check engine ISUZU KB P190 2007 Workshop Service Manual

[x] Cancel search | Manufacturer: ISUZU, Model Year: 2007, Model line: KB P190, Model: ISUZU KB P190 2007Pages: 6020, PDF Size: 70.23 MB

Page 724 of 6020

BRAKES 5C-25

Filling Master Cylinder Reservoir

CAUTION:

Use only specified brake fluid. Do not use any fluid which

contains a petroleum base. Do not use a container which

has been used for petroleum based fluids or a containe

r

which is wet with water. Petroleum based fluid will cause

swelling and distortion of rubber parts in the hydraulic

brake system. Water mixed with brake fluid lowers the

fluid boiling point. Keep all fluid containers capped to

prevent contamination.

Always fill the master cylinder reservoir when the engine

is cold.

Never allow the brake fluid to come in contact with the

painted surfaces.

The master cylinder reservoir must be kept properly filled

to ensure adequate reserve and to prevent air and

moisture from entering the hydraulic system. However,

because of expansion due to heat absorbed from the

brakes and the engine, the reservoir must not be

overfilled. Thoroughly clean reservoir cap before removal

to avoid getting dirt into reservoir. Add fluid as required to

bring level to the “MAX” mark on the reservoir tank. Use

“DOT 3” Hydraulic Brake Fluid.

Leakage of Brake Fluid

W ith engine idling, set shift lever in the neutral position and

continue to depress brake pedal at a constant pedal

application force.

Should the pedal stroke become deeper gradually, leakage

from the hydraulic pressure system is possible.

Make sure by visual check that there is no leak.

BLEEDING OF THE BRAKE HYDRAULIC

CIRCUIT

If air enters the bake lines, it will cause poor brake action.

Therefore, bleeding should be performed if the brakes have

been used with the level of brake fluid in the reservoi

r

excessively low or if brake pipes have been disconnected in

the course of brake servicing.

The bleeding operation calls for co-operative action of 2

persons.

• Set the parking brake firmly while bleeding.

• Perform bleeding operation with ENGINE RUNNING, to

prevent damage to push rod seal.

Make sure exhaust is suitably ventilated.

• Bleed the hydraulic system with the fluid reservoir filled to

the specified level.

• Bleed the system starting with the rear wheel cylinde

r

farthest from the master cylinder.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 725 of 6020

5C-26 BRAKES

A bleeding operation is necessary to remove air from the

hydraulic brake system whenever air is introduced into the

hydraulic system. It may be necessary to bleed the hydraulic

system at all four brakes if air has been introduced through a

low fluid level or by disconnecting brake pipes at the maste

r

cylinder. If a brake pipe is disconnected at one wheel, only that

wheel cylinder/caliper needs to be bled. If the pipes are

disconnected at any fitting located between the master cylinde

r

and brakes, then the brake system served by the disconnected

pipe must be bled.

1. Set the parking brake completely, then start the engine.

NOTE:

The vacuum booster will be damaged if the bleeding operation

is performed with the engine off.

