height ISUZU KB P190 2007 Workshop Owner's Manual

[x] Cancel search | Manufacturer: ISUZU, Model Year: 2007, Model line: KB P190, Model: ISUZU KB P190 2007Pages: 6020, PDF Size: 70.23 MB

Page 515 of 6020

FRONT WHEEL DRIVE 4C1-11

Removal

1. Jack up the vehicle and support it using jack stand.

2. Remove the tire and wheel.

3. Remove the stone guard.

4. Remove the brake caliper fixing bolt and hang the caliper. Refer to Disc Brakes in Brake section.

5. Remove the antilock brake system speed sensor.

Refer to Front W heel Speed Sensor in Brake section.

6. Remove the hub and disc assembly.

Refer to Front Hub and Disc in this section.

7. Remove the propeller shaft, refer to Front Propeller Shaft in this section.

8. Loosen the height control arm of the torsion bar, then remove the torsion bar from lower control arm.

Refer to Torsion Bar in Suspension section.

9. Remove the suspension crossmember.

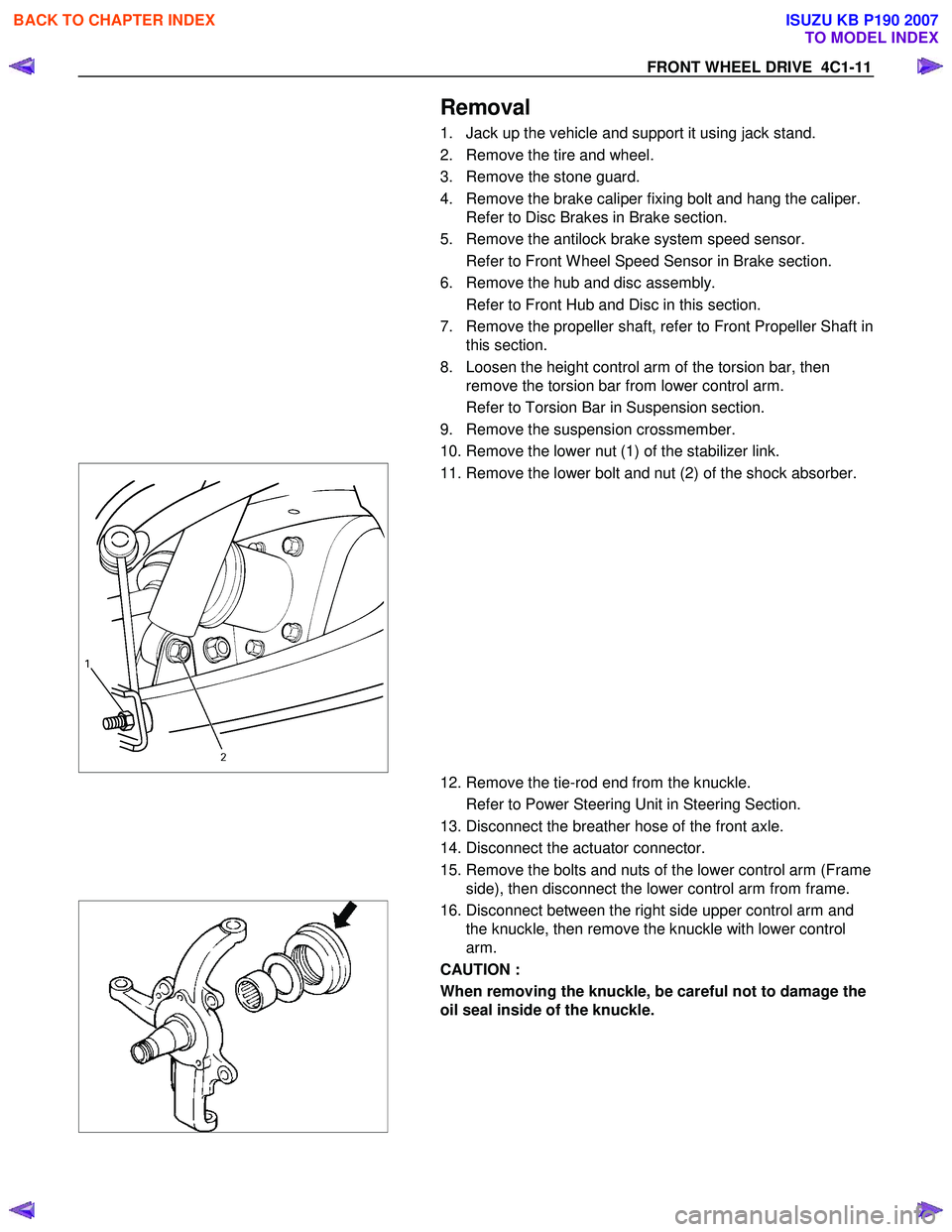

10. Remove the lower nut (1) of the stabilizer link.

11. Remove the lower bolt and nut (2) of the shock absorber.

12. Remove the tie-rod end from the knuckle.

Refer to Power Steering Unit in Steering Section.

