fuse ISUZU KB P190 2007 Workshop Repair Manual

[x] Cancel search | Manufacturer: ISUZU, Model Year: 2007, Model line: KB P190, Model: ISUZU KB P190 2007Pages: 6020, PDF Size: 70.23 MB

Page 5663 of 6020

9A-28 SUPPLEMENTAL RESTRAINT SYSTEM

20. The passenger inflator requires no special

precaution after deployment. 95% of the

particulate emission is potassium chloride (KLC),

which is commonly sold as an edible salt-

substitute. Even if water is applied, post

deployment products are relatively pH neutral.

Disposing of the inflator by burying it in a landfill

will not produce any hazardous products. As with

any dusty environment, safety goggles, dust mask

and gloves should be worn.

WARNING: SAFETY PRECAUTIONS MUST BE

OBSERVED WHEN HANDLING A DEPLOYED AIR

BAG ASSEMBLY. AFTER DEPLOYMENT, THE

METAL SURFACES OF THE AIR BAG ASSEMBLY

WILL BE HOT. ALLOW THE AIR BAG ASSEMBLY

TO COOL BEFORE HANDLING ANY METAL

PORTION OF IT. DO NOT PLACE THE DEPLOYED

INFLATOR MODULE NEAR ANY FLAMMABLE

OBJECTS. FAILURE TO FOLLOW PROCEDURES

MAY RESULT IN FIRE OR PERSONAL INJURY.

AFTER AN AIR BAG ASSEMBLY HAS BEEN

DEPLOYED, THE METAL CANISTER AND

SURROUNDING AREAS OF THE AIR BAG

ASSEMBLY WILL BE HOT. DO NOT TOUCH THE

METAL AREAS OF THE AIR BAG ASSEMBLY FOR

ABOUT THIRTY MINUTES AFTER DEPLOYMENT.

IF THE DEPLOYED AIR BAG ASSEMBLY MUST BE

MOVED BEFORE IT IS COOL, WEAR GLOVES AND

HANDLE BY THE AIR BAG ITSELF.

21. Disconnect the pigtail adapter from the air bag assembly as soon after deployment as possible to

avoid damage to the pigtail adapter or SRS

deployment harness from contacting the hot ai

r

bag assembly canister. The pigtail adapter and

SRS deployment harness are designed to be

reused. They should, however, be inspected fo

r

damage after each deployment and replaced if

necessary.

22. Dispose of the deployed air bag assembly through normal refuse channels after it has cooled for at

least 30 minutes.

23. W ash your hands with mild soap and wate

r

afterward.

NOTE: The remaining steps are to be followed in the

unlikely event that the air bag assembly did not deplo

y

after following the above procedures.

24. Ensure that the SRS deployment harness has been disconnected from the power source and that

its two banana plugs have been shorted togethe

r

by fully seating one banana plug into the other.

25. Disconnect the pigtail adapter from the air bag assembly.

WARNING: WHEN STORING A LIVE AIR BAG

ASSEMBLY OR WHEN LEAVING A LIVE AIR BAG

ASSEMBLY UNATTENDED ON A BENCH OR

OTHER SURFACE, ALWAYS FACE THE BAG UP

AND AWAY FROM THE SURFACE. THIS IS

NECESSARY SO THAT A FREE SPACE IS

PROVIDED TO ALLOW THE AIR BAG TO EXPAND

IN THE UNLIKELY EVENT OF

ACCIDENTAL

DEPLOYMENT. FAILURE TO FOLLOW

PROCEDURES MAY RESULT IN PERSONAL

INJURY.

26. Temporarily store the air bag assembly with the bag facing up, away from the surface upon which it

rests.

