torque ISUZU KB P190 2007 Workshop Repair Manual

[x] Cancel search | Manufacturer: ISUZU, Model Year: 2007, Model line: KB P190, Model: ISUZU KB P190 2007Pages: 6020, PDF Size: 70.23 MB

Page 1515 of 6020

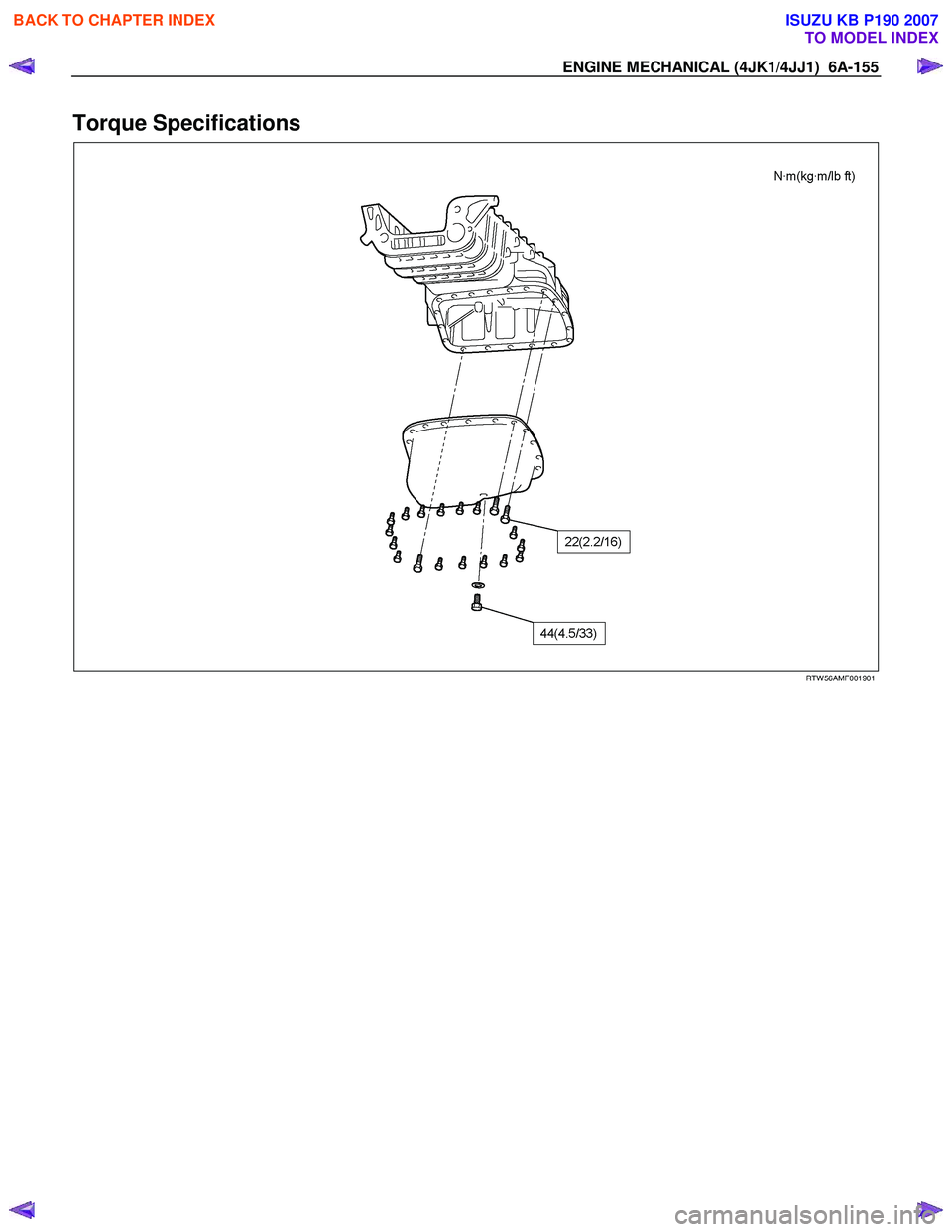

ENGINE MECHANICAL (4JK1/4JJ1) 6A-155

Torque Specifications

RTW 56AMF001901

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 1519 of 6020

ENGINE MECHANICAL (4JK1/4JJ1) 6A-159

RTW 56ASH025501

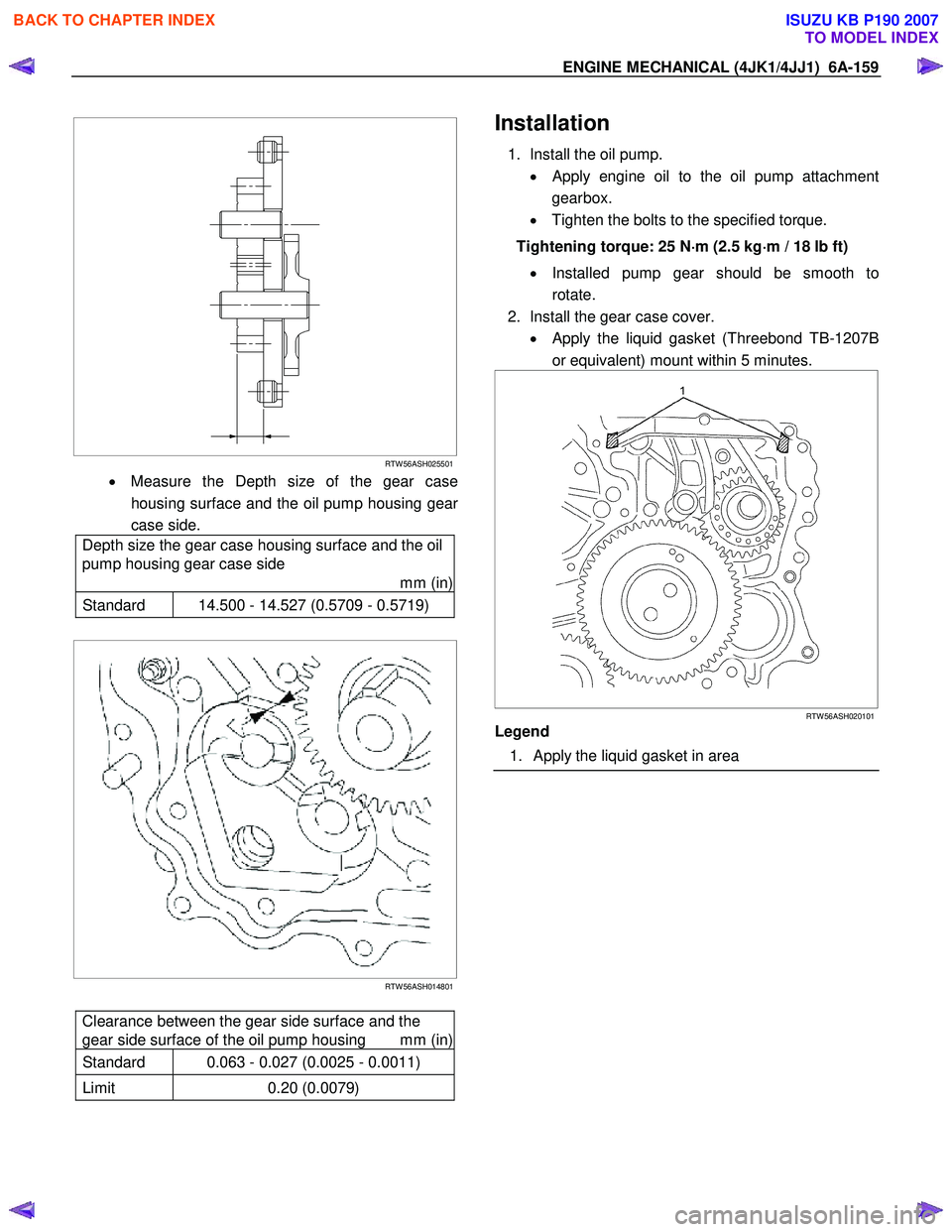

• Measure the Depth size of the gear case

housing surface and the oil pump housing gea

r

case side.

Depth size the gear case housing surface and the oil

pump housing gear case side

mm (in)

Standard 14.500 - 14.527 (0.5709 - 0.5719)

RTW 56ASH014801

Clearance between the gear side surface and the

gear side surface of the oil pump housing mm (in)

Standard 0.063 - 0.027 (0.0025 - 0.0011)

Limit 0.20 (0.0079)

Installation

1. Install the oil pump.

•

Apply engine oil to the oil pump attachment

gearbox.

• Tighten the bolts to the specified torque.

Tightening torque: 25 N ⋅

⋅⋅

⋅

m (2.5 kg ⋅

⋅⋅

⋅

m / 18 lb ft)

