engine coolant ISUZU KB P190 2007 Workshop Repair Manual

[x] Cancel search | Manufacturer: ISUZU, Model Year: 2007, Model line: KB P190, Model: ISUZU KB P190 2007Pages: 6020, PDF Size: 70.23 MB

Page 3325 of 6020

Engine Management – V6 – Diagnostics Page 6C1-2–47

6.7 Throttle Body Relearn

A throttle body relearn procedure is performed in one of two ways:

• Engine Control Module initiated throttle body relearn, or

• Tech 2 initiated throttle body relearn.

Engine Control Module Throttle Body Relearn

The engine control module (ECM) will automatically perform a throttle body relearn procedure if either of the following

conditions exist:

• The battery has been disconnected, or

• The ignition switch is in the ON position for greater than 29 seconds, and the following conditions are met:

− Engine speed is less than 40 rpm,

− Vehicle speed is 0 km/h,

− Engine coolant temperature is 5 – 60°C,

− Intake air temperature is 5 – 60°C,

− Accelerator pedal position sensor angle is less than 14.9%, and

− Ignition voltage is greater than 10 V.

Tech 2 Throttle Body Relearn

To perform a throttle body relearn using Tech 2, complete the following procedure:

NOTE

Tech 2 will not initiate a throttle body relearn if

the engine is running.

1 Connect Tech 2 to the data link connector (DLC) and turn the ignition on.

2 On Tech 2 select Engine / Programming / Throttle Body Relearn.

3 W hen Tech 2 displays ‘Do you really want to Reset?’, press the ‘Yes’ soft key.

4 W hen Tech 2 displays ‘Programming Completed’, and the electronic throttle control value displayed by Tech 2 is ‘11’, press the ‘Confirm’ soft key to return to the Tech 2 Programming screen.

5 The throttle body relearn is now complete.

6.8 Electronic Ignition (EI) System Diagnosis

Circuit Description

The engine control module (ECM) controls the ignition coils by pulsing the ignition control (IC) circuits, which triggers an

ignition coil and fires the spark plug. The ECM controls the sequencing and the timing of each ignition coil. The ignition

system consist of the following components:

• The six ignition coils

• The crankshaft position (CKP) sensor

• The four camshaft position (CMP) sensors

• The ECM

The ignition coils use the following circuits:

• An IC circuit

• An ignition 1 voltage circuit

• Two ground circuits

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3329 of 6020

Engine Management – V6 – Diagnostics Page 6C1-2–51

DTC Description Diagnostic Table

P0058 O2 Sensor Heater Circuit High Voltage (Bank 2, Sensor 2) 7.3 DTC P0030, P0031, P0032, P0036,

P0037, P0038, P0050, P0051, P0052,

P0056, P0057 or P0058

P0059 O2 Sensor Heater Resistance Range / Performance (Bank 2, Sensor 1) 7.5 DTC P0053 or P0059

P0101 Mass Air Flow Sensor Circuit Range / Performance 7.6 DTC P0101, P0102 or P0103

P0102 Mass Air Flow Sensor Voltage Low

7.6 DTC P0101, P0102 or P0103

P0103 Mass Air Flow Sensor Voltage High 7.6 DTC P0101, P0102 or P0103

P0112 Intake Air Temperature Sensor Circuit Low Voltage 7.7 DTC P0112 or P0113

P0113 Intake Air Temperature Sensor Circuit High Voltage 7.7 DTC P0112 or P0113

P0116 Engine Coolant Temperature Sensor Circuit Range /

Performance 7.8 DTC P0116, P0117, P0118, P0125 or

P1258

P0117 Engine Coolant Temperature Sensor Circuit Low Voltage 7.8 DTC P0116, P0117, P0118, P0125 or P1258

P0118 Engine Coolant Temperature Sensor Circuit High Voltage 7.8 DTC P0116, P0117, P0118, P0125 or P1258

P0121 Throttle Position Sensor 1 Circuit Range / Performance 7.9 DTC P0121, P0122, P0123, P0221, P0222,or P0223

P0122 Throttle Position Sensor 1 Circuit Low Voltage 7.9 DTC P0121, P0122, P0123, P0221,

P0222,or P0223

P0123 Throttle Position Sensor 1 Circuit High Voltage 7.9 DTC P0121, P0122, P0123, P0221,

P0222,or P0223

P0125 Insufficient Engine Coolant Temperature For Closed Loop Fuel Control 7.8 DTC P0116, P0117, P0118, P0125 or

P1258

P0130 O2 Sensor Circuit Malfunction (Bank 1, Sensor 1) 7.10 DTC P0130, P0131, P0132, P0135, P0137, P0138, P0140, P0141, P0150

P0151, P0152, P0155, P0157, P0158,

P0160, P0161, P2243, P2247, P2270,

P2271, P2272, P2273, P2297 or P2298

P0131 O2 Sensor Circuit Low Voltage (Bank 1, Sensor 1) 7.10 DTC P0130, P0131, P0132, P0135, P0137, P0138, P0140, P0141, P0150

P0151, P0152, P0155, P0157, P0158,

P0160, P0161, P2243, P2247, P2270,

P2271, P2272, P2273, P2297 or P2298

P0132 O2 Sensor Circuit High Voltage (Bank 1 Sensor 1) 7.10 DTC P0130, P0131, P0132, P0135, P0137, P0138, P0140, P0141, P0150

P0151, P0152, P0155, P0157, P0158,

P0160, P0161, P2243, P2247, P2270,

P2271, P2272, P2273, P2297 or P2298

P0133 O2 Sensor Circuit Slow Response (Bank 1 Sensor 1) 7.11 DTC P0133 or P0153

P0135 O2 Sensor Heater Circuit Range / Performance (Bank 1, Sensor 1) 7.10 DTC P0130, P0131, P0132, P0135,