Deployment Inside Vehicle (Vehicle

Scrapping Procedure)

Deployment inside the vehicle is proper when the

vehicle is to be destroyed or salvaged for component

parts. This includes, but is not limited to, the following

situations:

1. The vehicle has completed its useful life.

2. The vehicle has been damaged beyond repair in a nondeployment type accident.

3. The vehicle has been stripped or damaged beyond repair in a theft.

4. The vehicle will be salvaged for component parts to be used on a vehicle with a different Vehicle

Identification Number (VIN) as opposed to being

rebuilt with the same VIN. Never use SRS

components from another vehicle.

WARNING: FAILURE TO FOLLOW PROPER SRS

AIR BAG ASSEMBLY DISPOSAL PROCEDURES

CAN RESULT IN AIR BAG DEPLOYMENT WHICH

MAY CAUSE PERSONAL INJURY. UNDEPLOYED

AIR BAG ASSEMBLIES MUST NOT BE DISPOSED

OF THROUGH NORMAL REFUSE CHANNELS.

THE UNDEPLOYED AIR BAG ASSEMBLY

CONTAINS SUBSTANCES THAT CAN CAUSE

SEVERE ILLNESS OR PERSONAL INJURY IF THE

SEALED CONTAINER IS DAMAGED DURING

DISPOSAL. DISPOSAL IN ANY MANNER

INCONSISTENT WITH PROPER PROCEDURES

MAY BE A VIOLATION OF FEDERAL, STATE

AND/OR LOCAL LAWS.

1. Turn the ignition switch to “LOCK,” remove the ke

y

and put on the safety glasses.

2. Remove all loose objects from the front seats.

3. Disconnect the driver air bag assembly yello

w

connector located at the base of the steering

column.

4. Cut the driver air bag assembly yellow harness connector from the vehicle leaving at least 15 cm

(six inches) of wire at the connector.

BACK TO CHAPTER INDEX TO MODEL INDEXISUZU KB P190 2007

Page 5667 of 6020

9A-32 SUPPLEMENTAL RESTRAINT SYSTEM

Service Precautions for SRS

Component Service

CAUTION: When fasteners are removed, always

reinstall them at the same location from which

they were removed. If a fastener needs to be

replaced, use the correct part number fastener fo

r

that application. If the correct part number

fastener is not available, a fastener of equal size

and strength (or stronger) may be used. Fasteners

that are not reused, and those requiring a thread

locking compound will be called out. The correct

torque value must be used when installing

fasteners that require it. If the above conditions

are not followed, parts or system damage could

result.

WARNING: WHEN PERFORMING SERVICE ON OR

AROUND SRS COMPONENTS OR SRS WIRING,

FOLLOW THE PROCEDURES LISTED BELOW TO

TEMPORARILY DISABLE THE SRS. FAILURE TO

FOLLOW PROCEDURES COULD RESULT IN

POSSIBLE AIR BAG DEPLOYMENT, PERSONAL

INJURY OR OTHERWISE UNNEEDED SRS

REPAIRS.

The SRS control unit in the Driver–Passenger SRS

can maintain sufficient voltage to cause a deployment

for up to 15 seconds after the ignition switch is turned

“OFF,” the battery is disconnected, or the fuse

powering the SRS control unit is removed.

Many of the service procedures require removal of the

“SRS” fuse, and disconnection of the air bag assembl

y

from the deployment loop to avoid an accidental

deployment. If the air bag assembly is disconnected

from the deployment loop as noted in the “Disabling

the SRS” procedure that follows, service can begin

immediately without waiting for the 15 second time

period to expire.

Disabling The SRS

Removal

Turn the ignition switch to “OFF” and turn the steering

wheel so that the vehicle's wheels are pointing straight

ahead.

1. Remove the SRS fuse “SRS” from the left dash side lower fuse block or disconnect the battery.

2. Disconnect the yellow connector at the base o

f

steering column.

3. Remove the glove box assembly; Refer to “Passenger air bag assembly replacement” in this

section.

4. Disconnect the passenger air bag assembly yello

w

connector behind the glove box assembly.

CAUTION: With the “SRS” fuse removed and the

ignition switch to “ON,” the “SRS” warning lamp

will be “ON.” This is normal operation and does

not indicate an SRS malfunction.

