fuse ISUZU KB P190 2007 Workshop Repair Manual

[x] Cancel search | Manufacturer: ISUZU, Model Year: 2007, Model line: KB P190, Model: ISUZU KB P190 2007Pages: 6020, PDF Size: 70.23 MB

Page 5561 of 6020

ELECTRICAL-BODY AND CHASSIS 8A-623

No. Connector face No. Connector face

E89

White

Immobilizer engine control unit E107

MAP sensor

E90

Black

ECM J1 E108

Blue Cylinder revolution

E92

Silver

Fuse & relay box E109

Blue SPGA

E94

~

E95 NOT USED E110

Brown

Backup light switch

E96

Black

Reverse switch E111

BrownNeutral switch

E97

~

E98 NOT USED E112

Gray

1st switch

E99

Black

O2 sensor-RH E113

Gray Clutch sleave cylinder

E100

Black

O2 sensor-LH E114

~

E115 NOT USED

E101

~

E105 NOT USED E116

Backup light switch

E106

EVRV: Turbo

BACK TO CHAPTER INDEX

TO MODEL INDEXISUZU KB P190 2007

Page 5568 of 6020

8A-630 ELECTRICAL-BODY AND CHASSIS

No. Connector face No. Connector face

P1

Silver

Battery (+) P9

(4JA1T- (L))

SilverACG (B)

P2

Silver

Relay & Fuse box P9

(4JH1-TC)

Silver

ACG (B)

P3

Black

Starter (S) P10

SilverEngine ground

P4

(HFV6)

Silver

Starter (B) P11

SilverFuse & relay box

P4

Silver

Starter (B) P12

NOT USED

P5

Silver

Battery (-) P13

Gray Shift on the fly actuator

P6

Silver

Body earth (Ground) P14

NOT USED

P7

Battery (ALT) P15

Silver2nd battery (+)

P8

Green

ACG (L)

P9

(HFV6)

Silver

ACG (B)

BACK TO CHAPTER INDEX

TO MODEL INDEXISUZU KB P190 2007

Page 5593 of 6020

Cruise Control – HFV6 Page 8C–15

Step Action Yes No

3 Check the ignition supply circuits to the Stop Lamp Switch assembly

connector C – 44 pin 1 is serviceable using a multimeter set to

measure voltage, refer to 2.3 W iring Diagrams in this Section

Is there a +12 volt signal present at connector C – 44 pin 1?

Go to Step 4 Replace the faulty

fusible link Main,

IG2 or Stop Light fuse (refer to Note 1).

If either of the

fusible links or fuse blows again, repair

or replace the faulty circuit (refer to

Note 1)

4 1 Connect Tech 2 to the DLC.

2 On Tech 2 select: Body / Powertrain Interface Module / Diagnostic Data

Display.

3 Scroll to Cruise Main Switch.

4 W hile monitoring Tech 2, press the cruise control switch ON– OFF button.

Does Tech 2 display the following:

• Inactive and Active as the cruise control switch is pressed?

Go to Step 5 Go to Step 11

5 1 Scroll to Cruise Resume Switch.

2 While monitoring Tech 2, rotate the cruise control switch.

Does Tech 2 display the following:

• Inactive when the cruise control switch is in the neutral

position?

• Res / Acc when the cruise control switch is rotated to the RES–

ACC. Position? Go to Step 6 Go to Step 12

6

1 Scroll to Cruise Set Switch.

2 W hile monitoring Tech 2, press the cruise control switch.

Does Tech 2 display the following:

• Inactive when the cruise control switch is in the neutral

position?

• Set / Coast when the cruise control switch is pressed to the

SET–COAST position? Go to Step 7 Go to Step 13

7 1 Scroll to Cruise Cancel Switch.

2 While monitoring Tech 2, rotate the cruise control switch.

Does Tech 2 display the following:

• Inactive when the cruise control switch is in the neutral

position?

• Cancel when the cruise control switch is rotated to the CANCEL

position? Go to Step 8 Go to Step 14

BACK TO CHAPTER INDEX

TO MODEL INDEXISUZU KB P190 2007

Page 5596 of 6020

Cruise Control – HFV6 Page 8C–18

Step Action Yes No

24 1 Disconnect the PIM connector B – 97.

