cooling ISUZU KB P190 2007 Workshop Repair Manual

[x] Cancel search | Manufacturer: ISUZU, Model Year: 2007, Model line: KB P190, Model: ISUZU KB P190 2007Pages: 6020, PDF Size: 70.23 MB

Page 3511 of 6020

Engine Management – V6 – Diagnostics Page 6C1-2–233

APP Sensor 2 (Accelerator Pedal Position) V 0.47 0.47

TP Sensor 1 (Throttle Position) V 0.73 0.57

TP Sensor 2 (Throttle Position) V 4.27 4.43

TP Sensor 1 Learned Lower Position (Throttle Position) V 0.53 0.53

TP Sensor 2 Learned Lower Position (Throttle Position) V 4.49 4.49

Electronic Throttle Control Learn Counter Counts 11 11

Brake Lamp Switch Inactive / Active Inactive Inactive

Brake Switch Signal Status Valid / Invalid Valid Valid

Initial Brake Apply Signal Inactive / Active Inactive Inactive

Engine Speed RPM 0 598

Desired Engine Idle Speed RPM 680 600

Coolant Temperature

°C 38 96

Intake Air Temperature

°C 32 29

Mass Air Flow Sensor

V 1.0 1.1

Mass Air Flow g/s 0.00 3.11

Barometric Pressure kPa 102 102

Barometric Pressure V 4.88 4.88

Engine Load % 100 20

Volumetric Efficiency % 99 14

Ignition Accessory Signal Off / On On On

Ignition On Signal Off / On On On

Engine Control Ignition Relay Off / On On On

Engine Control Ignition Relay Feedback V 11.7 14.0

DTC Set This Ignition No DTC / DTC Set No DTC No DTC

Vehicle Speed km/h 0 0

Engine Runtime h:m:s 00:00:00 00:16:25

(1) Automatic Transmission Only (2) Manual Transmission Only

Cooling/HVAC Data

Tech 2 Display Units Displayed Ignition On Engine Running

Coolant Temperature

°C 37 100

Cooling Fan

Off / On Off Off

Intake Air Temperature

°C 32 30

A/C Request

No / Yes No No

A/C Relay (Air Conditioning) Off / On Off Off

A/C Pressure Sensor (Air Conditioning) V 1.0 1.5

A/C Pressure Sensor (Air Conditioning) kPa 732.55 1121.25

A/C Cutoff Mode (Air Conditioning) Inactive / Pressure /

Max. Acceleration / Active Inactive Inactive

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3518 of 6020

Engine Management – V6 – Diagnostics Page 6C1-2–240

Cruise Control Switch: This parameter displays the state of the cruise control on/off switch input to the control module.

Cruise Control Disengagement Reason: The parameter displays which of a possible 28 causes for the cruise control

to disengage.

CC Disengagement 1 – 8 History (Cruise Control): The parameter displays the last 8 cruise control disengages in

order from 1 to 8, with 8 being the most recent. There are about 28 possible causes for the cruise control to disengage.

Cruise Resume/Acceleration Switch: This parameter displays the state of the cruise control resume/accel switch

position input to the ECM.

Cruise Set / Coast Switch: This parameter displays the state of the cruise controls set/decel. switch position input to

the ECM.

Cycles of Misfire: This parameter displays the number of misfire tests during 200 engine revolutions.

Cylinder 1 – 6 Injector Circuit Status: This parameter displays the state of the fuel injector control circuit. The

parameter displays ‘Fault’ if the fuel injector control circuit is open, shorted to ground, or shorted to voltage. This

parameter displays ‘Undefined Status’ until the control circuit has been commanded ‘On’.

Dec. Fuel Cutoff (Deceleration): This parameter displays the status of the ECM operating mode, used to turn off the

fuel injectors and the evaporative emission (EVAP) canister purge valve during certain deceleration conditions.

Desired Engine Idle Speed: This parameter displays the desired engine idle speed as commanded by the ECM.

Desired Throttle Position: This parameter displays the desired throttle position (TP) angle commanded by the ECM.

Distance Since DTC Cleared: This parameter displays the distance (km) travelled since any diagnostic trouble code

(DTC) has been cleared from the ECM memory.

DTC Set This Ignition: This parameter displays Yes if a DTC set on the current ignition cycle.

ECM Immobilized: This parameter displays ‘Yes’ when an internal control module reset occurs. Tech 2 will display ‘No’

under normal operating conditions.

Electronic Throttle Control Learn Counter: W hen the ECM performs a throttle body relearn procedure, the throttle

plate is commanded to move from the rest position (7% open) to full closed (0%), then to around 10% open.

At the start of this procedure, the Tech 2 ‘TAC Learn Counter’ parameter should display 0, then count up to 11 after the

procedure is completed. If the counter did not start at 0 or if the counter did not end at 11, a fault has occurred and a

DTC should set.

