check engine ISUZU KB P190 2007 Workshop Repair Manual

[x] Cancel search | Manufacturer: ISUZU, Model Year: 2007, Model line: KB P190, Model: ISUZU KB P190 2007Pages: 6020, PDF Size: 70.23 MB

Page 2379 of 6020

ENGINE DRIVEABILITY AND EMISSIONS 6E–209

Diagnostic Trouble Code (DTC) P0650

Malfunction Indicator Lamp (MIL) Control Circuit Malfunction

Step Action Value(s) Yes No

1 Was the “On-Board Diagnostic (OBD) System Check” performed?

—Go to Step 2Go to

On Board

Diagnostic

(OBD) System Check

2 1. Connect the Tech 2. 2. Review and record the failure information.

3. Select “F0: Read DTC Infor By Priority” in “F0: Diagnostic Trouble Code”.

Is the DTC P0650 stored as “Present Failure”? — Go to Step 3Refer to

Diagnostic Aids and Go to Step

3

3 1. Using the Tech2, ignition “On” and engine “Off”. 2. Select “Clear DTC Information” with the Tech2 andclear the DTC information.

3. Operate the vehicle and monitor the “F5: Failed This Ignition” in “F2: DTC Information”.

Was the DTC P0650 stored in this ignition cycle? — Go to Step 4Refer to

Diagnostic Aids and Go to Step

4

4 1. Ignition “On”, engine “Off”. 2. Check the “Check Engine” lamp.

Does the lamp turn “On”? — Go to Step 5Go to Step 6

5 1. Ignition “On”, engine “Off”. 2. Check the “Check Engine” lamp.

Does the lamp turn “Off”? — Go to Step 9Go to Step 7

6 Check the “Check Engine” lamp bulb. If the bulb is burnt out, repair as necessary.

Was the problem found? — Verify repair Go to Step 7

7 Check for poor/faulty connection at the meter connector and ECM connector. If a poor/faulty

connection is found, repair as necessary.

Was the problem found?

— Verify repair Go to Step 8

32

17

C-56(J2)B-24

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 2380 of 6020

6E–210 ENGINE DRIVEABILITY AND EMISSIONS

8 Using the DVM and check the “Check Engine” lampcircuit.

Breaker box is available:

1. Ignition “Off”, engine “Off”.

2. Install the breaker box as type A. (ECM disconnected) Refer to 6E-88 page.

3. Remove the meter connector.

4. Check the circuit for open or short to ground circuit.

Was the problem found?

Breaker box is not available: 1. Ignition “Off”, engine “Off”.

2. Disconnect the ECM connector.

3. Remove the meter connector.

4. Check the circuit for open or short to ground circuit.

Was the problem found?

—Repair faulty

harness and verify repair Go to Step 9

9 Is the ECM programmed with the latest software release?

If not, download the latest software to the ECM using

the “SPS (Service Programming System)”.

Was the problem solved? — Verify repair Go to Step 10

10 Replace the ECM. Is the action complete?

IMPORTANT: The replacement ECM must be

programmed. Refer to section of the Service

Programming System (SPS) in this manual.

Following ECM programming, the immobilizer system

(if equipped) must be linked to the ECM. Refer to

section 11 “Immobilizer System-ECM replacement” for

the ECM/Immobilizer linking procedure. — Verify repair —

Step

Action Value(s) Yes No

J2-25

Breaker BoxB-2411

ΩΩ

C-56(J2)

B-24

3217

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 2381 of 6020

ENGINE DRIVEABILITY AND EMISSIONS 6E–211

DIAGNOSTIC TROUBLE CODE (DTC) P1167 FUEL SUPPLY SYSTEM RICH DURING DECELERATION FUEL CUT OFF

Condition for setting the DTC and action taken when the DTC sets

Circuit Description

The engine control module (ECM) internal circuitry can

identify if the vehicle fuel system is capable of supplying

adequate amounts of fuel during deceleration (fuel cut

off). The ECM monitors the voltage of the oxygen

sensor during fuel cut off. When a fuel cut off mode of

operation is requested during “Closed Loop” operation

(by deceleration), the ECM will provide more fuel to the

engine. Under these conditions the ECM should detect

a “lean” condition (low oxygen sensor voltage). If this “lean” exhaust is not detected at this time, a Diagnostic

Trouble Code P1167 will set.

