warning light ISUZU KB P190 2007 Workshop Owner's Guide

[x] Cancel search | Manufacturer: ISUZU, Model Year: 2007, Model line: KB P190, Model: ISUZU KB P190 2007Pages: 6020, PDF Size: 70.23 MB

Page 3979 of 6020

TRANSMISSION CONTROL SYSTEM (AW30–40LE) 7A2-13

Item Description

Reverse lock out control If the select lever is moved to "R" position during forward driving, the TCM prohibits

reverse driving by turn off the S1 and turn on the S2 for prevention of danger and

protection of the automatic transmission.

1. Enable condition a) Vehicle speed is more than 11km/h (7mph).

2. Disable condition a) Vehicle speed is less than 9km/h (6mph).

b) W hen except "R" position is detected.

Auto cruise mode control If the auto cruise control can’t keep the setting speed like a uphill driving, the TCM selects the auto cruise mode shift pattern for downshifting, thus keeping the vehicle

speed.

W arm-up mode control TCM selects the warm-up mode shift pattern in engine cold condition for improvement of drivability and facilitation of warm-up.

Squat control W hen the TCM detects N→D garage shift, the TCM controls 1-3-1 shift by setting

timer, in order to improve the shift feel at N →D.

Coast down control The TCM switches to the coast down control at the coasting, in order to reduce the

roughness of shifting.

Uphill control W hen the TCM detected uphill, the TCM automatically switches to the uphill mode

in two-stage in proportion to inclination pitch to prevent the busy shifting and to

obtain an enough torque.

Downhill control W hen the TCM detected downhill, the TCM automatically switches to the downhill

mode, and shifts to the 3rd or keeps in the 3rd in order to prevent the vehicle

acceleration. Then, the brake load is reduced by a moderate engine brake and fuel

consumption is improved by the fuel cut.

Line pressure control The TCM controls the impressed current of the pressure control solenoid based on the throttle opening, and regulates suitable throttle pressure.

Engine truque management

control The TCM controls engine torque for improvement of shift quality or durability under

the following conditions.

• Upshift and downshift

• Garageshift

Indicate driving mode function The TCM indicates the following driving mode on instrument panel.

• Power mode

• 3rd start mode

Indicate oil temperature

warning function If the transmission oil temperature sensor senses that transmission oil temperature

is greater than 146 °C (295 °F) , the TCM turns on ATF warning lamp. (The warning

lamp is turned off, if oil temperature is less than 126 °C/ 259 °F .)

Fail-safe function W hen trouble occurs to vehicle sensor and each solenoid, TCM automatically exerts

fail-safe control not to spoil driveability.

• This control is exerted when sensor or actuator is in trouble, while TCM works

normally.

• The "CHECK TRANS" light flashes to alert the driver, and the transmission

must be manually shifted as follows.

Select lever position Gear position

D 4 (Fourth)

3 4 (Fourth)

2 3 (Third)

L 3 (Third)

R Reverse

Shift are firmer to prevent clutch slip and consequent wear. The fault should be

corrected as soon as possible.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3989 of 6020

TRANSMISSION CONTROL SYSTEM (AW30–40LE) 7A2-23

Diagnostic Trouble Codes

The purpose of the “Diagnostic Trouble Codes” mode is

to display stored TCM trouble codes.

W hen “Diagnostic Trouble Codes” is selected an

“Application Menu” screen appears.

Read DTC Information

W hen “Read DTC Information” is selected, an

“Application Menu” appears with a list of DTC

information function keys addressing DTC specifics and

their origins.

Function key selections may vary for particular vehicle

and/or system.

Requested emission-related DTCs

Clear DTC Information

The purpose of the “Clear DTC Information” mode is to

command the clearing of stored TCM trouble codes.

W hen “Clear DTC Information” is selected, a “Clea

r

DTC Information”, warning screen appears. This screen

informs you that by cleaning DTC's, “all stored DTC

information in controller will be erased”.

Do you want to clear DTC's (Yes/No).

Press either the Yes or No key when answering.

After clearing codes, confirm system operation by test-

driving the vehicle.

Allow the vehicle to shift through all four forward gears

in a manner which attempts to repeat the failure

condition.

NOTE: W hen the trouble has not been repaired and

the trouble code cannot be erased, check the vehicle

again.

Data Display

The purpose of the “Data Display” mode is to

continuously monitor data parameters.

The current actual values of all important sensors and

signals in the system are displayed through F1 mode.