2 Using a multimeter set to measure voltage, back probe between the harness connector B – 97 pin 15 and a known ground.

3 With the aid of an assistant, monitor the voltage on the multimeter and press and release the cruise control switch to

SET–COAST button.

• With the switch in the rest position, the multimeter should

display 0 V.

• With the switch pressed, the multimeter should display

battery voltage.

Does the multimeter display as described? Go to Step 30 Check for short to

ground or open

circuit on circuit.

Repair as required (refer to Note 1).

Go to Step 32

25 1 Disconnect the PIM connector B – 97.

2 Using a multimeter set to measure voltage, back probe between the harness connector B – 97 pin 17 and a known ground.

3 W ith the aid of an assistant, monitor the voltage on the multimeter and rotate and release the cruise control switch to

CANCEL position.

• With the switch in the rest position, the multimeter should

display 0 V.

• W ith the switch rotated clockwise, the multimeter should

display battery voltage.

Does the multimeter display as described? Go to Step 30 Check for short to

ground or open

circuit on circuit.

Repair as required (refer to Note 1).

Go to Step 32

26 1 Disconnect the ECM connector C – 56.

2 Using a multimeter set to measure voltage, back probe between the harness connector C – 56 pin 10 and ground.

3 With the aid of an assistant, monitor the voltage on the multimeter and press and release the brake pedal.

• W ith the brake pedal in the rest position, the multimeter

should display 0 V

• W ith the brake pedal pressed, the multimeter should

display battery voltage

Does the multimeter display as described? Go to Step 30 Check for a blown

fuse C-18.

Check for short to

ground or open circuit

Repair as required (refer to Note 1).

Go to Step 32

27 1 Disconnect the ECM connector C – 56.

2 Using a multimeter set to measure voltage, back probe between the harness connector C – 56 pin 46 and ground.

3 With the aid of an assistant, monitor the voltage on the multimeter and press and release the brake pedal.

• W ith the brake pedal in the rest position, the multimeter

should display battery voltage

• W ith the brake pedal pressed, the multimeter should

display 0 V.

Does the multimeter display as described? Go to Step 28 Check for a blown

fuse C-10.

Check for short to ground or open

circuit

Repair as required (refer to Note 1).

Go to Step 32

BACK TO CHAPTER INDEX TO MODEL INDEXISUZU KB P190 2007

Page 5597 of 6020

Cruise Control – HFV6 Page 8C–19

Step Action Yes No

28 1 Disconnect the ECM connector C – 56.

2 Using a multimeter set to measure voltage, back probe between the harness connector C – 56 pin 53 and ground.

3 W ith the aid of an assistant, monitor the voltage on the multimeter and press and release the clutch pedal.

• With the clutch pedal in the rest position, the multimeter

should display battery voltage

• W ith the clutch pedal pressed, the multimeter should

display 0 V

Does the multimeter display as described? Go to Step 31 Check for a blown

fuse C-4.

Check for short to ground or open circuit

Repair as required (refer to Note 2).

Go to Step 32

29 Check all associated circuits and connectors for the following:

• Loose or damaged connections

• Intermittent faults.

Refer to the Wiring Diagrams in this Section and repair as required.

W as the repair completed? Go to Step 32 —

30 Replace the PIM, refer to 6E1 Powertrain Interface Module – V6.

W as the repair completed? Go to Step 32 —

31 Replace the ECM module, refer to 6C1-3 Engine Management – V6

Service Operations.

W as the repair completed? Go to Step 32 —

32 Operate the system in order to verify the repair.

Did you correct the condition? System OK Go to Step 1

When all diagnosis and repairs are completed, clear all DTCs and check the system for correct operation.