P0137, P0138, P0140, P0141, P0150

P0151, P0152, P0155, P0157, P0158,

P0160, P0161, P2243, P2247, P2270,

P2271, P2272, P2273, P2297 or P2298

P0137 O2 Sensor Circuit Low Voltage (Bank 1, Sensor 2) 7.10 DTC P0130, P0131, P0132, P0135, P0137, P0138, P0140, P0141, P0150

P0151, P0152, P0155, P0157, P0158,

P0160, P0161, P2243, P2247, P2270,

P2271, P2272, P2273, P2297 or P2298

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3334 of 6020

Engine Management – V6 – Diagnostics Page 6C1-2–56

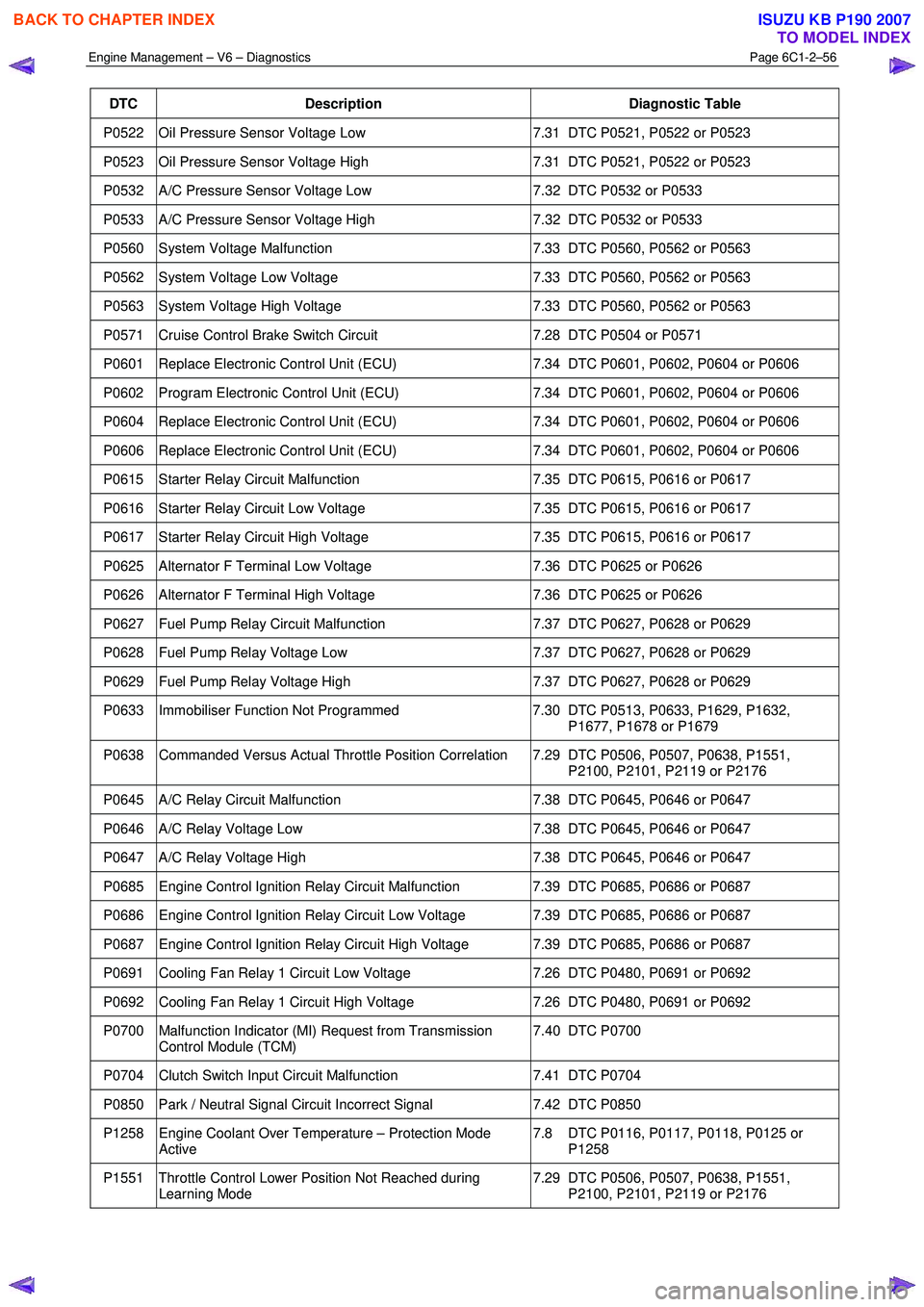

DTC Description Diagnostic Table

P0522 Oil Pressure Sensor Voltage Low 7.31 DTC P0521, P0522 or P0523

P0523 Oil Pressure Sensor Voltage High 7.31 DTC P0521, P0522 or P0523

P0532 A/C Pressure Sensor Voltage Low 7.32 DTC P0532 or P0533

P0533 A/C Pressure Sensor Voltage High 7.32 DTC P0532 or P0533

P0560 System Voltage Malfunction 7.33 DTC P0560, P0562 or P0563

P0562 System Voltage Low Voltage 7.33 DTC P0560, P0562 or P0563

P0563 System Voltage High Voltage 7.33 DTC P0560, P0562 or P0563

P0571 Cruise Control Brake Switch Circuit 7.28 DTC P0504 or P0571

P0601 Replace Electronic Control Unit (ECU) 7.34 DTC P0601, P0602, P0604 or P0606

P0602 Program Electronic Control Unit (ECU) 7.34 DTC P0601, P0602, P0604 or P0606

P0604 Replace Electronic Control Unit (ECU) 7.34 DTC P0601, P0602, P0604 or P0606

P0606 Replace Electronic Control Unit (ECU) 7.34 DTC P0601, P0602, P0604 or P0606

