manual transmission ISUZU KB P190 2007 Workshop Owner's Guide

[x] Cancel search | Manufacturer: ISUZU, Model Year: 2007, Model line: KB P190, Model: ISUZU KB P190 2007Pages: 6020, PDF Size: 70.23 MB

Page 3254 of 6020

Engine Management – V6 – General Information Page 6C1-1–12

Battery Voltage Correction Mode

The ECM monitors the battery voltage circuit to ensure the voltage available to the engine management system stays

within the specified range. A low system voltage changes the voltage across the fuel injectors, which affects the fuel

injector flow rate. In addition, a low system voltage fault condition may cause other engine management system

components to malfunction.

The ECM switches to battery voltage correction mode when the ECM detects a low battery voltage fault condition. W hile

in battery voltage correction mode, the ECM performs the following functions to compensate for the low system voltage:

• Increases the injector on-time to maintain the correct amount of fuel being delivered, and

• Increases the idle speed to increase the generator output.

Limp Mode

The programming in the ECM software allows the engine to run in a back-up fuel strategy or limp mode when the ECM

fails to receive signal inputs from critical sensors or when a critical engine management fault condition exists.

The ECM switches to limp mode to enable the vehicle to be driven until service operations can be performed.

Engine Protection Mode

Engine protection mode is engaged to protect engine components from friction damage in the event of an engine over-

temperature condition being detected by the ECM.

W hen the ECM is in engine protection mode, fuel injectors are systematically disabled and re-activated. The injectors

that have been shut down allow the air being drawn into the engine to assist with engine cooling.

Clear Flood Mode

If the engine is flooded with fuel during starting and will not start, the clear flood mode can be manually selected by

depressing the accelerator pedal to wide open throttle (W OT). In this mode, the ECM will completely disable the fuel

injectors, and will maintain this state during engine cranking as long as the ECM detects a W OT condition with engine

speed less than 1,000 rpm.

3.3 Ignition Control System

The electronic ignition system provides a spark to ignite the compressed air / fuel mixture at the correct time. The ECM

maintains correct spark timing and dwell for all engine operating conditions. The ECM calculates the optimum spark

parameters from information received from the various sensors and triggers the appropriate ignition module / coil to fire

the spark plug.

3.4 Starter Motor Operation

The engine control module controls the activation of the start relay in response to inputs from:

• Ignition switch,

• Battery,

• Immobiliser system, and

• Automatic transmission gear selector position / clutch pedal position switch for vehicles with manual transmissions.

3.5 Throttle Actuator Control System

Description

The throttle actuator control (TAC) system is used to improve emissions, fuel economy and driveability. The TAC system

eliminates the mechanical link between the accelerator pedal and the throttle plate and eliminates the need for a cruise

control module and idle air control motor. The TAC system comprises of:

