engine coolant ISUZU KB P190 2007 Workshop Repair Manual

[x] Cancel search | Manufacturer: ISUZU, Model Year: 2007, Model line: KB P190, Model: ISUZU KB P190 2007Pages: 6020, PDF Size: 70.23 MB

Page 3274 of 6020

Engine Management β V6 β General Information Page 6C1-1β32

4.16 Intake Air Temperature Sensor

The intake air temperature (IAT) sensor is a thermistor,

which is a resistor that changes itβs resistance value based

on temperature.

The IAT sensor is part of the air mass sensor and is not a

serviceable item. The sensor is a negative temperature

coefficient (NTC) type, intake air temperature produces a

high sensor resistance while high engine coolant

temperature causes low sensor resistance.

Legend

A Temperature

B Resistance

The ECM provides a 5 V reference signal to the IAT and

monitors the return signal which enables it to calculate the

intake air temperature.

The ECM uses this signal to make corrections to the

operating parameters of the system based on changes in air

intake temperature.

Figure 6C1-1 β 40

4.17 Knock Sensor

The knock sensor (KS) signal is used by the ECM to provide

optimum ignition timing while minimising engine knock or

detonation.

The ECM monitors the voltage of the left-hand (Bank 2)

sensor during the 45 degrees after cylinder 2, 4, or 6 has

fired and the voltage of the right-hand (Bank 1) sensor

during the 45 degrees after cylinder 1, 3, or 5 has fired.

If knock occurs in any of the cylinders, the ignition will be

retarded by three degrees for that particular cylinder. If the

knocking then stops, the ignition will be restored to what it

was before in steps of 0.75 degrees.

Should knocking continue in the same cylinder despite of

the ignition being retarded, the ECM will retard the ignition

an additional step of three degrees, and so on, up to a

maximum of 12.75 degrees. The ignition will also be

retarded at high ambient temperatures to counteract

knocking tendencies provoked by high intake air

temperatures.

Should either Bank 1 or Bank 2 sensor fail to work, or

should an open circuit occur, the ignition timing will then be

set at a default strategy that will retard the ignition much

more than normal.