13. Disconnect the breather hose of the front axle.

14. Disconnect the actuator connector.

15. Remove the bolts and nuts of the lower control arm (Frame side), then disconnect the lower control arm from frame.

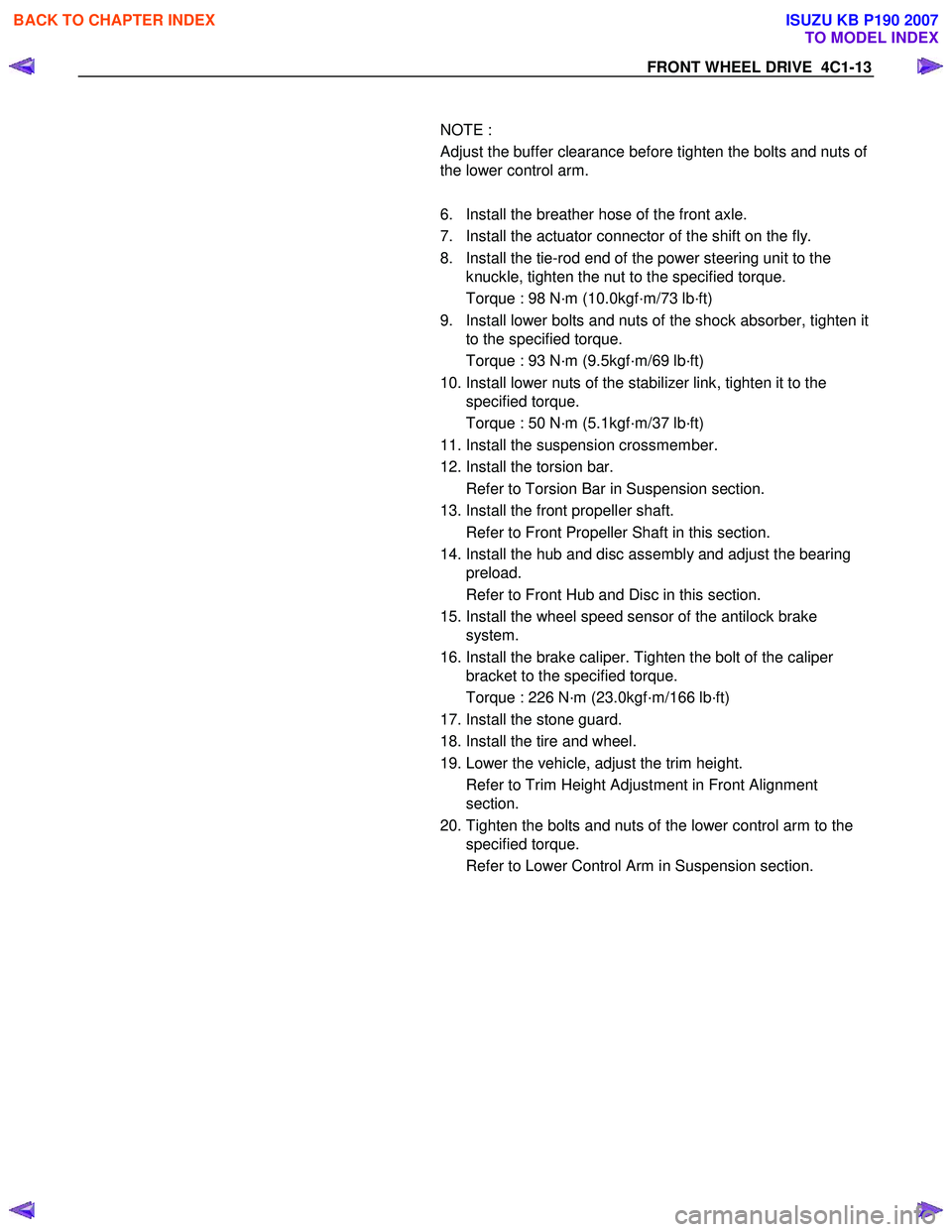

16. Disconnect between the right side upper control arm and

the knuckle, then remove the knuckle with lower control

arm.

CAUTION :

When removing the knuckle, be careful not to damage the

oil seal inside of the knuckle.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 517 of 6020

FRONT WHEEL DRIVE 4C1-13

NOTE :

Adjust the buffer clearance before tighten the bolts and nuts of

the lower control arm.

6. Install the breather hose of the front axle.

7. Install the actuator connector of the shift on the fly.

8. Install the tie-rod end of the power steering unit to the knuckle, tighten the nut to the specified torque.

Torque : 98 N·m (10.0kgf·m/73 lb·ft)

9. Install lower bolts and nuts of the shock absorber, tighten it to the specified torque.

Torque : 93 N·m (9.5kgf·m/69 lb·ft)

10. Install lower nuts of the stabilizer link, tighten it to the specified torque.

Torque : 50 N·m (5.1kgf·m/37 lb·ft)

11. Install the suspension crossmember.

12. Install the torsion bar.

Refer to Torsion Bar in Suspension section.

13. Install the front propeller shaft.

Refer to Front Propeller Shaft in this section.

14. Install the hub and disc assembly and adjust the bearing preload.

Refer to Front Hub and Disc in this section.

15. Install the wheel speed sensor of the antilock brake system.

16. Install the brake caliper. Tighten the bolt of the caliper bracket to the specified torque.

Torque : 226 N·m (23.0kgf·m/166 lb·ft)

17. Install the stone guard.

18. Install the tire and wheel.

19. Lower the vehicle, adjust the trim height.

Refer to Trim Height Adjustment in Front Alignment section.