P0615 Starter Relay Circuit Malfunction 7.35 DTC P0615, P0616 or P0617

P0616 Starter Relay Circuit Low Voltage 7.35 DTC P0615, P0616 or P0617

P0617 Starter Relay Circuit High Voltage 7.35 DTC P0615, P0616 or P0617

P0625 Alternator F Terminal Low Voltage 7.36 DTC P0625 or P0626

P0626 Alternator F Terminal High Voltage 7.36 DTC P0625 or P0626

P0627 Fuel Pump Relay Circuit Malfunction 7.37 DTC P0627, P0628 or P0629

P0628 Fuel Pump Relay Voltage Low 7.37 DTC P0627, P0628 or P0629

P0629 Fuel Pump Relay Voltage High 7.37 DTC P0627, P0628 or P0629

P0633 Immobiliser Function Not Programmed 7.30 DTC P0513, P0633, P1629, P1632,

P1677, P1678 or P1679

P0638 Commanded Versus Actual Throttle Position Correlation 7.29 DTC P0506, P0507, P0638, P1551, P2100, P2101, P2119 or P2176

P0645 A/C Relay Circuit Malfunction 7.38 DTC P0645, P0646 or P0647

P0646 A/C Relay Voltage Low 7.38 DTC P0645, P0646 or P0647

P0647 A/C Relay Voltage High 7.38 DTC P0645, P0646 or P0647

P0685 Engine Control Ignition Relay Circuit Malfunction 7.39 DTC P0685, P0686 or P0687

P0686 Engine Control Ignition Relay Circuit Low Voltage 7.39 DTC P0685, P0686 or P0687

P0687 Engine Control Ignition Relay Circuit High Voltage 7.39 DTC P0685, P0686 or P0687

P0691 Cooling Fan Relay 1 Circuit Low Voltage 7.26 DTC P0480, P0691 or P0692

P0692 Cooling Fan Relay 1 Circuit High Voltage 7.26 DTC P0480, P0691 or P0692

P0700 Malfunction Indicator (MI) Request from Transmission

Control Module (TCM) 7.40 DTC P0700

P0704 Clutch Switch Input Circuit Malfunction

7.41 DTC P0704

P0850 Park / Neutral Signal Circuit Incorrect Signal 7.42 DTC P0850

P1258 Engine Coolant Over Temperature – Protection Mode

Active 7.8 DTC P0116, P0117, P0118, P0125 or

P1258

P1551 Throttle Control Lower Position Not Reached during Learning Mode 7.29 DTC P0506, P0507, P0638, P1551,

P2100, P2101, P2119 or P2176

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3339 of 6020

Engine Management – V6 – Diagnostics Page 6C1-2–61

• DTCs P0341, P0342, P0343, ran and passed:

• The engine is running.

• The ECM has learned the camshafts position.

DTC P0016

Run continuously once the following conditions are met.

• DTCs P0335, P0336, P0338, P0341, P0342 and P0343 ran and passed:

• The calculated engine oil temperature is less than 95 °C.

• The engine coolant temperature is 20 – 90 °C.

• The engine is running for greater than 5 seconds.

Conditions for Setting the DTC

DTC P0008

The ECM detects that both camshafts on bank 1 of the engine are misaligned with the crankshaft.

DTC P0009

The ECM detects that both camshafts on bank 2 of the engine are misaligned with the crankshaft.

DTC P0016

The ECM detects the following deviation in the correlation between the camshaft position and the crankshaft position for

greater than 10 minutes:

• a camshaft position is too advanced in relationship to the crankshaft, or

• a camshaft position is too retarded in relationship to the crankshaft.

Conditions for Clearing DTC

The CKP / CMP sensor correlation DTCs are Type B DTCs. Refer to 1.4 Diagnostic Trouble Codes in this Section, for

action taken when Type B DTCs set and conditions for clearing Type B DTCs.

Additional Information

• Refer to 6C1-1 Engine Management – V6 – General Information for details of the CMP system operation.

• Inspect the engine for recent engine mechanical repairs. Incorrect camshaft, camshaft actuator or timing chain

installation will trigger these DTCs.

• The engine oil condition has a major impact on the operation of the camshaft actuator.

• A low oil level may set these DTCs.

• For an intermittent fault condition, refer to 5.2 Intermittent Fault Conditions in this Section.

• Since fault condition in a wiring connector may trigger DTCs, always test the connectors related to this diagnostic

procedure for shorted terminals or poor wiring connection before replacing any component. Refer to 8A Electrical -

Body and Chassis for information on electrical fault diagnosis.

• To assist diagnosis, refer to 3 W iring Diagrams and Connector Charts in this Section, for the system wiring

diagram and connector charts.

Test Description

The following numbers refer to the step numbers in the diagnostic table:

3 A fault condition in any of the listed sensors will trigger these DTCs.

5 Incorrect camshaft, camshaft actuator or timing chain installation will trigger these DTCs.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3353 of 6020