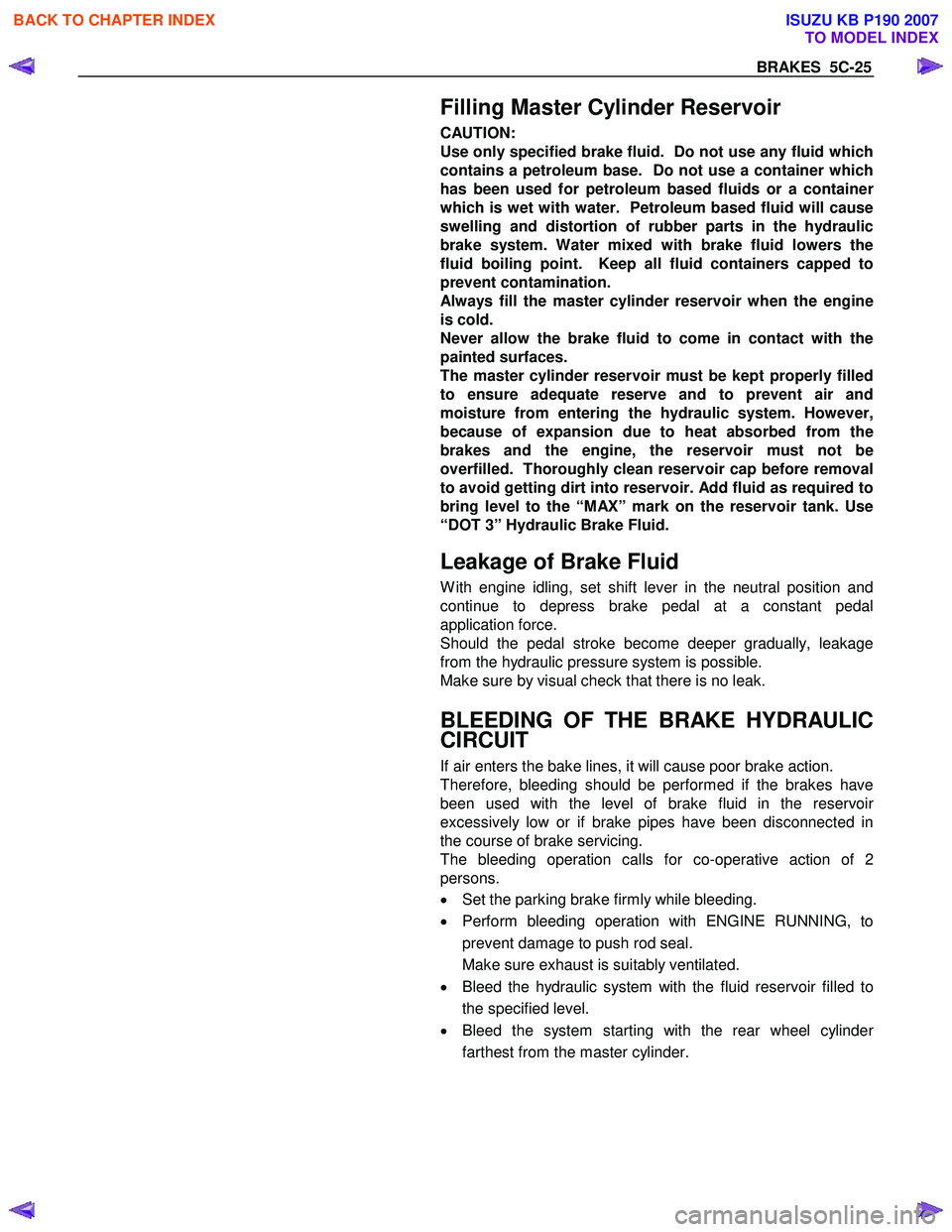

2. Remove the master cylinder reservoir cap.

RTW 75CSH001701

3. Fill the master cylinder reservoir with brake fluid. Keep the

reservoir at least half full during the air bleeding operation.

4. Always use new brake fluid for replenishment.

5. In replenishing brake fluid, take care that air bubbles do not enter the brake fluid.

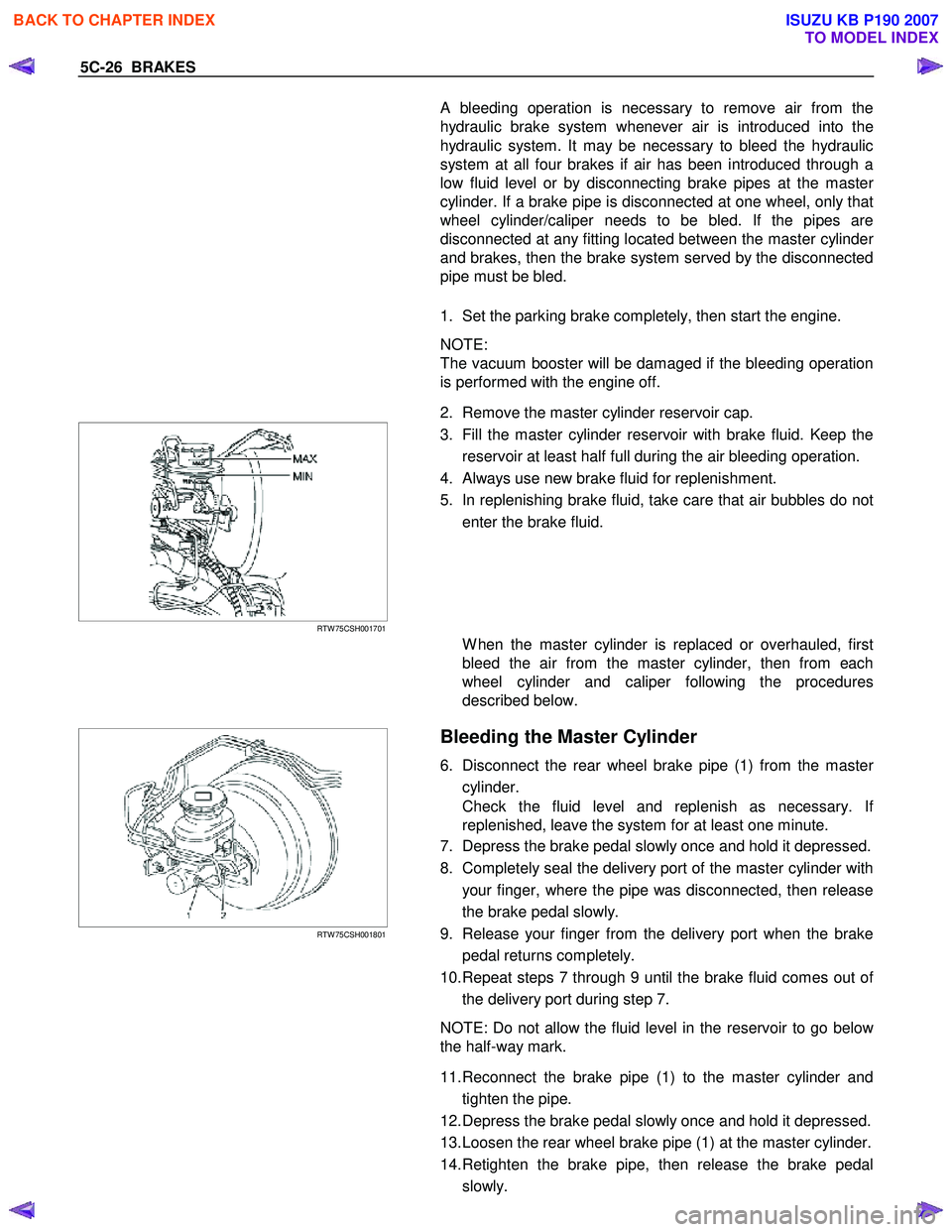

W hen the master cylinder is replaced or overhauled, first

bleed the air from the master cylinder, then from each

wheel cylinder and caliper following the procedures

described below.