• Installed pump gear should be smooth to

rotate.

2. Install the gear case cover. • Apply the liquid gasket (Threebond TB-1207B

or equivalent) mount within 5 minutes.

RTW 56ASH020101

Legend

1. Apply the liquid gasket in area

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 1520 of 6020

6A-160 ENGINE MECHANICAL (4JK1/4JJ1)

• Install the gasket in the slot of the gear case

cover.

• Tighten the bolts to the specified torque.

Tightening torque: 8 N ⋅

⋅⋅

⋅

m (0.8 kg ⋅

⋅⋅

⋅

m / 69 lb in)

RTW 56ASH012101

3. Install the crank pulley.

• Tighten the bolts to the specified torque.

Tightening torque: 294 N ⋅

⋅⋅

⋅

m (30.0 kg ⋅

⋅⋅

⋅

m / 217 lb ft)

4. Install the noise cover to the timing chain cove

r

lower.

• Tighten the bolts to the specified torque.

Tightening torque: 10 N ⋅

⋅⋅

⋅

m (1.0 kg ⋅

⋅⋅

⋅

m / 87 lb in)

5. Install the vacuum pump. • Tighten the nuts to the specified torque.

Tightening torque: 25 N ⋅

⋅⋅

⋅

m (2.5 kg ⋅

⋅⋅

⋅

m / 18 lb ft)

• Install the oil pipe (feed side and return side) o

f

vacuum pump.

• Install the vacuum pipe bracket and vacuum

pipe.