BACK TO CHAPTER INDEX

TO MODEL INDEXISUZU KB P190 2007

Page 5628 of 6020

ACCESSORIES 9-23

No. Connector face No. Connector face

D-22

White

Tweeter -LH P-1

SilverBattery (+)

H-14

White

Rear body ∼ Rear door -LH P-2

SilverRelay & Fuse box

H-16

White

Rear body ∼ Rear door -RH P-5

SilverBattery (-)

H-18

White

Engine room ∼ INST P-6

SilverBody earth

H-36

White

INST ~ Front door-RH P-10

SilverEngine ground

H-37

White

INST ~ Front door-LH R-7

BlackRear speaker -LH

H-39

White

INST ~ Front door-LH R-8

BlackRear speaker -RH

H-42

White

INST ~ Front door-driver

H-43

INST ~ Body

H-43

White

INST ~ Body

BACK TO CHAPTER INDEX TO MODEL INDEXISUZU KB P190 2007

Page 5656 of 6020

SUPPLEMENTAL RESTRAINT SYSTEM 9A-21

On–Vehicle Service

Service Precaution

WARNING: WHEN PERFORMING SERVICE ON OR

AROUND SRS COMPONENTS OR SRS WIRING,

FOLLOW THE PROCEDURES LISTED BELOW TO

TEMPORARILY DISABLE THE SRS. FAILURE TO

FOLLOW PROCEDURES COULD RESULT IN

POSSIBLE AIR BAG DEPLOYMENT, PERSONAL

INJURY OR OTHERWISE UNNECESSARY SRS

REPAIRS.

The SRS control unit in Driver–Passenger SRS can

maintain sufficient voltage to cause a deployment fo

r

up to 15 seconds after the ignition switch is turned

“OFF,” the battery is disconnected, or the fuse

powering the SRS control unit is removed.

Many of the service procedures require removal of the

“SRS” fuse, and disconnection of the air bag assembl

y

from the deployment loop to avoid an accidental

deployment. If the air bag assembly is disconnected

from the deployment loop as noted in the “Disabling

the SRS” procedure that follows, service can begin

immediately without waiting for the 15 second time

period to expire.

Disabling The SRS

Removal

Turn the ignition switch to “LOCK” and remove the

key.

1. Remove the SRS fuse “SRS”, from the side of the driver’s side of the instrument panel fuse block o

r

disconnect the battery.

2. Disconnect the yellow connector at the base of the steering column.

3. Remove the glove box assembly, refer to “Passenger Air Bag Assembly Replacement” in

this manual.

4. Disconnect the yellow connector behind the glove box assembly.

CAUTION: With the “SRS” fuse removed and

ignition switched “ON”, the “SRS” warning lamp

will be “ON”. This is normal operation and does

not indicate an SRS malfunction.

Enabling The SRS

Installation

CAUTION: Never use the air bag assembly from

another vehicle or different model year air bag

assembly.

Use only a new air bag assembly matched to the

TFR/S which is being repaired.

Turn the ignition switch to “LOCK” and remove the

key.

1. Connect the yellow connector passenger air bag assembly.

2. Install the glove box assembly. Refer to “Passenger air bag assembly replacement” in this

manual.

3. Connect the yellow connector at the base of the steering column.

4. Install the “AIR BAG” fuse “SRS” to the side of the driver’s side of the instrument panel fuse block o

r

connect the battery.

Turn the ignition switch to “ON” and verify that the

“SRS” warning lamp flashes seven times and then

turns to “LOCK”. If it does not operate as described,

perform the “SRS Diagnostic System Check” in this

manual.

Handling / Installation / Diagnosis

1. The air bag assembly should not be subjected to temperatures above 65

°C (150°F).

2. The air bag assembly, and SRS control unit, should not be used if they have been dropped from

a height of 100 centimeters (3.28 feet) or more.

3. W hen the SRS control unit is replaced, it must be oriented with the arrow on the sensor pointing

toward the front of the vehicle. It is very important

for the SRS control unit to be located flat on the

mounting surface, parallel to the vehicle datum

line. It is important that the SRS control unit

mounting surface is free of any dirt or other foreign

material.

4. Do not apply power to the SRS unless all components are connected or a diagnostic chart

requests it, as this will set a diagnostic trouble

code.

5. The “SRS Diagnostic System Check” must be the starting point of any SRS diagnostics. The “SRS

Diagnostic System Check” will verify proper “SRS”

warning lamp operation and will lead you to the

correct chart to diagnose any SRS malfunctions.

Bypassing these procedures may result in

extended diagnostic time, incorrect diagnosis, and

incorrect parts replacement.

BACK TO CHAPTER INDEX TO MODEL INDEXISUZU KB P190 2007

Page 5658 of 6020

SUPPLEMENTAL RESTRAINT SYSTEM 9A-23

Air Bag Assembly Scrapping Procedure

During the course of a vehicle's useful life, certain

situations may arise which will necessitate the disposal

of a live (undeployed) air bag assembly. This

information covers proper procedures for disposing o

f

a live air bag assembly.