Figure 6C1-1 β 41

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3277 of 6020

Engine Management β V6 β General Information Page 6C1-1β35

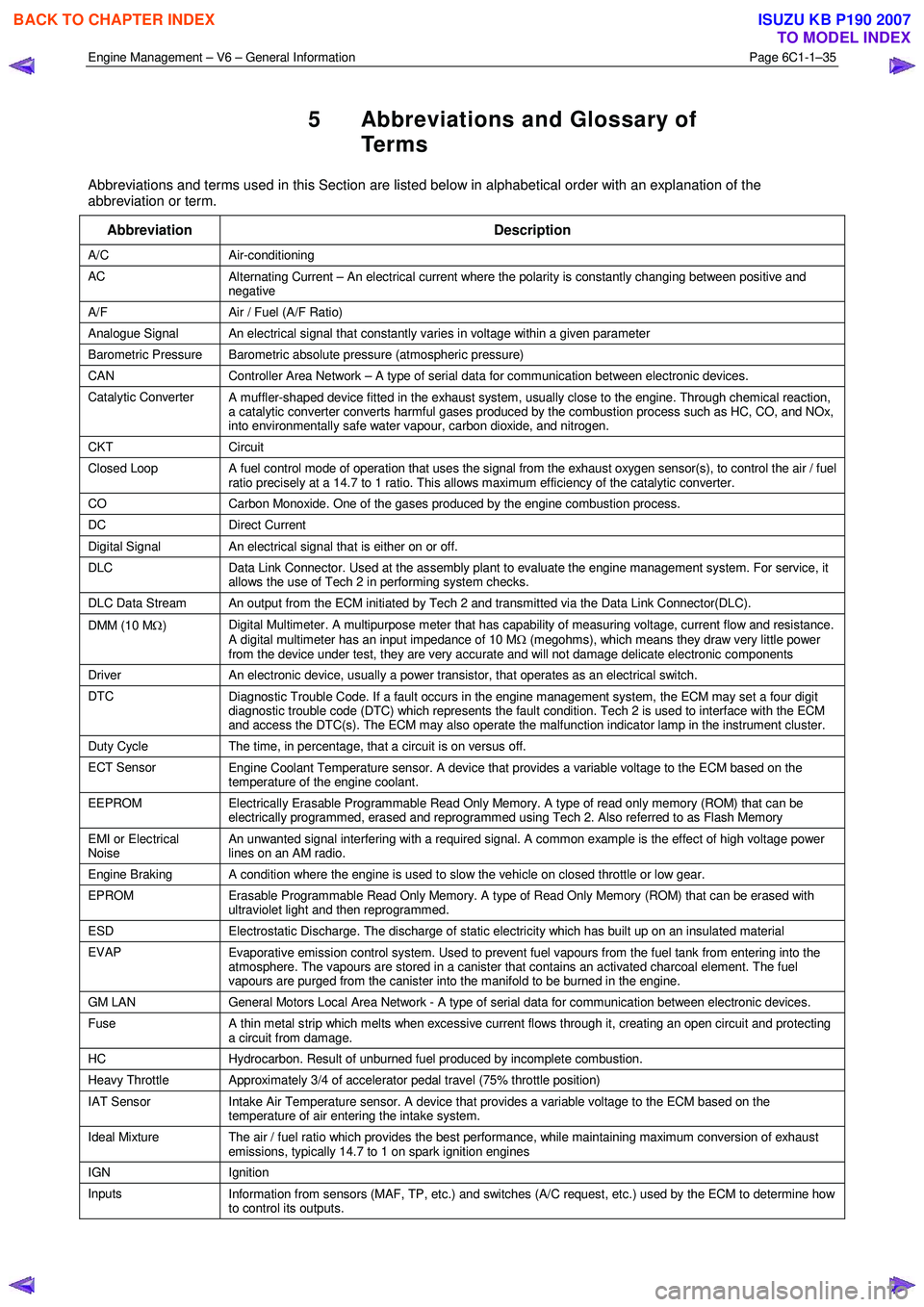

5 Abbreviations and Glossary of

Te r m s

Abbreviations and terms used in this Section are listed below in alphabetical order with an explanation of the

abbreviation or term.

Abbreviation Description

A/C Air-conditioning

AC Alternating Current β An electrical current where the polarity is constantly changing between positive and

negative

A/F Air / Fuel (A/F Ratio)

Analogue Signal An electrical signal that constantly varies in voltage within a given parameter

Barometric Pressure Barometric absolute pressure (atmospheric pressure)

CAN Controller Area Network β A type of serial data for communication between electronic devices.

Catalytic Converter

A muffler-shaped device fitted in the exhaust system, usually close to the engine. Through chemical reaction,

a catalytic converter converts harmful gases produced by the combustion process such as HC, CO, and NOx,

into environmentally safe water vapour, carbon dioxide, and nitrogen.

CKT Circuit

Closed Loop A fuel control mode of operation that uses the signal from the exhaust oxygen sensor(s), to control the air / fuel

ratio precisely at a 14.7 to 1 ratio. This allows maximum efficiency of the catalytic converter.

CO Carbon Monoxide. One of the gases produced by the engine combustion process.

DC Direct Current

Digital Signal An electrical signal that is either on or off.

DLC

Data Link Connector. Used at the assembly plant to evaluate the engine management system. For service, it

allows the use of Tech 2 in performing system checks.

DLC Data Stream An output from the ECM initiated by Tech 2 and transmitted via the Data Link Connector(DLC).

DMM (10 M β¦) Digital Multimeter. A multipurpose meter that has capability of measuring voltage, current flow and resistance.

A digital multimeter has an input impedance of 10 M β¦ (megohms), which means they draw very little power

from the device under test, they are very accurate and will not damage delicate electronic components

Driver An electronic device, usually a power transistor, that operates as an electrical switch.

DTC

Diagnostic Trouble Code. If a fault occurs in the engine management system, the ECM may set a four digit

diagnostic trouble code (DTC) which represents the fault condition. Tech 2 is used to interface with the ECM

and access the DTC(s). The ECM may also operate the malfunction indicator lamp in the instrument cluster.

Duty Cycle The time, in percentage, that a circuit is on versus off.

ECT Sensor

Engine Coolant Temperature sensor. A device that provides a variable voltage to the ECM based on the

temperature of the engine coolant.