Engine Control Ignition Relay: This parameter displays the state of the control circuit for control module power relay

as commanded by the ECM.

Engine Control Ignition Relay Feedback: This parameter displays the voltage available at the engine control ignition

relay pin of the control module.

Engine Load: This parameter displays the calculated engine load in percent based on inputs to the control module from

various engine sensors.

Engine Oil Life Remaining: This parameter displays the percentage of engine oil life remaining. The controller

calculates the engine oil life by monitoring engine load, collant temperature and engine speed.

Engine Oil Pressure: This parameter displays the oil pressure in kPa from the ECM, developed from the engine oil

pressure (EOP) sensor input.

Engine Oil Pressure Sensor: This parameter displays ‘High’ if the engine oil pressure is within the correct range. If the

ECM detects that the engine oil pressure is not within the correct range, Tech 2 will display ‘Low’.

Engine Runtime: This parameter displays the time elapsed since the engine was started.

Engine Speed: This parameter displays the speed of the engine crankshaft rotation from information received from the

CKP sensor. If there is a CKP sensor DTC, the ECM calculates the engine speed from one of the camshaft position

(CMP) sensors.

EVAP Purge Solenoid (Evaporative Emission): This parameter displays the on-time or duty cycle of the EVAP

canister purge solenoid commanded by the ECM. Zero percent indicates no purge. One hundred percent indicates full

purge.

EVAP Purge Solenoid Valve Circuit Status (Evaporative Emission): This parameter displays the state of the EVAP

purge solenoid control circuit. The parameter displays ‘Fault’ if the EVAP purge solenoid control circuit is open, shorted

to ground, or shorted to voltage. The parameter displays ‘Undefined Status’ until the circuit has been established as

‘OK’.

Cooling Fan Relay: This parameter displays the control module commanded state of the fan relay control circuit.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3519 of 6020

Engine Management – V6 – Diagnostics Page 6C1-2–241

Cooling Fan Relay Circuit Status: This parameter displays the state of the fan relay control circuit. The parameter

displays ‘Fault’ if the fan relay control circuit is open, shorted to ground, or shorted to voltage. The parameter displays

‘Undefined’ until the relay control circuit has been determined as being ‘OK’.

Fuel Level: This parameter displays the amount of fuel in the fuel tank in litres, as calculated by the ECM from data

received from the fuel level sensor.

Fuel Level Sensor: This parameter displays the voltage received from the fuel level sensor in the fuel tank, by the ECM.

Fuel Pump Relay Circuit Status: This parameter displays the state of the fuel pump relay control circuit. The

parameter displays ‘Fault’ if the fuel pump relay control circuit is open, shorted to ground, or shorted to voltage. The

parameter displays ‘Undefined’ until the relay control circuit has been determined as being ‘OK’.

Fuel Pump Relay: This parameter displays the ECM commanded state of the fuel pump relay control circuit.

Fuel Trim Learn: This parameter displays ‘Enabled’ when conditions are appropriate for enabling long term fuel trim

corrections. This indicates that the long term fuel trim is adapting continuing amounts of short term fuel trim. If Tech 2

displays ‘Disabled’, then long term fuel trim will not respond to changes in short term fuel trim.

Ignition Accessory Signal: This parameter displays ‘On’ when the control module detects a voltage at the

ignition ‘ACC’ terminal, X1-4 of the ignition switch.

Ignition On Signal: This parameter displays ‘On’ when the control module detects a voltage at the ignition ‘IGN’

terminal X1-3 of the ignition switch.

Initial Brake Apply Signal: This parameter displays the status of the brake lamp switch. Before the cruise control can

be activated, this switch contact must be open circuit when the brake pedal is pressed.

Injection Time Cylinder 1 – 6: This parameter displays the amount of fuel injector On-time or pulse width as

commanded by the ECM.

Intake Air Temperature: This parameter displays the temperature of the air entering the air induction system based on

input to the ECM from the intake air temperature (IAT) sensor.

Knock Sensor Signal (Bank 1 or Bank 2): This parameters displays the voltage input to the control module from the

knock sensor (KS).

Knock Retard: This parameter indicates the amount of spark advance in crankshaft degrees, that the ECM removes

from the ignition control (IC) spark advance in response to the signal from the knock sensors.

Knock Retard Cylinder 1 – 6: This parameter displays the knock retard as commanded by the ECM for cylinders 1-6.

Each cylinder is controlled individually based on both knock sensor signal inputs.