Enabling The SRS

Installation

Turn the ignition switch to “LOCK” and remove the

key.

1. Connect the yellow connector passenger air bag assembly.

2. Install the glove box assembly. Refer to “Passenger Air Bag Assembly Replacement” in

this section.

3. Connect the yellow connector at the base of the steering column.

4. Install the “AIR BAG” fuse “SRS” to the left dash side lower fuse block or connect the battery.

Turn the ignition switch to “ON” and verify that the

“SRS” warning lamp flashes seven times and then

turns to “LOCK”. If it does not operate as described,

perform the “SRS Diagnostic System Check” in this

section.

Handling / Installation / Diagnosis

1. Air bag assembly should not be subjected to

temperatures above 65 °C (150 °F).

2.

Air bag assembly, and SRS control unit should not

be used if they have been dropped from a height

of 100 centimeters (3.28 feet) or more.

3. W hen a SRS control unit is replaced, it must be oriented with the arrow on the SRS control unit

pointing toward the front of the vehicle. It is ver

y

important for the SRS control unit to be located flat

on the mounting surface, parallel to the vehicle

datum line. It is important that the SRS control unit

mounting surface is free of any dirt or other foreign

material.

4. Do not apply power to the SRS unless all components are connected or a diagnostic chart

requests it, as this will set a diagnostic trouble

code.

5. The “SRS Diagnostic System Check” must be the starting point of any SRS diagnostics. The “SRS

Diagnostic System Check” will verify proper “SRS”

warning lamp operation and will lead you to the

correct chart to diagnose any SRS malfunctions.

Bypassing these procedures may result in

extended diagnostic time, incorrect diagnosis, and

incorrect parts replacements.

BACK TO CHAPTER INDEX TO MODEL INDEXISUZU KB P190 2007

Page 5690 of 6020

9A1-8 RESTRAINT CONTROL SYSTEM

Circuit Description

W hen the ignition switch is first turned “ON”, “Ignition 1”

voltage is applied from the “SRS” fuse to the SRS

control unit at the “Ignition 1” input terminals “1”. The

SRS control unit responds by flashing the “SRS”

warning lamp seven times, while performing tests on

the SRS.

Notes On System Check Chart

1. The “SRS” warning lamp should flash seven times after the ignition is first turned “ON”.

2.

After the “SRS” warning lamp flashes seven times, it

should turn to “LOCK”

3. This test checks for the proper operation of the “Serial Data” line. This test will also determine

whether history diagnostic trouble codes are stored

and, if so, identify them.

4. Improper operation of the “SRS” warning lamp is indicated. This test differentiates between ‘a

warning lamp stays “ON” condition’ and ‘a warning

lamp does not come “ON” condition’.

5. This test checks for proper operation of the “Serial Data” line. This test will also identify the stored

diagnostic trouble codes and whether they are

current or history.

Diagnostic Aids

The order in which diagnostic trouble codes are

diagnosed is very important. Failure to diagnose the

diagnostic trouble codes in the order specified ma

y

result in extended diagnostic time, incorrect diagnosis

and incorrect parts replacement.

SRS Diagnostic System Check

Step Action Yes No

1 Note the “SRS” warning lamp as the ignition switch is turned

“ON”.

Does the “SRS” warning lamp flash seven (7) times? Go to Step 2 Go to Step 3

2 Note the “SRS” warning lamp after it flashed 7 times.

Does the “SRS” warning lamp go “OFF”? Go to Step 4 Go to Step 5

3 Note the “SRS” warning lamp as the ignition switch is turned

“ON”.

Does the “SRS” warning lamp come “ON” steady? Go to Chart B. Go to Chart C.

4

1. Note the “SRS” warning lamp as the ignition switch is turned

“ON”.

Ignition switch is at “LOCK”.