20. Tighten the bolts and nuts of the lower control arm to the specified torque.

Refer to Lower Control Arm in Suspension section.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 730 of 6020

BRAKES 5C-31

ADJUSTMENT PROCEDURE OF BRAKE PEDAL

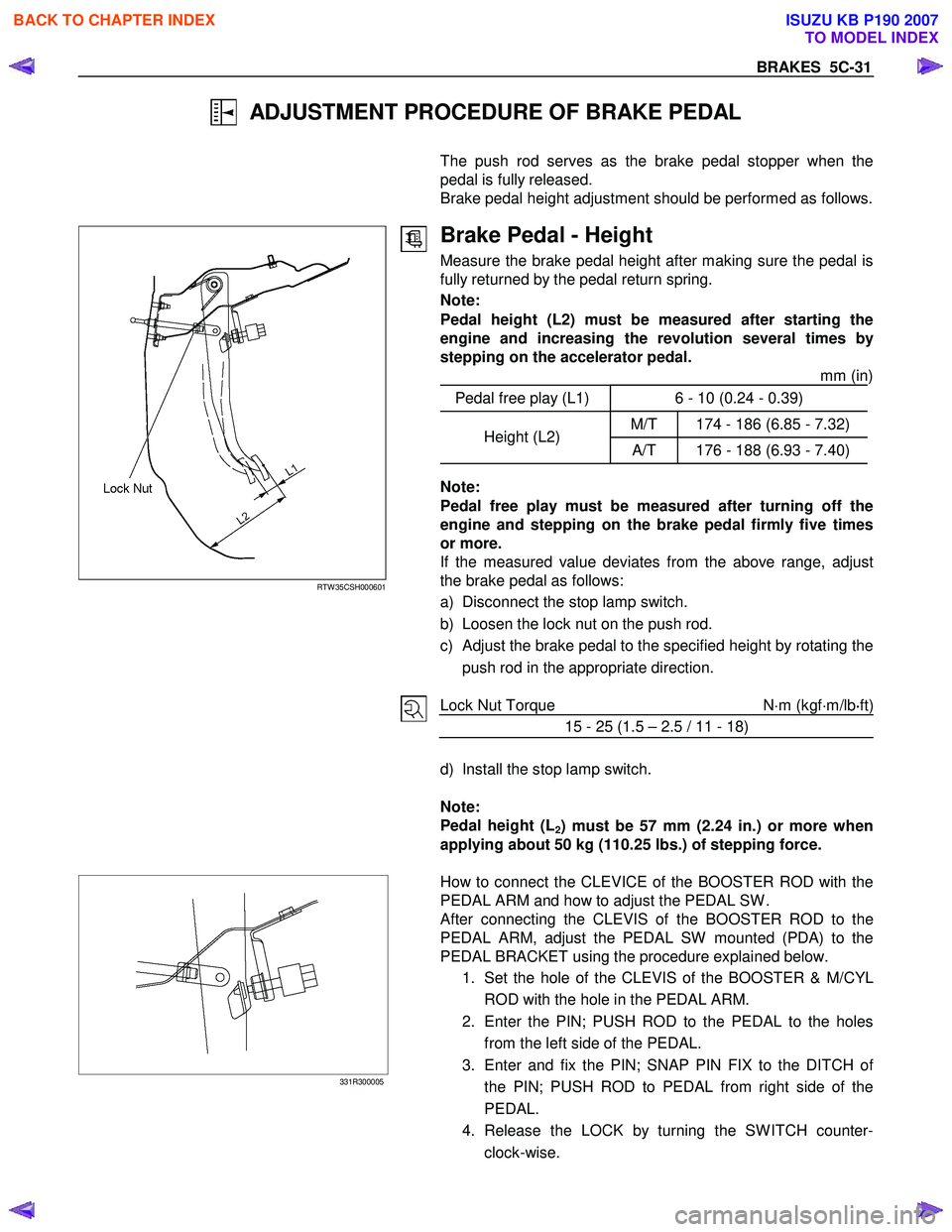

The push rod serves as the brake pedal stopper when the

pedal is fully released.

Brake pedal height adjustment should be performed as follows.

RTW 35CSH000601

Brake Pedal - Height

Measure the brake pedal height after making sure the pedal is

fully returned by the pedal return spring.

Note:

Pedal height (L2) must be measured after starting the

engine and increasing the revolution several times by

stepping on the accelerator pedal. mm (in)

Pedal free play (L1) 6 - 10 (0.24 - 0.39)

M/T 174 - 186 (6.85 - 7.32) Height (L2)

A/T 176 - 188 (6.93 - 7.40)

Note:

Pedal free play must be measured after turning off the

engine and stepping on the brake pedal firmly five times

or more.

If the measured value deviates from the above range, adjust

the brake pedal as follows:

a) Disconnect the stop lamp switch.

b) Loosen the lock nut on the push rod.

c)

Adjust the brake pedal to the specified height by rotating the

push rod in the appropriate direction.

Lock Nut Torque

N⋅m (kgf ⋅m/lb ⋅

⋅⋅

⋅

ft)

15 - 25 (1.5 – 2.5 / 11 - 18)

d) Install the stop lamp switch.

Note:

Pedal height (L

2) must be 57 mm (2.24 in.) or more when

applying about 50 kg (110.25 lbs.) of stepping force.

331R300005

How to connect the CLEVICE of the BOOSTER ROD with the

PEDAL ARM and how to adjust the PEDAL SW .

After connecting the CLEVIS of the BOOSTER ROD to the

PEDAL ARM, adjust the PEDAL SW mounted (PDA) to the

PEDAL BRACKET using the procedure explained below.

1. Set the hole of the CLEVIS of the BOOSTER & M/CYL

ROD with the hole in the PEDAL ARM.

2. Enter the PIN; PUSH ROD to the PEDAL to the holes from the left side of the PEDAL.

3. Enter and fix the PIN; SNAP PIN FIX to the DITCH o

f

the PIN; PUSH ROD to PEDAL from right side of the

PEDAL.