RTW 75CSH001801

Bleeding the Master Cylinder

6. Disconnect the rear wheel brake pipe (1) from the master

cylinder.

Check the fluid level and replenish as necessary. I

f

replenished, leave the system for at least one minute.

7. Depress the brake pedal slowly once and hold it depressed.

8. Completely seal the delivery port of the master cylinder with your finger, where the pipe was disconnected, then release

the brake pedal slowly.

9. Release your finger from the delivery port when the brake pedal returns completely.

10. Repeat steps 7 through 9 until the brake fluid comes out o

f

the delivery port during step 7.

NOTE: Do not allow the fluid level in the reservoir to go belo

w

the half-way mark.

11. Reconnect the brake pipe (1) to the master cylinder and tighten the pipe.

12. Depress the brake pedal slowly once and hold it depressed.

13. Loosen the rear wheel brake pipe (1) at the master cylinder.

14. Retighten the brake pipe, then release the brake pedal slowly.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 727 of 6020

5C-28 BRAKES

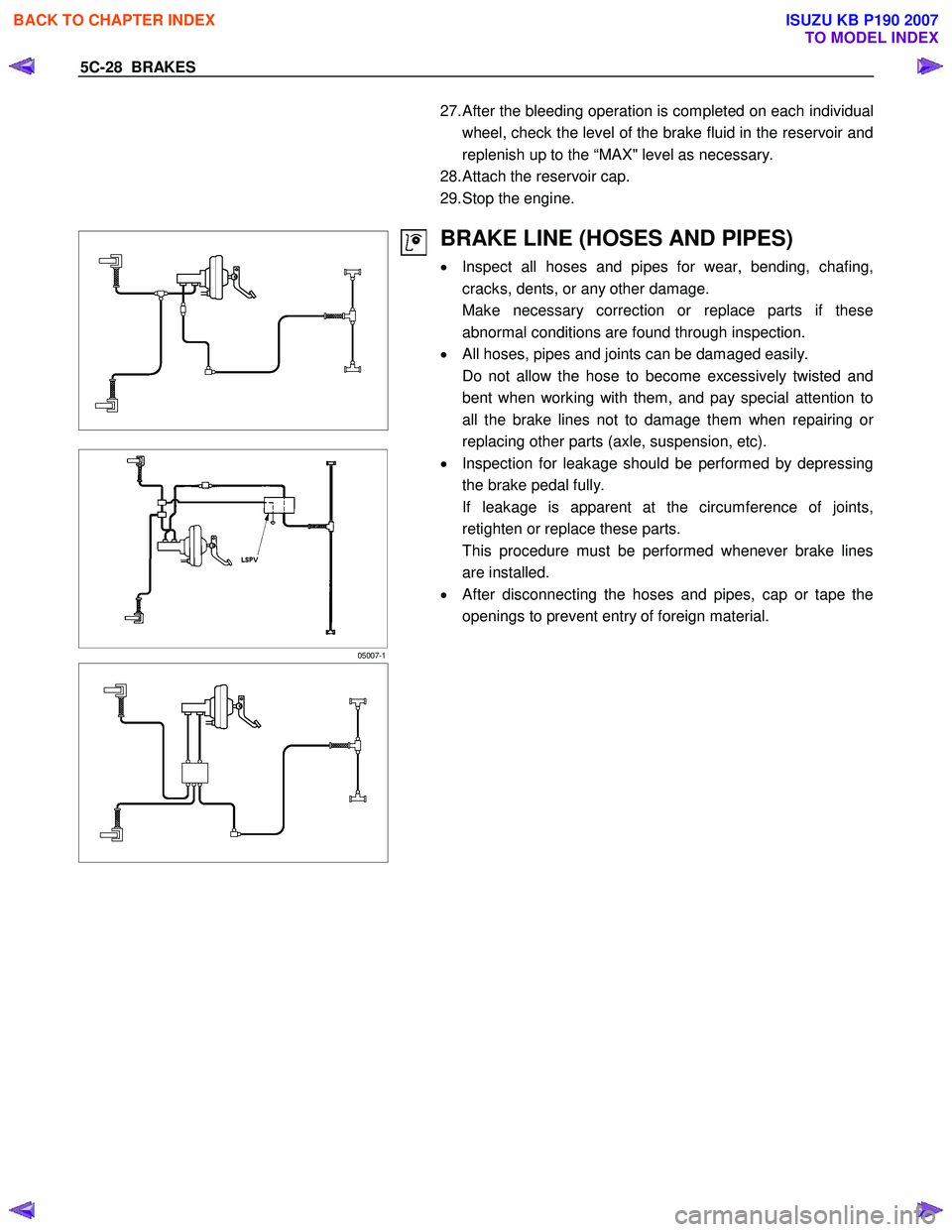

27. After the bleeding operation is completed on each individual

wheel, check the level of the brake fluid in the reservoir and

replenish up to the “MAX" level as necessary.

28. Attach the reservoir cap.

29. Stop the engine.

05007-1

BRAKE LINE (HOSES AND PIPES)

• Inspect all hoses and pipes for wear, bending, chafing,

cracks, dents, or any other damage.

Make necessary correction or replace parts if these abnormal conditions are found through inspection.

• All hoses, pipes and joints can be damaged easily.

Do not allow the hose to become excessively twisted and bent when working with them, and pay special attention to

all the brake lines not to damage them when repairing o

r

replacing other parts (axle, suspension, etc).