Diagnostic Aids

Check the following items:

• Fuel pressure - The system will go rich if pressure is too high. The ECM can compensate for some

increase. However, if fuel pressure is too high, a

Diagnostic Trouble Code P1167 may be set. Refer to

Fuel System Diagnosis .

Code Type DTC Name DTC Setting Condition Fail-Safe (Back Up)

P1167 D Fuel Supply System Rich During Deceleration Fuel Cutoff 1. No DTC relating to MAP sensor, TPS,

EVAP purge, ECT sensor, CKP sensor,

VSS, injector control circuit and ignition

control circuit.

2. O

2 sensor bank 1 output voltage is more

than 550mV in deceleration fuel cutoff

mode. No fail-safe function.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 2382 of 6020

6E–212 ENGINE DRIVEABILITY AND EMISSIONS

• Perform “Injector Balance Test” - Refer to Fuel

System Diagnosis .

• Check the EVAP canister for fuel saturation - If full of fuel, check canister control and hoses. Refer to

Evaporative (EVAP) Emission Control System .

• Check for a leak in the fuel pressure regulator diaphragm by checking the vacuum line to toe

regulator for the presence of fuel. • An intermittent TP sensor output will cause the

system to go rich due to a false indication of the

engine accelerating.

• Silicon contamination of the HO2S can also cause a high HO2S voltage to be indicated. This condition is

indicated by a powdery white deposit on the portion

of the HO2S exposed to the exhaust stream. If

contamination is noticed, replace the affected HO2S.