Loop Status B1S1 / B2S1 (Bank 1 or Bank 2 Sensor 1): This parameter displays the state of the fuel control system

as commanded by the ECM. ‘Closed’ Loop operation indicates that the ECM is controlling the fuel delivery based on the

oxygen sensors input signal. In ‘Open’ Loop operation the ECM ignores the oxygen sensor input signal and bases the

amount of fuel to be delivered on other sensor inputs.

LTFT Idle/Deceleration (Bank 1 or Bank 2) (Long Term Fuel Trim): This parameter displays the commanded Long

Term Fuel Trim correction by the ECM for bank 1 or bank 2 for idle and deceleration conditions.

LTFT Cruise/Acceleration (Bank 1 or Bank 2) (Long Term Fuel Trim): This parameter displays the commanded Long

Term Fuel Trim correction by the ECM for bank 1 or bank 2 for cruise and acceleration conditions.

Malfunction Indicator (MI): This parameter displays the commanded (‘On, ‘Off’ or ‘Flashing’) state of the malfunction

indicator lamp (MIL) control circuit by the ECM.

Malfunction Indicator (MI) Circuit Status: This parameter displays the state of the MIL control circuit. The parameter

displays ‘Fault’ if the MIL control circuit is open, shorted to ground, or shorted to voltage. This parameter displays

‘Undefined Status’ until the circuit has been determined as being ‘OK’.

Mass Air Flow: This parameter displays the measured quantity (g/s) of air flowing into the engine during all operating

conditions.

Mass Air Flow Sensor: This parameter displays the signal voltage from the mass air flow (MAF) sensor to the ECM.

Misfire Current Cyl. #1 – #6: Tech 2 displays a range of 0 – 200 counts. This parameter displays the number of

misfires that have been detected during the last 200 cylinder firing events. The counters may normally display some

activity, but the activity should be nearly equal for all of the cylinders, and in low numbers.

Misfire History Cyl. #1 – #6: Tech 2 displays a range of 0 – 65,535 counts. The misfire history counters display the total

level of misfire that has been detected on each cylinder. The misfire history counters will not update or show any activity

until a misfire DTC P0300 has become active. The misfire history counters will update every 200 cylinder firing events.

Oil Level: W hen the ECM receives information from the engine oil level switch, where the engine oil level is within

preset parameters, Tech 2 will display ‘Normal’. If not within preset parameters, the display will show ‘Low’.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3522 of 6020

Engine Management – V6 – Diagnostics Page 6C1-2–244

Precondition: Ignition ‘On’.

Cooling Fan (PWM)

Take care that no-one can access the engine

compartment during these tests!

This test allows the Technician to turn the cooling fan on in increments to its maximum speed.

Precondition: Ignition ‘On’ Air conditioning is ‘Off’..

Alternator L Terminal

This test allows the Technician to turn ‘On’ and ‘Off’, the commanded state of the voltage regulator in the alternator. ‘On’

displays a commanded state of 99%, while ‘Off’ displays a commanded state of 0%.

Precondition: Engine running.

EVAP Purge Solenoid

This test allows the Technician to control the EVAP purge solenoid valve. The normal commanded state is ‘0%’. The

system will increase or decrease the amount of purge by changing the duty cycle of the purge valve in 10% increments

within a range of 0 – 100%. The system will remain in the commanded state until cancelled by Tech 2.

NOTE

The EVAP Purge Solenoid Command parameter

may not change states when using this output

control.

Precondition: Ignition ‘On’, engine ‘Off’.

Engine Speed Control

Other DTCs may set when the Engine Speed

Control function is used. Disregard those

DTCs that set under this condition.

Allows the increase / decrease of the engine speed in 20 – 30 rpm increments from the base idle speed, up to 1,600

rpm.

NOTE

If the engine coolant temperature is below the

prescribed minimum, a message to that effect is

displayed and access to engine speed control is

blocked.

Preconditions: Engine running, engine temperature above 80 °C, transmission in Park or Neutral.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3540 of 6020

Engine Management – V6 – Service Operations Page 6C1-3–16

2.6 Engine Coolant Temperature Sensor

Remove

To avoid serious personal injury, never

remove the engine coolant temperature (ECT)

sensor when the engine is hot. Allow the

engine to cool to ambient temperature (less

than 50 °

°°

°

C) before performing this procedure.

1 Turn the ignition switch off.

To avoid serious personal injury, never

remove the coolant filler cap when the engine

is hot. Allow the engine to cool to ambient

temperature (less than 50 °

°°

°

C) before

performing this procedure.

2 Allow the engine to cool to ambient temperature less than 50 °C, and slowly remove coolant filler cap located on the

coolant outlet housing.