• Inspection for leakage should be performed by depressing

the brake pedal fully.

If leakage is apparent at the circumference of joints, retighten or replace these parts.

This procedure must be performed whenever brake lines are installed.

• After disconnecting the hoses and pipes, cap or tape the

openings to prevent entry of foreign material.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 760 of 6020

BRAKES 5C-61

RTW 75CSH002701

Important Operation-Removal

1. Brake pipe

W hen hurdling, be careful not to spill brake fluid over the

painted surfaces, as damage to the paint finish will result.

2. Master Cylinder Fixing Nut

3. Bracket

4. Master Cylinder Assembly

NOTE:

W hen removing the master cylinder from the vacuum booster,

be sure to get rid of the internal negative pressure of the

vacuum booster (by, for instance, disconnecting the vacuum

hose) in advance.

If any negative pressure remains in the vacuum booster, the

piston may possibly come out when the master cylinder is

being removed, letting the brake fluid run out.

W hile removing the master cylinder, do not hold the piston as it

can be easily pulled out.

Inspection and Repair

Vacuum Hose (The built in check valve)

360R300002

1) Inspect the check valve, which is installed inside the

vacuum hose.

2) Blow air into the hose from the booster side as shown in the illustration. The air should pass freely through the

hose.

3) Blow air into the hose from the engine side. The check valve should close to block the passage of air.

The vacuum hose and built-in check valve must be

replaced as a set if either is found to be defective.

Important Operation-Installation

10. Vacuum Booster Assembly

Note:

•

Adjustment of push rod of vacuum booster is not carried

out. W hen vacuum booster is damaged it exchanges for a

new article. (Push rod is adjusted)

• Measurement of primary piston position by the side o

f

master cylinder is unnecessary.

9. Spacer

8. Gasket

7. Vacuum Booster Fixing Nut

6. Snap Pin

Install the vacuum booster assembly to the dash panel and

pedal mounting bracket.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 761 of 6020

5C-62 BRAKES

360r300003

5. Vacuum Hose

The check valve (2) is built-in to the vacuum hose.

W hen installing the vacuum hose make sure that the arrow on

the hose is facing the engine (1).

Note:

• Do not apply oil to the vacuum hose.