2. Connect a scan tool to data link connector.

3. Follow direction given in the scan tool instruction manual.

Ignition switch is “ON”.

4. Request the SRS diagnostic trouble code display, recode all

history diagnostic trouble code(s), specifying as current or

history in repair order.

Is (are) diagnostic trouble code(s) displayed?

Ignition switch

“LOCK”.

W hen DTC B0071 is set, go to DTC B0071 Chart.

For all other history codes refer to

“Diagnostic Aids” For that specific DTC.

A history DTC indicates the

malfunction has

been repaired or is intermittent. SRS is functional

and free of

malfunctions, no

further diagnosis is required.

If scan tool

indicated “NO DATA

RECEIVED,” refer to chassis

electrical section 8.

BACK TO CHAPTER INDEX TO MODEL INDEX

ISUZU KB P190 2007

Page 5694 of 6020

9A1-12 RESTRAINT CONTROL SYSTEM

Chart B “SRS” Warning Lamp Comes “ON” Steady

RTW 79ALF000301

Circuit Description

W hen the ignition switch is first turned “ON”, “Ignition 1”

voltage is applied from the “METER” fuse to the “SRS”,

warning lamp which is connected to “SRS W arning

Lamp”, terminal “4”. The “SRS” fuses apply system

voltage to the “Ignition 1” inputs, terminals “1”. The

SRS control unit responds by flashing the “SRS”

warning lamp 7 times. If “Ignition 1” is less than 9 volts,

the “SRS” warning lamp will come “ON” solid with no

DTCs set.

Chart Test Description

Number(s) below refer to step number(s) on the

diagnostic chart:

2. This test checks for an open in the “Ignition 1” circuit to the SRS control unit.

3. This test checks for the voltage of “Ignition 1”.

4. This test determines whether the malfunction is a short to ground in the SRS warning lamp circuit.

BACK TO CHAPTER INDEX TO MODEL INDEX

ISUZU KB P190 2007

Page 5696 of 6020

9A1-14 RESTRAINT CONTROL SYSTEM

Chart C “SRS” Warning Lamp Does Not Come “ON” Steady

RTW 79ALF000301

Circuit Description

W hen the ignition switch is first turned “ON”, “Ignition 1”

voltage is applied from the “METER” fuse to the “SRS”

warning lamp which is connected to the “SRS W arning

Lamp”, terminal “4”. The “SRS” fuse applies system

voltage to the “Ignition 1” inputs, terminals “35”. The

SRS control unit responds by flashing the “SRS”

warning lamp seven times. If “Ignition 1” is more than

16 volts, the “SRS” warning lamp will still be “OFF” solid

with no DTCs set.

Chart Test Description

Number(s) below refer to step number(s) on the

diagnostic chart:

1. This test decides whether power is available to the

SRS control unit warning lamp power feed circuit.

2. This test determines whether the voltage is present

in the warning lamp circuit.

3. This test determines if the malfunction is in the

instrument cluster.

4. This test checks for open in the warning lamp

circuitry.

5. This test isolates the SRS warning lamp circuit and

checks for a short in the SRS warning lamp circuit to

B+.

8. This test checks for a short from the SRS control

unit warning lamp power feed circuit to ground.

9. This test determines whether the short to ground is

due to a short in the wiring.

BACK TO CHAPTER INDEX TO MODEL INDEX

ISUZU KB P190 2007

Page 5697 of 6020

RESTRAINT CONTROL SYSTEM 9A1-15

Chart C “SRS” Warning Lamp Does Not Come “ON” Steady

Step Action Yes No

1

1. W hen measurements are requested in this chart, use a 5-

8840-0366-0DMM with a correct terminal adapter from 5-

8840-0385-0.

2. Ignition switch is at “LOCK”.

3. Remove and inspect the “METER” fuse to the “SRS” warning lamp.

Is the fuse good? Go to Step 2 Go to Step 7

2

1. Ignition switch is at “LOCK”.

2. Disconnect the SRS coil and passenger air bag assembly

yellow connector which is located at the base of the steering

column and behind the glove box assembly.