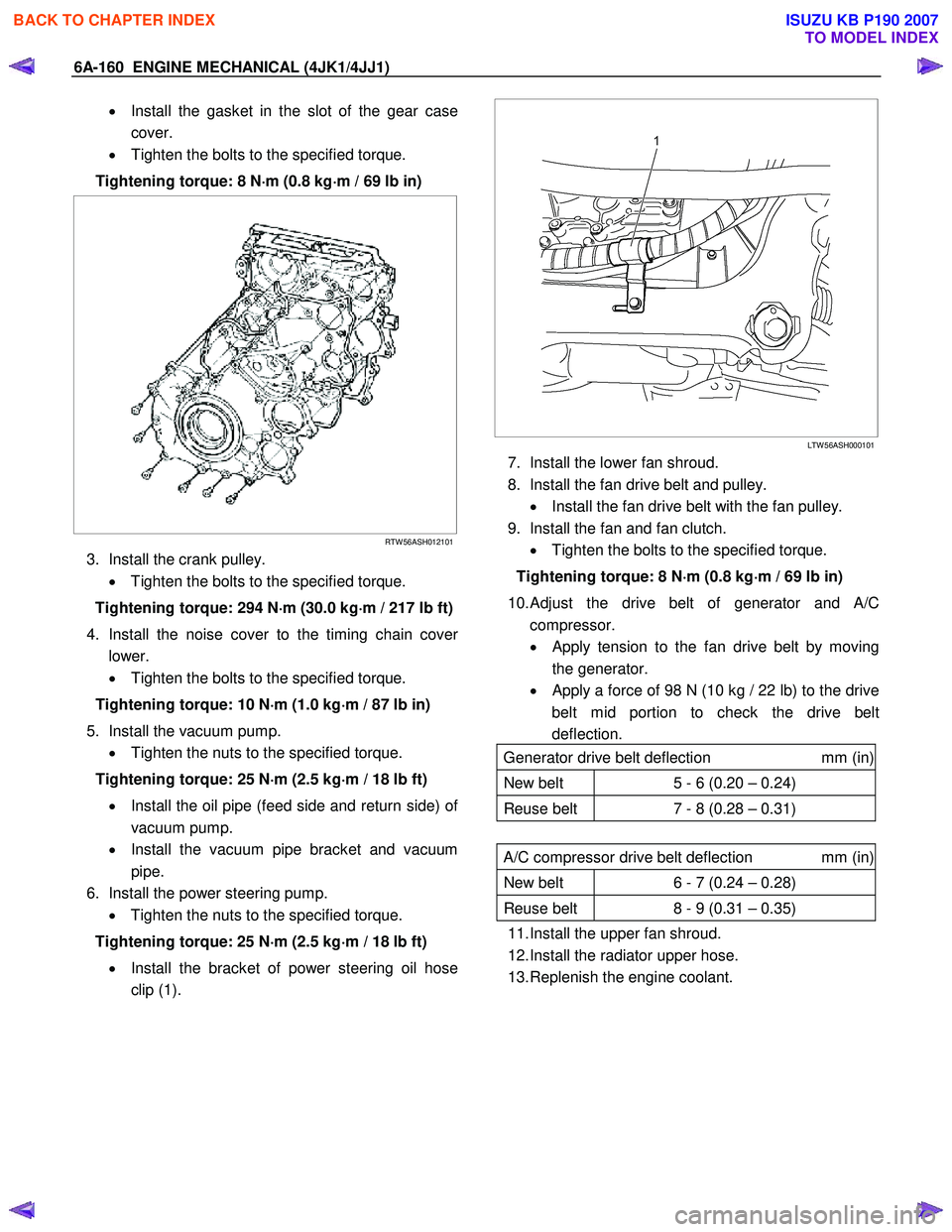

6. Install the power steering pump. • Tighten the nuts to the specified torque.

Tightening torque: 25 N ⋅

⋅⋅

⋅

m (2.5 kg ⋅

⋅⋅

⋅

m / 18 lb ft)

• Install the bracket of power steering oil hose

clip (1).

LTW 56ASH000101

7. Install the lower fan shroud.

8. Install the fan drive belt and pulley. • Install the fan drive belt with the fan pulley.

9. Install the fan and fan clutch. • Tighten the bolts to the specified torque.

Tightening torque: 8 N ⋅

⋅⋅

⋅

m (0.8 kg ⋅

⋅⋅

⋅

m / 69 lb in)

10.

Adjust the drive belt of generator and A/C

compressor.

• Apply tension to the fan drive belt by moving

the generator.

•

Apply a force of 98 N (10 kg / 22 lb) to the drive

belt mid portion to check the drive belt

deflection.