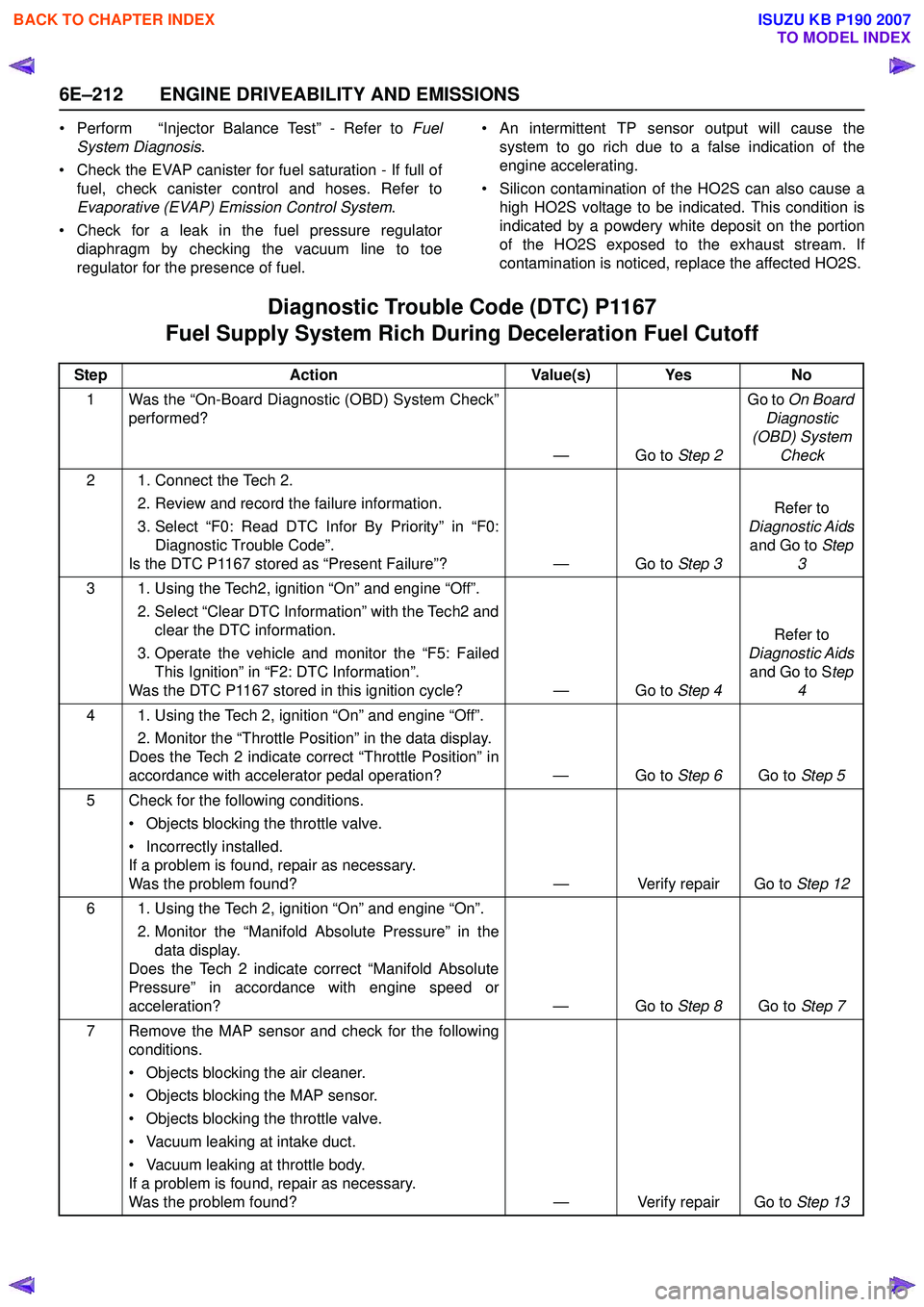

Diagnostic Trouble Code (DTC) P1167

Fuel Supply System Rich During Deceleration Fuel Cutoff

Step Action Value(s) Yes No

1 Was the “On-Board Diagnostic (OBD) System Check” performed?

—Go to Step 2Go to

On Board

Diagnostic

(OBD) System Check

2 1. Connect the Tech 2. 2. Review and record the failure information.

3. Select “F0: Read DTC Infor By Priority” in “F0: Diagnostic Trouble Code”.

Is the DTC P1167 stored as “Present Failure”? — Go to Step 3Refer to

Diagnostic Aids and Go to Step

3

3 1. Using the Tech2, ignition “On” and engine “Off”. 2. Select “Clear DTC Information” with the Tech2 andclear the DTC information.

3. Operate the vehicle and monitor the “F5: Failed This Ignition” in “F2: DTC Information”.

Was the DTC P1167 stored in this ignition cycle? — Go to Step 4Refer to

Diagnostic Aids and Go to S tep

4

4 1. Using the Tech 2, ignition “On” and engine “Off”. 2. Monitor the “Throttle Position” in the data display.

Does the Tech 2 indicate correct “Throttle Position” in

accordance with accelerator pedal operation? — Go to Step 6Go to Step 5

5 Check for the following conditions. • Objects blocking the throttle valve.

• Incorrectly installed.

If a problem is found, repair as necessary.

Was the problem found? — Verify repair Go to Step 12

6 1. Using the Tech 2, ignition “On” and engine “On”. 2. Monitor the “Manifold Absolute Pressure” in thedata display.

Does the Tech 2 indicate correct “Manifold Absolute

Pressure” in accordance with engine speed or

acceleration? — Go to Step 8Go to Step 7

7 Remove the MAP sensor and check for the following conditions.

• Objects blocking the air cleaner.

• Objects blocking the MAP sensor.

• Objects blocking the throttle valve.

• Vacuum leaking at intake duct.

• Vacuum leaking at throttle body.

If a problem is found, repair as necessary.