Before a live air bag assembly can be disposed of, it

must be deployed.

A live air bag assembly must not

be disposed of through normal refuse channels.

WARNING: FAILURE TO FOLLOW PROPER

SUPPLEMENTAL RESTRAINT SYSTEM (SRS) AIR

BAG ASSEMBLY DISPOSAL PROCEDURES CAN

RESULT IN AIR BAG DEPLOYMENT WHICH MAY

CAUSE PERSONAL INJURY. AN UNDEPLOYED

AIR BAG ASSEMBLY MUST NOT BE DISPOSED

OF THROUGH NORMAL REFUSE CHANNELS.

THE UNDEPLOYED AIR BAG ASSEMBLY

CONTAINS SUBSTANCES THAT CAN CAUSE

SEVERE ILLNESS OR PERSONAL INJURY IF THE

SEALED CONTAINER IS DAMAGED DURING

DISPOSAL. DISPOSAL IN ANY MANNER

INCONSISTENT WITH PROPER PROCEDURES

MAY BE A VIOLATION OF FEDERAL, STATE, AND

/

OR LOCAL LAW.

In situations which require deployment of a live air bag

assembly, deployment may be accomplished inside o

r

outside the vehicle. The method employed depends

upon the final disposition of the particular vehicle, as

noted in “Deployment Outside Vehicle” and

“Deployment Inside Vehicle” in this section.

Deployment Outside Vehicle (Driver Air

Bag Assembly)

Deployment outside the vehicle is proper when the

vehicle is to be returned to service. This includes, fo

r

example, situations in which the vehicle will be

returned to useful service after a functionally o

r

cosmetically deficient air bag assembly is replaced.

Deployment and disposal of a malfunctioning air bag

assembly is, of course, subject to any required

retention period.

For deployment of a live (undeployed) air bag

assembly outside the vehicle, the deployment

procedure must be followed exactly. Always wea

r

safety glasses during this deployment procedure until

a deployed air bag assembly is scrapped or until an

undeployed air bag assembly is shipped. Before

performing the procedures you should be familiar with

servicing the SRS and with proper handling of the ai

r

bag assembly. Procedures should be read fully before

they are performed.

The following procedure requires use of a 5-8840-

2468-06 SRS deployment harness with appropriate

pigtail adapter. Do not attempt the procedure without

a 5-8840-2468-0 adapter.

WARNING: F

AILURE TO FOLLOW PROCEDURES

IN THE ORDER LISTED MAY RESULT IN

PERSONAL INJURY. NEVER CONNECT THE

DEPLOYMENT HARNESS TO ANY POWER

SOURCE BEFORE CONNECTING THE

DEPLOYMENT HARNESS TO THE DRIVER AIR

BAG ASSEMBLY. DEPLOYMENT HARNESS

SHALL REMAIN SHORTED AND NOT BE

CONNECTED TO A POWER SOURCE UNTIL THE

AIR BAG IS TO BE DEPLOYED. THE AIR BAG

ASSEMBLY WILL IMMEDIATELY DEPLOY THE AIR

BAG WHEN A POWER SOURCE IS CONNECTED

TO IT. WEAR SAFETY GLASSES THROUGHOUT

THIS ENTIRE DEPLOYMENT AND DISPOSAL

PROCEDURE.

NOTE: This information applies only to driver air bag

assembly. Refer to “Deployment Outside Vehicle

(Passenger Air Bag assembly)” in this section fo

r

information on passenger air bag assembly scrapping.

1. Turn the ignition switch to “LOCK”, remove the ke

y

and put on safety glasses.