W hen “Data Display” is selected an “Application Menu”

appears. “Transmission Data Display”.

See “Transmission Data” on next page.

Snapshot

W hen “Snapshot” is selected an “Application Menu”

appears.

W hen “Transmission Snapshot” application is selected

from the “Application Menu”, a “Snapshot Menu”

appears, displaying several options. “Snapshot” options

may vary from one system to another.

“Snapshot” allows a recording of all vehicle parameters.

There parameters may then be replayed at a future

point in time.

This action allows you to focus on making the condition

occur, rather than trying to view all of the data in

anticipation of the fault. The snapshot will collect

parameter information around a trigger point that you

select.

W hen a snapshot is taken, it is recorded onto the

PCMCIA memory card. W hen the Tech 2 is powered

down. Snapshots are not lost.

Actuator Test

The purpose of “Actuator Test” mode is to check fo

r

correct operation of electronic system actuators.

Solenoid 2-3 Test, Solenoid 1-2/3-4 and Test TCC

Solenoid Test

You can operate the solenoids by pressing the “ON”

and “OFF” buttons.

Preconditions: P–N position, no vehicle speed, no

engine speed

Pressure Control Solenoid (PCS)

You can set desired PCS Current using the “ON” and

“OFF” button. The PCS Data informs about PCS

Current, Pressure and Duty Cycle.

Preconditions: P–N position, no engine speed, no

vehicle speed

3rd Start Lamp Test, Power Lamp Test, AT Oil

Temperature Lamp Test and Check Light Test

You can operate the lamps by pressing the “ON” and

“OFF” buttons.