Was the problem found? — Verify repair Go to Step 13

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 2383 of 6020

ENGINE DRIVEABILITY AND EMISSIONS 6E–213

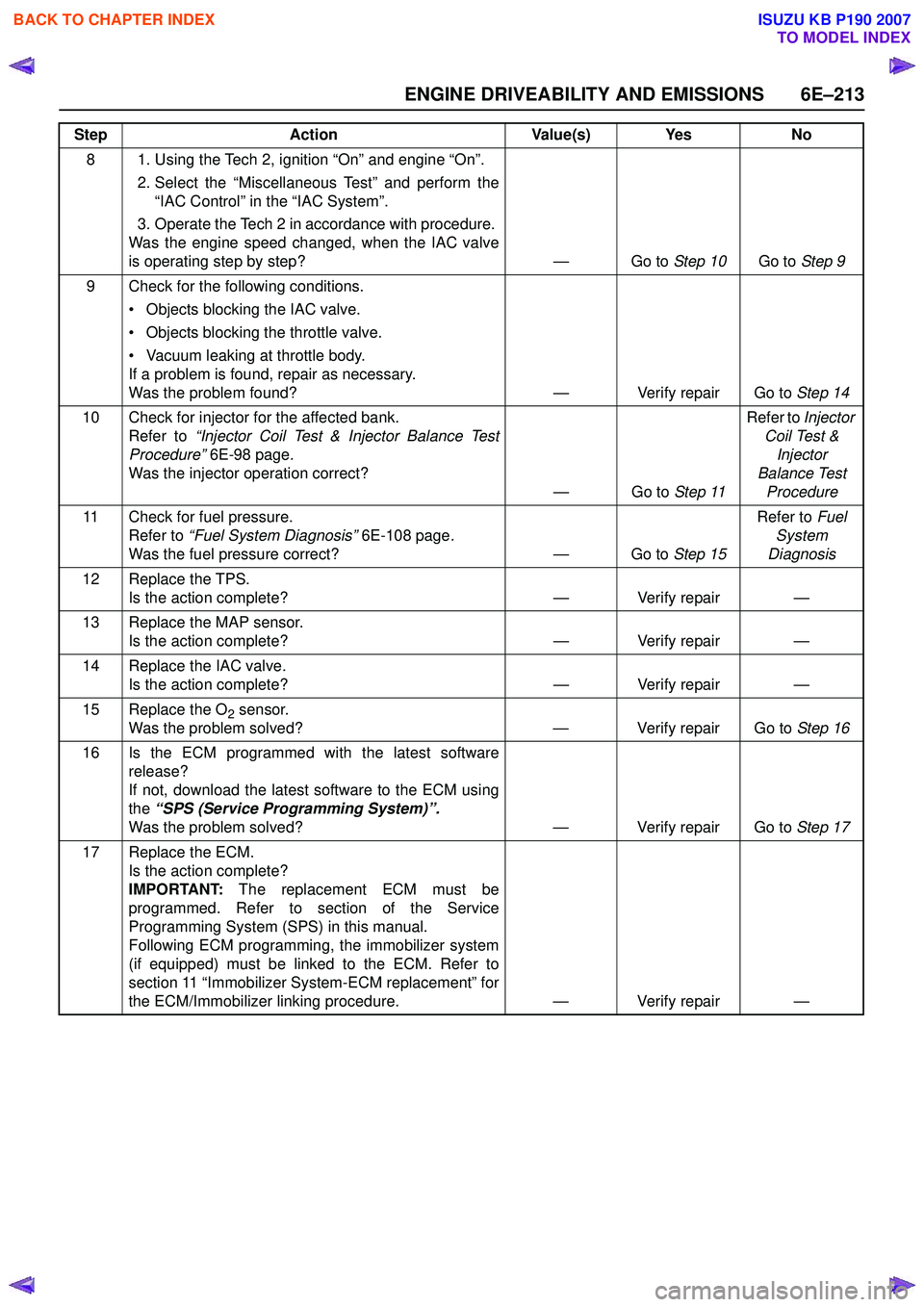

8 1. Using the Tech 2, ignition “On” and engine “On”. 2. Select the “Miscellaneous Test” and perform the“IAC Control” in the “IAC System”.

3. Operate the Tech 2 in accordance with procedure.

Was the engine speed changed, when the IAC valve

is operating step by step? — Go to Step 10Go to Step 9

9 Check for the following conditions. • Objects blocking the IAC valve.

• Objects blocking the throttle valve.

• Vacuum leaking at throttle body.

If a problem is found, repair as necessary.

Was the problem found? — Verify repair Go to Step 14

10 Check for injector for the affected bank. Refer to “Injector Coil Test & Injector Balance Test

Procedure” 6E-98 page .