Generator drive belt deflection mm (in)

New belt 5 - 6 (0.20 – 0.24)

Reuse belt 7 - 8 (0.28 – 0.31)

A/C compressor drive belt deflection mm (in)

New belt 6 - 7 (0.24 – 0.28)

Reuse belt 8 - 9 (0.31 – 0.35)

11. Install the upper fan shroud.

12. Install the radiator upper hose.

13. Replenish the engine coolant.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 1522 of 6020

6A-162 ENGINE MECHANICAL (4JK1/4JJ1)

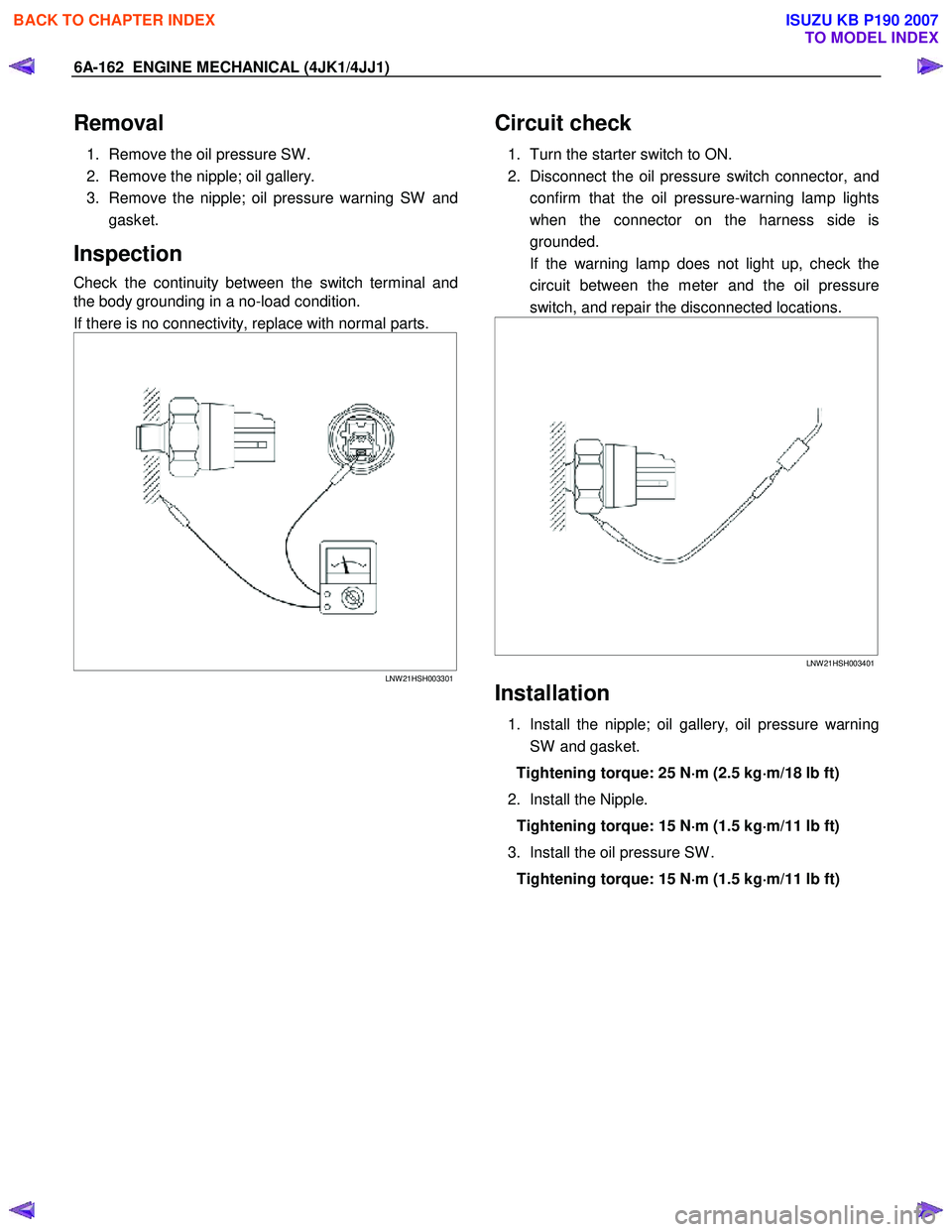

Removal

1. Remove the oil pressure SW .

2. Remove the nipple; oil gallery.

3. Remove the nipple; oil pressure warning SW and gasket.

Inspection

Check the continuity between the switch terminal and

the body grounding in a no-load condition.

If there is no connectivity, replace with normal parts.

LNW 21HSH003301

Circuit check

1. Turn the starter switch to ON.

2. Disconnect the oil pressure switch connector, and confirm that the oil pressure-warning lamp lights

when the connector on the harness side is

grounded.

If the warning lamp does not light up, check the circuit between the meter and the oil pressure

switch, and repair the disconnected locations.

LNW 21HSH003401

Installation

1. Install the nipple; oil gallery, oil pressure warning

SW and gasket.

Tightening torque: 25 N ⋅

⋅⋅

⋅

m (2.5 kg ⋅

⋅⋅

⋅

m/18 lb ft)

2. Install the Nipple. Tightening torque: 15 N ⋅

⋅⋅

⋅

m (1.5 kg ⋅

⋅⋅

⋅

m/11 lb ft)

3. Install the oil pressure SW . Tightening torque: 15 N ⋅

⋅⋅

⋅

m (1.5 kg ⋅

⋅⋅

⋅

m/11 lb ft)

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 1532 of 6020

ENGINE COOLING (4JK1/4JJ1) 6B-9

Inspection and Repair

The water pump is not disassembled type.