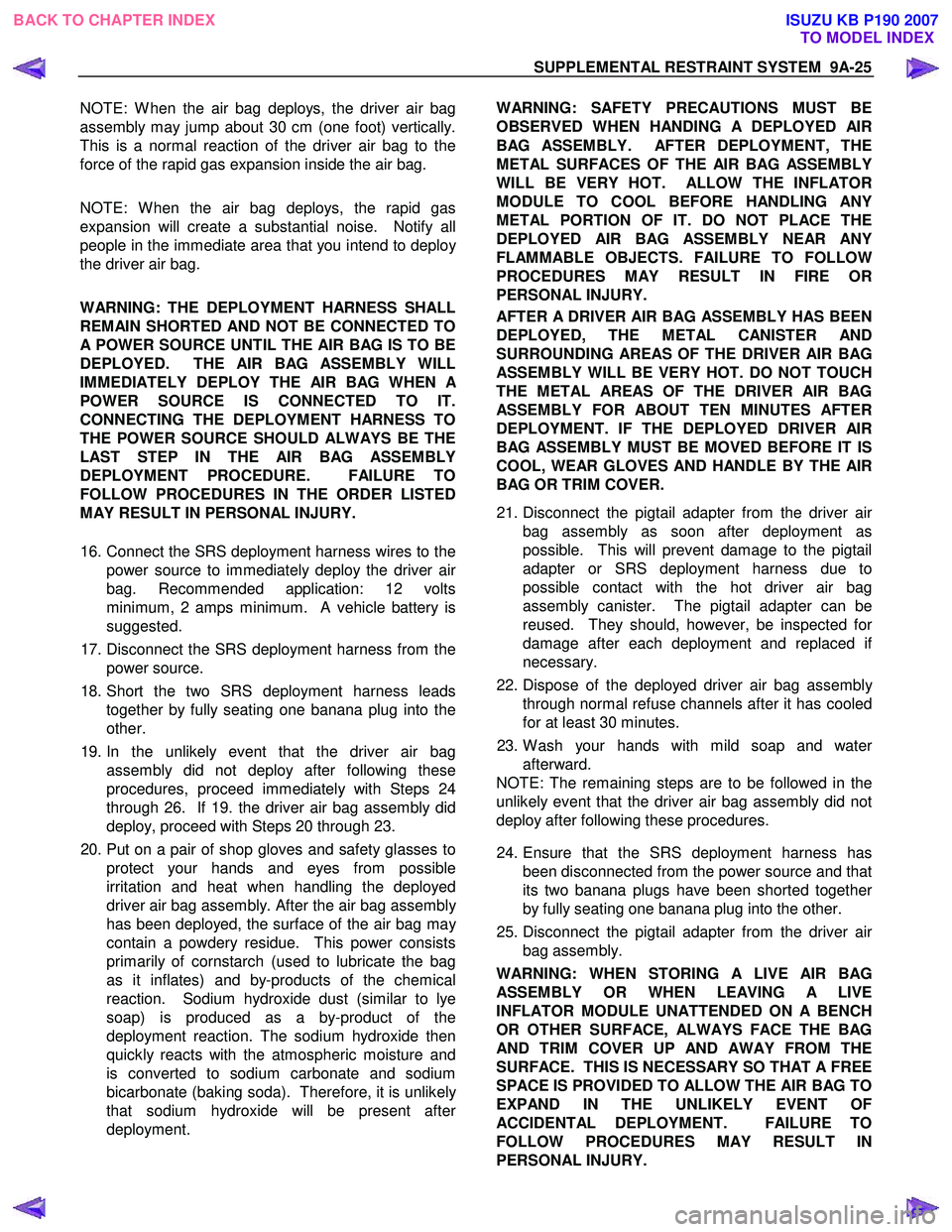

2. Inspect the 5-8840-2468-0 SRS Deployment Harness and appropriate pigtail adapter fo

r

damage. If the harness or pigtail adapter is

damaged, discard and obtain a replacement.

3. Short the two SRS deployment harness leads together by fully seating one banana plug into the

other. The SRS deployment harness shall remain

shorted and not be connected to a power source

until the air bag is to be deployed.

827RS004

4. Connect the appropriate pigtail adapter to the SRS deployment harness.

5. Remove the driver air bag assembly from the vehicle. Refer to “Inflator Module Removal” in this

manual.

BACK TO CHAPTER INDEX TO MODEL INDEXISUZU KB P190 2007

Page 5660 of 6020

SUPPLEMENTAL RESTRAINT SYSTEM 9A-25

NOTE: W hen the air bag deploys, the driver air bag

assembly may jump about 30 cm (one foot) vertically.

This is a normal reaction of the driver air bag to the

force of the rapid gas expansion inside the air bag.