• Installation direction is very important. The booster will not

operate if the vacuum hose is installed in the wrong

direction.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 787 of 6020

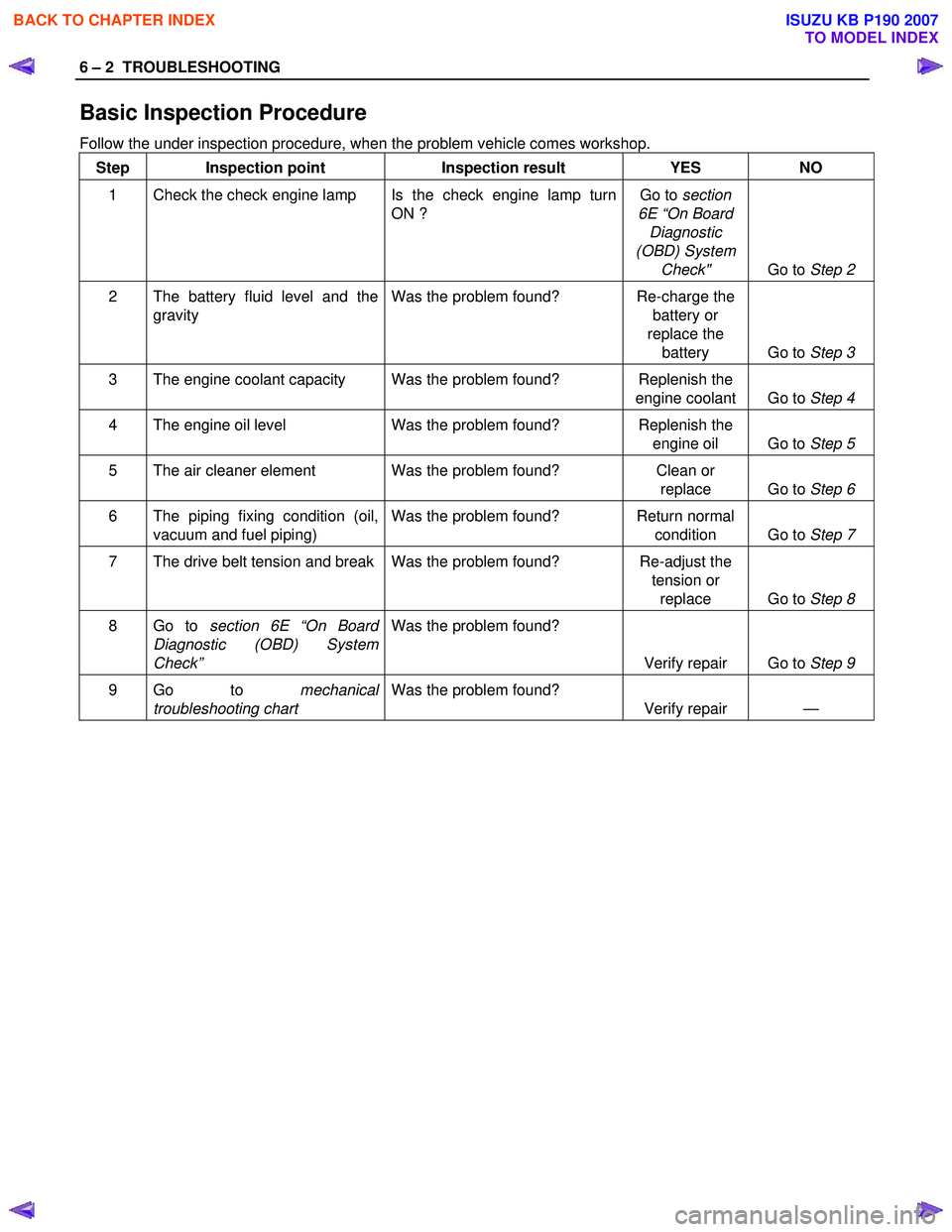

6 – 2 TROUBLESHOOTING

Basic Inspection Procedure

Follow the under inspection procedure, when the problem vehicle comes workshop. Step Inspection point Inspection result YES NO

1 Check the check engine lamp Is the check engine lamp turn ON ? Go to

section

6E “On Board Diagnostic

(OBD) System Check" Go to Step 2

2 The battery fluid level and the

gravity Was the problem found? Re-charge the

battery or

replace the battery Go to Step 3

3 The engine coolant capacity Was the problem found? Replenish the

engine coolant Go to Step 4

4 The engine oil level Was the problem found? Replenish the

engine oil Go to Step 5

5 The air cleaner element Was the problem found? Clean or

replace Go to Step 6

6 The piping fixing condition (oil,

vacuum and fuel piping) Was the problem found? Return normal

condition Go to Step 7

7 The drive belt tension and break Was the problem found? Re-adjust the

tension or replace Go to Step 8

8 Go to section 6E “On Board

Diagnostic (OBD) System

Check” Was the problem found?

Verify repair Go to Step 9

9 Go to mechanical

troubleshooting chart Was the problem found?

Verify repair —

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 788 of 6020

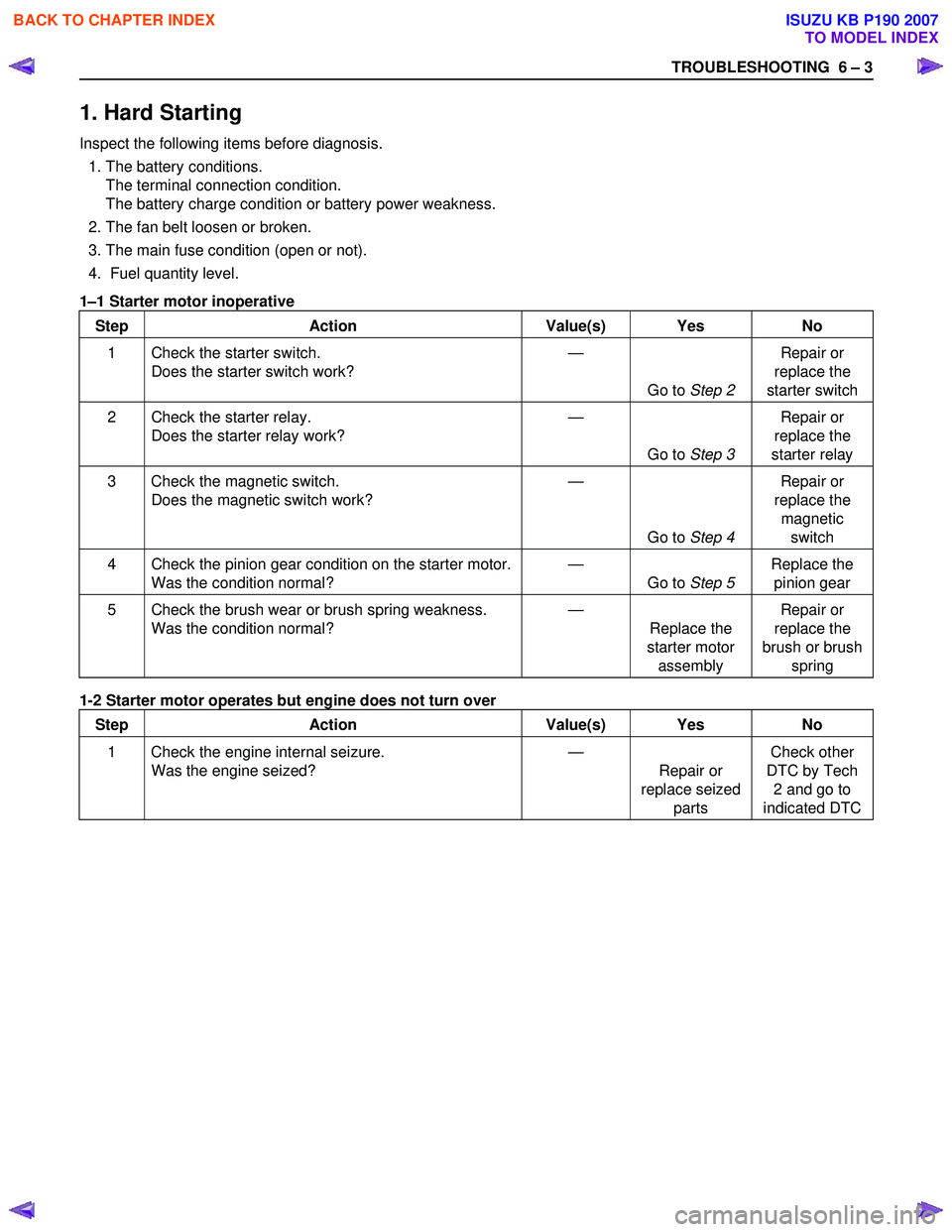

TROUBLESHOOTING 6 – 3

1. Hard Starting

Inspect the following items before diagnosis.