4. Release the LOCK by turning the SW ITCH counter- clock-wise.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 866 of 6020

ENGINE MECHANICAL 6A – 61

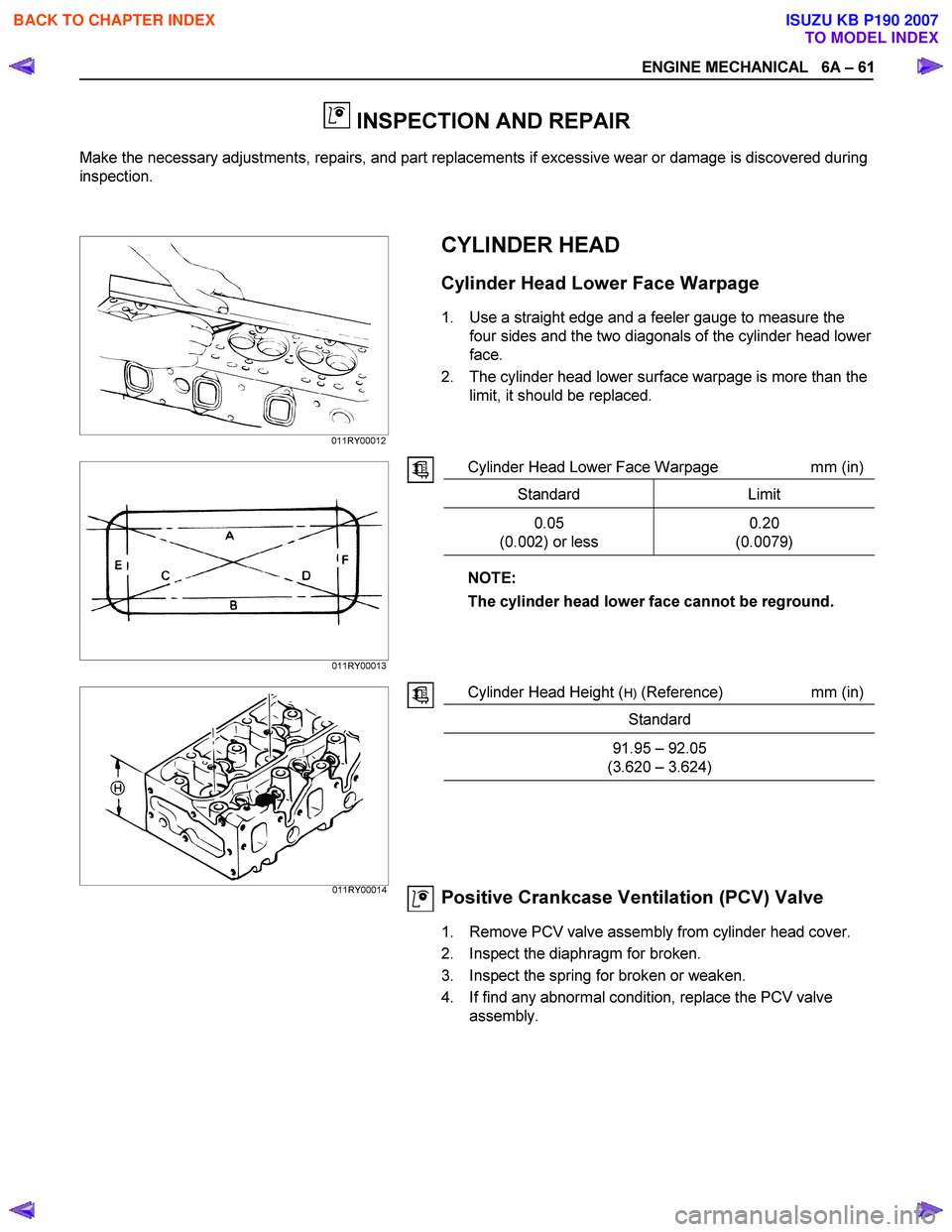

INSPECTION AND REPAIR

Make the necessary adjustments, repairs, and part replacements if excessive wear or damage is discovered during

inspection.

CYLINDER HEAD

Cylinder Head Lower Face Warpage

1. Use a straight edge and a feeler gauge to measure the four sides and the two diagonals of the cylinder head lower

face.

2. The cylinder head lower surface warpage is more than the limit, it should be replaced.

Cylinder Head Lower Face Warpage mm (in)

Standard Limit

0.05

(0.002) or less 0.20

(0.0079)

NOTE:

The cylinder head lower face cannot be reground.

Cylinder Head Height (

H) (Reference) mm (in)

Standard

91.95 – 92.05

(3.620 – 3.624)