Make necessary parts replacement if extreme wear o

r

damage is found during inspection. Should any of the

following problems occur, the entire water pump

assembly must be replaced.

• Cracks in the water pump body.

• Coolant leakage from the sealed unit.

• Excessive radial play or abnormal noise in the fan

center when rotated by hand.

• Excessive thrust play in the fan center (Standard

play: less than 0.2 mm (0.0078 in)).

• Cracks or corrosion in the impeller.

Installation

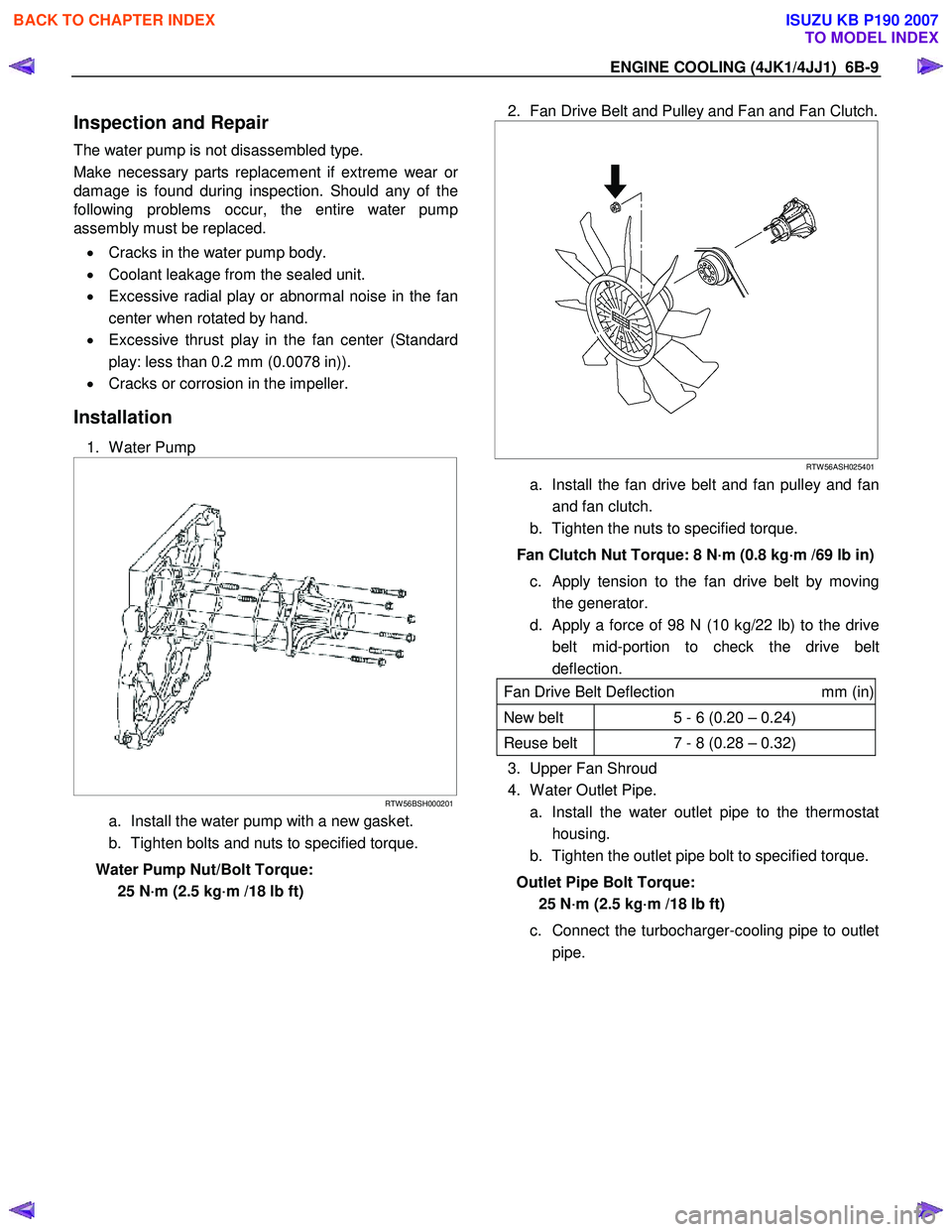

1. W ater Pump

RTW 56BSH000201

a. Install the water pump with a new gasket.

b. Tighten bolts and nuts to specified torque.