Engine Management – V6 – Diagnostics Page 6C1-2–75

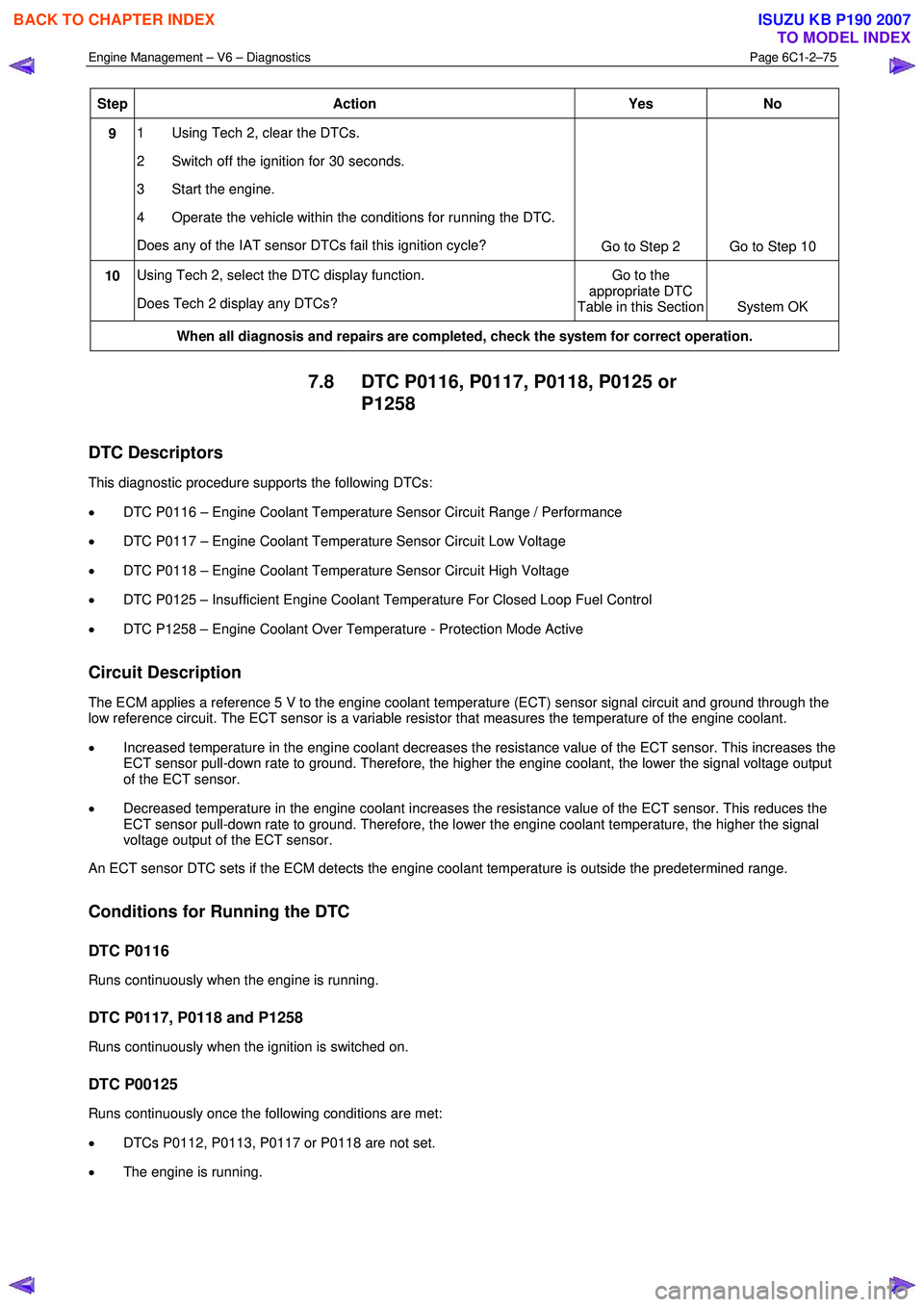

Step Action Yes No

9 1 Using Tech 2, clear the DTCs.

2 Switch off the ignition for 30 seconds.

3 Start the engine.

4 Operate the vehicle within the conditions for running the DTC.

Does any of the IAT sensor DTCs fail this ignition cycle? Go to Step 2 Go to Step 10

10 Using Tech 2, select the DTC display function.

Does Tech 2 display any DTCs? Go to the

appropriate DTC

Table in this Section System OK

When all diagnosis and repairs are completed, check the system for correct operation.

7.8 DTC P0116, P0117, P0118, P0125 or

P1258

DTC Descriptors

This diagnostic procedure supports the following DTCs:

• DTC P0116 – Engine Coolant Temperature Sensor Circuit Range / Performance

• DTC P0117 – Engine Coolant Temperature Sensor Circuit Low Voltage

• DTC P0118 – Engine Coolant Temperature Sensor Circuit High Voltage

• DTC P0125 – Insufficient Engine Coolant Temperature For Closed Loop Fuel Control

• DTC P1258 – Engine Coolant Over Temperature - Protection Mode Active

Circuit Description

The ECM applies a reference 5 V to the engine coolant temperature (ECT) sensor signal circuit and ground through the

low reference circuit. The ECT sensor is a variable resistor that measures the temperature of the engine coolant.

• Increased temperature in the engine coolant decreases the resistance value of the ECT sensor. This increases the

ECT sensor pull-down rate to ground. Therefore, the higher the engine coolant, the lower the signal voltage output

of the ECT sensor.

• Decreased temperature in the engine coolant increases the resistance value of the ECT sensor. This reduces the

ECT sensor pull-down rate to ground. Therefore, the lower the engine coolant temperature, the higher the signal

voltage output of the ECT sensor.

An ECT sensor DTC sets if the ECM detects the engine coolant temperature is outside the predetermined range.

Conditions for Running the DTC

DTC P0116

Runs continuously when the engine is running.

DTC P0117, P0118 and P1258

Runs continuously when the ignition is switched on.

DTC P00125

Runs continuously once the following conditions are met:

• DTCs P0112, P0113, P0117 or P0118 are not set.