Positive Crankcase Ventilation (PCV) Valve

1. Remove PCV valve assembly from cylinder head cover.

2. Inspect the diaphragm for broken.

3. Inspect the spring for broken or weaken.

4. If find any abnormal condition, replace the PCV valve assembly.

011RY00012

011RY00013011RY00014

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 868 of 6020

ENGINE MECHANICAL 6A – 63

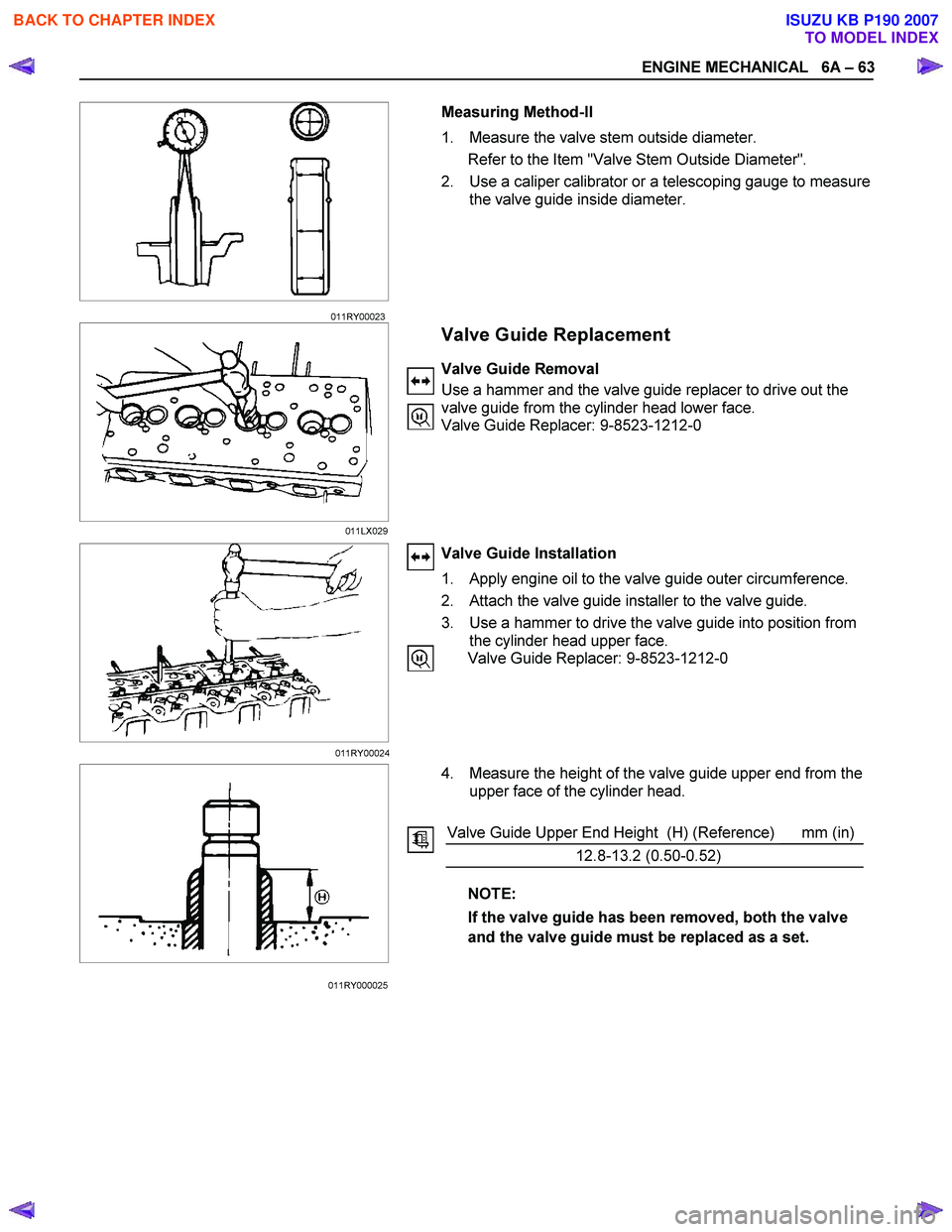

Measuring Method-II

1. Measure the valve stem outside diameter. Refer to the Item "Valve Stem Outside Diameter".

2. Use a caliper calibrator or a telescoping gauge to measure the valve guide inside diameter.

Valve Guide Replacement

Valve Guide Removal

Use a hammer and the valve guide replacer to drive out the

valve guide from the cylinder head lower face.

Valve Guide Replacer: 9-8523-1212-0

Valve Guide Installation

1. Apply engine oil to the valve guide outer circumference.

2. Attach the valve guide installer to the valve guide.

3. Use a hammer to drive the valve guide into position from the cylinder head upper face.

Valve Guide Replacer: 9-8523-1212-0

4. Measure the height of the valve guide upper end from the

upper face of the cylinder head.

Valve Guide Upper End Height (H) (Reference) mm (in)

12.8-13.2 (0.50-0.52)

NOTE:

If the valve guide has been removed, both the valve

and the valve guide must be replaced as a set.