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3310 of 6020

Engine Management – V6 – Diagnostics Page 6C1-2–32

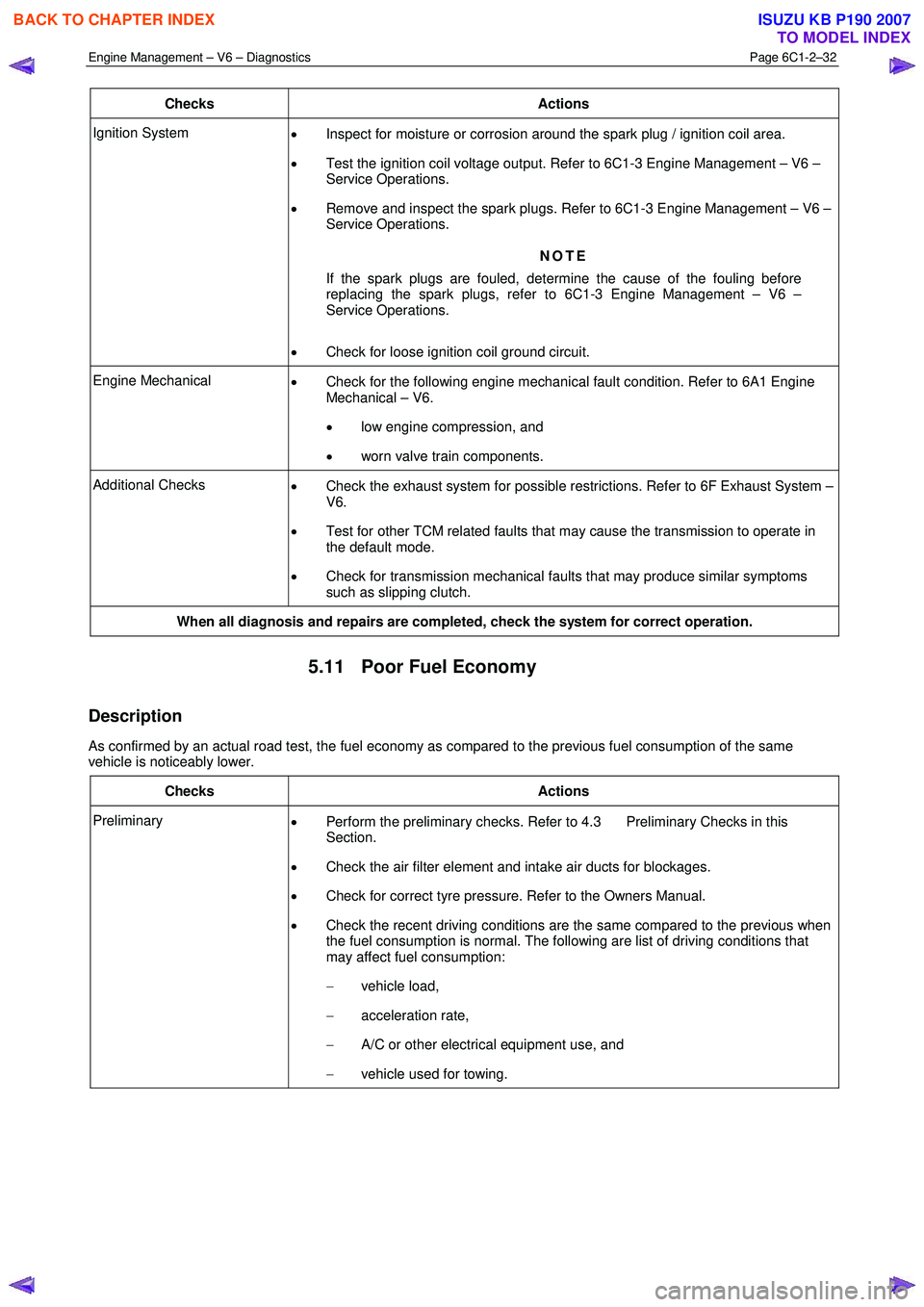

Checks Actions

Ignition System

• Inspect for moisture or corrosion around the spark plug / ignition coil area.

• Test the ignition coil voltage output. Refer to 6C1-3 Engine Management – V6 –

Service Operations.

• Remove and inspect the spark plugs. Refer to 6C1-3 Engine Management – V6 –

Service Operations.

NOTE

If the spark plugs are fouled, determine the cause of the fouling before

replacing the spark plugs, refer to 6C1-3 Engine Management – V6 –

Service Operations.

• Check for loose ignition coil ground circuit.

Engine Mechanical

• Check for the following engine mechanical fault condition. Refer to 6A1 Engine

Mechanical – V6.

• low engine compression, and

• worn valve train components.

Additional Checks

• Check the exhaust system for possible restrictions. Refer to 6F Exhaust System –

V6.

• Test for other TCM related faults that may cause the transmission to operate in

the default mode.

• Check for transmission mechanical faults that may produce similar symptoms

such as slipping clutch.

When all diagnosis and repairs are completed, check the system for correct operation.

5.11 Poor Fuel Economy

Description

As confirmed by an actual road test, the fuel economy as compared to the previous fuel consumption of the same

vehicle is noticeably lower.

Checks Actions

Preliminary • Perform the preliminary checks. Refer to 4.3 Preliminary Checks in this

Section.

• Check the air filter element and intake air ducts for blockages.

• Check for correct tyre pressure. Refer to the Owners Manual.