• The engine is running.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3354 of 6020

Engine Management – V6 – Diagnostics Page 6C1-2–76

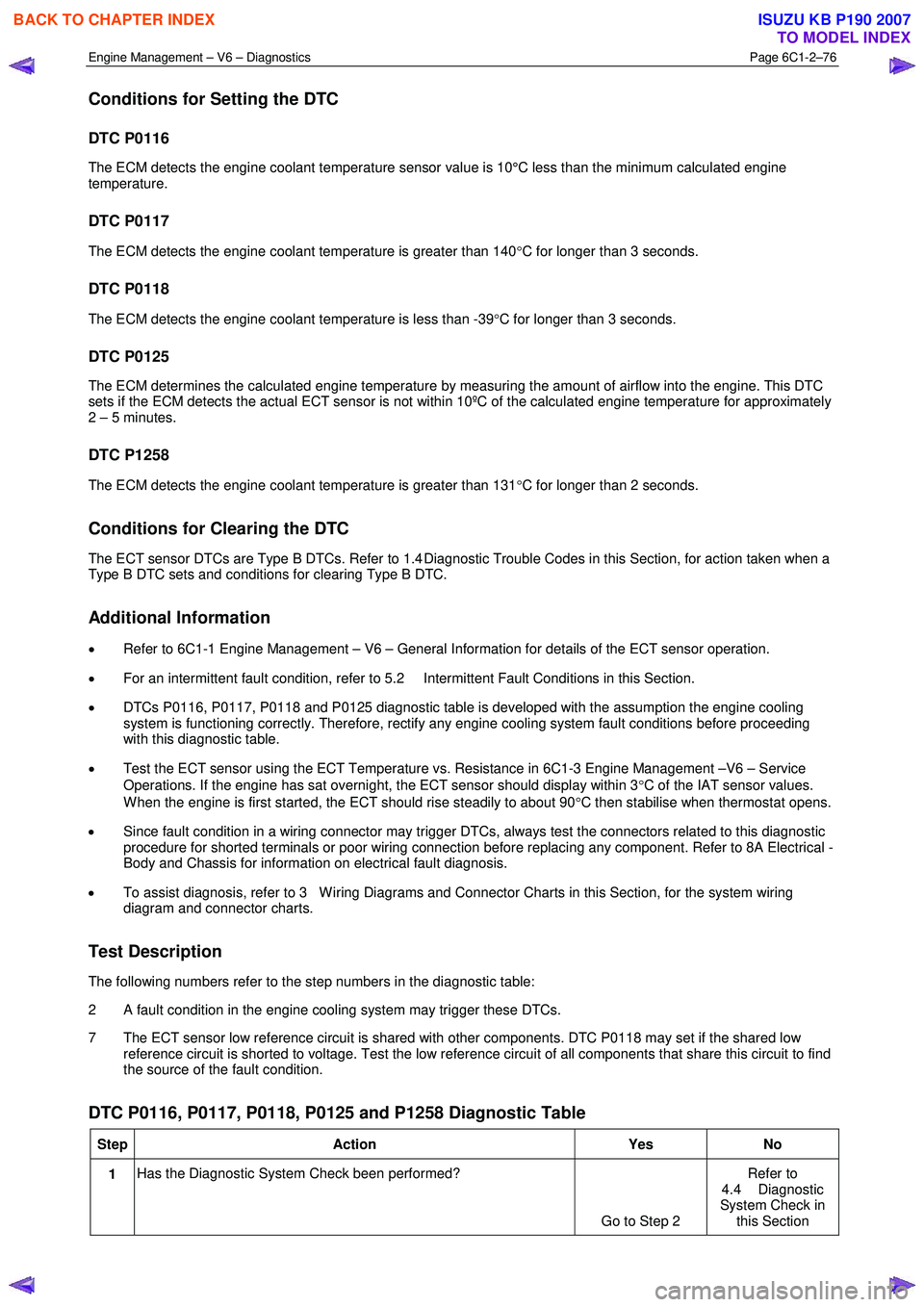

Conditions for Setting the DTC

DTC P0116

The ECM detects the engine coolant temperature sensor value is 10°C less than the minimum calculated engine

temperature.

DTC P0117

The ECM detects the engine coolant temperature is greater than 140 °C for longer than 3 seconds.

DTC P0118

The ECM detects the engine coolant temperature is less than -39 °C for longer than 3 seconds.

DTC P0125

The ECM determines the calculated engine temperature by measuring the amount of airflow into the engine. This DTC

sets if the ECM detects the actual ECT sensor is not within 10ºC of the calculated engine temperature for approximately

2 – 5 minutes.

DTC P1258

The ECM detects the engine coolant temperature is greater than 131 °C for longer than 2 seconds.

Conditions for Clearing the DTC

The ECT sensor DTCs are Type B DTCs. Refer to 1.4 Diagnostic Trouble Codes in this Section, for action taken when a

Type B DTC sets and conditions for clearing Type B DTC.

Additional Information

• Refer to 6C1-1 Engine Management – V6 – General Information for details of the ECT sensor operation.

• For an intermittent fault condition, refer to 5.2 Intermittent Fault Conditions in this Section.

• DTCs P0116, P0117, P0118 and P0125 diagnostic table is developed with the assumption the engine cooling

system is functioning correctly. Therefore, rectify any engine cooling system fault conditions before proceeding

with this diagnostic table.

• Test the ECT sensor using the ECT Temperature vs. Resistance in 6C1-3 Engine Management –V6 – Service

Operations. If the engine has sat overnight, the ECT sensor should display within 3 °C of the IAT sensor values.

W hen the engine is first started, the ECT should rise steadily to about 90 °C then stabilise when thermostat opens.

• Since fault condition in a wiring connector may trigger DTCs, always test the connectors related to this diagnostic

procedure for shorted terminals or poor wiring connection before replacing any component. Refer to 8A Electrical -

Body and Chassis for information on electrical fault diagnosis.

• To assist diagnosis, refer to 3 W iring Diagrams and Connector Charts in this Section, for the system wiring

diagram and connector charts.

Test Description

The following numbers refer to the step numbers in the diagnostic table:

2 A fault condition in the engine cooling system may trigger these DTCs.

7 The ECT sensor low reference circuit is shared with other components. DTC P0118 may set if the shared low reference circuit is shorted to voltage. Test the low reference circuit of all components that share this circuit to find

the source of the fault condition.