011LX029

011RY00024

011RY000025 011RY00023

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 872 of 6020

ENGINE MECHANICAL 6A – 67

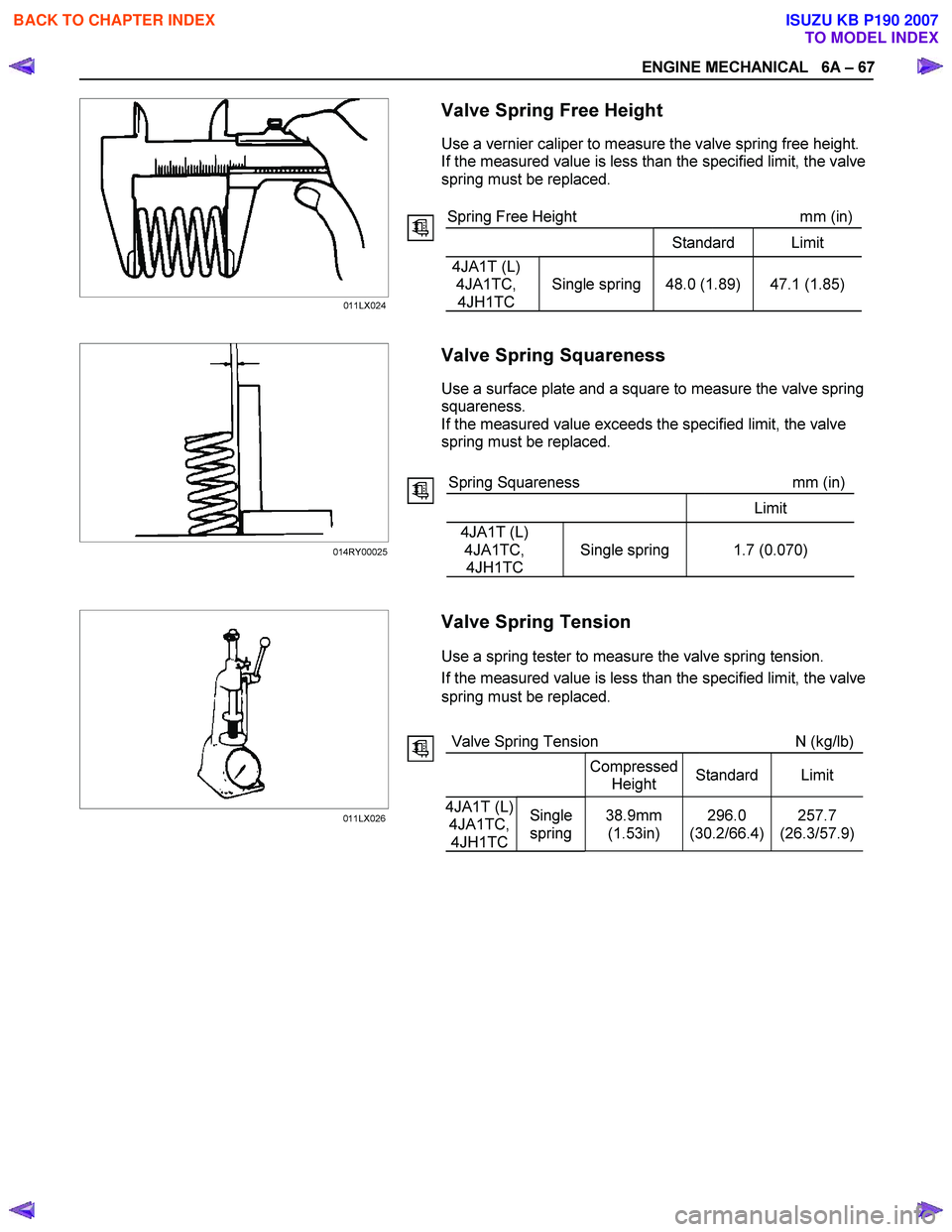

Valve Spring Free Height

Use a vernier caliper to measure the valve spring free height.

If the measured value is less than the specified limit, the valve

spring must be replaced.

Spring Free Height mm (in)

Standard Limit

4JA1T (L) 4JA1TC, 4JH1TC Single spring 48.0 (1.89) 47.1 (1.85)

Valve Spring Squareness

Use a surface plate and a square to measure the valve spring

squareness.

If the measured value exceeds the specified limit, the valve

spring must be replaced.

Spring Squareness mm (in)

Limit

4JA1T (L) 4JA1TC, 4JH1TC Single spring 1.7 (0.070)

Valve Spring Tension

Use a spring tester to measure the valve spring tension.

If the measured value is less than the specified limit, the valve

spring must be replaced.

Valve Spring Tension N (kg/lb)

Compressed

Height Standard Limit

4JA1T (L)

4JA1TC, 4JH1TC Single

spring 38.9mm

(1.53in) 296.0

(30.2/66.4) 257.7

(26.3/57.9)

011LX024

014RY00025

011LX026

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 874 of 6020

ENGINE MECHANICAL 6A – 69

3. Check that the rocker arm oil port is free of obstructions. If necessary, use compressed air to clean the rocker arm

oil port.

Rocker Arm Correction

Inspect the rocker arm valve stem contact surfaces for step

wear (1) and scoring (2).

If the contact surfaces have light step wear or scoring, they

may be honed with an oil stone.

If the step wear or scoring is severe, the rocker arm must be

replaced.

CYLINDER BODY

Cylinder Body Upper Face Warpage

1. Remove the cylinder body dowel.

2. Remove the cylinder liner. Refer to "Cylinder Liner Replacement".

3. Use a straight edge (1) and a feeler gauge (2) to measure

the four sides and the two diagonals of the cylinder body

upper face.

If the measured values exceeds the limit, the cylinder body

must be replaced.

Cylinder Body Upper Face Warpage mm (in)

Standard Limit

0.05 (0.002) or less 0.20 (0.008)

Cylinder Body Height (H) (Reference) mm (in)

Standard

4JA1T(L), 4JA1TC : 244.945-245.055 (9.6435-9.6478)

4JH1TC : 269.945-270.055 (10.6277-10.6320)