Water Pump Nut/Bolt Torque: 25 N·m (2.5 kg·m /18 lb ft)

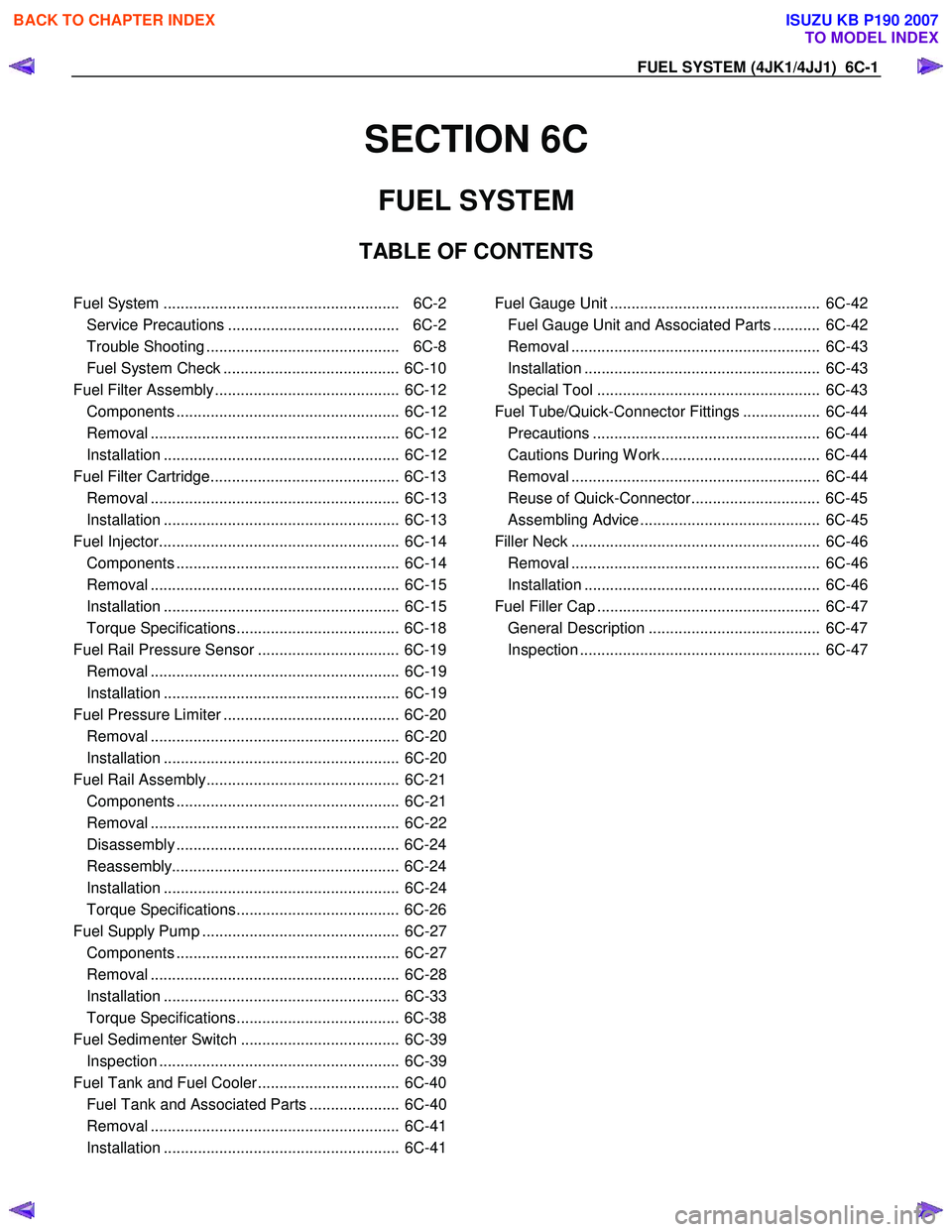

2. Fan Drive Belt and Pulley and Fan and Fan Clutch.

RTW 56ASH025401

a. Install the fan drive belt and fan pulley and fan

and fan clutch.

b. Tighten the nuts to specified torque.

Fan Clutch Nut Torque: 8 N·m (0.8 kg·m /69 lb in) c. Apply tension to the fan drive belt by moving the generator.

d. Apply a force of 98 N (10 kg/22 lb) to the drive belt mid-portion to check the drive belt

deflection.

Fan Drive Belt Deflection mm (in)

New belt 5 - 6 (0.20 – 0.24)

Reuse belt 7 - 8 (0.28 – 0.32)

3. Upper Fan Shroud

4. W ater Outlet Pipe.

a. Install the water outlet pipe to the thermostat housing.

b. Tighten the outlet pipe bolt to specified torque.

Outlet Pipe Bolt Torque: 25 N·m (2.5 kg·m /18 lb ft)

c. Connect the turbocharger-cooling pipe to outlet pipe.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 1535 of 6020

6B-12 ENGINE COOLING (4JK1/4JJ1)

MFW 41CSH001401

Legend

1. W ooden Piece

2. Agitating Rod

Installation

1. Thermostat

Install the thermostat.

Mount the jiggle valve with the valve facing engine front.

RTW 56BSH000101

Legend

1. Front

2. Thermostat

3. Jiggle Valve

2. W ater Outlet Pipe.

a. Install the water outlet pipe with new gasket to the thermostat housing.

b. Tighten the outlet pipe bolt to specified torque.

Outlet Pipe Bolt Torque: 25 N·m (2.5 kg·m /18 lb ft)

c. Connect the turbocharger-cooling pipe to outlet pipe.

d. Install the engine harness clip.

3. Radiator Upper Hose.

RTW 56FSH000101

a. Connect the radiator upper hose to the water

outlet pipe.

b. The knob of the clamp should be directed to the horizontal side.

c. Replenish the engine coolant.