DTC P0116, P0117, P0118, P0125 and P1258 Diagnostic Table

Step Action Yes No

1 Has the Diagnostic System Check been performed?

Go to Step 2 Refer to

4.4 Diagnostic

System Check in this Section

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3362 of 6020

Engine Management – V6 – Diagnostics Page 6C1-2–84

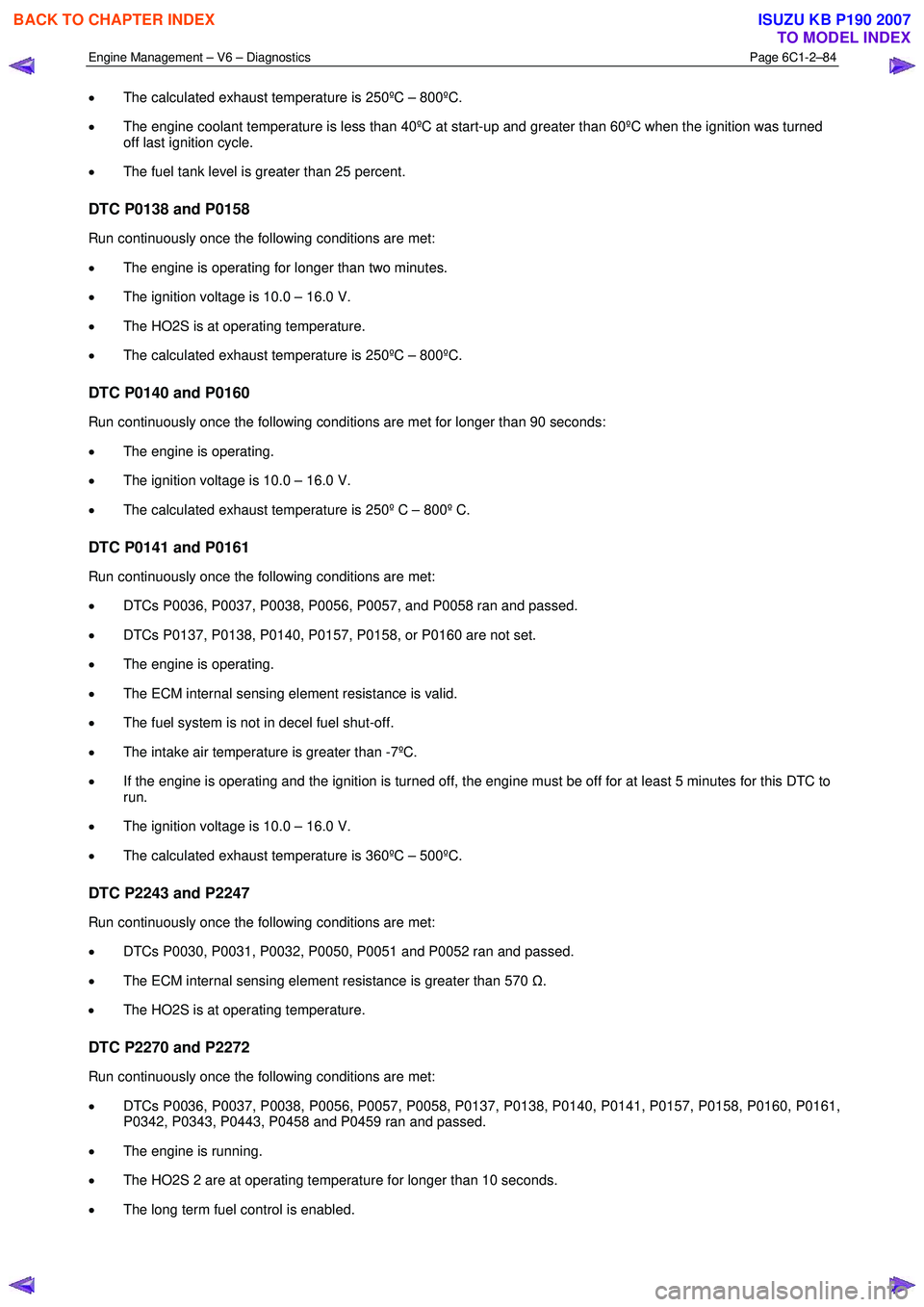

• The calculated exhaust temperature is 250ºC – 800ºC.

• The engine coolant temperature is less than 40ºC at start-up and greater than 60ºC when the ignition was turned

off last ignition cycle.

• The fuel tank level is greater than 25 percent.

DTC P0138 and P0158

Run continuously once the following conditions are met:

• The engine is operating for longer than two minutes.

• The ignition voltage is 10.0 – 16.0 V.

• The HO2S is at operating temperature.

• The calculated exhaust temperature is 250ºC – 800ºC.

DTC P0140 and P0160

Run continuously once the following conditions are met for longer than 90 seconds:

• The engine is operating.

• The ignition voltage is 10.0 – 16.0 V.

• The calculated exhaust temperature is 250º C – 800º C.

DTC P0141 and P0161

Run continuously once the following conditions are met:

• DTCs P0036, P0037, P0038, P0056, P0057, and P0058 ran and passed.

• DTCs P0137, P0138, P0140, P0157, P0158, or P0160 are not set.

• The engine is operating.

• The ECM internal sensing element resistance is valid.

• The fuel system is not in decel fuel shut-off.

• The intake air temperature is greater than -7ºC.

• If the engine is operating and the ignition is turned off, the engine must be off for at least 5 minutes for this DTC to

run.

• The ignition voltage is 10.0 – 16.0 V.

• The calculated exhaust temperature is 360ºC – 500ºC.