Was the injector operation correct? —Go to Step 11Refer to

Injector

Coil Test & Injector

Balance Test Procedure

11 Check for fuel pressure. Refer to “Fuel System Diagnosis” 6E-108 page.

Was the fuel pressure correct? — Go to Step 15Refer to

Fuel

System

Diagnosis

12 Replace the TPS. Is the action complete? — Verify repair —

13 Replace the MAP sensor. Is the action complete? — Verify repair —

14 Replace the IAC valve. Is the action complete? — Verify repair —

15 Replace the O

2 sensor.

Was the problem solved? — Verify repair Go to Step 16

16 Is the ECM programmed with the latest software release?

If not, download the latest software to the ECM using

the “SPS (Service Programming System)”.

Was the problem solved? — Verify repair Go to Step 17

17 Replace the ECM. Is the action complete?

IMPORTANT: The replacement ECM must be

programmed. Refer to section of the Service

Programming System (SPS) in this manual.

Following ECM programming, the immobilizer system

(if equipped) must be linked to the ECM. Refer to

section 11 “Immobilizer System-ECM replacement” for

the ECM/Immobilizer linking procedure. — Verify repair —

Step

Action Value(s) Yes No

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 2385 of 6020

ENGINE DRIVEABILITY AND EMISSIONS 6E–215

Diagnostic Aids

Check for the following conditions:

• Heated oxygen sensor wiring - The sensor pigtail may be routed incorrectly and contacting the exhaust

system.

• Poor ECM to engine block ground.

• Fuel pressure - The system will go lean if pressure is too low. The ECM can compensate for some

decrease. However, if fuel pressure is too low, a

diagnostic Trouble Code P1171 may be set. Refer to

Fuel System Diagnosis .

• Lean injector(s) - Perform “Injector Balance Test.” • Vacuum leaks - Check for disconnected or damaged

vacuum hoses and for vacuum leaks at the intake

manifold, throttle body, and PCV system.

• Exhaust leaks - An exhaust leak may cause outside air to be pulled into the exhaust gas stream past the

HO2S, causing the system to appear lean. Check for

exhaust leaks that may cause a false lean condition

to be indicated.

• Fuel contamination - Water, even in small amounts, can be delivered to the fuel injectors. The water can

cause a lean exhaust to be indicated, Excessive

alcohol in the fuel can also cause this condition.

Refer to Fuel System Diagnosis for the procedure to

check for fuel contamination.

