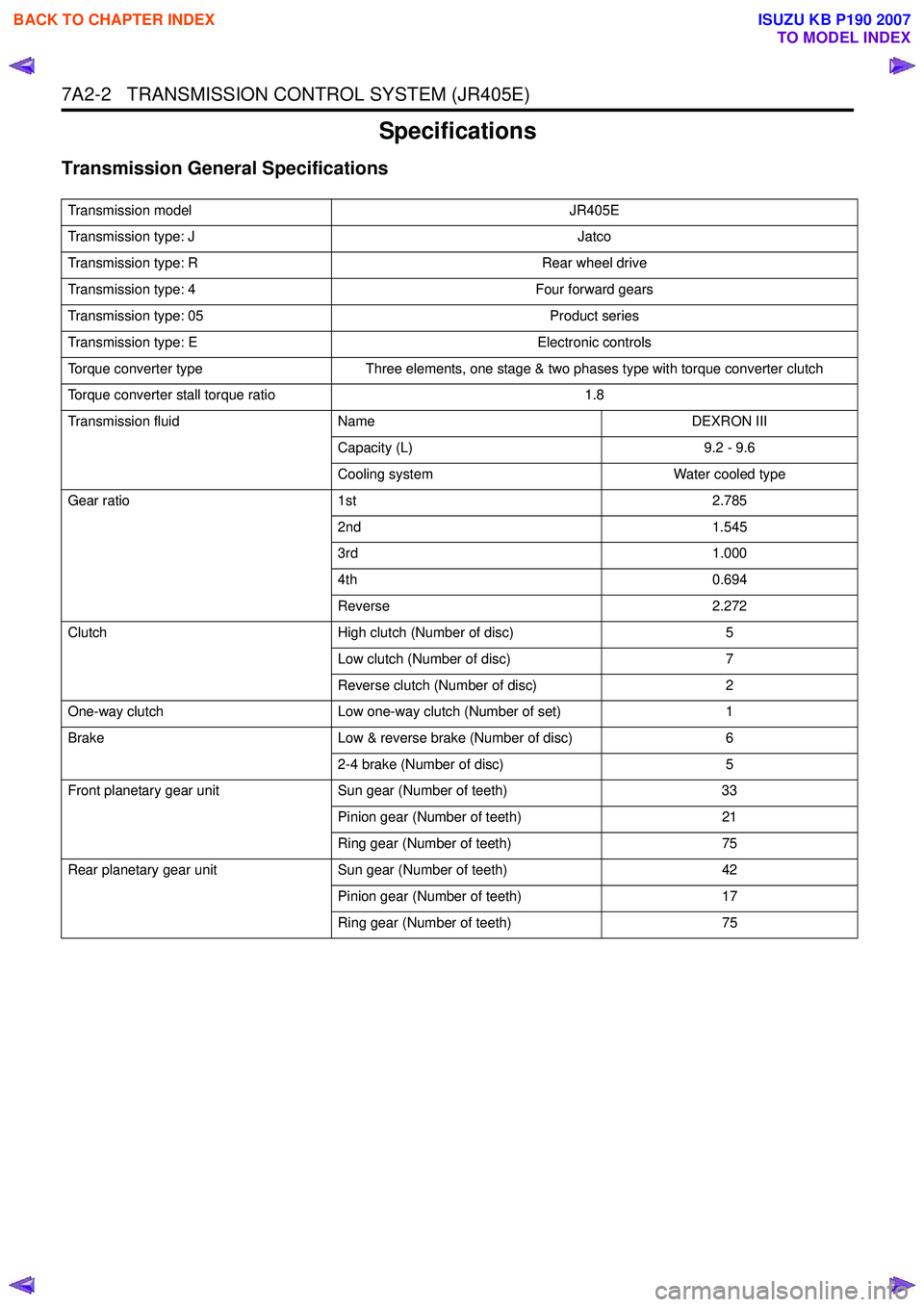

7A2-2 TRANSMISSION CONTROL SYSTEM (JR405E)

Specifications

Transmission General Specifications

Transmission modelJR405E

Transmission type: J Jatco

Transmission type: R Rear wheel drive

Transmission type: 4 Four forward gears

Transmission type: 05 Product series

Transmission type: E Electronic controls

Torque converter type Three elements, one stage & two phases type with torque converter clutch