DTC P2243 and P2247

Run continuously once the following conditions are met:

• DTCs P0030, P0031, P0032, P0050, P0051 and P0052 ran and passed.

• The ECM internal sensing element resistance is greater than 570 Ω.

• The HO2S is at operating temperature.

DTC P2270 and P2272

Run continuously once the following conditions are met:

• DTCs P0036, P0037, P0038, P0056, P0057, P0058, P0137, P0138, P0140, P0141, P0157, P0158, P0160, P0161,

P0342, P0343, P0443, P0458 and P0459 ran and passed.

• The engine is running.

• The HO2S 2 are at operating temperature for longer than 10 seconds.

• The long term fuel control is enabled.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3369 of 6020

Engine Management – V6 – Diagnostics Page 6C1-2–91

Step Action Yes No

7 NOTE

If both DTCs are set, determine and correct the cause of

the contamination before replacing a sensor.

1 Inspect for the following conditions:

• Fuel contamination – refer to 6.5 Alcohol / Contaminants

in Fuel Diagnosis in this Section.

• The correct RTV sealant.

• Engine oil consumption – refer to 6A1 Engine Mechanical

– V6.

• Engine coolant consumption – refer to 6B1 Engine Cooling

– V6.

2 Replace the HO2S. Refer to 6C1-3 Engine Management – V6 – Service Operations.

Did you complete the replacement? Go to Step 8 —

8 1 Use Tech 2 to Clear the DTCs.

2 Turn OFF the ignition for 30 seconds.

3 Start the engine.

4 Operate the vehicle within the Conditions for Running the DTC. You may also operate the vehicle within the conditions that you

observed from the Freeze Frame / Failure Records.

Did the DTC fail this ignition? Go to Step 2 Go to Step 9

9 1 Using Tech 2, select the DTC display function.

Does Tech 2 display any DTCs? Go to the

appropriate DTC

Table in this Section System OK

When all diagnosis and repairs are completed, clear all DTCs and verify correct operation

7.12 DTC P0139 or P0159

DTC Descriptors

This diagnostic procedure supports the following DTCs:

• DTC P0139 – O2 Sensor Circuit Slow Response (Bank 1 Sensor 2)

• DTC P0159 – O2 Sensor Circuit Slow Response (Bank 2 Sensor 2)

Circuit Description

The post catalytic converter heated oxygen sensor (HO2S) produces a voltage that varies between 100 – 900 mV under

normal operating conditions. The engine control module (ECM) produces a bias voltage on the HO2S signal circuit of

420 – -480 mV. The reference ground for the sensor is provided through the ECM.

The ECM monitors the signal voltage to determine if the exhaust is lean or rich. The oxygen sensor voltage is high when

the exhaust is rich, and low when the exhaust is lean. The ECM constantly monitors the HO2S signal during the Closed

Loop operation. If the ECM detects that the decel fuel cut-off rich-to-lean transition time is too long, DTC P0139 will set

for bank 1 sensor 2, or DTC P0159 will set for bank 2 sensor 2.

Conditions for Running the DTC

• DTCs P0021, P0024, P0030, P0031, P0032, P0036, P0037, P0038, P0050, P0051, P0052, P0056, P0057, P0058,

P0101, P0102, P0103, P0106, P0107, P0108, P0116, P0117, P0118, P0121, P0122, P0123, P0125, P0128,

P0131, P0132, P0135, P0137, P0138, P0139, P0140, P0141, P0151, P0152, P0155, P0157, P0158, P0159,

P0160, P0161, P0201-P0208, P0221, P0222, P0223, P0261, P0262, P0264, P0265, P0267, P0268, P0270,

P0271, P0273, P0274, P0276, P0277, P0279, P0280, P0282, P0283, P0300, P0301-P0308, P0335, P0336,

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3384 of 6020

Engine Management – V6 – Diagnostics Page 6C1-2–106

− Damaged accessory drive belt

• For an intermittent condition, refer to 5.2 Intermittent Fault Conditions in this Section.

• Since a fault condition in a wiring connector may trigger DTCs, always test the connectors related to this

diagnostic procedure for shorted terminals or poor wiring connection before replacing any component. Refer to 8A

Electrical - Body and Chassis for information on electrical fault diagnosis.

• To assist diagnosis, refer to 3 W iring Diagrams and Connector Charts in this Section, for the system wiring

diagram and connector charts.