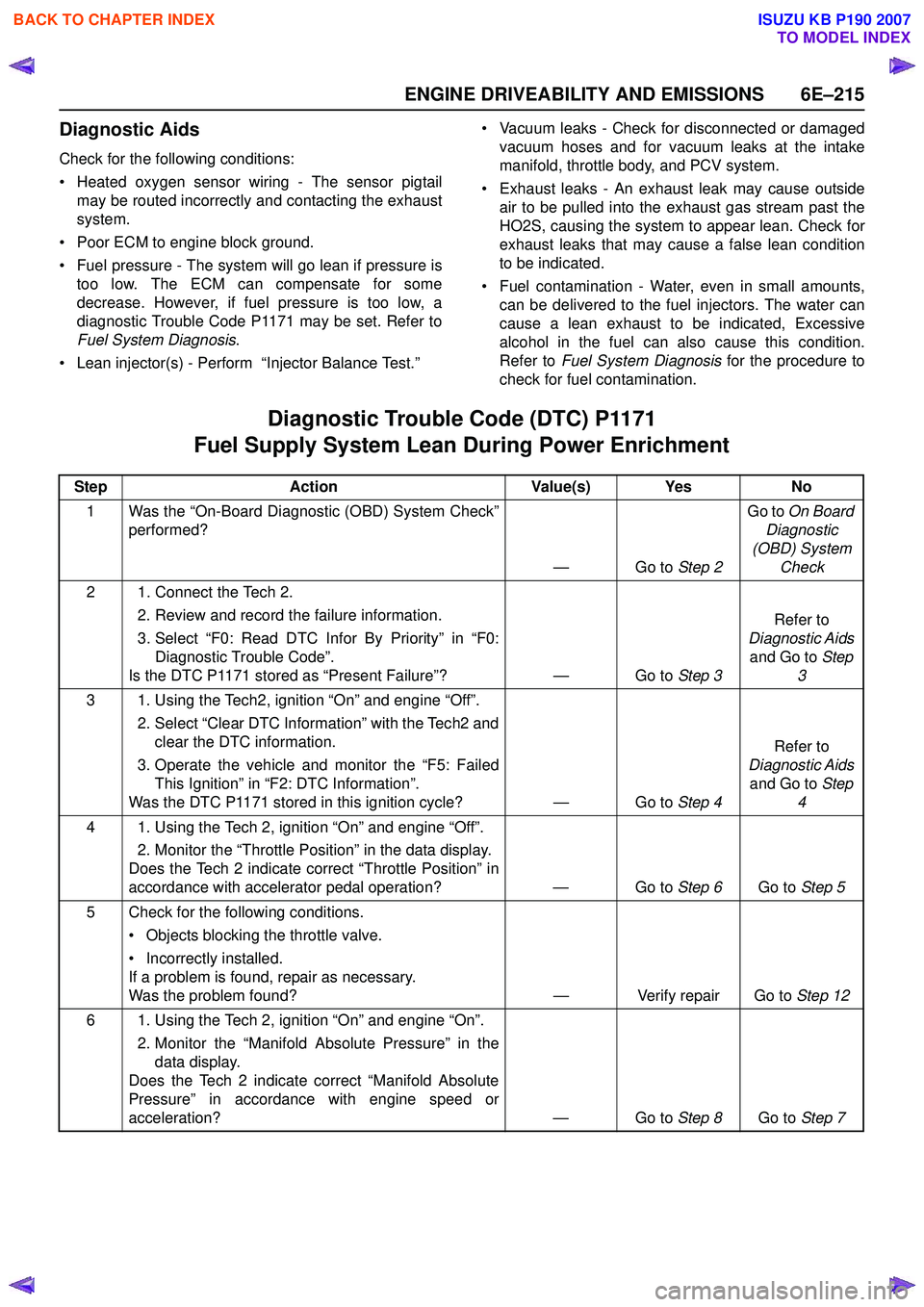

Diagnostic Trouble Code (DTC) P1171

Fuel Supply System Lean During Power Enrichment

Step Action Value(s) Yes No

1 Was the “On-Board Diagnostic (OBD) System Check” performed?

—Go to Step 2Go to

On Board

Diagnostic

(OBD) System Check

2 1. Connect the Tech 2. 2. Review and record the failure information.

3. Select “F0: Read DTC Infor By Priority” in “F0: Diagnostic Trouble Code”.

Is the DTC P1171 stored as “Present Failure”? — Go to Step 3Refer to

Diagnostic Aids and Go to Step

3

3 1. Using the Tech2, ignition “On” and engine “Off”. 2. Select “Clear DTC Information” with the Tech2 andclear the DTC information.

3. Operate the vehicle and monitor the “F5: Failed This Ignition” in “F2: DTC Information”.

Was the DTC P1171 stored in this ignition cycle? — Go to Step 4Refer to

Diagnostic Aids and Go to Step

4

4 1. Using the Tech 2, ignition “On” and engine “Off”. 2. Monitor the “Throttle Position” in the data display.

Does the Tech 2 indicate correct “Throttle Position” in

accordance with accelerator pedal operation? — Go to Step 6Go to Step 5

5 Check for the following conditions. • Objects blocking the throttle valve.

• Incorrectly installed.

If a problem is found, repair as necessary.

Was the problem found? — Verify repair Go to Step 12

6 1. Using the Tech 2, ignition “On” and engine “On”. 2. Monitor the “Manifold Absolute Pressure” in thedata display.