Preconditions: none

NOTE: Freeze Frame

Freeze Frame is an element of the Diagnostic

Management System which stores various vehicle

information at the moment an emission-related fault

is stored in memory and when the Check Trans

Lamp is commanded on. These data can help to

identity the cause of a fault. Refer to Storing An

d

Erasing Freeze Frame Data for more detaile

d

information.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 4256 of 6020

CONSTRUCTION AND FUNCTION 7A1-17

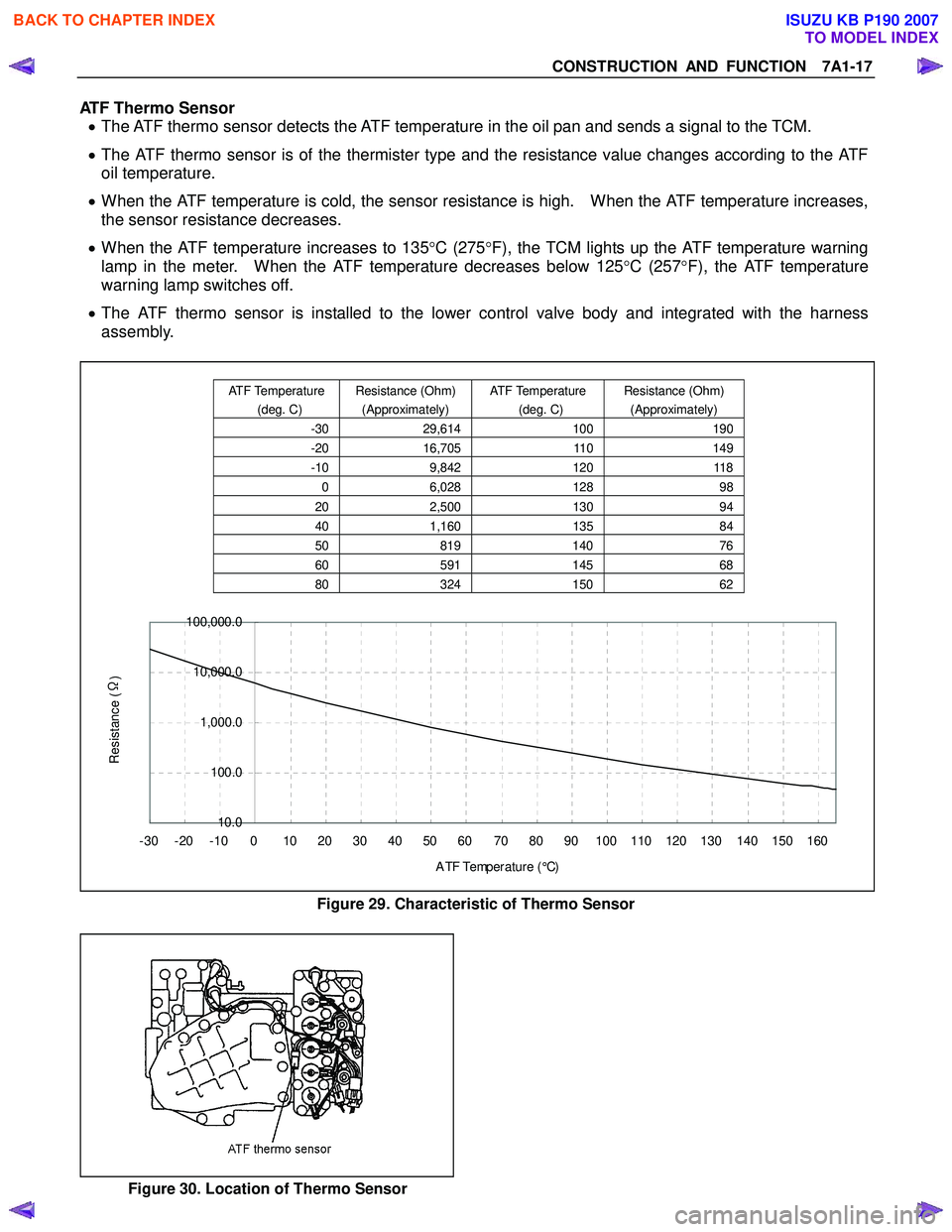

ATF Thermo Sensor • The ATF thermo sensor detects the ATF temperature in the oil pan and sends a signal to the TCM.

• The ATF thermo sensor is of the thermister type and the resistance value changes according to the ATF

oil temperature.

• When the ATF temperature is cold, the sensor resistance is high. When the ATF temperature increases,

the sensor resistance decreases.

• When the ATF temperature increases to 135 °C (275 °F), the TCM lights up the ATF temperature warning

lamp in the meter. When the ATF temperature decreases below 125 °C (257 °F), the ATF temperature

warning lamp switches off.

• The ATF thermo sensor is installed to the lower control valve body and integrated with the harness

assembly.

10.0

100.0

1,000.0

10,000.0

100,000.0

-30 -20 -10 0 10 20 30 40 50 60 70 80 90 100 110 120 130 140 150 160 A TF Temp er a t ur e ( °C)

Resistance (Ω

)

Figure 29. Characteristic of Thermo Sensor

Figure 30. Location of Thermo Sensor

ATF Temperature

(deg. C) Resistance (Ohm)

(Approximately) ATF Temperature

(deg. C) Resistance (Ohm)

(Approximately)

-30 29,614 100190

-20 16,705 110149

-10 9,842 120118

0 6,028 128 98

20 2,500 130 94

40 1,160 135 84

50 819 140 76

60 591 14568

80 324 15062

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 4425 of 6020

TRANSMISSION CONTROL SYSTEM (JR405E) 7A2-141

d. If there is already stored in the scan tool, theexisting data is displayed on the screen. The

scan tool asks user to keep existing data “Keep

Data” or “Continue” to request new vehicle

information from the TCM. If there is no data in

the scan tool, it will immediately start vehicle

identification.

e. Select the vehicle description by following the on-screen instructions based on stamped VIN

or affixed VIN plate on the vehicle.

f. During obtaining information, the scan tool is receiving information from all modules at the

same time. But only ECM information is

displayed on the screen.

g. Turn OFF all accessories and press “Okay”.

h. Verify that the correct VIN is displayed on the scan tool. If the VIN is incorrect or no VIN,

record the correct VIN.

2. Turn OFF the ignition.

3. Turn OFF the scan tool and disconnect from the vehicle.

4. Transfer the data from the terminal to the scan tool using the following procedure:

Notice: The TIS supports service programming with

the Tech 2 scan tool only.

a. Connect the scan tool to the terminal.

b. Launch the TIS application.

c. Select the Service Programming System at the main screen.

d. Highlight the following information on the Select Diagnostic Tool and Programming Process

screen, then click “Next”.

• Select Diagnostic Tool - Tech 2

• Select Programming Process - Identify whether an existing TCM is being

reprogrammed or a TCM is being replaced

with a new one

• Select ECU Location - Vehicle

e. Verify the connections on the Preparing for Communication screen, then click “Next”.

f. Verify the VIN on the Validate Vehicle Identification Number (VIN) screen, then click

“Next”.