3 Drain approximately two litres of coolant into a suitable container, refer to 6B1 – Engine Cooling – V6.

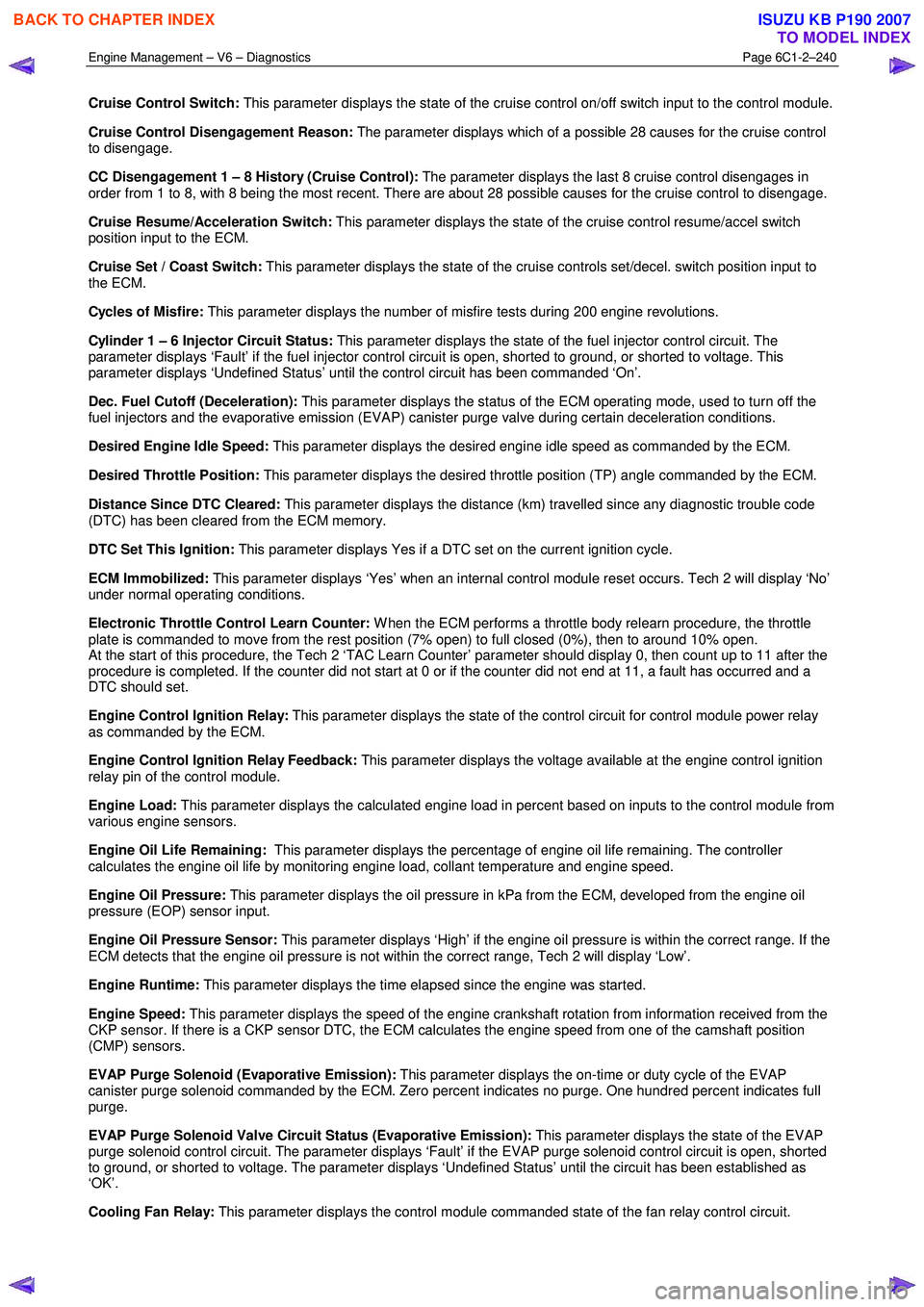

4 Disconnect the wiring harness connector (1) from the ECT sensor (2).

Figure 6C1-3 – 12

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3541 of 6020

Engine Management – V6 – Service Operations Page 6C1-3–17

Clean the area around the ECT before

removal to avoid debris from entering the

engine.