4. Reinstall the cylinder liner. Refer to "Cylinder Liner Replacement".

5. Reinstall the cylinder body dowel.

014RY00024

012R100001

012RY00009 014RY00023

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 875 of 6020

6A – 70 ENGINE MECHANICAL

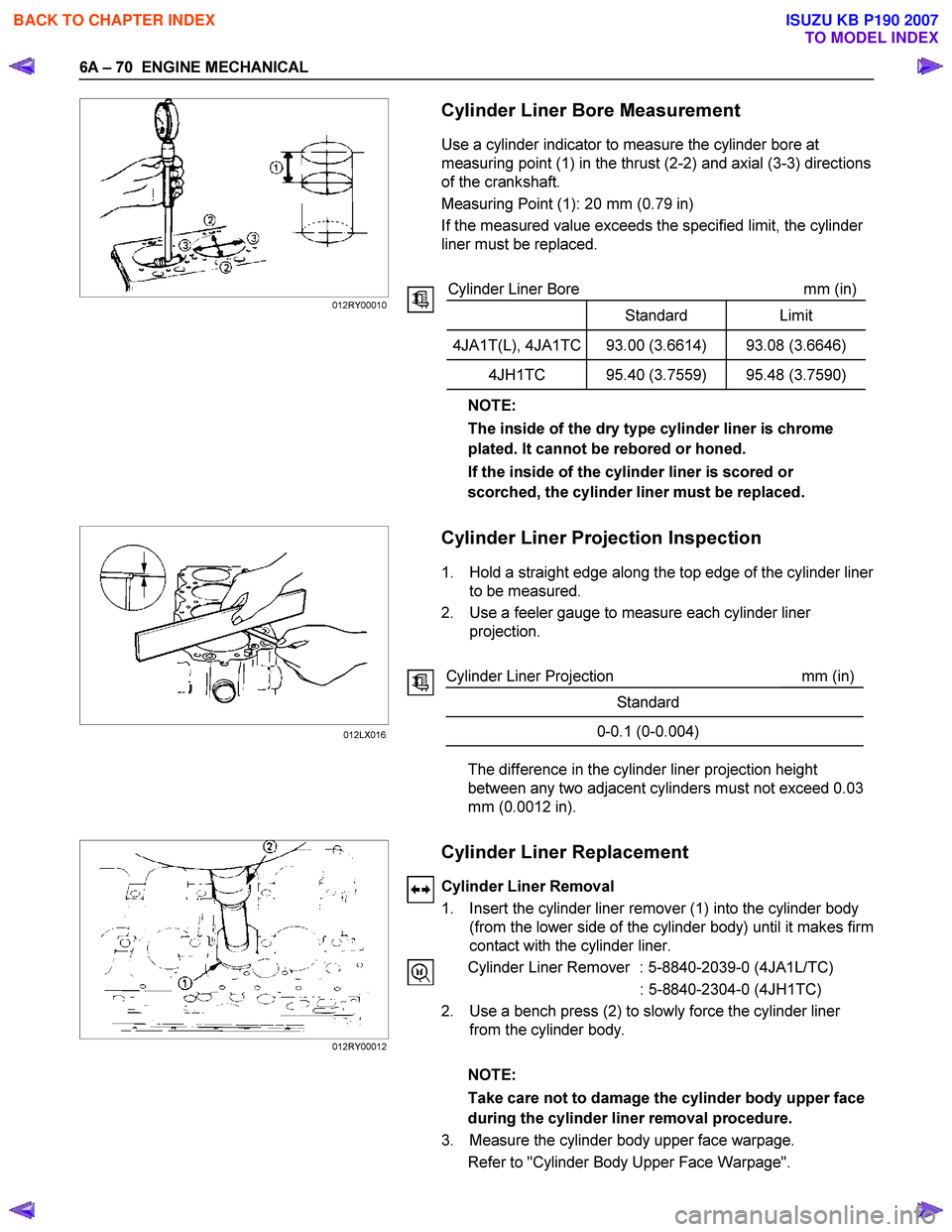

Cylinder Liner Bore Measurement

Use a cylinder indicator to measure the cylinder bore at

measuring point (1) in the thrust (2-2) and axial (3-3) directions

of the crankshaft.

Measuring Point (1): 20 mm (0.79 in)

If the measured value exceeds the specified limit, the cylinder

liner must be replaced.

Cylinder Liner Bore mm (in)

Standard Limit

4JA1T(L), 4JA1TC 93.00 (3.6614) 93.08 (3.6646)

4JH1TC 95.40 (3.7559) 95.48 (3.7590)

NOTE:

The inside of the dry type cylinder liner is chrome

plated. It cannot be rebored or honed.

If the inside of the cylinder liner is scored or

scorched, the cylinder liner must be replaced.

Cylinder Liner Projection Inspection

1. Hold a straight edge along the top edge of the cylinder liner

to be measured.

2. Use a feeler gauge to measure each cylinder liner projection.

Cylinder Liner Projection mm (in)

Standard

0-0.1 (0-0.004)

The difference in the cylinder liner projection height

between any two adjacent cylinders must not exceed 0.03

mm (0.0012 in).

Cylinder Liner Replacement

Cylinder Liner Removal

1. Insert the cylinder liner remover (1) into the cylinder body (from the lower side of the cylinder body) until it makes firm

contact with the cylinder liner.

Cylinder Liner Remover : 5-8840-2039-0 (4JA1L/TC)

: 5-8840-2304-0 (4JH1TC)

2. Use a bench press (2) to slowly force the cylinder liner from the cylinder body.

NOTE:

Take care not to damage the cylinder body upper face

during the cylinder liner removal procedure.