• Check the recent driving conditions are the same compared to the previous when

the fuel consumption is normal. The following are list of driving conditions that

may affect fuel consumption:

− vehicle load,

− acceleration rate,

− A/C or other electrical equipment use, and

− vehicle used for towing.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3378 of 6020

Engine Management – V6 – Diagnostics Page 6C1-2–100

Step Action Yes No

7 1 Remove the upper intake manifold. Refer to 6A1-Engine

Mechanical – V6.

2 Test the control circuit and the ignition voltage circuit of the appropriate fuel injector, between the interconnect connector

and the appropriate fuel injector connector, for a high

resistance, open circuit, short to ground or short to voltage fault

condition. Refer to 8A Electrical - Body and Chassis for

information on electrical fault diagnosis.

W as any fault found and rectified? Go to Step 10 Go to Step 8

8 Replace the appropriate fuel injector. Refer to 6C1-3 Engine

Management – V6 – Service Operations.

W as the repair completed? Go to Step 10 —

9 Replace the ECM. Refer to 6C1-3 Engine Management – V6 –

Service Operations.

W as the repair completed? Go to Step 10 —

10 1 Using Tech 2, clear the DTCs.

2 Switch off the ignition for 30 seconds.

3 Start the engine.

4 Operate the vehicle within the conditions for running the DTC.

Does any of the fuel injector control circuit DTCs fail this ignition

cycle? Go to Step 2 Go to Step 11

11 Using Tech 2, select the DTC display function.

Does Tech 2 display any DTCs? Go to the

appropriate DTC

Table in this Section System OK

When all diagnosis and repairs are completed, check the system for correct operation.

7.15 DTC P0219

DTC Descriptor

This diagnostic procedure supports DTC P0219 – Engine Overspeed Condition.

Circuit Description

The ECM continually monitors the engines operating environment. A engine over-speed condition DTC sets if the ECM

detects an engine speed in excess of 7200 RPM.

NOTE

An over-speed condition will occur when a low

gear on a manual transmission vehicle has been

selected whilst the vehicle is travelling at high

road speed. This DTC will not set if the engine is

free-revved as the ECM will limit engine speed.

Conditions for Running the DTC

DTC P0219 runs continuously when the following conditions are met:

• The vehicle is fitted with a manual transmission

• The engine is running.

• The ignition voltage is between 10.0 – 16.0 V.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3408 of 6020

Engine Management – V6 – Diagnostics Page 6C1-2–130

Step Action Yes No

8 Replace the ECM. Refer to 6C1-3 Engine Management – V6 –

Service Operations.

W as the repair completed? Go to Step 9 —

9 1 Using Tech 2, clear the DTCs.

2 Switch off the ignition for 30 seconds.

3 Start the engine.

4 Operate the vehicle within the conditions for running the DTC.

Does any of the cooling fan relay control circuit DTCs fail this ignition

cycle? Go to Step 2 Go to Step 10

10 Using Tech 2, select the DTC display function.

Does Tech 2 display any DTCs? Go to the

appropriate DTC

Table in this Section System OK

When all diagnosis and repairs are completed, check the system for correct operation.

7.27 DTC P0500

DTC Descriptor

This diagnostic procedure supports DTC P0500 – Vehicle Speed Sensor Circuit Malfunction (Manual Transmission).

Circuit Description

Vehicle speed information is provided to the engine control module (ECM) by the vehicle speed sensor (VSS). The

ignition control relay applies ignition positive voltage to the VSS, and the ground circuit of the VSS is directly connected

to ground.

The VSS is a Hall effect switch. In conjunction with an 18 tooth reluctor wheel, the VSS provide a signal voltage to the

ECM. The ECM uses this signal voltage to determine vehicle speed.

If the ECM detects no vehicle speed, while other sensors indicate that the vehicle is moving, then DTC P0500 sets.

Conditions for Running the DTC

Runs once the following conditions are met:

• The engine coolant temperature is greater than 40º C,

• the ECM is in fuel shut-off mode, and

• the engine speed is between 1,520 and 3,520 rpm

Conditions for Setting the DTC

The ECM detects a speed of less than 0 km/h for 8 seconds continuously, or 50 seconds cumulative.

Conditions for Clearing the DTC

The vehicle speed sensor circuit malfunction DTC is a Type C DTC. Refer to 1.4 Diagnostic Trouble Codes in this

Section, for action taken when Type C DTCs set and conditions for clearing Type C DTCs.