EEPROM Electrically Erasable Programmable Read Only Memory. A type of read only memory (ROM) that can be

electrically programmed, erased and reprogrammed using Tech 2. Also referred to as Flash Memory

EMI or Electrical

Noise An unwanted signal interfering with a required signal. A common example is the effect of high voltage power

lines on an AM radio.

Engine Braking A condition where the engine is used to slow the vehicle on closed throttle or low gear.

EPROM Erasable Programmable Read Only Memory. A type of Read Only Memory (ROM) that can be erased with

ultraviolet light and then reprogrammed.

ESD Electrostatic Discharge. The discharge of static electricity which has built up on an insulated material

EVAP

Evaporative emission control system. Used to prevent fuel vapours from the fuel tank from entering into the

atmosphere. The vapours are stored in a canister that contains an activated charcoal element. The fuel

vapours are purged from the canister into the manifold to be burned in the engine.

GM LAN General Motors Local Area Network - A type of serial data for communication between electronic devices.

Fuse

A thin metal strip which melts when excessive current flows through it, creating an open circuit and protecting

a circuit from damage.

HC Hydrocarbon. Result of unburned fuel produced by incomplete combustion.

Heavy Throttle Approximately 3/4 of accelerator pedal travel (75% throttle position)

IAT Sensor

Intake Air Temperature sensor. A device that provides a variable voltage to the ECM based on the

temperature of air entering the intake system.

Ideal Mixture The air / fuel ratio which provides the best performance, while maintaining maximum conversion of exhaust

emissions, typically 14.7 to 1 on spark ignition engines

IGN Ignition

Inputs Information from sensors (MAF, TP, etc.) and switches (A/C request, etc.) used by the ECM to determine how

to control its outputs.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3285 of 6020

Engine Management β V6 β Diagnostics Page 6C1-2β7

β’ Damage to the vehicle,

β’ Unnecessary vehicle repairs or component replacement,

β’ Faulty operation or performance of any system or component being repaired,

β’ Damage to any system or components which depend on the proper operation of the system or component being

repaired,

β’ Faulty operation or performance of any systems or components which depend on the proper operation or

performance of the system or component under repair,

β’ Damage to fasteners, basic tools or special tools and / or

β’ Leakage of coolant, lubricant or other vital fluids.

NOTE defined

A NOTE statement immediately precedes or follows an operating procedure, maintenance practice or condition that

requires highlighting. A NOTE statement also emphasises necessary characteristics of a diagnostic or repair procedure.

A NOTE statement is designed to:

β’ Clarify a procedure,

β’ Present additional information for accomplishing a procedure,

β’ Give insight into the reasons for performing a procedure in the recommended manner, and / or

β’ Present information that gives the technician the benefit of past experience in accomplishing a procedure with