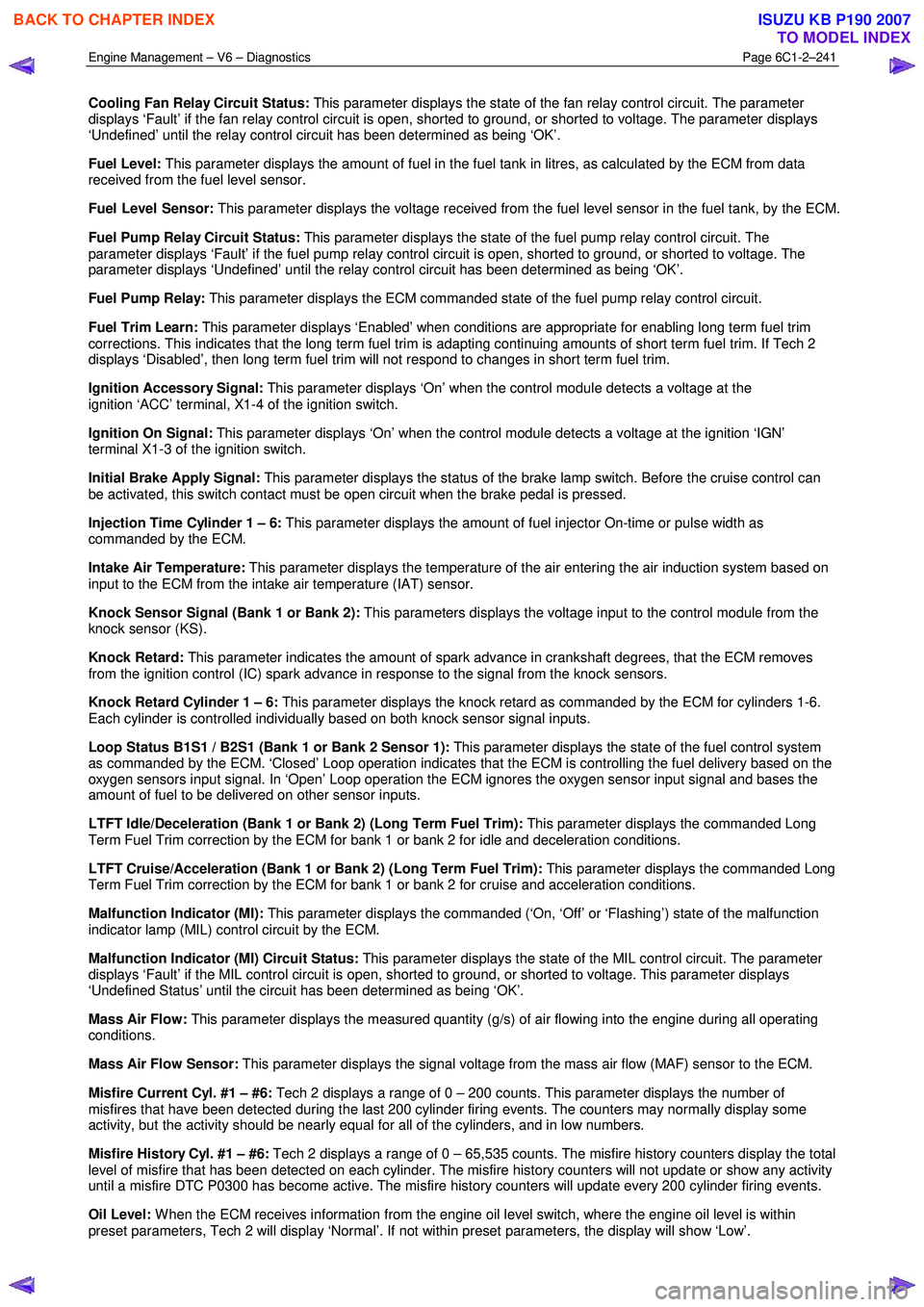

5 Remove the ECT sensor (1). NOTE

If coolant leaks from the cylinder head as the

sensor is removed, screw the sensor back into

the cylinder head and drain more coolant from

the cooling system.

6 If required, test the ECT sensor, refer to the Test in this Section.

Figure 6C1-3 – 13

Test

To prevent component damage, use

connector test adaptor kit J 35616-A.