Additional Information

• For an intermittent fault condition, refer to 5.2 Intermittent Fault Conditions in this Section.

• Refer to 6C1-1 Engine Management – V6 – General Information for details on:

• VSS operation, and

• fuel shut-off mode.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3409 of 6020

Engine Management – V6 – Diagnostics Page 6C1-2–131

• Refer to 7B1 Manual Transmission – V6 for VSS replacement procedures.

• Since a fault condition in a wiring connector may trigger DTCs, always test the connectors related to this

diagnostic procedure for shorted terminals or poor wiring connection before replacing any component. Refer to 8A

Electrical - Body and Chassis for information on electrical fault diagnosis.

• To assist diagnosis, refer to 3 W iring Diagrams and Connector Charts in this Section, for the system wiring

diagram and connector charts.

DTC P0500 Diagnostic Table

Step Action Yes No

1 Has the diagnostic system check been performed?

Go to Step 2 Refer to

4.4 Diagnostic System Check in this Section

2 1 Switch off the ignition for 30 seconds.

2 Operate the vehicle within the conditions for running the DTC.

3 Using Tech 2, select the DTC display function.

Does DTC P0500 fail this ignition cycle? Go to Step 3 Refer to Additional

Information in this DTC

3 1 Switch off the ignition.

2 Disconnect the wiring connector from the VSS.

3 Connect a test lamp between the ignition circuit of the VSS and ground.

4 Switch on the ignition with the engine not running.

Does the test lamp illuminate? Go to Step 5 Go to Step 4

4 Repair the high resistance or open circuit fault condition in the ignition

circuit of the VSS. Refer to 8A Electrical - Body and Chassis for

information on electrical wiring repair procedures.

W as the repair completed? Go to Step 12 —

5 1 Connect a test lamp between the ground circuit and ignition

circuit of the VSS.

2 Switch on the ignition with the engine not running.

Does the test lamp illuminate? Go to Step 7 Go to Step 6

6 Repair the high resistance or open circuit fault condition in the ground

circuit of the VSS. Refer to 8A Electrical - Body and Chassis for

information on electrical wiring repair procedures.