greater ease.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3304 of 6020

Engine Management β V6 β Diagnostics Page 6C1-2β26

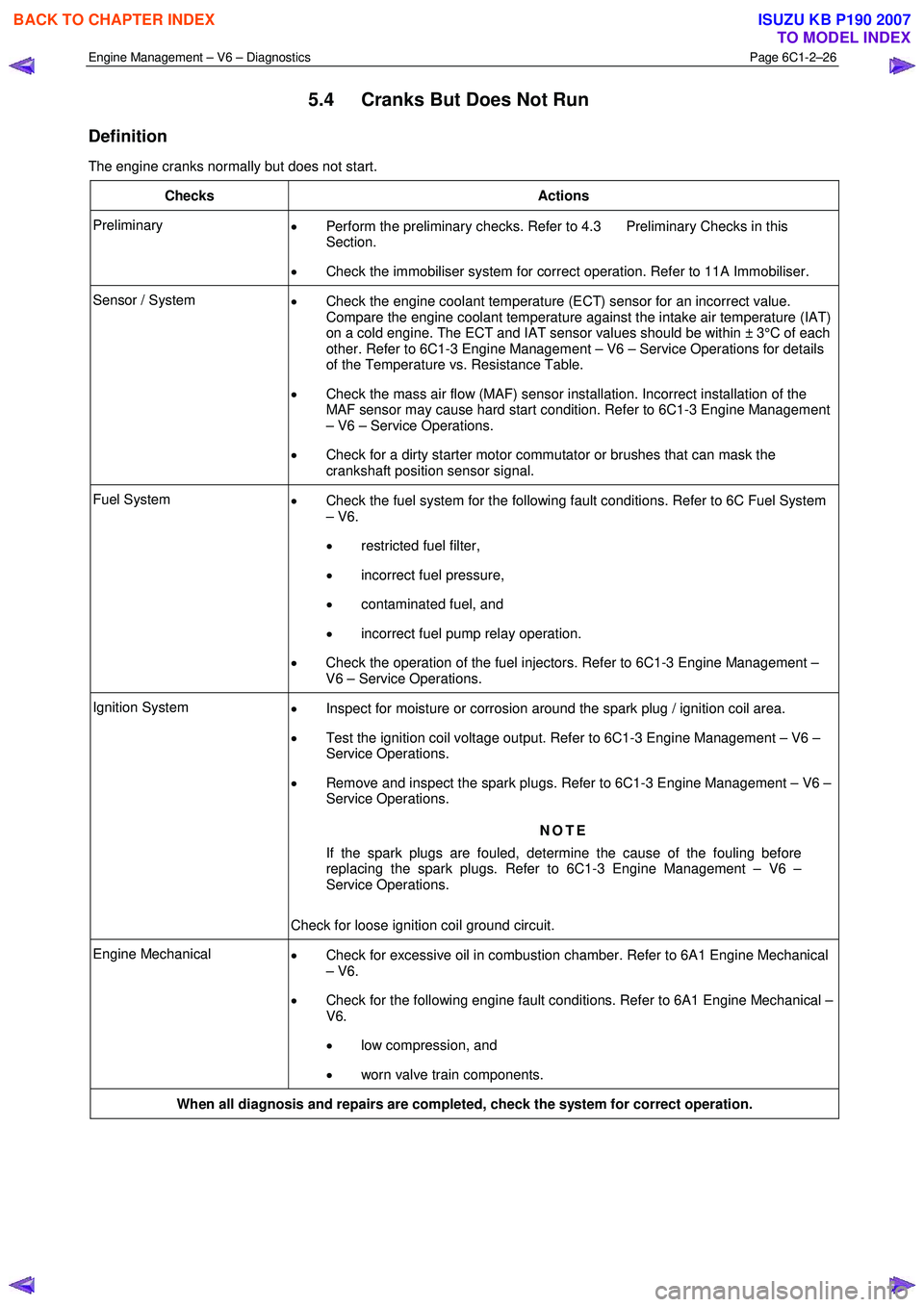

5.4 Cranks But Does Not Run

Definition

The engine cranks normally but does not start.

Checks Actions

Preliminary β’ Perform the preliminary checks. Refer to 4.3 Preliminary Checks in this

Section.

β’ Check the immobiliser system for correct operation. Refer to 11A Immobiliser.

Sensor / System

β’ Check the engine coolant temperature (ECT) sensor for an incorrect value.

Compare the engine coolant temperature against the intake air temperature (IAT)

on a cold engine. The ECT and IAT sensor values should be within Β± 3Β°C of each

other. Refer to 6C1-3 Engine Management β V6 β Service Operations for details

of the Temperature vs. Resistance Table.

β’ Check the mass air flow (MAF) sensor installation. Incorrect installation of the

MAF sensor may cause hard start condition. Refer to 6C1-3 Engine Management

β V6 β Service Operations.

β’ Check for a dirty starter motor commutator or brushes that can mask the

crankshaft position sensor signal.

Fuel System β’ Check the fuel system for the following fault conditions. Refer to 6C Fuel System

β V6.

β’ restricted fuel filter,

β’ incorrect fuel pressure,

β’ contaminated fuel, and

β’ incorrect fuel pump relay operation.

β’ Check the operation of the fuel injectors. Refer to 6C1-3 Engine Management β

V6 β Service Operations.

Ignition System β’ Inspect for moisture or corrosion around the spark plug / ignition coil area.

β’ Test the ignition coil voltage output. Refer to 6C1-3 Engine Management β V6 β

Service Operations.

β’ Remove and inspect the spark plugs. Refer to 6C1-3 Engine Management β V6 β

Service Operations.