4. Install the engine cover.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 1540 of 6020

ENGINE COOLING (4JK1/4JJ1) 6B-17

Fan Clutch with Cooling Fan

Inspection and Repair

Make necessary correction or parts replacement if

wear, damage or any other abnormal conditions are

found through inspection.

Visually inspect for damage, leak (silicon grease) o

r

other abnormal conditions.

1. Inspection (on-vehicle) a) Turn the fan clutch by hand when in a lo

w

temperature condition before starting the

engine, and confirm that it can be turned

readily.

b) Start the engine to warm it up until the temperature at the fan clutch portion gets to

around 85°C (185°F). Then stop the engine and

confirm that the fan clutch can be turned with

considerable effort (clutch torque) when turned

by hand.

If the fan clutch rotates more readily, however, this indicates that the silicone grease is leaking

internally.

Replace the fan clutch with a new one.

RTW 56ASH025401

2. Inspection (in unit)

W arm up the bimetal of the fan clutch by using the heat gun until the temperature gets to about 85°C

when measured with the thermistor. Then confirm

that the fan clutch can be turned with considerable

effort (clutch torque).

If the fan clutch rotates more readily at this time, this indicates that the silicone grease is leaking

internally.

Replace the fan clutch with a new one.

033RY00011

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 1542 of 6020

FUEL SYSTEM (4JK1/4JJ1) 6C-1

SECTION 6C

FUEL SYSTEM

TABLE OF CONTENTS

Fuel System ....................................................... 6C-2 Service Precautions ........................................ 6C-2

Trouble Shooting ............................................. 6C-8

Fuel System Check ......................................... 6C-10

Fuel Filter Assembly ........................................... 6C-12 Components .................................................... 6C-12

Removal .......................................................... 6C-12

Installation ....................................................... 6C-12

Fuel Filter Cartridge............................................ 6C-13 Removal .......................................................... 6C-13

Installation ....................................................... 6C-13

Fuel Injector........................................................ 6C-14 Components .................................................... 6C-14

Removal .......................................................... 6C-15

Installation ....................................................... 6C-15

Torque Specifications...................................... 6C-18

Fuel Rail Pressure Sensor ................................. 6C-19 Removal .......................................................... 6C-19

Installation ....................................................... 6C-19

Fuel Pressure Limiter ......................................... 6C-20 Removal .......................................................... 6C-20

Installation ....................................................... 6C-20

Fuel Rail Assembly............................................. 6C-21 Components .................................................... 6C-21

Removal .......................................................... 6C-22

Disassembly .................................................... 6C-24

Reassembly..................................................... 6C-24

Installation ....................................................... 6C-24

Torque Specifications...................................... 6C-26

Fuel Supply Pump .............................................. 6C-27 Components .................................................... 6C-27

Removal .......................................................... 6C-28

Installation ....................................................... 6C-33

Torque Specifications...................................... 6C-38

Fuel Sedimenter Switch ..................................... 6C-39 Inspection ........................................................ 6C-39

Fuel Tank and Fuel Cooler ................................. 6C-40 Fuel Tank and Associated Parts ..................... 6C-40

Removal .......................................................... 6C-41

Installation ....................................................... 6C-41

Fuel Gauge Unit ................................................. 6C-42 Fuel Gauge Unit and Associated Parts ........... 6C-42

Removal .......................................................... 6C-43

Installation ....................................................... 6C-43

Special Tool .................................................... 6C-43

Fuel Tube/Quick-Connector Fittings .................. 6C-44 Precautions ..................................................... 6C-44

Cautions During W ork ..................................... 6C-44

Removal .......................................................... 6C-44

Reuse of Quick-Connector.............................. 6C-45

Assembling Advice .......................................... 6C-45

Filler Neck .......................................................... 6C-46 Removal .......................................................... 6C-46

Installation ....................................................... 6C-46

Fuel Filler Cap .................................................... 6C-47 General Description ........................................ 6C-47

Inspection ........................................................ 6C-47

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 1547 of 6020

6C-6 FUEL SYSTEM (4JK1/4JJ1)