Torque converter stall torque ratio 1.8

Transmission fluid Name DEXRON III

Capacity (L) 9.2 - 9.6

Cooling system Water cooled type

Gear ratio 1st 2.785

2nd 1.545

3rd 1.000

4th 0.694

Reverse 2.272

Clutch High clutch (Number of disc) 5

Low clutch (Number of disc) 7

Reverse clutch (Number of disc) 2

One-way clutch Low one-way clutch (Number of set) 1

Brake Low & reverse brake (Number of disc) 6

2-4 brake (Number of disc) 5

Front planetary gear unit Sun gear (Number of teeth) 33

Pinion gear (Number of teeth) 21

Ring gear (Number of teeth) 75

Rear planetary gear unit Sun gear (Number of teeth) 42

Pinion gear (Number of teeth) 17

Ring gear (Number of teeth) 75

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 4473 of 6020

ON-VEHICLE SERVICE (JR405E) 7A3-19

Install or Connect

1. Align the manual valve and the manual plate of the

transmission case.

43ASSY119

2. Install the control valve assembly and tighten the 12 fixing bolts to the specified torque.

Number of bolts Length Color

10 (A) 40 mm (1.57 in) Gold

2 (B) 30 mm (1.18 in) Gold

Bolt torque : 8 N·m (0.8 kgf·m/69 lb·in)

3. Connect the 2 harness connectors.

4. If removed, install the oil strainer.

Refer to “Solenoids, Oil Pressure Switch and Oil Temperature Sensor” previously in this section.

5. Install the new gasket and oil pan.

Bolt torque : 8 N·m (0.8 kgf·m/69 lb·in)

6. Fill with the fluid.

Refer to “ATF CHANGE” in this section.

7. Connect the negative battery cable.

8. Remove the wheel blocks.

FLUSHING THE TRANSMISSION FLUID COOLER AND LINE

The fluid cooler and lines may be flushed under the

following condition. This will help prevent more trouble

after the transmission is repaired.

1. W hen an abnormal amount of debris is found.

2. W hen an abnormal wear or chips on gears and shafts is found while overhauling.

3. W hen there is abnormal clutch facing wear and oil contamination found.

Procedures

1. Block the wheels.

2. Disconnect the negative battery cable.

3. Raise the vehicle and support it with suitable safet

y

stands.

4. Disconnect the fluid cooler lines at the transmission case and fluid cooler.

5. Flush and back-flush the fluid cooler and lines using solvent and compressed air.

Note:

DO NOT exceed (200 kPa/2.0 kgf/cm

2/28 psi) air

pressure, or damage may result to oil cooler.

6. Remove all remaining solvent from the system with

compressed air.

7. Flush the cooling system again with Automatic Transmission Fluid (ATF).

After the final flush, connect all lines.

Cooler line joint connector torque :

44 N·m (4.5 kgf·m/33 lb·ft)

8. Replenish the ATF.

9. Start the engine to test the system for the free flow o

f

fluid. If the flow is restricted, the cooler assembly o

r

lines must be replaced.

Repeated cleaning and flushing may not remove all the debris from the fluid cooler circuit.

Move the select lever through the various ranges and return to neutral.

Check for fluid level.

If the fluid level is below the specified range, ATF must be added.