NOTE

If the spark plugs are fouled, determine the cause of the fouling before

replacing the spark plugs. Refer to 6C1-3 Engine Management β V6 β

Service Operations.

Check for loose ignition coil ground circuit.

Engine Mechanical β’ Check for excessive oil in combustion chamber. Refer to 6A1 Engine Mechanical

β V6.

β’ Check for the following engine fault conditions. Refer to 6A1 Engine Mechanical β

V6.

β’ low compression, and

β’ worn valve train components.

When all diagnosis and repairs are completed, check the system for correct operation.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3307 of 6020

Engine Management β V6 β Diagnostics Page 6C1-2β29

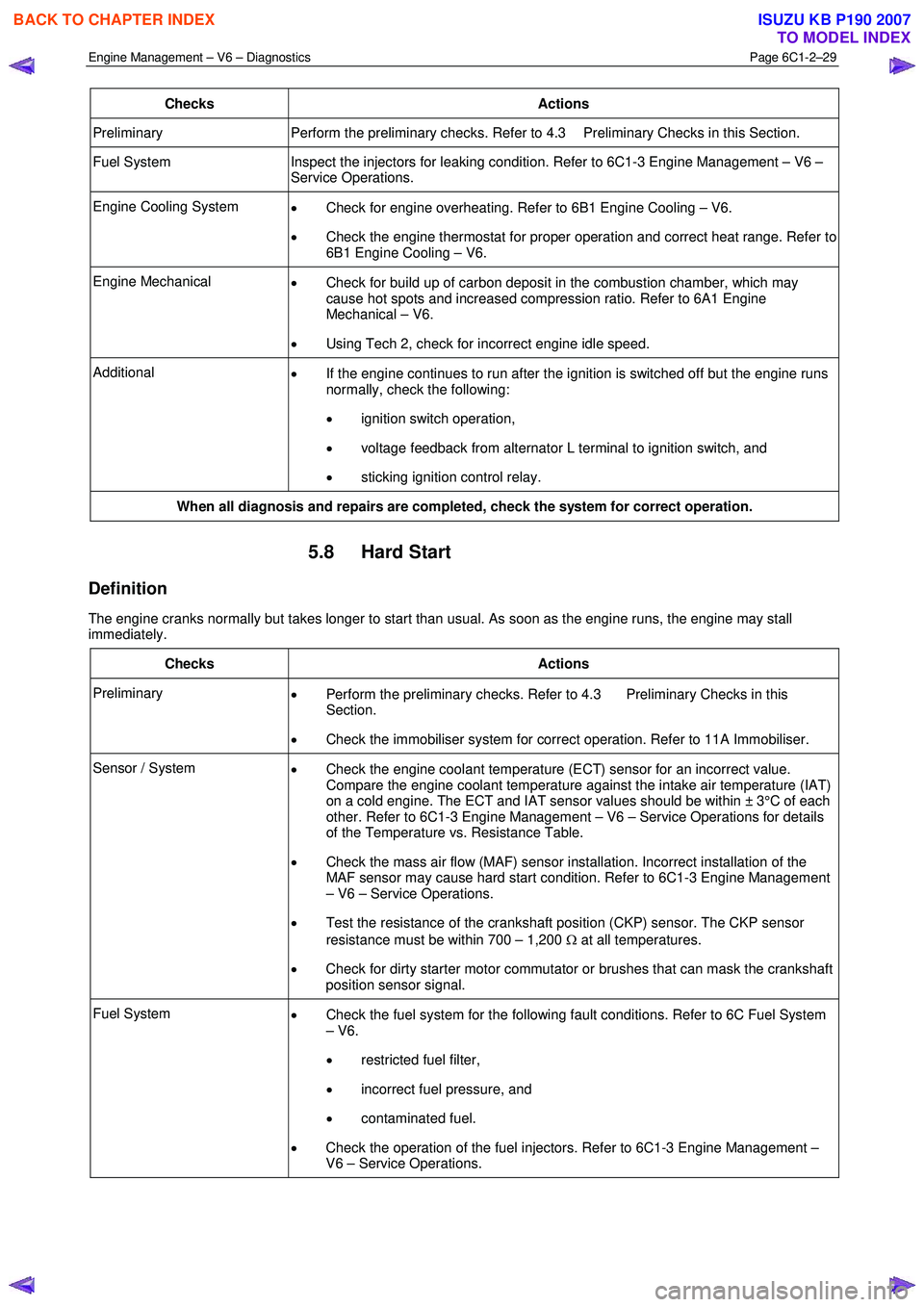

Checks Actions

Preliminary Perform the preliminary checks. Refer to 4.3 Preliminary Checks in this Section.