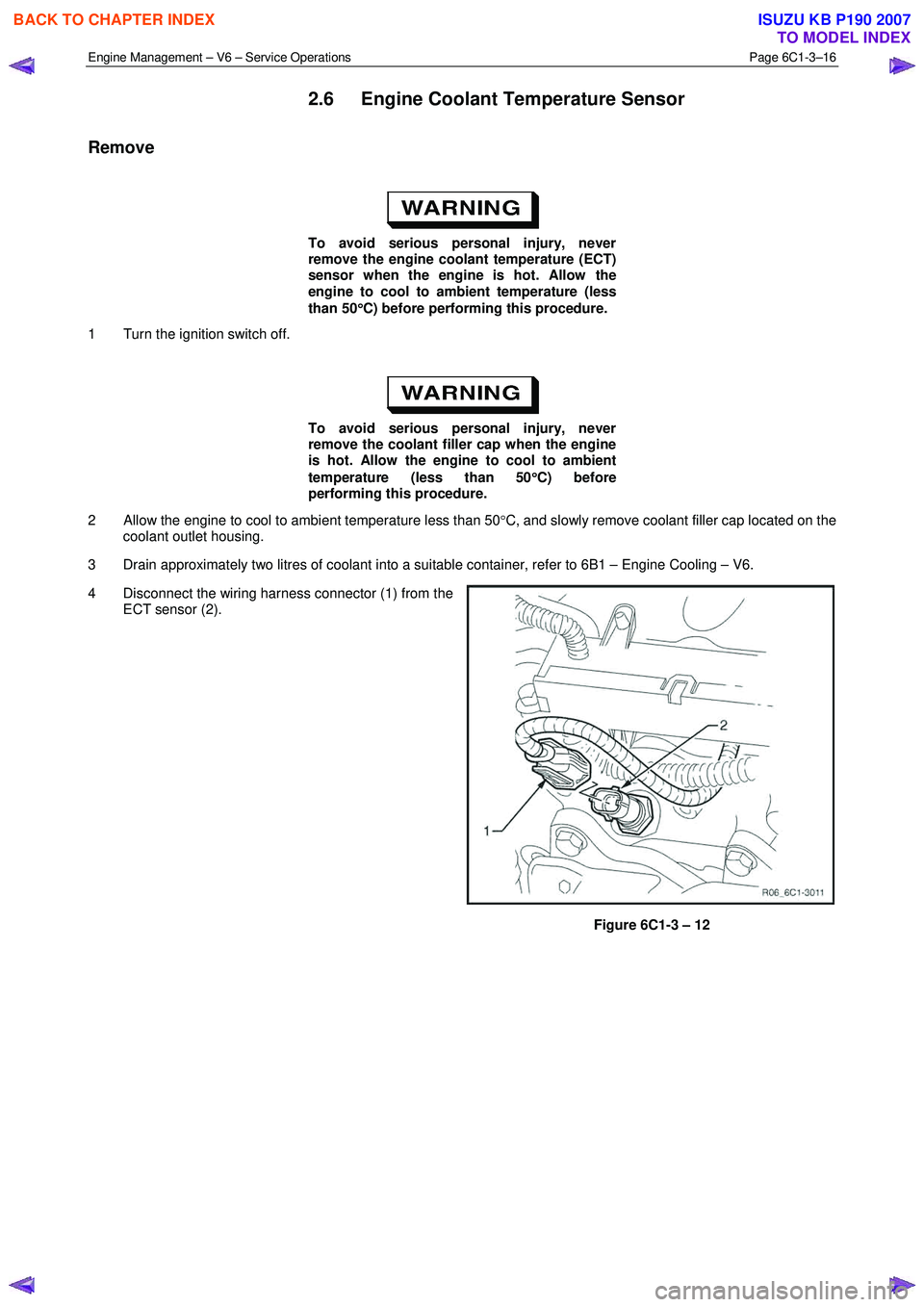

Resistance Check

1 Suspend the engine coolant temperature (ECT) sensor and a suitable thermometer in a container of 50/50 DEX- COOL® long life coolant or equivalent and water.

NOTE

Neither the ECT sensor or thermometer should

rest on the bottom of the container due to an

uneven concentration of heat at this point when

the container is heated.

2 Connect a digital ohmmeter using connector test adaptor kit J 35616-A to the ECT sensor.

3 Measure the resistance across terminals 1 and 2.

4 W hilst heating the container, observe the resistance values as the temperature increases and compare the

temperature / resistance change to the specifications.

Figure 6C1-3 – 14

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3542 of 6020

Engine Management – V6 – Service Operations Page 6C1-3–18

5 If the resistance is not within specifications, replace

the ECT sensor.

Engine Coolant Temperature Vs Resistance

Temperature °C Resistance – Ohms (

Ω)

-40 40490 – 50136

-20 14096 – 16827

-10 8642 – 10152

0 5466 – 6326

20 2351 – 2649

25 1941 – 2173

40 1118 – 1231

60 573 – 618

80 313 – 332

100 182 – 191

120 109 – 116

140 68 – 74

Reinstall

Reinstallation of the engine coolant temperature (ECT) sensor is the reverse of the removal procedure, noting the

following:

1 Tighten the ECT sensor to the correct torque specification.

Engine coolant temperature sensor

torque specification ............................................22.0 Nm

2 Refill the cooling system, refer to 6B1 Engine Cooling – V6.

3 Road test the vehicle and check for correct operation, taking particular note there is no coolant leakage.

2.7 Engine Control Module

Service of the engine control module (ECM) should normally consist of either replacement or ECM programming. If the

diagnostic procedures call for the ECM to be replaced, it should be first checked to ensure it is the correct part. If it is,

replace the faulty ECM.

Do not touch the ECM connector pins as

electrostatic discharge (ESD) damage may

result.

When removing or reinstalling the ECM wiring

harness connector/s, ensure the ignition

switch is in the OFF position and the battery

has been disconnected. Failure to do so may

result in damage to the ECM and / or

associated componentry.