W as the repair completed? Go to Step 12 —

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3410 of 6020

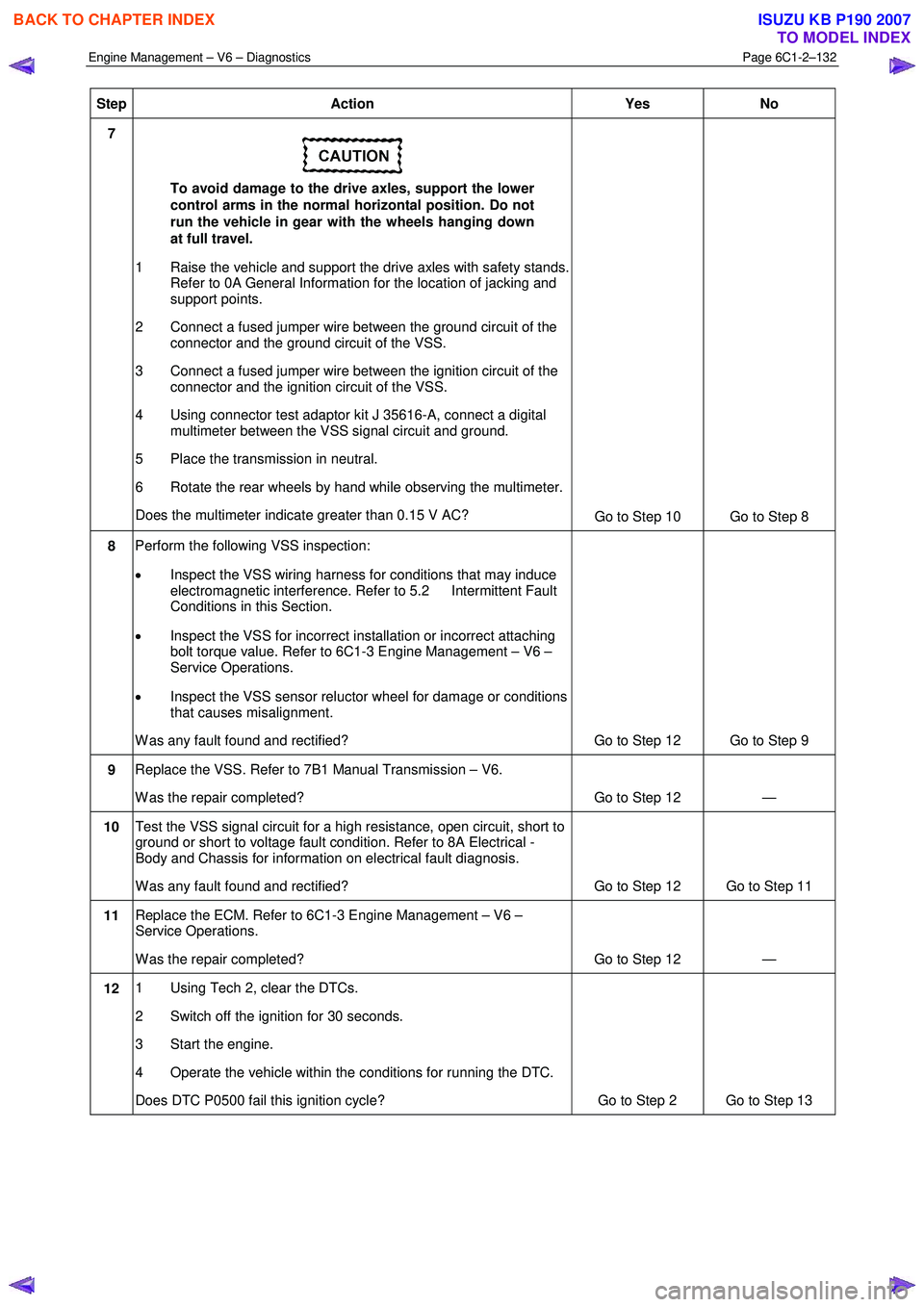

Engine Management – V6 – Diagnostics Page 6C1-2–132

Step Action Yes No

7

To avoid damage to the drive axles, support the lower

control arms in the normal horizontal position. Do not

run the vehicle in gear with the wheels hanging down

at full travel.

1 Raise the vehicle and support the drive axles with safety stands. Refer to 0A General Information for the location of jacking and

support points.

2 Connect a fused jumper wire between the ground circuit of the connector and the ground circuit of the VSS.

3 Connect a fused jumper wire between the ignition circuit of the connector and the ignition circuit of the VSS.

4 Using connector test adaptor kit J 35616-A, connect a digital multimeter between the VSS signal circuit and ground.

5 Place the transmission in neutral.

6 Rotate the rear wheels by hand while observing the multimeter.

Does the multimeter indicate greater than 0.15 V AC? Go to Step 10 Go to Step 8

8 Perform the following VSS inspection:

• Inspect the VSS wiring harness for conditions that may induce

electromagnetic interference. Refer to 5.2 Intermittent Fault

Conditions in this Section.

• Inspect the VSS for incorrect installation or incorrect attaching

bolt torque value. Refer to 6C1-3 Engine Management – V6 –

Service Operations.

• Inspect the VSS sensor reluctor wheel for damage or conditions

that causes misalignment.

W as any fault found and rectified? Go to Step 12 Go to Step 9

9 Replace the VSS. Refer to 7B1 Manual Transmission – V6.

W as the repair completed? Go to Step 12 —

10 Test the VSS signal circuit for a high resistance, open circuit, short to

ground or short to voltage fault condition. Refer to 8A Electrical -

Body and Chassis for information on electrical fault diagnosis.

W as any fault found and rectified? Go to Step 12 Go to Step 11

11 Replace the ECM. Refer to 6C1-3 Engine Management – V6 –

Service Operations.

W as the repair completed? Go to Step 12 —

12 1 Using Tech 2, clear the DTCs.