1. The battery conditions. The terminal connection condition.

The battery charge condition or battery power weakness.

2. The fan belt loosen or broken.

3. The main fuse condition (open or not).

4. Fuel quantity level.

1 –1 Starter motor inoperative

Step Action Value(s) Yes No

1 Check the starter switch. Does the starter switch work? —

Go to Step 2 Repair or

replace the

starter switch

2 Check the starter relay. Does the starter relay work? —

Go to Step 3 Repair or

replace the

starter relay

3 Check the magnetic switch. Does the magnetic switch work? —

Go to Step 4 Repair or

replace the magnetic switch

4 Check the pinion gear condition on the starter motor. Was the condition normal? —

Go to Step 5 Replace the

pinion gear

5 Check the brush wear or brush spring weakness. Was the condition normal? —

Replace the

starter motor assembly Repair or

replace the

brush or brush spring

1-2 Starter motor operates but engine does not turn over

Step Action Value(s) Yes No

1 Check the engine internal seizure. Was the engine seized? —

Repair or

replace seized parts Check other

DTC by Tech 2 and go to

indicated DTC

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 789 of 6020

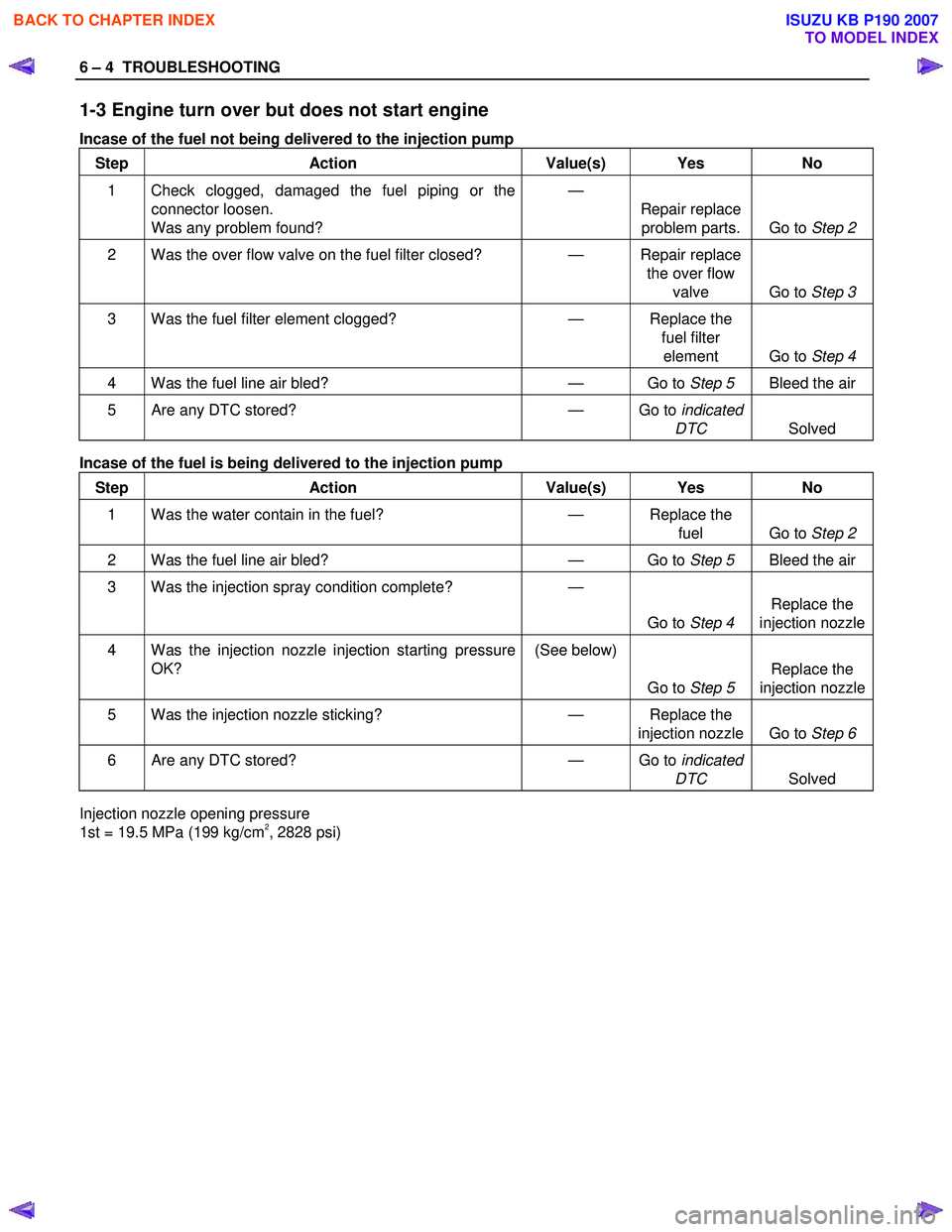

6 – 4 TROUBLESHOOTING

1-3 Engine turn over but does not start engine

Incase of the fuel not being delivered to the injection pump

Step Action Value(s) Yes No

1 Check clogged, damaged the fuel piping or the

connector loosen.