3. Disconnect the SRS control unit.

4. Ignition switch is “ON”.

5. Measure the voltage on the SRS control unit harness connector from the terminal “4” to terminal “3” (ground).

Is system voltage present on terminal “4”? Go to Step 4 Go to Step 3

3

1. Ignition switch is at “LOCK”.

2. Remove instrument meter cluster.

3. Check for proper connection to instrument cluster at the SRS warning lamp circuit terminal.

4. If ok, then remove and inspect the “AIR BAG” bulb.

Is the bulb good? Go to Step 5 Replace bulb.

Go to Step 6

4

1. Ignition switch is at “LOCK”.

2. Disconnect instrument meter cluster harness connector.

3. Ignition switch is “ON”.

4. Measure the voltage on the SRS control unit harness

connector from terminal “4” to terminal “3” (ground).

Is the voltage 1 volt or less? Go to Chart A Replace SRS

harness.

Go to Step 6

5

1. Install the bulb.

2. Measure the resistance from the instrument meter cluster

harness connector SRS warning lamp circuit terminal to the

SRS control unit harness connector terminal “4”.

Is the resistance 5.0 ohms or less? Service instrument

meter cluster.

Install instrument meter cluster. Go to Step 6 Replace SRS

harness.

Go to Step 6

6 Reconnect all SRS components and ensure all components are

properly mounted.

Is this step finished? Repeat the “SRS

Diagnostic System Check” Go to Step 6

7

Perform chart C.

Is this step finished? Go to Step 8 Go to Step 1

8

1. Replace the “METER” fuse.

2. Ignition switch is “ON”. W ait 10 Seconds then ignition switch

is at “LOCK”.

3. Remove and inspect the “METER” fuse.

Is the fuse good? Install “METER”

fuse.

Go to Step 10 Go to Step 9

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 5698 of 6020

9A1-16 RESTRAINT CONTROL SYSTEM

Step Action Yes No

9

1. Disconnect the SRS coil and the passenger air bag assembly

yellow connectors located at the base of the steering column

and behind the glove box assembly.

2. Disconnect the SRS control unit.

3. Replace the “METER” fuse.

4. Ignition switch is “ON”-wait 10 seconds.

5. Ignition switch is at “LOCK”.

6. Remove and inspect the “METER” fuse.

Is the fuse good? Install “METER”

fuse.

Go to Chart A Replace SRS

harness.

Replace “METER” fuse.

Go to Step 10

10 Reconnect all the SRS components and ensure all the

components are properly mounted.