NOTE: W hen the air bag deploys, the rapid gas

expansion will create a substantial noise. Notify all

people in the immediate area that you intend to deplo

y

the driver air bag.

WARNING: THE DEPLOYMENT HARNESS SHALL

REMAIN SHORTED AND NOT BE CONNECTED TO

A POWER SOURCE UNTIL THE AIR BAG IS TO BE

DEPLOYED. THE AIR BAG ASSEMBLY WILL

IMMEDIATELY DEPLOY THE AIR BAG WHEN

A

POWER SOURCE IS CONNECTED TO IT.

CONNECTING THE DEPLOYMENT HARNESS TO

THE POWER SOURCE SHOULD ALWAYS BE THE

LAST STEP IN THE AIR BAG ASSEMBLY

DEPLOYMENT PROCEDURE. FAILURE TO

FOLLOW PROCEDURES IN THE ORDER LISTED

MAY RESULT IN PERSONAL INJURY.

16. Connect the SRS deployment harness wires to the power source to immediately deploy the driver ai

r

bag. Recommended application: 12 volts

minimum, 2 amps minimum. A vehicle battery is

suggested.

17. Disconnect the SRS deployment harness from the power source.

18. Short the two SRS deployment harness leads together by fully seating one banana plug into the

other.

19. In the unlikely event that the driver air bag assembly did not deploy after following these

procedures, proceed immediately with Steps 24

through 26. If 19. the driver air bag assembly did

deploy, proceed with Steps 20 through 23.

20. Put on a pair of shop gloves and safety glasses to protect your hands and eyes from possible

irritation and heat when handling the deployed

driver air bag assembly. After the air bag assembl

y

has been deployed, the surface of the air bag may

contain a powdery residue. This power consists

primarily of cornstarch (used to lubricate the bag

as it inflates) and by-products of the chemical

reaction. Sodium hydroxide dust (similar to lye

soap) is produced as a by-product of the

deployment reaction. The sodium hydroxide then

quickly reacts with the atmospheric moisture and

is converted to sodium carbonate and sodium

bicarbonate (baking soda). Therefore, it is unlikel

y

that sodium hydroxide will be present after

deployment.

WARNING: SAFETY PRECAUTIONS MUST BE

OBSERVED WHEN HANDING A DEPLOYED AIR

BAG ASSEMBLY. AFTER DEPLOYMENT, THE

METAL SURFACES OF THE AIR BAG ASSEMBLY

WILL BE VERY HOT. ALLOW THE INFLATOR

MODULE TO COOL BEFORE HANDLING ANY

METAL PORTION OF IT. DO NOT PLACE THE

DEPLOYED AIR BAG ASSEMBLY NEAR ANY

FLAMMABLE OBJECTS. FAILURE TO FOLLOW

PROCEDURES MAY RESULT IN FIRE OR

PERSONAL INJURY.

AFTER A DRIVER AIR BAG ASSEMBLY HAS BEEN

DEPLOYED, THE METAL CANISTER AND

SURROUNDING AREAS OF THE DRIVER AIR BAG

ASSEMBLY WILL BE VERY HOT. DO NOT TOUCH

THE METAL AREAS OF THE DRIVER AIR BAG

ASSEMBLY FOR ABOUT TEN MINUTES AFTER

DEPLOYMENT. IF THE DEPLOYED DRIVER AIR

BAG ASSEMBLY MUST BE MOVED BEFORE IT IS

COOL, WEAR GLOVES AND HANDLE BY THE AIR

BAG OR TRIM COVER.

21. Disconnect the pigtail adapter from the driver ai

r

bag assembly as soon after deployment as

possible. This will prevent damage to the pigtail

adapter or SRS deployment harness due to

possible contact with the hot driver air bag

assembly canister. The pigtail adapter can be

reused. They should, however, be inspected fo

r

damage after each deployment and replaced i

f

necessary.

22. Dispose of the deployed driver air bag assembl

y

through normal refuse channels after it has cooled

for at least 30 minutes.

23. W ash your hands with mild soap and wate

r

afterward.

NOTE: The remaining steps are to be followed in the

unlikely event that the driver air bag assembly did not

deploy after following these procedures.

24. Ensure that the SRS deployment harness has been disconnected from the power source and that

its two banana plugs have been shorted togethe

r

by fully seating one banana plug into the other.