Disconnection of the battery affects certain

vehicle electronic systems. Refer to 6D1-3

Battery - V6 before disconnecting the battery.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3576 of 6020

Engine Management – V6 – Service Operations Page 6C1-3–52

Oil Fouled (3)

W et, oily deposits with minor electrode wear possibly due to oil leaking past worn piston rings.

Breaking in a new or recently overhauled engine before the rings are fully seated may also result in this condition.

Deposit Fouling A (4)

Red brown, yellow and white coloured coatings on the insulator tip which are by-products of combustion. They come

from fuel and lubricating oil which generally contain additives. Most powdery deposits have no adverse effect on spark

plug operation, however, they may cause intermittent missing under severe operating conditions.

Deposit Fouling B (5)

Deposits similar to those identified in deposit fouling A (4). These are also by-products of combustion from fuel and

lubricating oil. Excessive valve stem clearances and / or defective intake valve seals allow too much oil to enter the

combustion chamber. The deposits will accumulate on the portion of the spark plug that projects into the chamber and

will be heaviest on the side facing the intake valve. If this condition is only detected in one or two cylinders, check the

valve stem seals.

Deposit Fouling C (6)

Most powdery deposits identified in deposit fouling A (4) have no adverse effect on the operation of the spark plug as

long as they remain powdery.

Under certain conditions of operation however, these deposits melt and form a shiny glaze coating on the insulator.

W hen hot, this acts as a good electrical conductor allowing the current to flow along the deposit instead of sparking

across the gap.

Detonation (7)

Commonly referred to as engine knock or pinging, detonation causes severe shocks inside the combustion chamber

causing damage to parts.

Pre-ignition (8)

Burnt or blistered insulator tip and badly eroded electrodes probably due to the excessive heat.

This is often caused by a cooling system blockage, sticking valves, improperly installed spark plugs or plugs that are the

wrong heat rating (too hot).

Sustained high speed with a heavy load can produce temperatures high enough to cause pre-ignition.

Heat Shock Failure (9)

A rapid increase in spark plug tip temperature under severe operating conditions can cause heat shock and result in

fractured insulators. This is a common cause of broken and cracked insulator tips.

Insufficient Installation Torque (10)

Poor contact between the spark plug and the cylinder head seat.

The lack of proper heat transfer that results from poor seat contact causes overheating of the spark plug. In many cases,

severe damage occurs. Dirty threads in the cylinder head can cause the plug to seize before it is seated.

Ensure the cylinder head and spark plug threads are free of deposits, burrs and scale before installation.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3590 of 6020

Charging System – V6 Page 6D1-1-3

1 General Information

1.1 Components

Generator

The Mitsubishi generator can be identified visually by its two lower and one upper mounting lugs.

It is mounted to the lower right-hand side of the engine block. It is driven by the same drive belt that drives other engine

ancillaries and requires no periodic drive belt adjustment.

The generator has three phases, incorporating a rotor with six pole pairs fitted and two internal cooling fans; one on the

drive-end and one on the slip-ring end. The rotor is supported by ball bearings in both the drive and slip-ring end

housings. Surrounding the rotor is a stator, which has a three phase delta connected output winding construction on a

ring shaped lamination pack.

The output of the stator winding is rectified by eight diodes that are contained within the slip-ring end housing. Excitation

current is supplied to the rotor field coil via the voltage regulator, the brushes and slip-rings. The electronic voltage

regulator requires no adjustment in service.

The generator has four external connections (refer to Figure 6D1-1 1):

• Generator – Terminal P-9 to the battery positive terminal P-1 via fuse SBF1,

• Generator – E-4 pin 1 to the ECM connection E-60 pin 43 – regulator monitoring,

• Generator – E-4 pin 2 to the ECM connection E60 pin 21 – battery voltage sensing, and

• ground connection via the installation bolts.

Generator Types

The vehicle is fitted with a 120 amp generator.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3657 of 6020