Does the Tech 2 indicate correct “Manifold Absolute

Pressure” in accordance with engine speed or

acceleration? — Go to Step 8Go to Step 7

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 2386 of 6020

6E–216 ENGINE DRIVEABILITY AND EMISSIONS

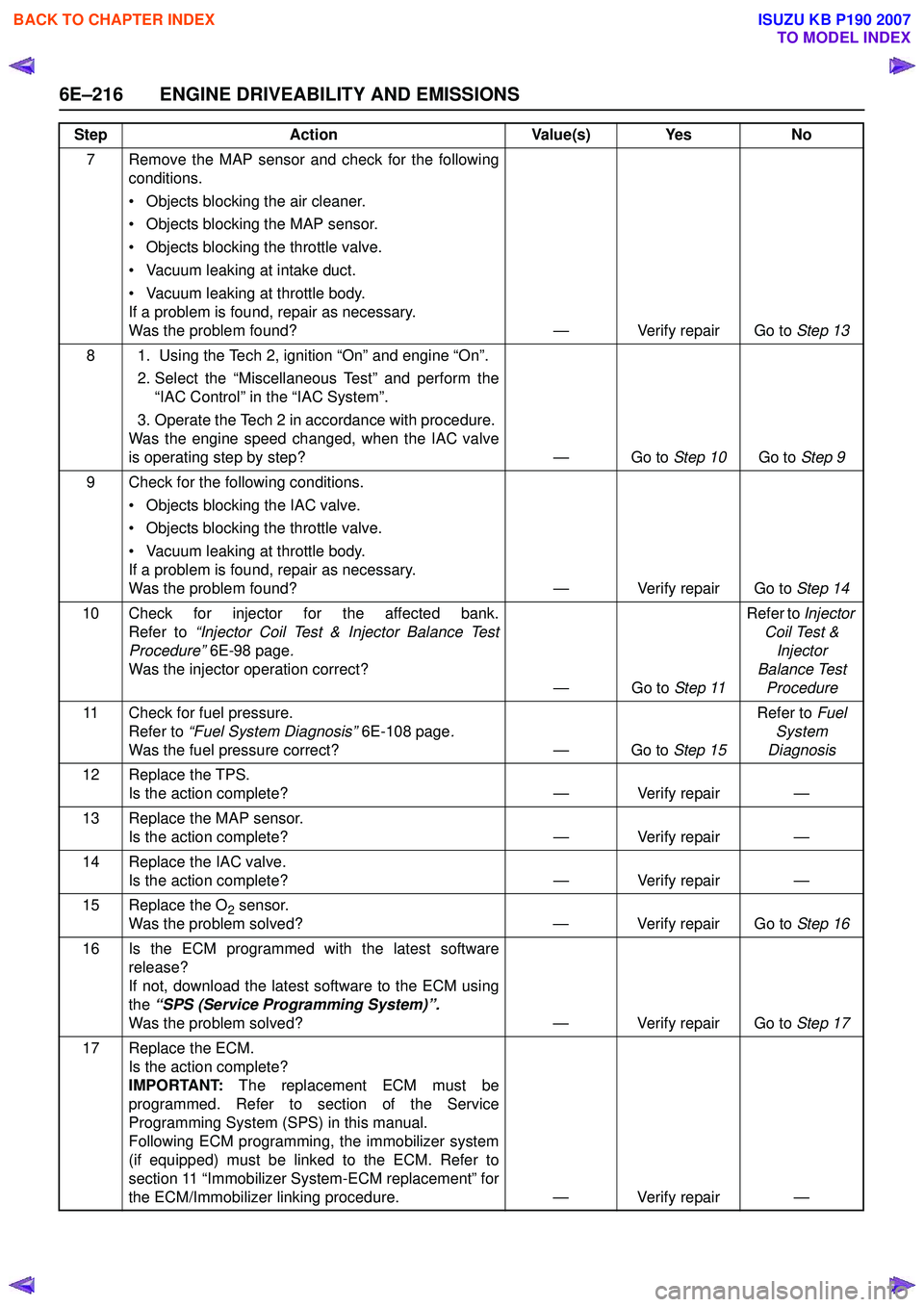

7 Remove the MAP sensor and check for the followingconditions.

• Objects blocking the air cleaner.

• Objects blocking the MAP sensor.

• Objects blocking the throttle valve.

• Vacuum leaking at intake duct.

• Vacuum leaking at throttle body.

If a problem is found, repair as necessary.

Was the problem found? — Verify repair Go to Step 13

8 1. Using the Tech 2, ignition “On” and engine “On”. 2. Select the “Miscellaneous Test” and perform the“IAC Control” in the “IAC System”.