2 Switch off the ignition for 30 seconds.

3 Start the engine.

4 Operate the vehicle within the conditions for running the DTC.

Does DTC P0500 fail this ignition cycle? Go to Step 2 Go to Step 13

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3502 of 6020

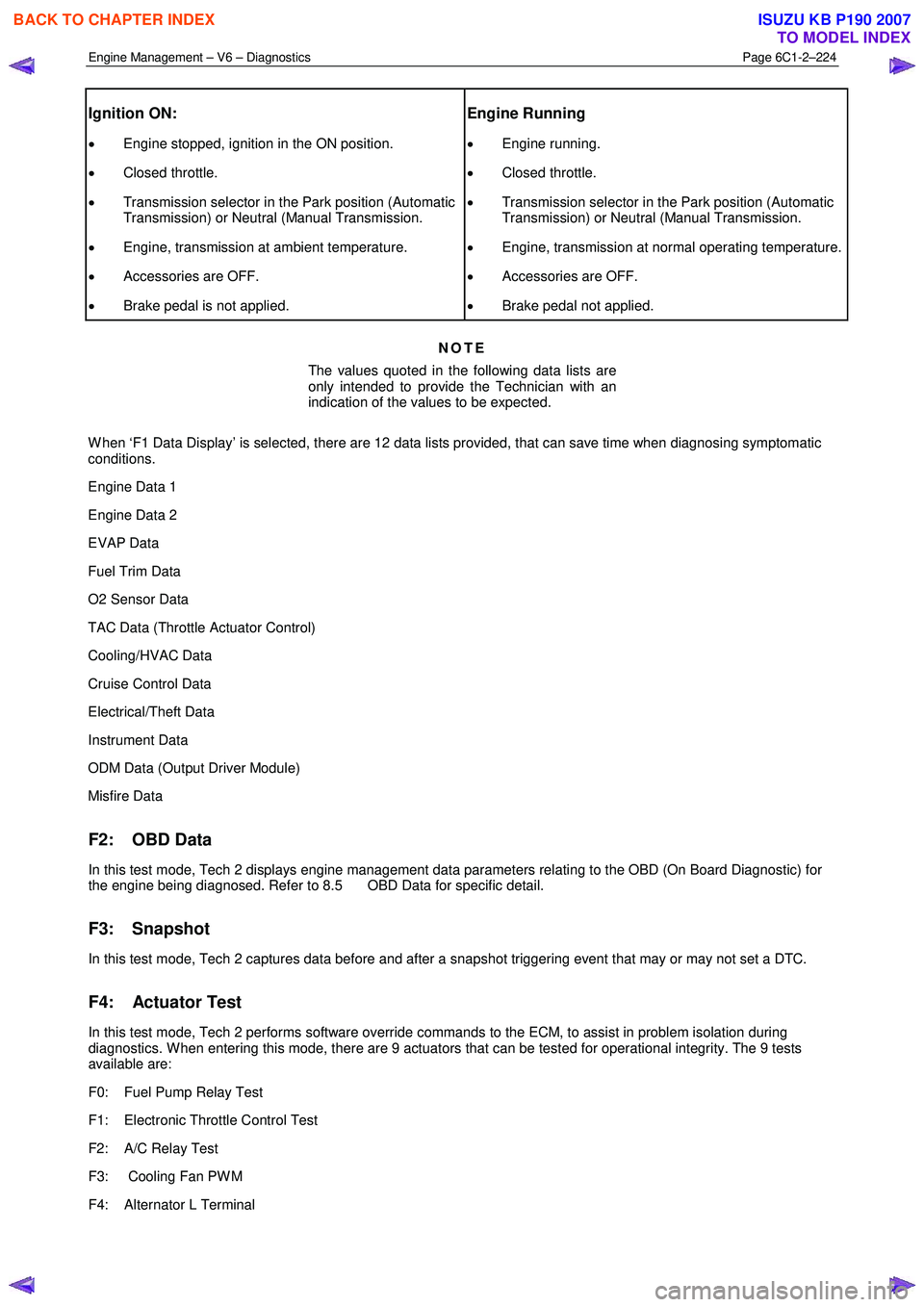

Engine Management – V6 – Diagnostics Page 6C1-2–224

Ignition ON:

• Engine stopped, ignition in the ON position.

• Closed throttle.

• Transmission selector in the Park position (Automatic

Transmission) or Neutral (Manual Transmission.

• Engine, transmission at ambient temperature.

• Accessories are OFF.

• Brake pedal is not applied.

Engine Running

• Engine running.

• Closed throttle.

• Transmission selector in the Park position (Automatic

Transmission) or Neutral (Manual Transmission.