25. Disconnect the pigtail adapter from the driver ai

r

bag assembly.

WARNING: WHEN STORING A LIVE AIR BAG

ASSEMBLY OR WHEN LEAVING A LIVE

INFLATOR MODULE UNATTENDED ON A BENCH

OR OTHER SURFACE, ALWAYS FACE THE BAG

AND TRIM COVER UP AND AWAY FROM THE

SURFACE. THIS IS NECESSARY SO THAT A FREE

SPACE IS PROVIDED TO ALLOW THE AIR BAG TO

EXPAND IN THE UNLIKELY EVENT OF

ACCIDENTAL DEPLOYMENT. FAILURE TO

FOLLOW PROCEDURES MAY RESULT IN

PERSONAL INJURY.

BACK TO CHAPTER INDEX TO MODEL INDEXISUZU KB P190 2007

Page 5661 of 6020

9A-26 SUPPLEMENTAL RESTRAINT SYSTEM

26. Temporarily store the driver air bag assembly with

its trim cover facing up, away from the surface

upon which it rests.

Deployment Outside Vehicle (Passenger

Air Bag Assembly)

WARNING: FAILURE TO FOLLOW PROPER SRS

AIR BAG ASSEMBLY DISPOSAL PROCEDURES

CAN RESULT IN AIR BAG DEPLOYMENT WHICH

MAY CAUSE PERSONAL INJURY. UNDEPLOYED

AIR BAG ASSEMBLIES MUST NOT BE DISPOSED

OF THROUGH NORMAL REFUSE CHANNELS.

THE UNDEPLOYED AIR BAG ASSEMBLY

CONTAINS SUBSTANCES THAT CAN CAUSE

SEVERE ILLNESS OR PERSONAL INJURY IF THE

SEALED CONTAINER IS DAMAGED DURING

DISPOSAL. DISPOSAL IN ANY MANNER

INCONSISTENT WITH PROPER PROCEDURES

MAY BE A VIOLATION OF FEDERAL, STATE

AND/OR LOCAL LAWS.

Deployment out of the vehicle is proper when the

vehicle is to be returned to service. This includes, fo

r

example, situations in which a functionally or

cosmetically deficient air bag assembly is replaced.

Deployment and disposal of an air bag assembly is, o

f

course, subject to any required retention period.

For deployment of a live air bag assembly out of the

vehicle, the deployment procedure must be followed

exactly. Always wear safety glasses during this

deployment procedure until the deployed air bag

assembly is scrapped. Before performing the

procedures, you should be familiar with servicing the

SRS system and with proper handling of the air bag

assembly. Procedures should be read fully before

they are performed.

The following procedure requires use of a 5-8840-

2468-0 SRS Deployment Harness with the appropriate

pigtail adapter. The procedure also requires the use

of a 5-8840-2420-0 Passenger Side SRS Module

Deployment Fixture. Do not attempt this procedure

without a 5-8840-2468-0 and adapter, and a 5-8840-

2420-0.

WARNING: FAILURE TO FOLLOW PROCEDURES

IN THE ORDER LISTED MA

Y RESULT IN

PERSONAL INJURY. NEVER CONNECT THE

DEPLOYMENT HARNESS TO ANY POWER

SOURCE BEFORE CONNECTING THE

DEPLOYMENT HARNESS TO THE AIR BAG

ASSEMBLY. THE DEPLOYMENT HARNESS SHALL

REMAIN SHORTED AND NOT BE CONNECTED TO

A POWER SOURCE UNTIL THE AIR BAG IS TO BE

DEPLOYED. THE AIR BAG ASSEMBLY WILL

IMMEDIATELY DEPLOY THE AIR BAG WHEN

A

POWER SOURCE IS CONNECTED TO IT. WEAR

SAFETY GLASSES THROUGHOUT THIS ENTIRE

DEPLOYMENT AND DISPOSAL PROCEDURE.

NOTE: This information applies only to passenger ai

r

bag assembly. Information for disposing of a live

driver air bag assembly can be found in “Deployment

Outside Vehicle” (Driver Air Bag Assembly) in this

section.