Notice: If the TCM is replaced to new one, VIN does

not displayed. Input correct VIN reading from stamped

VIN or affixed VIN plate on the vehicle. If the TCM from

another vehicle is installed, input correct VIN by same

way.

g. Highlight Transmission on the Select SystemType screen, then click “Next”, if on-screen

instruction displayed.

h. Complete the following information based on the service ID plate on the Validate Vehicle

Data screen until “Next” is highlighted, then

click “Next”.

• Model • Model year

• Engine type

• Model designator

• Destination code

• Transmission type

i. Verify your selection on the Summary screen.

Notice: Refer to Service Bulletin and Description

column before service programming is performed if the

bulletins are listed along with the calibration files.

Notice: Select Cancel if you receive a message stating

that the calibration selected is already the current

calibration in the TCM and reprogramming with the

same download is not allowed.

j. Click “Reprog”.

k. The Transfer Data screen will appear until the progress bar reaches 100%.

5. Close the application and return to the TIS application selection screen after the download is

completed.

6. Turn OFF the scan tool and disconnect from the terminal.

7. Transfer the data from the scan tool to the TCM using the following procedure:

a. Install a scan tool.

b. Turn ON the ignition, with the engine OFF.

c. Select Service Programming System (SPS) > Program ECU.

d. Turn OFF all accessories and press “Continue”.

e. Programming in Process will appear until the progress bar reaches 100%.

Notice: Some warning lamp may turn ON or blink while

programming the TCM since communication between

the TCM and other modules are interrupted. Clear DTC

in any module after programming.

f. Press “Continue” and exit the program after thescan tool displays “Programming Was

Successful”.

8. Turn OFF the ignition.

9. Turn OFF the scan tool and disconnect from the vehicle.

Service Programming System (SPS) (Pass-

Thru Procedure)

Pass-Thru programming allows the scan tool to remain

connected to the terminal and to the vehicle throughout

the programming process. The vehicle must be in close

proximity to the terminal while using Pass-Thru.

1. Launch the TIS application.

2. Select the Service Programming System at the main screen.

3. Highlight the following information on the Select Diagnostic Tool and Programming Process screen,

then click “Next”:

• Select Diagnostic Tool-Select Pass - Thru

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 4426 of 6020

7A2-142 TRANSMISSION CONTROL SYSTEM (JR405E)

• Select Programming Process - Identifywhether as existing TCM is being

reprogrammed or an TCM is being replaced

with a new one.

• Select ECU Location - Vehicle

4. Complete all vehicle data on the Preparing for Communication/ Determine Vehicle screen until

“Next” is highlighted, then click “Next”.

5. Follow the instruction on the Preparing for Communication screen, then click “Next”.

Notice: In order to reduce the potential for signal loss,

the RS-232 cable should not be more than 25 feet long.

6. Verify the VIN on the Validate Vehicle Identification Number (VIN) screen, then click “Next”.

Notice: If the TCM is replaced to new one, VIN does

not displayed. Input correct VIN reading from stamped

VIN or affixed VIN plate on the vehicle. If the TCM from

another vehicle is installed, input correct VIN by same

way.

7. Highlight Transmission on the Select System Type screen, then click “Next”, if on-screen instruction

displayed.

8. Complete the following information based on the service ID plate on the Validate Vehicle Data

screen until “Next” is highlighted, then click “Next”.

• Model

• Model year

• Engine type

• Model designator

• Destination code

• Transmission type

9. Verify your selection on the Summary screen.

Notice: Refer to Service Bulletin and Description

column before service programming is performed if the

bulletins are listed along with the calibration files.

Notice: Select Cancel if you receive a message stating

that the calibration selected is already the current

calibration in the TCM and reprogramming with the

same download is not allowed.

10. Click “Reprog”.

11. The Transfer Data screen will appear until the progress bar reaches 100%.

Notice: Some warning lamp may turn ON or blink while

programming the TCM since communication between

the TCM and other modules are interrupted. Clear DTC

in any module after programming.

12. Close the application and return to the TIS application selection screen after the download is

completed.

13. Turn OFF the ignition.

14. Turn OFF the scan tool and disconnect from the vehicle.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 4881 of 6020

TRANSFER CONTROL SYSTEM 7D1-7

7B4-PDF3

4L indicator (in meter panel)

This lamp indicates following items:

Valve check

Driving status (High-Low)

Operating status (2Hz: Actuator in operation, mechanism

standby)

Restrictions on operation (4Hz)

RTW 77DSH000601

Neutral indicator (in operation switch panel)

This LED indicates following items:

LED check

Driving status (Neutral)

Operating status (2Hz: Actuator in operation, mechanism

standby)

Restrictions on operation (4Hz)

7B4-PDF5

Check 4WD warning light (in meter panel)

This light indicates following items:

Valve check

Faulty actuator limit SW , and circuit related faults with the limit

switch

RTW 77DSH000501

4WD switch

Switch to transmit a switching command to the 2H, 4H,

Neutral, or 4L position.