Battery Page 6D1-3–17

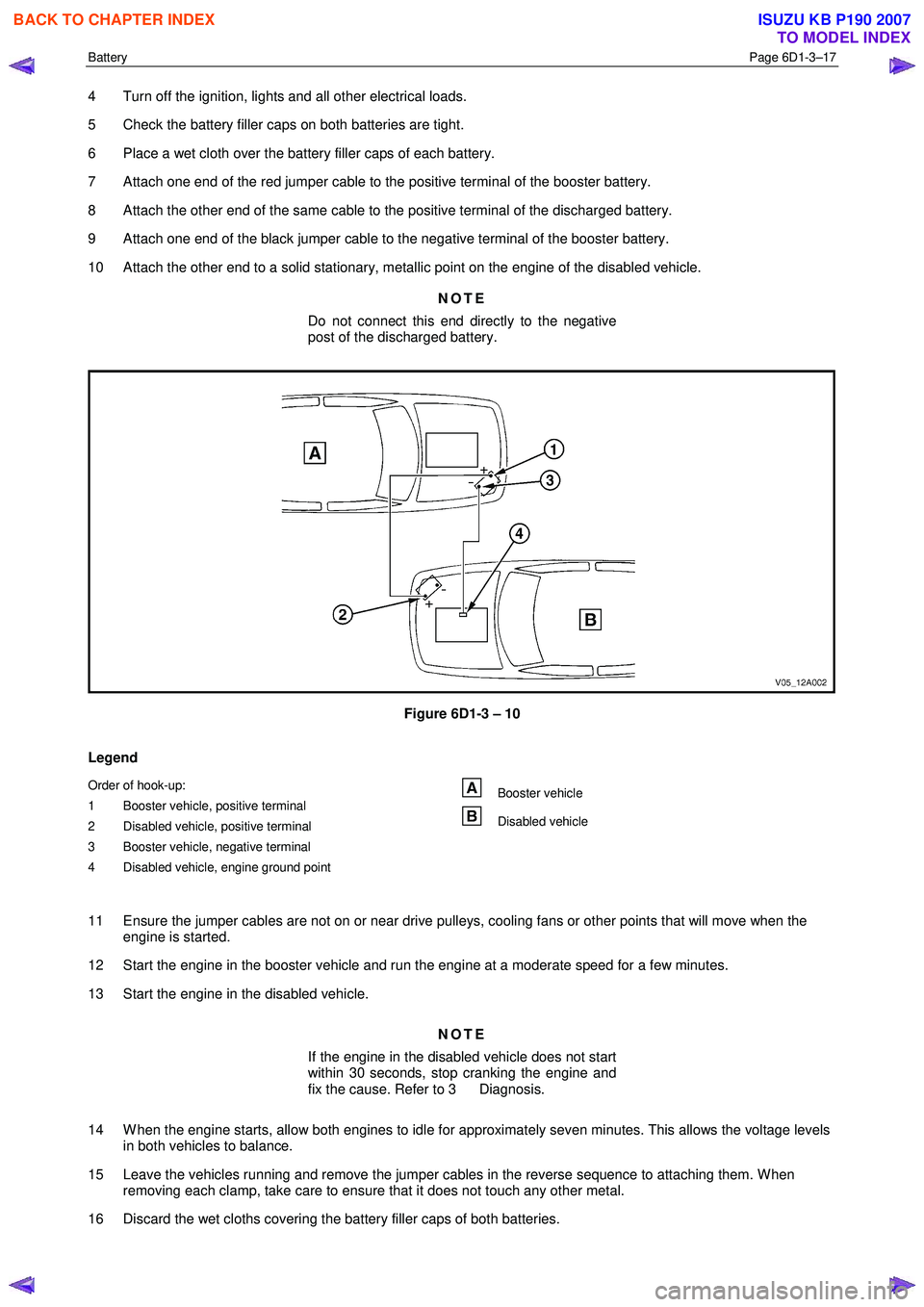

4 Turn off the ignition, lights and all other electrical loads.

5 Check the battery filler caps on both batteries are tight.

6 Place a wet cloth over the battery filler caps of each battery.

7 Attach one end of the red jumper cable to the positive terminal of the booster battery.

8 Attach the other end of the same cable to the positive terminal of the discharged battery.

9 Attach one end of the black jumper cable to the negative terminal of the booster battery.

10 Attach the other end to a solid stationary, metallic point on the engine of the disabled vehicle.

NOTE

Do not connect this end directly to the negative

post of the discharged battery.

Figure 6D1-3 – 10

Legend

Order of hook-up:

1 Booster vehicle, positive terminal

2 Disabled vehicle, positive terminal

3 Booster vehicle, negative terminal

4 Disabled vehicle, engine ground point Booster vehicle

Disabled vehicle

11 Ensure the jumper cables are not on or near drive pulleys, cooling fans or other points that will move when the engine is started.

12 Start the engine in the booster vehicle and run the engine at a moderate speed for a few minutes.

13 Start the engine in the disabled vehicle.

NOTE

If the engine in the disabled vehicle does not start

within 30 seconds, stop cranking the engine and

fix the cause. Refer to 3 Diagnosis.

14 W hen the engine starts, allow both engines to idle for approximately seven minutes. This allows the voltage levels in both vehicles to balance.

15 Leave the vehicles running and remove the jumper cables in the reverse sequence to attaching them. W hen removing each clamp, take care to ensure that it does not touch any other metal.

16 Discard the wet cloths covering the battery filler caps of both batteries.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007