10. Connect the negative battery cable.

11. Remove the safety stands.

12. Remove the wheel blocks.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 4475 of 6020

ON-VEHICLE SERVICE (JR405E) 7A3-21

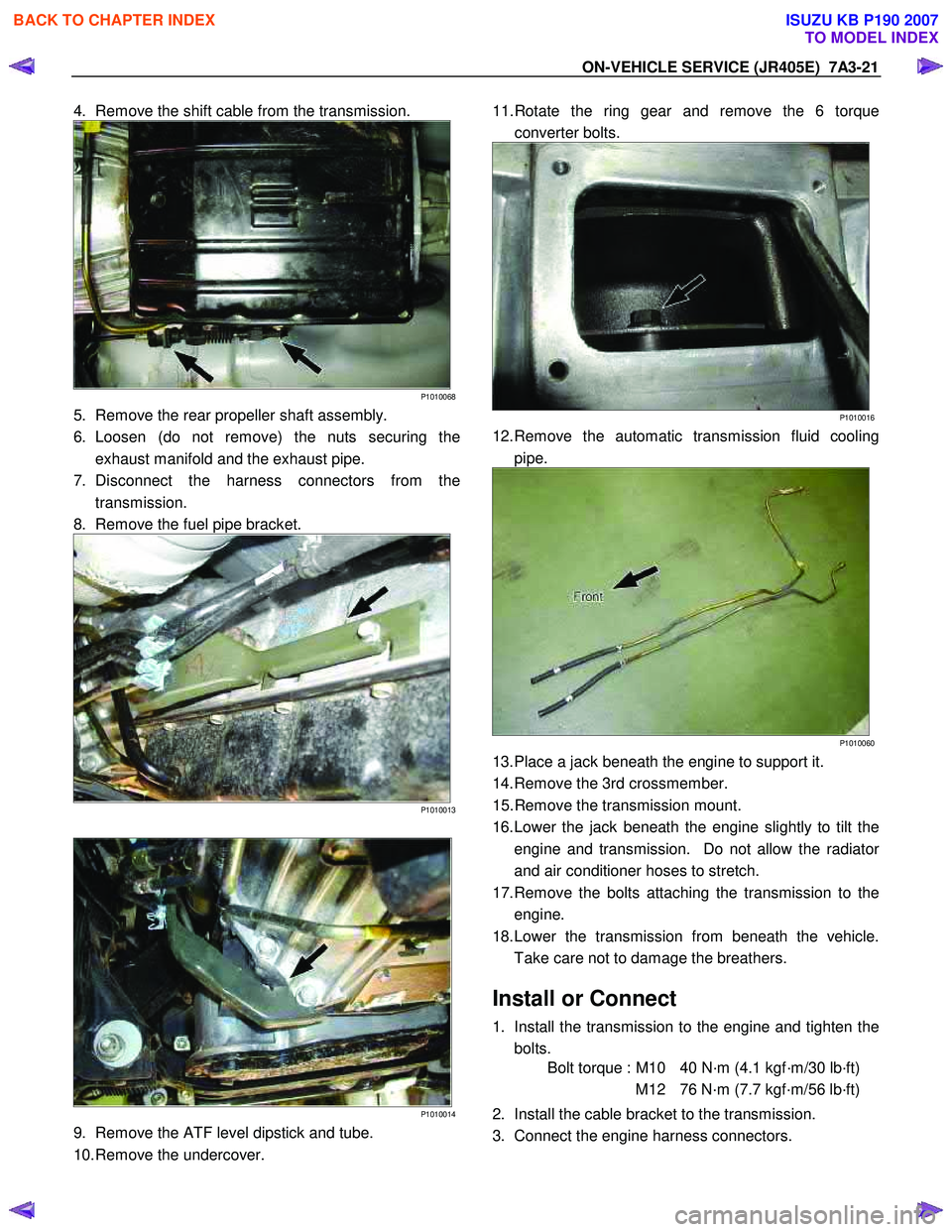

4. Remove the shift cable from the transmission.

P1010068

5. Remove the rear propeller shaft assembly.

6. Loosen (do not remove) the nuts securing the exhaust manifold and the exhaust pipe.

7. Disconnect the harness connectors from the transmission.

8. Remove the fuel pipe bracket.

P1010013

P1010014

9. Remove the ATF level dipstick and tube.

10. Remove the undercover.

11. Rotate the ring gear and remove the 6 torque

converter bolts.

P1010016

12. Remove the automatic transmission fluid cooling pipe.

P1010060

13. Place a jack beneath the engine to support it.

14. Remove the 3rd crossmember.

15. Remove the transmission mount.

16. Lower the jack beneath the engine slightly to tilt the engine and transmission. Do not allow the radiato

r

and air conditioner hoses to stretch.