Is this step finished? Repeat the “SRS

Diagnostic System Check” —

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 5750 of 6020

9A1-68 RESTRAINT CONTROL SYSTEM

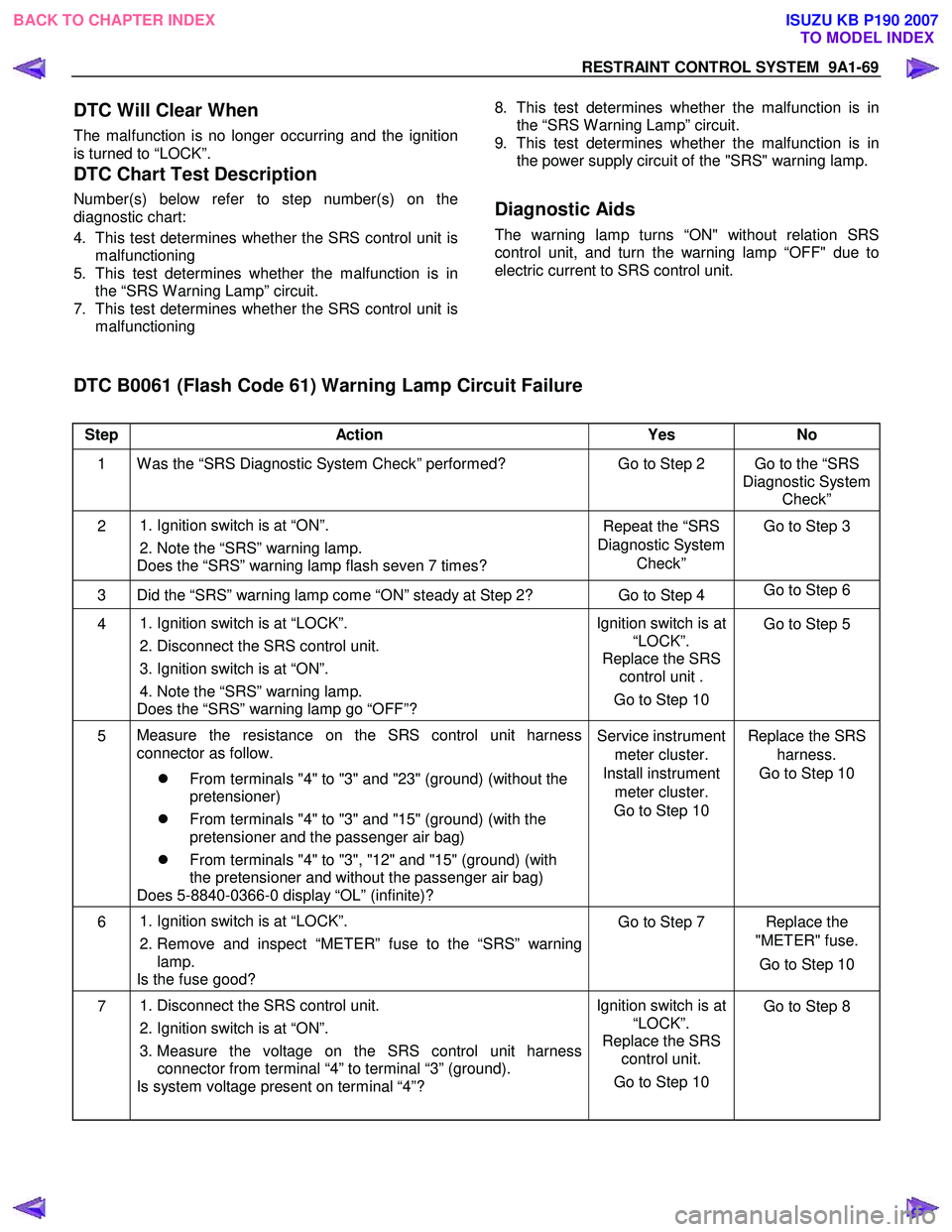

DTC B0061 (Flash Code 61) Warning Lamp Circuit Failure

RTW 79ALF000301

Circuit Description

W hen the ignition switch is first turned “ON”, “Ignition 1”

voltage is applied from the “METER” fuse to the “SRS”

warning lamp which is connected to “SRS" warning

lamp, terminal “4”. The “SRS” fuse applies system

voltage to the “Ignition 1” inputs, terminal “1”. The SRS

control unit responds by flashing the “SRS” warning

lamp 7 times. The SRS control unit monitors the “SRS

W arning Lamp" terminal "4" for conditions that are

incorrect for the commanded state of the "SRS" warning

lamp.

For example, a failure condition exists if the SRS

control unit detects low voltage when the "SRS" warning

lamp is commanded OFF, or high voltage when the

"SRS" warning lamp is commanded ON. If the SRS

control unit detects an improper voltage on the “SRS

W arning Lamp" terminal "4", DTC B0061 will set.

DTC Will Set When

The SRS control unit try to turn "ON" the "SRS" warning

lamp but the battery voltage is not supplied to terminal

"4".

The SRS control unit try to turn "OFF" the "SRS"

warning lamp but the battery voltage is supplied to

terminal "4".