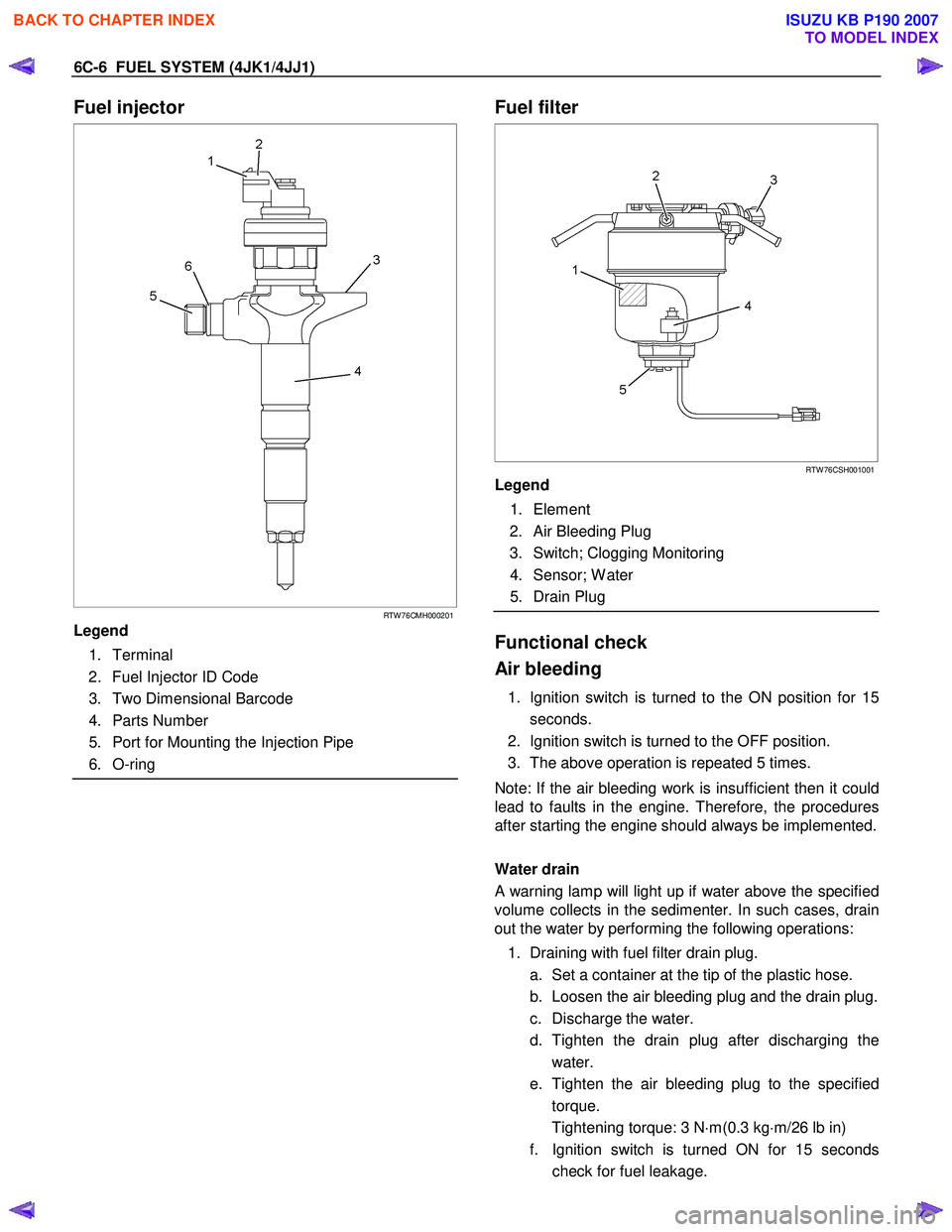

Fuel injector

RTW 76CMH000201

Legend

1. Terminal

2. Fuel Injector ID Code

3. Two Dimensional Barcode

4. Parts Number

5. Port for Mounting the Injection Pipe

6. O-ring

Fuel filter

RTW 76CSH001001

Legend

1. Element

2. Air Bleeding Plug

3. Switch; Clogging Monitoring

4. Sensor; W ater

5. Drain Plug

Functional check

Air bleeding

1. Ignition switch is turned to the ON position for 15 seconds.

2. Ignition switch is turned to the OFF position.

3. The above operation is repeated 5 times.

Note: If the air bleeding work is insufficient then it could

lead to faults in the engine. Therefore, the procedures

after starting the engine should always be implemented.

Water drain

A warning lamp will light up if water above the specified

volume collects in the sedimenter. In such cases, drain

out the water by performing the following operations:

1. Draining with fuel filter drain plug. a. Set a container at the tip of the plastic hose.

b. Loosen the air bleeding plug and the drain plug.

c. Discharge the water.

d. Tighten the drain plug after discharging the water.

e. Tighten the air bleeding plug to the specified torque.

Tightening torque: 3 N ⋅m(0.3 kg ⋅m/26 lb in)

f. Ignition switch is turned ON for 15 seconds check for fuel leakage.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 1554 of 6020

FUEL SYSTEM (4JK1/4JJ1) 6C-13

Fuel Filter Element

Removal

1. Detach the drain hose on the lower part of the fuel

filter or the drain plug, loosen the air bleed plug,

and drain the fuel from the fuel filter.

2. Detach the water-in-fuel switch harness.

3. Turn the element case counterclockwise to detach, and remove the filter element.

4. Replace the O-ring and confirm the snap-fit position, and fit a new filter element inside the

element case.

NOTE

It is strongly advisable to use the ISUZU/GM genuine

fuel filter for replacement.

RTW 76CSH000901

Legend

1. Element

2. O-ring

3. Sedimenter Sensor

Installation

1. Apply a light coat of new diesel oil to the O-ring

and gasket.

2. Turn the element case clockwise until it is completely seated against the upper cover. Then

check that the drain hose is in its correct position,

and then use a filter wrench and tighten to the

specified torque.

Tightening torque: 25 N ⋅

⋅⋅

⋅

m (2.5 kg ⋅

⋅⋅

⋅

m / 18 lb ft)

3. Use a clip to fix the drain hose at the base of the fuel filter, and fit the water-in-fuel switch harness.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007