Fuel System Inspect the injectors for leaking condition. Refer to 6C1-3 Engine Management β V6 β

Service Operations.

Engine Cooling System β’ Check for engine overheating. Refer to 6B1 Engine Cooling β V6.

β’ Check the engine thermostat for proper operation and correct heat range. Refer to

6B1 Engine Cooling β V6.

Engine Mechanical β’ Check for build up of carbon deposit in the combustion chamber, which may

cause hot spots and increased compression ratio. Refer to 6A1 Engine

Mechanical β V6.

β’ Using Tech 2, check for incorrect engine idle speed.

Additional

β’ If the engine continues to run after the ignition is switched off but the engine runs

normally, check the following:

β’ ignition switch operation,

β’ voltage feedback from alternator L terminal to ignition switch, and

β’ sticking ignition control relay.

When all diagnosis and repairs are completed, check the system for correct operation.

5.8 Hard Start

Definition

The engine cranks normally but takes longer to start than usual. As soon as the engine runs, the engine may stall

immediately.

Checks Actions

Preliminary β’ Perform the preliminary checks. Refer to 4.3 Preliminary Checks in this

Section.

β’ Check the immobiliser system for correct operation. Refer to 11A Immobiliser.

Sensor / System

β’ Check the engine coolant temperature (ECT) sensor for an incorrect value.

Compare the engine coolant temperature against the intake air temperature (IAT)

on a cold engine. The ECT and IAT sensor values should be within Β± 3Β°C of each

other. Refer to 6C1-3 Engine Management β V6 β Service Operations for details

of the Temperature vs. Resistance Table.

β’ Check the mass air flow (MAF) sensor installation. Incorrect installation of the

MAF sensor may cause hard start condition. Refer to 6C1-3 Engine Management

β V6 β Service Operations.

β’ Test the resistance of the crankshaft position (CKP) sensor. The CKP sensor

resistance must be within 700 β 1,200 β¦ at all temperatures.

β’ Check for dirty starter motor commutator or brushes that can mask the crankshaft

position sensor signal.

Fuel System β’ Check the fuel system for the following fault conditions. Refer to 6C Fuel System

β V6.

β’ restricted fuel filter,

β’ incorrect fuel pressure, and

β’ contaminated fuel.

β’ Check the operation of the fuel injectors. Refer to 6C1-3 Engine Management β

V6 β Service Operations.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3315 of 6020

Engine Management β V6 β Diagnostics Page 6C1-2β37

6 Functional Checks

6.1 General Information

The items detailed in the following pages are to be used when there is a customer complaint and there are no diagnostic

trouble codes set, or one or more of the Tech 2 data values are not within the typical values. They are also to be used

when instructed from a DTC table. Before using these tables, you should refer to 5 Symptoms Diagnostics in this

Section, which may direct you to using the following functional checks.

The purpose of these tables is to diagnose engine control module (ECM) controlled components or sub-systems that do

not have diagnostic trouble codes assigned to them. Another purpose of these tables is for Technicians who feel

confident that a particular part of the sub-system is not operating properly and wants only to check that particular item

for proper operation without going through lengthy diagnostic procedures.

6.2 Fuel Injector Coil Test

The fuel injector coil test is divided into two parts. Begin by performing the fuel injector coil quick test. Then only perform

the Injector Coil Test β W ith Special Tool J39021 procedure if the quick test determines that there is a faulty fuel injector.

Fuel Injector Coil Quick Test

Test Description

The following numbers refer to the step numbers in the diagnostic table:

1 This step checks if the engine coolant temperature is within the correct range.

2 This step tests each fuel injector resistance within a specific temperature range.

3 This step determines if all of the fuel injectors are within 3 ohms of each other.

Step Action Value(s) Yes No

1 Using Tech 2, observe the engine coolant temperature

(ECT).