It comprises 3 PUSH momentary switches. By pushing the 2H

and 4L switches for 10 seconds,

operation is changed to the neutral position.

To shift from the neutral to another position, push another

switch for 10 seconds.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 4886 of 6020

7D1-12 TRANSFER CONTROL SYSTEM

Functions of Switch and indicator Lamp

Transfer-related indicator lamp and switch function

Item 4WD

lamp 4L lamp Neutral

lamp Check

4WD

warning light 4WD

switch Actu ato r

detection (limit)

switches

LS1, LS2, LS3. and LS4

1 = on

2 = off Transfer

4WD

switch Transfer

neutral switch SOF

actuator switch Or

Axl e

dummy Remarks

2H Off Off Off Off No

operation 1,0,1,0 Open Open Open -----

4H start

of

operation Off Off Off Off 4H position

for 0.1

second 1,0,1,0 Open Open Open Switch

operation sensor

Start of

operation Blinking

(2HZ) Off Off Off No

operation 1,1,1,0

0,0,1,0

0,1,1,0

0,1,1,1 Open Open Open

2H to 4H

while

driving

During

operation

(Synchro) Blinking

(2HZ) Off Off Off No

operation 1,1,1,0

0,0,1,0

0,1,1,0

0,1,1,1 Open Open Open 2H to 4H

using

synchro and

retrial

During

operation (Axle

drive) Blinking

(2HZ) Off Off Off No

operation 0,0,1,1 Closed Open Open Axle drive

Axle

waiting Blinking

(2HZ) Off Off Off No

operation 0,0,1,1 Closed Open Open Axle drive

4H On Off Off Off No

operation 0,0,1,1 Closed Open Closed -----

4L start

of

operation On Off Off Off 4L position

for 0.1

second 0,0,1,1 Closed Open Closed Switch

operation sensor

Start of

operation On Blinking

(2HZ) Off Off No

operation 0,0,0,1

0,1,0,1 Closed Open Closed 4H to 4L

while

driving

During

operation (N) Off

Blinking

(2HZ) Off Off No

operation 0,0,0,1

0,1,0,1 Closed Closed Closed 4H to 4L

through neutral

During

operation (N) Off

Blinking

(2HZ) Off Off No

operation 0,1,0,0 Closed Closed Closed 4H to 4L

through neutral

During

operation (N) Off

Blinking

(2HZ) Off Off No

operation 1,1,0,0 Closed Closed Closed 4H to 4L

through neutral

4L

waiting On Blinking

(2HZ) Off Off No

operation 1,1,0,1 Closed Closed Closed 4H to 4L

while

waiting

4L On On Off Off No

operation 1,1,0,1 Closed Open Closed -----

4H start of

operation On Off Off Off 4H position

for 0.1

second 1,1,0,1 Closed Open Closed Switch

operation sensor

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 4887 of 6020

TRANSFER CONTROL SYSTEM 7D1-13

Item 4WD

lamp 4L lamp Neutral

lamp Check

4WD

warning light 4WD

switch Actu ato r

detection (limit)