Action Taken

If circuits of the “SRS" warning lamp power supply and

ground are normal condition, the SRS control unit turns

“ON” the “SRS” warning lamp and sets a diagnostic

trouble code.

BACK TO CHAPTER INDEX TO MODEL INDEX

ISUZU KB P190 2007

Page 5751 of 6020

RESTRAINT CONTROL SYSTEM 9A1-69

DTC Will Clear When

The malfunction is no longer occurring and the ignition

is turned to “LOCK”.

DTC Chart Test Description

Number(s) below refer to step number(s) on the

diagnostic chart:

4. This test determines whether the SRS control unit is malfunctioning

5. This test determines whether the malfunction is in the “SRS W arning Lamp” circuit.

7. This test determines whether the SRS control unit is malfunctioning

8. This test determines whether the malfunction is in

the “SRS W arning Lamp” circuit.

9. This test determines whether the malfunction is in the power supply circuit of the "SRS" warning lamp.

Diagnostic Aids

The warning lamp turns “ON" without relation SRS

control unit, and turn the warning lamp “OFF" due to

electric current to SRS control unit.

DTC B0061 (Flash Code 61) Warning Lamp Circuit Failure

Step Action Yes No

1 W as the “SRS Diagnostic System Check” performed? Go to Step 2 Go to the “SRS

Diagnostic System Check”

2

1. Ignition switch is at “ON”.

2. Note the “SRS” warning lamp.

Does the “SRS” warning lamp flash seven 7 times? Repeat the “SRS

Diagnostic System Check” Go to Step 3

3 Did the “SRS” warning lamp come “ON” steady at Step 2? Go to Step 4

Go to Step 6

4

1. Ignition switch is at “LOCK”.

2. Disconnect the SRS control unit.

3. Ignition switch is at “ON”.

4. Note the “SRS” warning lamp.

Does the “SRS” warning lamp go “OFF”? Ignition switch is at

“LOCK”.

Replace the SRS control unit .

Go to Step 10 Go to Step 5

5

Measure the resistance on the SRS control unit harness

connector as follow.

�z From terminals "4" to "3" and "23" (ground) (without the

pretensioner)

�z From terminals "4" to "3" and "15" (ground) (with the

pretensioner and the passenger air bag)

�z From terminals "4" to "3", "12" and "15" (ground) (with

the pretensioner and without the passenger air bag)

Does 5-8840-0366-0 display “OL” (infinite)? Service instrument

meter cluster.

Install instrument meter cluster.

Go to Step 10 Replace the SRS

harness.

Go to Step 10

6

1. Ignition switch is at “LOCK”.

2. Remove and inspect “METER” fuse to the “SRS” warning lamp.

Is the fuse good? Go to Step 7 Replace the

"METER" fuse.

Go to Step 10

7 1. Disconnect the SRS control unit.

2. Ignition switch is at “ON”.

3. Measure the voltage on the SRS control unit harness connector from terminal “4” to terminal “3” (ground).

Is system voltage present on terminal “4”? Ignition switch is at

“LOCK”.

Replace the SRS control unit.