Was any problem found? —

Repair replace problem parts. Go to Step 2

2 Was the over flow valve on the fuel filter closed? — Repair replace

the over flow valve Go to Step 3

3 Was the fuel filter element clogged? — Replace the

fuel filter element Go to Step 4

4 Was the fuel line air bled? — Go to Step 5 Bleed the air

5 Are any DTC stored? — Go to indicated

DTC Solved

Incase of the fuel is being delivered to the injection pump

Step Action Value(s) Yes No

1 Was the water contain in the fuel? — Replace the

fuel Go to Step 2

2 Was the fuel line air bled? — Go to Step 5 Bleed the air

3 Was the injection spray condition complete? —

Go to Step 4 Replace the

injection nozzle

4 Was the injection nozzle injection starting pressure OK? (See below)

Go to Step 5 Replace the

injection nozzle

5 Was the injection nozzle sticking? — Replace the

injection nozzle Go to Step 6

6 Are any DTC stored? — Go to indicated

DTC Solved

Injection nozzle opening pressure

1st = 19.5 MPa (199 kg/cm2, 2828 psi)

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 803 of 6020

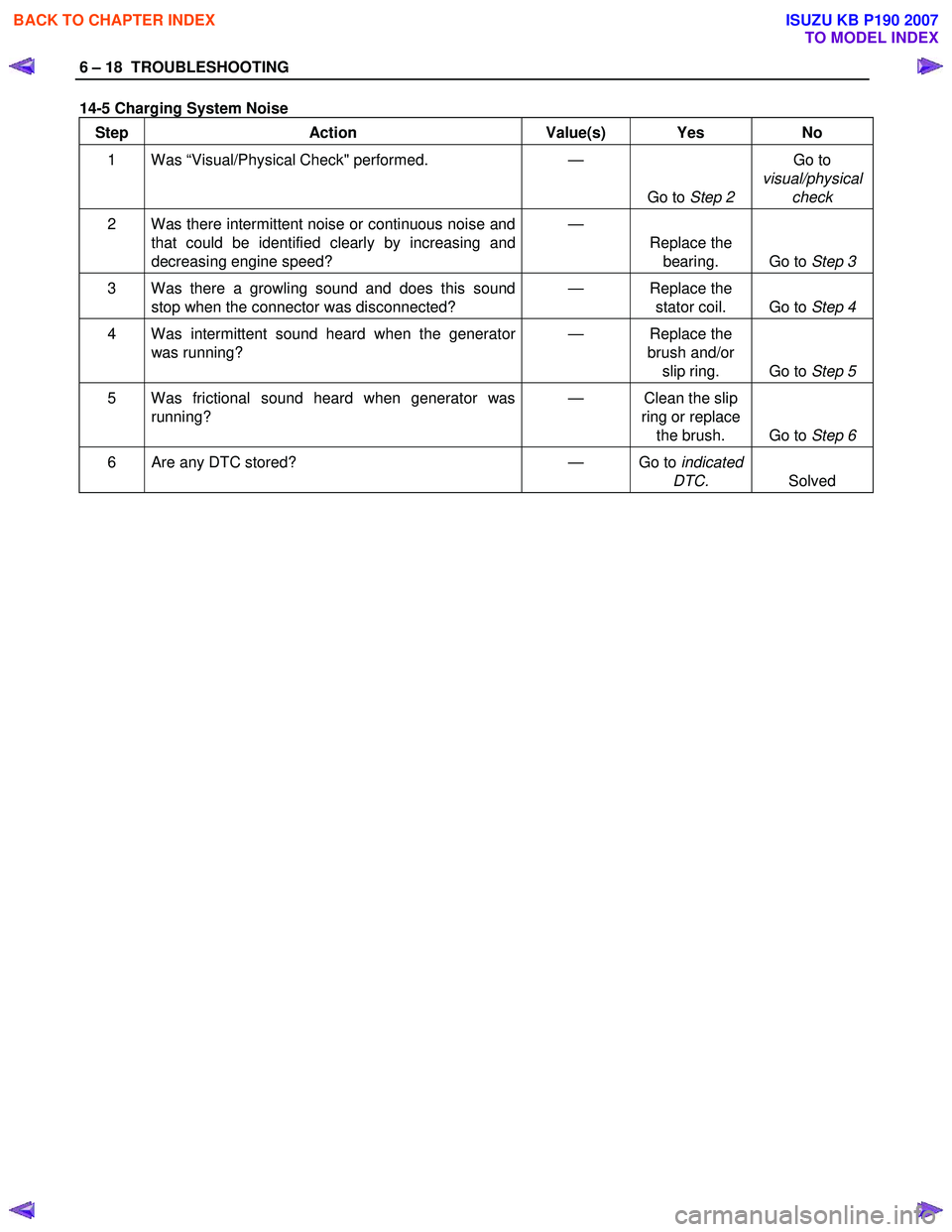

6 – 18 TROUBLESHOOTING

14-5 Charging System Noise Step Action Value(s) Yes No

1 Was “Visual/Physical Check" performed.

—

Go to Step 2 Go to

visual/physical check

2 Was there intermittent noise or continuous noise and

that could be identified clearly by increasing and

decreasing engine speed? —

Replace the bearing. Go to Step 3

3 Was there a growling sound and does this sound

stop when the connector was disconnected? —

Replace the

stator coil. Go to Step 4

4 Was intermittent sound heard when the generator

was running? —

Replace the

brush and/or slip ring. Go to Step 5

5 Was frictional sound heard when generator was

running? —

Clean the slip

ring or replace the brush. Go to Step 6