• Engine, transmission at normal operating temperature.

• Accessories are OFF.

• Brake pedal not applied.

NOTE

The values quoted in the following data lists are

only intended to provide the Technician with an

indication of the values to be expected.

W hen ‘F1 Data Display’ is selected, there are 12 data lists provided, that can save time when diagnosing symptomatic

conditions.

Engine Data 1

Engine Data 2

EVAP Data

Fuel Trim Data

O2 Sensor Data

TAC Data (Throttle Actuator Control)

Cooling/HVAC Data

Cruise Control Data

Electrical/Theft Data

Instrument Data

ODM Data (Output Driver Module)

Misfire Data

F2: OBD Data

In this test mode, Tech 2 displays engine management data parameters relating to the OBD (On Board Diagnostic) for

the engine being diagnosed. Refer to 8.5 OBD Data for specific detail.

F3: Snapshot

In this test mode, Tech 2 captures data before and after a snapshot triggering event that may or may not set a DTC.

F4: Actuator Test

In this test mode, Tech 2 performs software override commands to the ECM, to assist in problem isolation during

diagnostics. W hen entering this mode, there are 9 actuators that can be tested for operational integrity. The 9 tests

available are:

F0: Fuel Pump Relay Test

F1: Electronic Throttle Control Test

F2: A/C Relay Test

F3: Cooling Fan PW M

F4: Alternator L Terminal

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3505 of 6020

Engine Management – V6 – Diagnostics Page 6C1-2–227

Knock Retard Cylinder 3 °CA 0 0

Knock Retard Cylinder 4 °CA 0 0

Knock Retard Cylinder 5 °CA 0 0

Knock Retard Cylinder 6 °CA 0 0

Ignition Accessory Signal Off / On On On

Ignition On Signal Off / On On On

Malfunction Indicator (MI) Off / On / Flashing On Off

Fuel Pump Relay Off / On Off On

Engine Control Ignition Relay Off / On On On

Engine Control Ignition Relay Feedback V 11.5 14.1

(1) Actual Gear -1- / -2- / -3- / -4- / -

5- / -P/N- / -R- / -Invalid- -P/N- -P/N-

Brake Lamp Switch

Inactive / Active Inactive Inactive

Reduced Engine Power Inactive / Active Inactive Inactive

DTC Set This Ignition No DTC / DTC Set No DTC No DTC

Vehicle Speed km/h 0 0

Engine Runtime h:m:s 00:00:00 00:05:20

(2) Clutch Pedal Switch Inactive / Active Inactive Inactive

(1) Automatic Transmission Only (2) Manual Transmission Only

Engine Data 2

Tech 2 Display

Units Displayed Ignition On Engine Running

Engine Speed RPM 0 751

Desired Engine Idle Speed RPM 830 750

Coolant Temperature °C 21 78

Cooling Fan On/Off Off On

Calculated ECT – Closed Loop Fuel Control (Engine

Coolant Temperature) °C 21 37

Calculated ECT – Thermostat Diagnosis (Engine

Coolant Temperature) °C 22 78

Intake Air Temperature

°C 31 27

Start Up ECT (Engine Coolant Temperature) °C 21 21

Start Up IAT (Intake Air Temperature) °C –48 30

Mass Air Flow Sensor V 1.00 1.3

Mass Air Flow g/s 0.00 5.47

Engine Load % 100 25

Volumetric Efficiency % 99 19

Power Enrichment No / Yes No No

Dec. Fuel Cutoff (Deceleration) Inactive / Active Inactive Inactive

Calculated Pedal Position % 0 0

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3506 of 6020

Engine Management – V6 – Diagnostics Page 6C1-2–228

Desired Throttle Position % 4 3

Calculated Throttle Position % 6 3

Barometric Pressure kPa 100 100

Barometric Pressure V 4.78 4.80

Loop Status B1S1 (Bank 1 Sensor 1) Open / Closed Open Closed

Loop Status B2S1 (Bank 2 Sensor 1) Open / Closed Open Closed

B1 Short Term Fuel Trim (Bank 1) % 0 –3

B1 LTFT Idle/Deceleration (Bank 1 Long Term Fuel

Trim) % 0 0

B1 LTFT Cruise/Acceleration (Bank 1 Long Term Fuel

Trim) % 0 0

B2 Short Term Fuel Trim (Bank 2)