Go to Step 10

Go to Step 8

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 5752 of 6020

9A1-70 RESTRAINT CONTROL SYSTEM

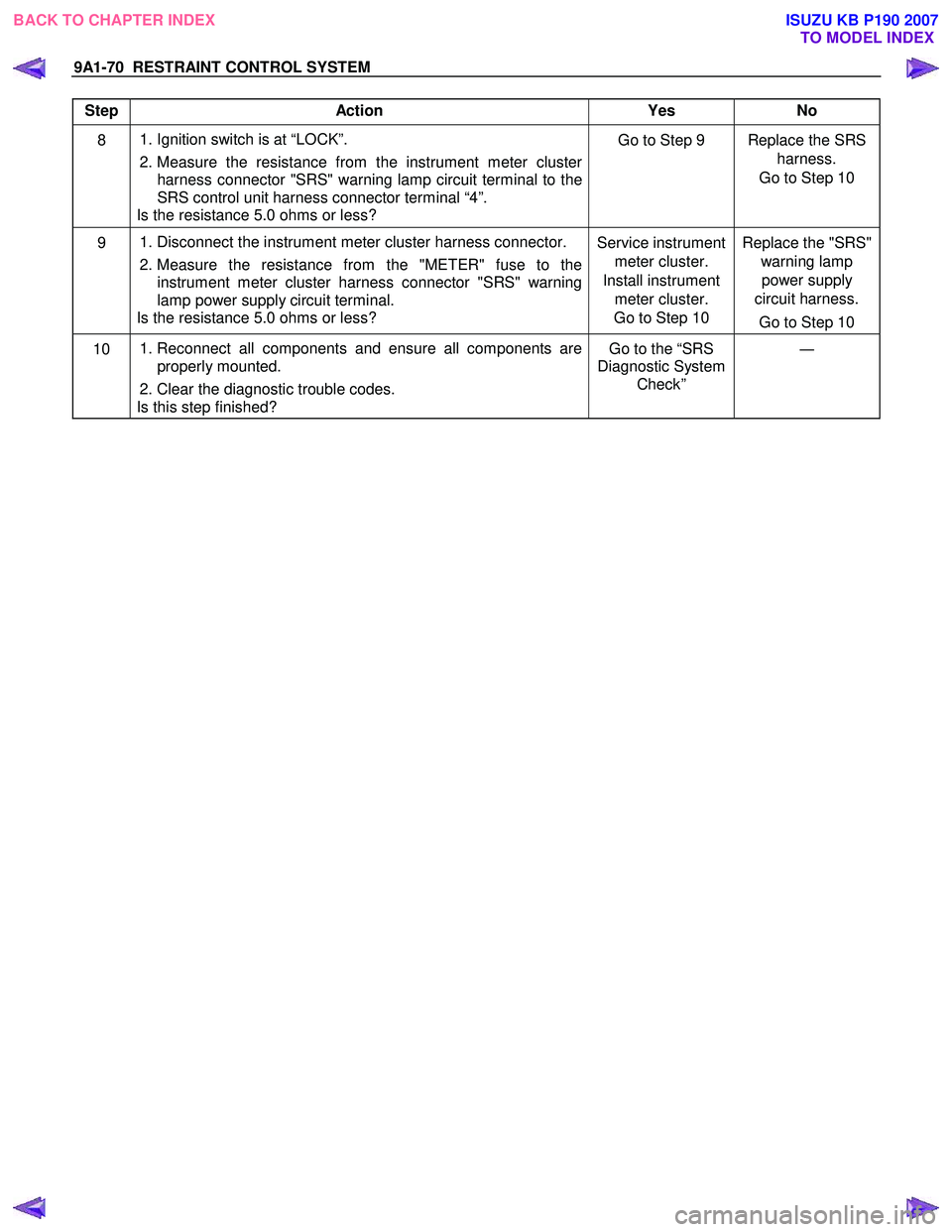

Step Action Yes No

8 1. Ignition switch is at “LOCK”.

2. Measure the resistance from the instrument meter cluster harness connector "SRS" warning lamp circuit terminal to the

SRS control unit harness connector terminal “4”.

Is the resistance 5.0 ohms or less? Go to Step 9 Replace the SRS

harness.

Go to Step 10

9 1. Disconnect the instrument meter cluster harness connector.

2. Measure the resistance from the "METER" fuse to the instrument meter cluster harness connector "SRS" warning

lamp power supply circuit terminal.

Is the resistance 5.0 ohms or less? Service instrument

meter cluster.

Install instrument meter cluster.

Go to Step 10 Replace the "SRS"

warning lamp power supply

circuit harness.

Go to Step 10

10 1. Reconnect all components and ensure all components are

properly mounted.

2. Clear the diagnostic trouble codes.

Is this step finished? Go to the “SRS

Diagnostic System Check” ―

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007