3. Measure the cylinder body upper face warpage. Refer to "Cylinder Body Upper Face Warpage".

012RY00010

012LX016

012RY00012

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 882 of 6020

ENGINE MECHANICAL 6A – 77

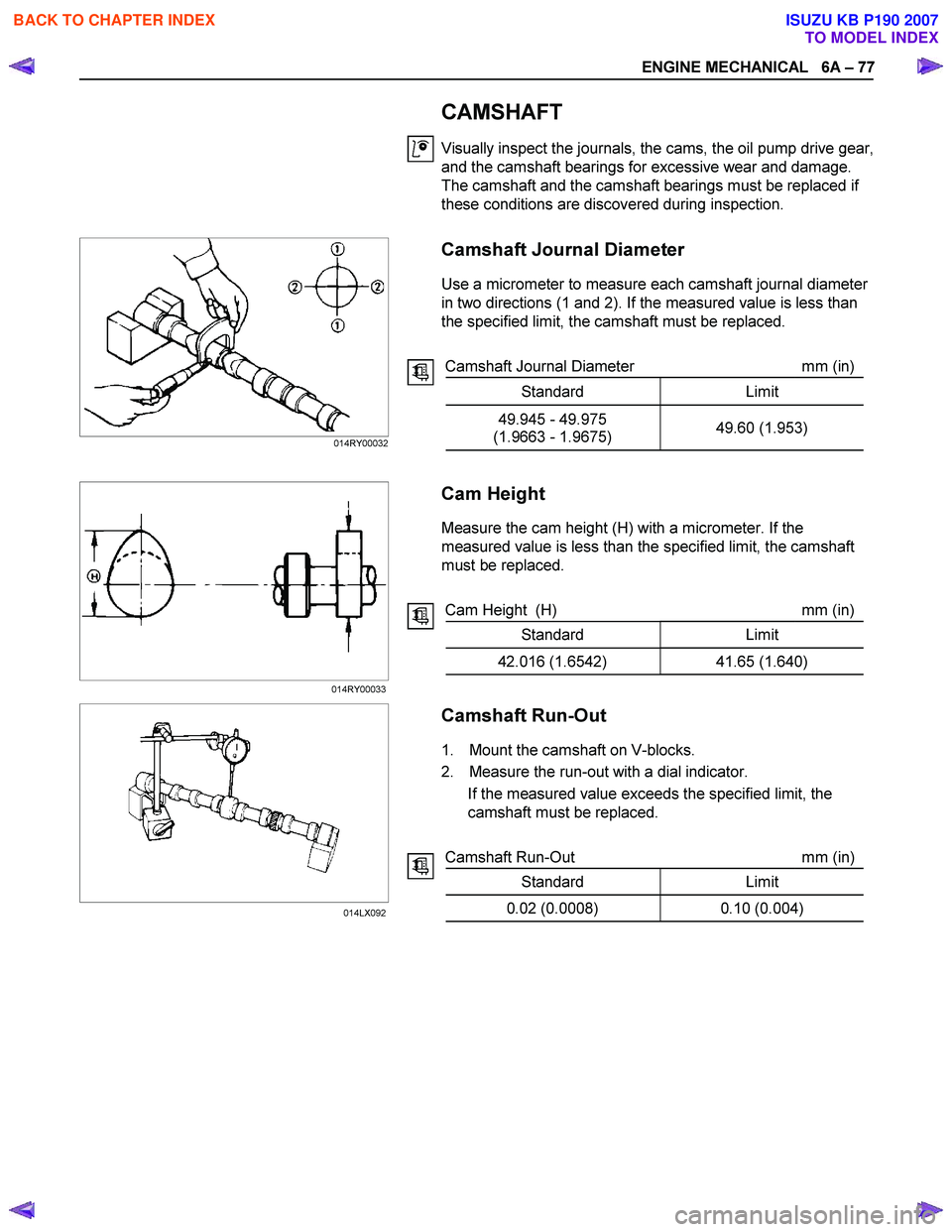

CAMSHAFT

Visually inspect the journals, the cams, the oil pump drive gear,

and the camshaft bearings for excessive wear and damage.

The camshaft and the camshaft bearings must be replaced if

these conditions are discovered during inspection.

Camshaft Journal Diameter

Use a micrometer to measure each camshaft journal diameter

in two directions (1 and 2). If the measured value is less than

the specified limit, the camshaft must be replaced.

Camshaft Journal Diameter mm (in)

Standard Limit

49.945 - 49.975

(1.9663 - 1.9675) 49.60 (1.953)

Cam Height

Measure the cam height (H) with a micrometer. If the

measured value is less than the specified limit, the camshaft

must be replaced.

Cam Height (H) mm (in)

Standard Limit

42.016 (1.6542) 41.65 (1.640)

Camshaft Run-Out

1. Mount the camshaft on V-blocks.

2. Measure the run-out with a dial indicator. If the measured value exceeds the specified limit, the

camshaft must be replaced.

Camshaft Run-Out mm (in)

Standard Limit

0.02 (0.0008) 0.10 (0.004)

014RY00032

014RY00033 014LX092

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 1422 of 6020

6A-62 ENGINE MECHANICAL (4JK1/4JJ1)

3. Remove the dowel pin.

4. Inspect the camshaft visually. • Check if the journal and cam parts of the

camshaft are worn or damaged, if so, replace

it.

LNW 21BSH020201

5. Inspect an end clearance of the camshaft.

• Use a thickness gauge to measure an end

clearance of the camshaft gear and the

camshaft bracket.

• If the measurement exceeds the limit, replace

the camshaft gear or the camshaft.

End clearance of the camshaft mm (in)

Standard 0.085 − 0.205 (0.003 − 0.008)

Limit 0.25 (0.010)

Note:

Measure an end clearance of the camshaft before

disassembling.

RTW 56ASH013901

6. Check if the cam lobe is worn.

• Use a micrometer to measure the height of the

cam lobe.

• If the height of the cam lobe is at the limit o

r

less, replace the camshaft.

Height of the cam lobe mm (in)

Inlet Exhaust

Standard 40.6 (1.60) 40.6 (1.60)

Limit 39.6 (1.56) 39.6 (1.56)

LNW 21BSH020401

7. Check if the camshaft journal is worn.

• Use a micrometer to measure wear which is

not even with a diameter of the camshaft

journal.

• If the measured uneven wear exceeds the limit,

replace the camshaft.

External diameter of the camshaft journal part

mm (in)

Standard 29.909 − 29.930

(1.1775 − 1.1783)

Limit 29.809 (1.1736)

Partial wear of the camshaft journal part mm (in)

Limit 0.05 (0.0020)

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007