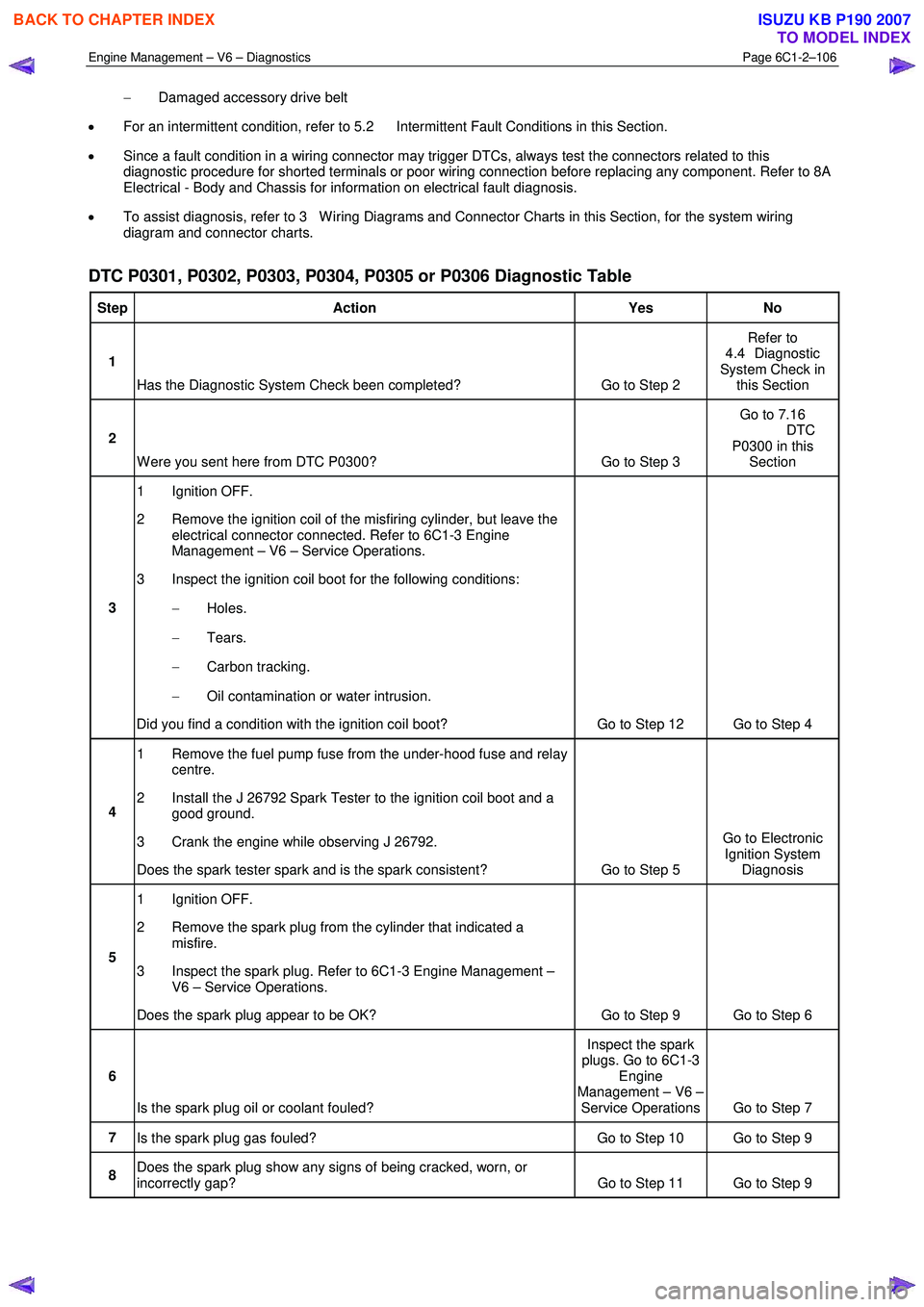

DTC P0301, P0302, P0303, P0304, P0305 or P0306 Diagnostic Table

Step Action Yes No

1

Has the Diagnostic System Check been completed? Go to Step 2 Refer to

4.4 Diagnostic

System Check in this Section

2

W ere you sent here from DTC P0300? Go to Step 3 Go to 7.16

DTC P0300 in this Section

3 1 Ignition OFF.

2 Remove the ignition coil of the misfiring cylinder, but leave the electrical connector connected. Refer to 6C1-3 Engine

Management – V6 – Service Operations.

3 Inspect the ignition coil boot for the following conditions:

− Holes.

− Tears.

− Carbon tracking.

− Oil contamination or water intrusion.

Did you find a condition with the ignition coil boot? Go to Step 12 Go to Step 4

4 1 Remove the fuel pump fuse from the under-hood fuse and relay

centre.

2 Install the J 26792 Spark Tester to the ignition coil boot and a good ground.

3 Crank the engine while observing J 26792.

Does the spark tester spark and is the spark consistent? Go to Step 5 Go to Electronic

Ignition System Diagnosis

5 1 Ignition OFF.

2 Remove the spark plug from the cylinder that indicated a misfire.

3 Inspect the spark plug. Refer to 6C1-3 Engine Management – V6 – Service Operations.

Does the spark plug appear to be OK? Go to Step 9 Go to Step 6

6

Is the spark plug oil or coolant fouled? Inspect the spark

plugs. Go to 6C1-3 Engine

Management – V6 – Service Operations Go to Step 7

7 Is the spark plug gas fouled? Go to Step 10 Go to Step 9

8 Does the spark plug show any signs of being cracked, worn, or

incorrectly gap? Go to Step 11 Go to Step 9

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3386 of 6020

Engine Management – V6 – Diagnostics Page 6C1-2–108

Test One

The ECM performs the following:

1 Turns off the knock sensor signal circuits.

2 Applies different test signals to the ECM internal KS circuitry.

3 Verifies each test signal output response is within range.

4 If the ECM detects any of the tested signals are not within the normal range, DTC P0324 sets.

Test Two

The ECM performs the following:

1 Turns off the knock sensor signal circuits.

2 Tests for any output response when no test signals are applied.

3 If the ECM detects an output response, DTC P0324 sets.

Test Three

1 Turns off the knock sensor signal circuits.

2 Generates an internal test pulse then monitors the return signal.

3 If the return test pulse is less than a calibrated threshold, DTC P0324 sets.

DTC P0324 sets if the ECM detects an incorrect response to the ECM internal KS circuitry tests.

Conditions for Running the DTC

Condition One

Runs continuously once the following conditions are met:

• The ECM is controlling the ignition spark.

• The engine speed is less than 2,300 rpm and steady.

• The volumetric efficiency is steady.

Condition Two

Runs continuously once the following conditions are met:

• The ECM is controlling the ignition spark.

• The engine speed is 1,000 – 4,000 rpm

• The engine coolant temperature is greater than 60 ° C.

• The volumetric efficiency is steady.

Condition Three

Runs continuously once the following conditions are met:

• The ECM is controlling the ignition spark.

• The engine speed is less than 2,300 rpm and steady.

• The engine coolant temperature is greater than 40 ° C.

• The volumetric efficiency is steady.

Conditions for Setting the DTC

The ECM detects an incorrect response to an internal ECM KS circuitry test.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007