% 0 –1

B2 LTFT Idle/Deceleration (Bank 2 Long Term Fuel

Trim) % 0 0

B2 LTFT Cruise/Acceleration (Bank 2 Long Term Fuel

Trim) % 0 0

Injection Time Cylinder 1

ms 0.0 2.5

Injection Time Cylinder 2 ms 0.0 2.5

Injection Time Cylinder 3 ms 0.0 2.5

Injection Time Cylinder 4 ms 0.0 2.5

Injection Time Cylinder 5 ms 0.0 2.5

Injection Time Cylinder 6 ms 0.0 2.5

Spark Advance °CA 0 12

Ignition Accessory Signal Off / On On On

Ignition On Signal Off / On On On

(1) Transmission Gear P-N / In Gear P-N P-N

(1) Actual Gear -1- / -2- / -3- / -4- / -

5- / -P/N- / -R- / -Invalid- -P/N- -P/N-

Fuel Pump Relay

Off / On Off On

A/C Relay (Air Conditioning) Off / On Off Off

(1) Transmission Gear Selector Signal Valid / Invalid Valid

Valid

Distance Since DTC Cleared km 0 0

Reduced Engine Power Inactive / Active Inactive Inactive

Vehicle Speed km/h 0 0

Engine Runtime h:m:s 00:00:00 00:09:20

(1) Automatic Transmission Only (2) Manual Transmission Only

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3508 of 6020

Engine Management – V6 – Diagnostics Page 6C1-2–230

Vehicle Speed km/h 0 0

Engine Runtime h:m:s 00:00:00 00:10:25

Fuel Pump Relay Off / On Off On

(1) Automatic Transmission Only (2) Manual Transmission Only

Fuel Trim Data

Tech 2 Display Units Displayed Ignition On Engine Running

B1 Short Term Fuel Trim (Bank 1) % 0 –1

B1 LTFT Idle/Deceleration (Bank 1 Long Term Fuel

Trim) % 0 1

B1 LTFT Cruise/Acceleration (Bank 1 Long Term Fuel

Trim) % 0 0

B1 Total Fuel Trim (Bank 1)

% 0 4

B2 Short Term Fuel Trim (Bank 2) % 0 0

B2 LTFT Idle/Deceleration (Bank 2 Long Term Fuel

Trim) % 0 1

B2 LTFT Cruise/Acceleration (Bank 2 Long Term Fuel

Trim) % 0 0

B2 Total Fuel Trim (Bank 2)

% 0 4

Fuel Trim Learn Disabled / Enabled Disabled Disabled

Loop Status B1S1 (Bank 1 Sensor 1) Open / Closed Open Closed

Loop Status B2S1 (Bank 2 Sensor 1) Open / Closed Open Closed

Injection Time Cylinder 1 ms 0.0 2.5

Injection Time Cylinder 2 ms 0.0 2.5

Injection Time Cylinder 3 ms 0.0 2.5

Injection Time Cylinder 4 ms 0.0 2.5

Injection Time Cylinder 5 ms 0.0 2.5

Injection Time Cylinder 6 ms 0.0 2.5

Requested Torque % 99 99

Catalyst Protection Mode Inactive / Active Inactive Inactive

B1 Catalyst Temperature (Bank 1)

°C 300 300

B2 Catalyst Temperature (Bank 2)

°C 300 300

B1S1 O2 Sensor (Bank 1 Sensor 1)

:1 (= Lambda) 0.99 0.99

B1S2 O2 Sensor (Bank 1 Sensor 2) mV 438 520

B2S1 O2 Sensor (Bank 2 Sensor 1) :1 (= Lambda) 0.99 0.99

B2S2 O2 Sensor (Bank 2 Sensor 2) mV 438 516

B1 Average Injection Time (Bank 1) ms 0.0 2.5

B2 Average Injection Time (Bank 2) ms 0.0 2.5

Power Enrichment No / Yes No No

Dec. Fuel Cutoff (Deceleration) Inactive / Active Inactive Inactive

EVAP Purge Solenoid (Evaporative Emission) % 0 32

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007