switches

LS1, LS2, LS3. and LS4

1 = on

2 = off Transfer

4WD

switch Transfer

neutral switch SOF

actuator switch Or

Axl e

dummy Remarks

During

operation On Blinking

(2HZ) Off Off No

operation 1,1,0,1 Closed Open Closed 4L to 4H

while

driving

During

operation (N) Off

Blinking

(2HZ) Off Off No

operation 1,1,0,0 Closed Closed Closed 4L to 4H

through neutral

During

operation Off Blinking

(2HZ) Off Off No

operation 0,1,0,1

0,0,0,1 Closed Closed Closed 4L to 4H

while

driving

4H

waiting Off Blinking

(2HZ) Off Off No

operation 0,0,1,1 Closed Closed Closed

4L to 4H

while

waiting

4H On Off Off Off No

operation 0,0,1,1 Closed Open Closed -----

2H start of

operation On Off Off Off 2H position

for 0.1

second 0,0,1,1 Closed Open Closed Switch

operation sensor

Start of

operation Blinking

(2HZ) Off Off Off No

operation 0,1,1,1

0,1,1,0

0,0,1,0

1,1,1,0 Closed Open Closed

2H to 4H

while

driving

During

operation (Axle) Blinking

(2HZ) Off Off Off No

operation 0,1,1,1

0,1,1,0

0,0,1,0

1,1,1,0 Open Open Closed Axle drive

Axle

waiting

Blinking

(2HZ) Off Off Off No

operation 1,0,1,0 Open Open Closed Axle

waiting

2H Off Off Off Off No

operation 1,0,1,0 Open Open Open -----

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 4888 of 6020

7D1-14 TRANSFER CONTROL SYSTEM

2H to 4H retrial

Item 4WD

lamp 4L lamp Neutral

lamp Check

4WD

warning light 4WD

switch Actu ato r

detection (limit)

switches

LS1, LS2, LS3. and LS4

1 = on

2 = off Transfer

4WD

switch Transfer

neutral switch SOF

actuator switch Or

Axl e

dummy Remarks

2H Off Off Off Off No

operation1,0,1,0 Open Open Open -----

4H start

of

operation Off Off Off Off 4H

position for 0.1

second 1,0,1,0 Open Open Open -----

Start of

operation Blinking

(2HZ) Off Off Off No

operation 1,1,1,0

0,0,1,0

0,1,1,0

0,1,1,1 Open Open Open

2H to 4H

while

driving

During

operation

(Synchro)

(Go to 4H if synchro

complete) Blinking

(2HZ) Off Off Off No

operation 1,1,1,0

0,0,1,0

0,1,1,0

0,1,1,1 Open Open Open 2H to 4H

using

synchro

and retrial X 2

Abandoned

operation (2H) Blinking

(4HZ) Off Off Off No

operation 1,0,1,0 Open Open Open Return to

2H

2H

indication

after

10second

s

Off Off Off Off No

operation1,0,1,0 Open Open Open -----

• Completion of transfer case H-L area and axle shift timing may cause some variation in the 2Hz blinking pattern.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 4890 of 6020

7D1-16 TRANSFER CONTROL SYSTEM

Transfer-related indicator lamp and switch function

Skip operation

Item 4WD

lamp 4L lamp Neutral

lamp Check

4WD

warning light 4WD

switch Actu ato r

detection (limit)

switches LS1,

LS2,

LS3. and LS4

1 = on

2 = off Transfer

4WD

switch Transfer

neutral switch SOF

actuator switch Or

Axl e

dummy Remarks

2H Off Off Off Off No

operation1,0,1,0 Open Open Open -----

4L start of

operation Off Off Off Off 4L

position for 0.1

second 1,0,1,0 Open Open Open

Switch

operation sensor

Start of

operation Blinking

(2HZ) Blinking

(2HZ) Off Off No

operation 1,1,1,0

0,0,1,0

0,1,1,0

0,1,1,1 Open Open Open

2H to 4H

while

driving

During

operation

(Synchro) Blinking

(2HZ) Blinking

(2HZ) Off Off No

operation 1,1,1,0

0,0,1,0

0,1,1,0

0,1,1,1 Open Open Open 2H to 4H

using

synchro

and retrial

During

operation (Passing through 4H) Off

Blinking

(2HZ) Off Off No

operation 0,0,1,1 Closed Open Open -----

During

operation (Passing through 4H) Off

Blinking

(2HZ) Off Off No

operation 0,0,1,1

0,1,0,1 Closed Open Open -----

During

operation

(N)

On Blinking

(2HZ) Off Off No

operation

0,0,1,1

0,1,0,1 Closed Open Closed -----

During

operation (N) On

Blinking

(2HZ) Off Off No

operation 0,1,0,0 Closed Open Closed Switch

operation sensor

During

operation (N) On

Blinking

(2HZ) Off Off No

operation 0,0,1,1 Closed Open Closed 4H to 4L

while

driving

During

operation (Axle

drive) Blinking

(2HZ) Blinking

(2HZ) Off Off No

operation 0,0,1,1 Closed Open Open

-----

Axle

waiting Blinking

(2HZ) Blinking

(2HZ) Off Off No

operation 0,0,1,1 Closed Open Open -----

4L waiting On Blinking

(2HZ) Off Off No

operation 1,1,0,1 Closed Closed Closed 4H to 4L

while

waiting

4L On On Off Off No

operation1,1,0,1 Closed Open Closed -----

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007