Is the ECT within the specified range? 10 β 32 Β°C Go to Step 2 Go to Step 3

2 1 Disconnect the fuel injector harness connector,

refer to 2.13 Fuel Rail Assembly, in 6C1-3 Engine

Management β V6 β Service Operations.

2 Using a digital ohmmeter and connector test adaptor kit J 35616-A, measure the resistance of

each fuel injector between the ignition voltage

circuit and the fuel injector control circuit. Refer to

8A Electrical - Body and Chassis for information

on testing for continuity and to Figure 6C1-2 β 9

and Figure 6C1-2 β 10 for the fuel injector

harness connector.

Do any of the fuel injectors display a resistance outside

the specified range? 11 β 14 β¦Refer to Injector

Coil Test β W ith

Special Tool J39021 in this Section Injectors OK

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3317 of 6020

Engine Management β V6 β Diagnostics Page 6C1-2β39

Injector Coil Test β With Special Tool J39021

1 Depressurise the fuel system, refer to 6C Fuel System β V6.

2 Turn the ignition OFF.

NOTE

After removing the upper intake manifold, plug

the lower manifold opening to prevent dirt and

other contaminants from entering.

3 Remove the upper intake manifold assembly, refer to 6A1 Engine Mechanical β V6.

4 Using Tech 2, observe the engine coolant temperature (ECT). If the ECT is 10 β 32 Β°C, refer to Engine Coolant

Temperature Between 10 β 32 Β°C, or if the ECT is outside this range, refer to Engine Coolant Temperature Outside

10 β 32 Β°C.

Engine Coolant Temperature Between 10 β 32 Β°

°°

Β°

C

Step Action Value(s) Yes No

1 1 Set the amperage supply selector switch on the

fuel injector tester (1), special tool J 39021 to the

Coil Test 0.5 A position. Refer to

Figure 6C1-2 β 11.

2 Connect the fuel injector tester leads (4 and 5) to B+ and ground.

3 Connect the digital multimeter (2) positive and negative lead to the fuel injector tester. Set the

multimeter to read DC Voltage.

4 Connect the fuel injector tester, using fuel injector harness adapter, special tool J44602 to a fuel

injector.

5 Press the Push to Start Test button on the fuel injector tester.

6 Observe and record the voltage reading on the digital multimeter.

NOTE

The voltage reading may rise during the

test. Record the voltage reading after one

second of the test.

7 Repeat steps 4 through 6 for each fuel injector. NOTE

The table in Figure 6C1-2 β 12 shows an

example of the results from a fuel injector

coil test.

Did any fuel injector have an erratic voltage reading

(large fluctuations in voltage that did not stabilise), or

voltage readings outside of the specified value? 5.5 β 6.6 V Replace the faulty

fuel injector/s. Refer to 2.13 Fuel Rail

Assembly, in 6C1-3 Engine

Management β V6 β Service Operations. System OK

When all repairs are completed, check the system for fuel leaks and correct operation.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3318 of 6020

Engine Management β V6 β Diagnostics Page 6C1-2β40

Engine Coolant Temperature Outside 10 β 32Β°

°°

Β°

C

Step Action Value(s) Yes No

1 1 Set the amperage supply selector switch on the

fuel injector tester (1), special tool J 39021 to the

Coil Test 0.5 A position. Refer to

Figure 6C1-2 β 11.

2 Connect the fuel injector tester leads (4 and 5) to B+ and ground.

3 Connect the digital multimeter (2) positive and negative lead to the fuel injector tester. Set the

multimeter to read DC Voltage.

4 Connect the fuel injector tester, using injector harness adapter, special tool J44602 to a fuel

injector.

5 Press the Push to Start Test button on the fuel injector tester.

6 Observe and record the voltage reading on the digital multimeter.

NOTE

The voltage reading may rise during the

test. Record the voltage reading after one

second of the test.

7 Repeat steps 4 through 6 for each fuel injector.

8 Identify the highest voltage reading recorded from the six fuel injectors tested that is 9.5 V or less.

NOTE

Disregard those voltage readings that are

greater than 9.5 V. Voltage readings greater

than 9.5 V indicate a faulty fuel injector.