6 Are any DTC stored? — Go to indicated

DTC. Solved

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 804 of 6020

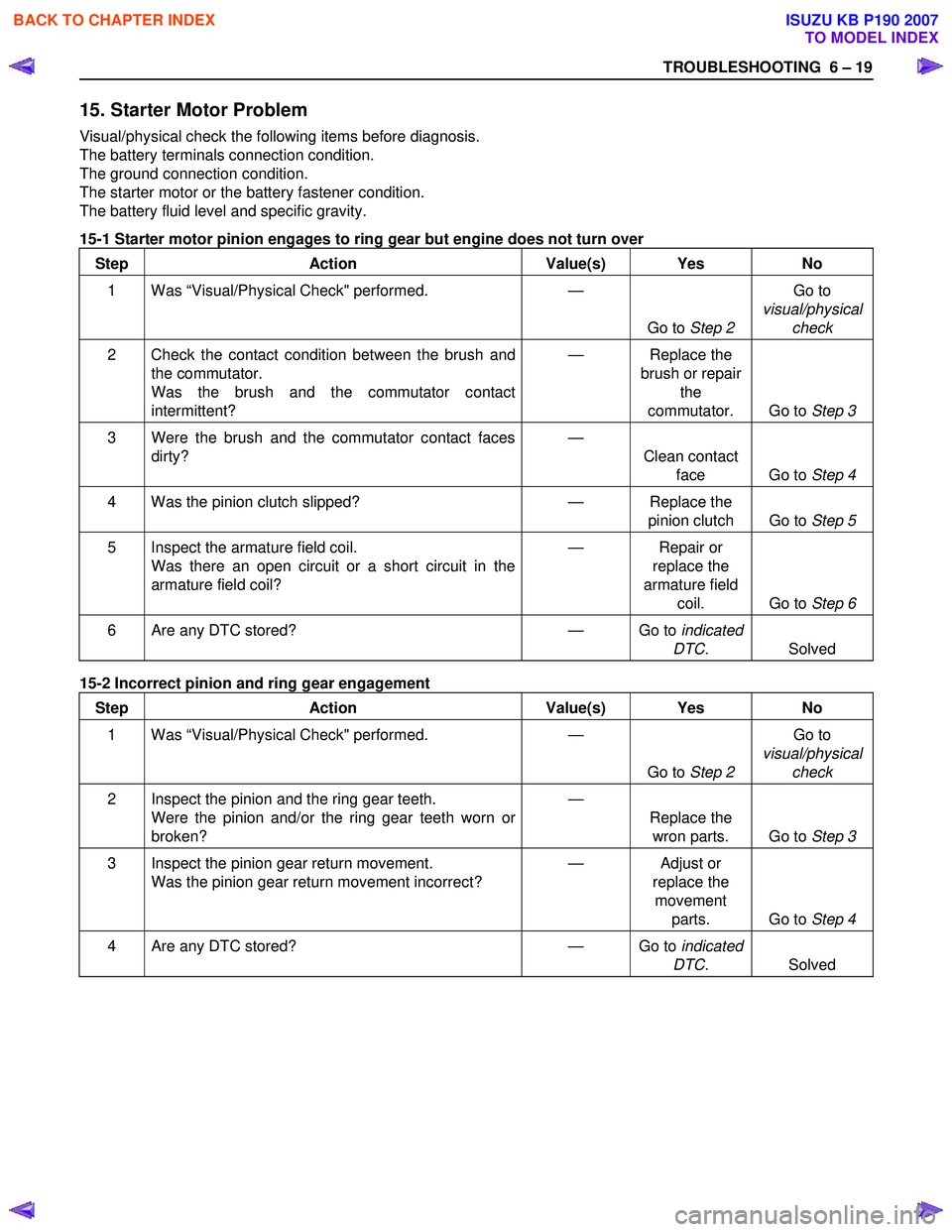

TROUBLESHOOTING 6 – 19

15. Starter Motor Problem

Visual/physical check the following items before diagnosis.

The battery terminals connection condition.

The ground connection condition.

The starter motor or the battery fastener condition.

The battery fluid level and specific gravity.

15-1 Starter motor pinion engages to ring gear but engine does not turn over

Step Action Value(s) Yes No

1 Was “Visual/Physical Check" performed.

—

Go to Step 2 Go to

visual/physical check

2 Check the contact condition between the brush and

the commutator.

Was the brush and the commutator contact

intermittent? —

Replace the

brush or repair the

commutator. Go to Step 3

3 Were the brush and the commutator contact faces

dirty?

—

Clean contact face Go to Step 4

4 Was the pinion clutch slipped? — Replace the

pinion clutch Go to Step 5

5 Inspect the armature field coil.

Was there an open circuit or a short circuit in the

armature field coil? —

Repair or

replace the

armature field coil. Go to Step 6

6 Are any DTC stored? — Go to indicated

DTC. Solved

15-2 Incorrect pinion and ring gear engagement

Step Action Value(s) Yes No

1 Was “Visual/Physical Check" performed.

—

Go to Step 2 Go to

visual/physical check

2 Inspect the pinion and the ring gear teeth.

Were the pinion and/or the ring gear teeth worn or

broken? —

Replace the wron parts. Go to Step 3

3 Inspect the pinion gear return movement.

Was the pinion gear return movement incorrect? —

Adjust or

replace the movement parts. Go to Step 4

4 Are any DTC stored? — Go to indicated

DTC. Solved

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007