1. Turn the ignition switch to “LOCK”, remove the key, and put on the safety glasses.

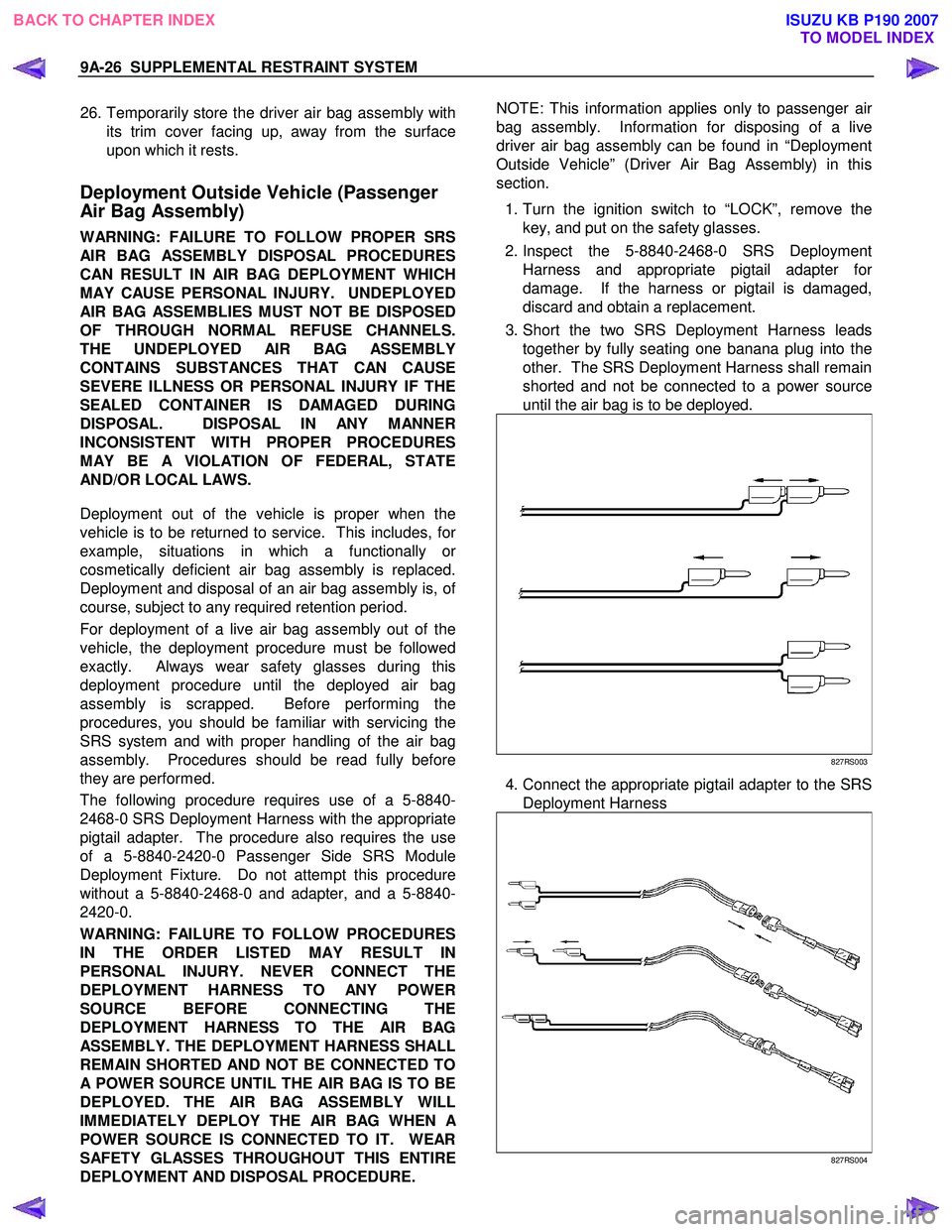

2. Inspect the 5-8840-2468-0 SRS Deployment Harness and appropriate pigtail adapter fo

r

damage. If the harness or pigtail is damaged,

discard and obtain a replacement.

3. Short the two SRS Deployment Harness leads together by fully seating one banana plug into the

other. The SRS Deployment Harness shall remain

shorted and not be connected to a power source

until the air bag is to be deployed.

827RS003

4. Connect the appropriate pigtail adapter to the SRS Deployment Harness

827RS004

BACK TO CHAPTER INDEX TO MODEL INDEXISUZU KB P190 2007