9 Subtract the remaining voltage readings recorded in Step 8, from the highest voltage reading.

Are any of the values recorded in Step 9 greater than

the specified value? 0.6 V

Go to Step 2 System OK

2 1 Replace any fuel injector that has any of the

following:

β a subtracted value exceeding 0.6 V,

β an initial reading greater than 9.5 V, and

β an erratic reading.

NOTE

The table in Figure 6C1-2 β 13 shows an

example of the results from a fuel injector

coil test.

Has the repair been completed? β System OK. β

When all repairs are completed, check the system for fuel leaks and correct operation.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3319 of 6020

Engine Management β V6 β Diagnostics Page 6C1-2β41

Figure 6C1-2 β 11

Legend

1 Fuel Injector Tester β Special Tool J39021

2 Digital Multimeter

3 Fuel Injector Harness Adapter β Special Tool J44602 4 To Battery Positive Terminal

5 Battery Earth

Fuel Injector Coil Test Example β Engine Coolant Temperature 10 β 32 Β°

°°

Β°

C (Typical Values Shown)

Fuel Injector No. Voltage Reading Pass / Fail (acceptable range 5.5 - 6.6 V)

1 6.6 Pass

2 5.4 Fail

3 6.2 Pass

4 6.1 Pass

5 6.7 Fail

6 6.0 Pass

Figure 6C1-2 β 12

Fuel Injector Coil Test Example β Engine Coolant Temperature Greater / Less Than 10 β 32 Β°

°°

Β°

C (Typical Values

Shown)

Fuel Injector No. Voltage Reading Highest Voltage Reading (9.5 V or less) Subtracted Value

(acceptable voltage 0.6 V) Pass / Fail

1 9.8 β β Fail

2 6.4 7.0 0.6 Pass

3 6.9 7.0 0.1 Pass

4 5.8 7.0 1.2 Fail

5 7.0 7.0 0.0 Pass

6 6.3 7.0 0.7 Fail

Figure 6C1-2 β 13

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3320 of 6020

Engine Management β V6 β Diagnostics Page 6C1-2β42

6.3 Fuel Injector Balance Test

To avoid irregular fuel pressure readings, do

not perform this procedure if the engine

coolant temperature is greater than 94 Β°

°°

Β°

C.

Fuel Injector Balance Test β With Tech 2

1 Check the engine coolant temperature is less than 94 Β°C.

2 Perform the fuel injector coil test and replace any fuel injectors that are not functioning correctly before proceeding. Refer to 6.2 Fuel Injector Coil Test.

3 Perform the fuel system pressure check and ensure the fuel system is functioning correctly before proceeding with the fuel injector balance test. Refer to 6C Fuel System β V6.

4 W hile the fuel pressure gauge is still connected to the fuel pressure test point, pressurise the fuel system. Refer to 6C Fuel System β V6.

5 W hen the fuel pressure reading stabilises, record the fuel pressure reading indicated by the fuel pressure gauge.

NOTE

The fuel pressure reading taken in Step 5 is

known as the first pressure reading.

6 Connect Tech 2 to the data link connector (DLC) and turn the ignition on.

7 On Tech 2 select Engine / V6 Engine / Actuator Test / Fuel Injector Balance .

8 Follow the Tech 2 prompts, recording the fuel pressure gauge reading for each injector.

NOTE

The fuel pressure readings taken in Step 8 are

known as the second pressure reading

9 Perform the Fuel Injector Pressure Drop Calculation in this Section.

Fuel Injector Balance Test β Without Tech 2

1 Check the engine coolant temperature is less than 94 Β°C.

2 Perform the fuel injector coil test and replace any fuel injectors that are not functioning correctly before proceeding. Refer to 6.2 Fuel Injector Coil Test.

3 Perform the fuel system pressure check and ensure the fuel system is functioning correctly before proceeding with the fuel injector balance test. Refer to 6C Fuel System β V6.

4 W hile the fuel pressure gauge is still connected to the fuel pressure test point, pressurise the fuel system. Refer to 6C Fuel System β V6.

5 W hen the fuel pressure reading stabilises, record the fuel pressure reading indicated by the fuel pressure gauge.

NOTE

The fuel pressure reading taken in Step 5 is

known as the first pressure reading.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007