17. Remove the bolts attaching the transmission to the engine.

18. Lower the transmission from beneath the vehicle. Take care not to damage the breathers.

Install or Connect

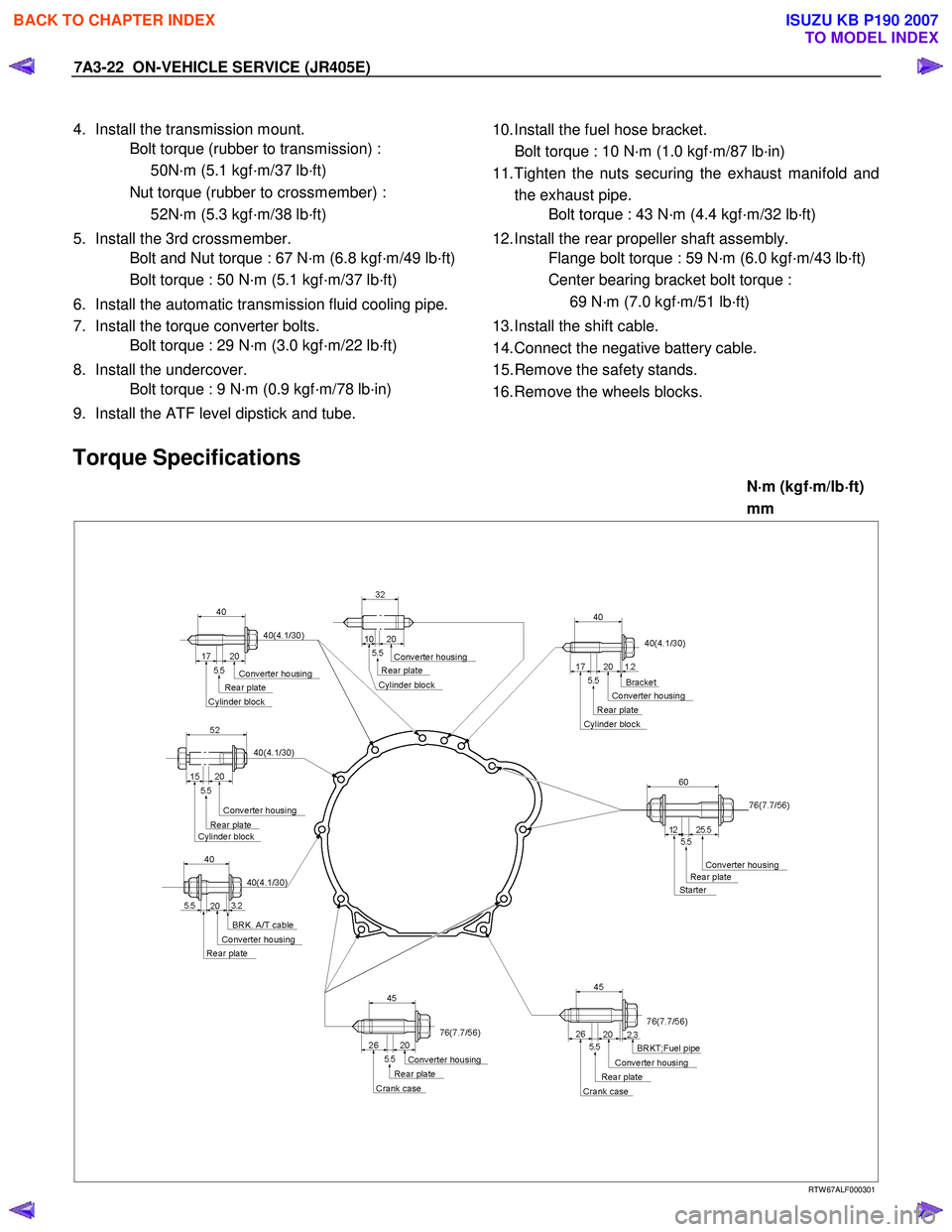

1. Install the transmission to the engine and tighten the bolts.

Bolt torque : M10 40 N·m (4.1 kgf·m/30 lb·ft)

M12 76 N·m (7.7 kgf·m/56 lb·ft)

2. Install the cable bracket to the transmission.

3. Connect the engine harness connectors.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 4476 of 6020

7A3-22 ON-VEHICLE SERVICE (JR405E)

4. Install the transmission mount.

Bolt torque (rubber to transmission) :

50N·m (5.1 kgf·m/37 lb·ft)

Nut torque (rubber to crossmember) :

52N·m (5.3 kgf·m/38 lb·ft)

5. Install the 3rd crossmember.

Bolt and Nut torque : 67 N·m (6.8 kgf·m/49 lb·ft)

Bolt torque : 50 N·m (5.1 kgf·m/37 lb·ft)

6. Install the automatic transmission fluid cooling pipe.

7. Install the torque converter bolts.

Bolt torque : 29 N·m (3.0 kgf·m/22 lb·ft)

8. Install the undercover.

Bolt torque : 9 N·m (0.9 kgf·m/78 lb·in)

9. Install the ATF level dipstick and tube.

10. Install the fuel hose bracket.

Bolt torque : 10 N·m (1.0 kgf·m/87 lb·in)

11. Tighten the nuts securing the exhaust manifold and the exhaust pipe.

Bolt torque : 43 N·m (4.4 kgf·m/32 lb·ft)

12. Install the rear propeller shaft assembly.

Flange bolt torque : 59 N·m (6.0 kgf·m/43 lb·ft)

Center bearing bracket bolt torque :

69 N·m (7.0 kgf·m/51 lb·ft)

13. Install the shift cable.

14. Connect the negative battery cable.

15. Remove the safety stands.

16. Remove the wheels blocks.

Torque Specifications

N ⋅

⋅⋅

⋅

m (kgf ⋅

⋅⋅

⋅

m/lb ⋅

⋅⋅

⋅

ft)

mm

RTW 67ALF000301

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007