3. Operate the Tech 2 in accordance with procedure.

Was the engine speed changed, when the IAC valve

is operating step by step? — Go to Step 10Go to Step 9

9 Check for the following conditions. • Objects blocking the IAC valve.

• Objects blocking the throttle valve.

• Vacuum leaking at throttle body.

If a problem is found, repair as necessary.

Was the problem found? — Verify repair Go to Step 14

10 Check for injector for the affected bank. Refer to “Injector Coil Test & Injector Balance Test

Procedure” 6E-98 page .

Was the injector operation correct? —Go to Step 11Refer to

Injector

Coil Test & Injector

Balance Test Procedure

11 Check for fuel pressure. Refer to “Fuel System Diagnosis” 6E-108 page.

Was the fuel pressure correct? — Go to Step 15Refer to

Fuel

System

Diagnosis

12 Replace the TPS. Is the action complete? — Verify repair —

13 Replace the MAP sensor. Is the action complete? — Verify repair —

14 Replace the IAC valve. Is the action complete? — Verify repair —

15 Replace the O

2 sensor.

Was the problem solved? — Verify repair Go to Step 16

16 Is the ECM programmed with the latest software release?

If not, download the latest software to the ECM using

the “SPS (Service Programming System)”.

Was the problem solved? — Verify repair Go to Step 17

17 Replace the ECM. Is the action complete?

IMPORTANT: The replacement ECM must be

programmed. Refer to section of the Service

Programming System (SPS) in this manual.

Following ECM programming, the immobilizer system

(if equipped) must be linked to the ECM. Refer to

section 11 “Immobilizer System-ECM replacement” for

the ECM/Immobilizer linking procedure. — Verify repair —

Step

Action Value(s) Yes No

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 2387 of 6020

ENGINE DRIVEABILITY AND EMISSIONS 6E–217

DIAGNOSTIC TROUBLE CODE (DTC) P1625 ECM SYSTEM RESET

Condition for setting the DTC and action taken when the DTC sets

Circuit Description

The engine control module (ECM) monitors unexpected

ECM reset. This will not turn on MIL light on, only

records code DTC P1625.

Diagnostic Aids

Check for the follwing conditions:

• P1625 alone stored does not need diagnosis. Clear DTC code.

NOTE: DTC P1625 is a DTC to record a ECM reset

history. If DTC P1625 is not reset and no engine

abnormality occurs after learing the DTC, no farther

diagnostic procedures are required.

Diagnostic Trouble Code (DTC) P1625 ECM System Reset

Code Type DTC Name DTC Setting Condition Fail-Safe (Back Up)

P1625 B ECM System Reset ECM reset has occurred other than “On”. Engine control disabled.

StepAction Value(s) Yes No

1 Was the “On-Board Diagnostic (OBD) System Check” performed?

—Go to Step 2Go to

On Board

Diagnostic

(OBD) System Check

2 1. Connect the Tech 2. 2. Review and record the failure information.

3. Select “F0: Read DTC Infor By Priority” in “F0: Diagnostic Trouble Code”.

Is the DTC P1625 stored as “Present Failure”? — Go to Step 3Refer to

Diagnostic Aids and Go to Step

3

3 1. Using the Tech2, ignition “On” and engine “Off”. 2. Select “Clear DTC Information” with the Tech2 andclear the DTC information.

3. Operate the vehicle and monitor the “F5: Failed This Ignition” in “F2: DTC Information”.

Was the DTC P1625 stored in this ignition cycle? — Go to Step 4Refer to

Diagnostic Aids and Go to Step

4

4 Is the Immobilizer function programmed in the ECM? — Verify repair Go to Step 5

5 Is the ECM programmed with the latest software release?

If not, download the latest software to the ECM using

the “SPS (Service Programming System)”.

Was the problem solved? — Verify repair Go to Step 6

6 Replace the ECM. Is the action complete?

IMPORTANT: The replacement ECM must be

programmed. Refer to section of the Service

Programming System (SPS) in this manual.

Following ECM programming, the immobilizer system

(if equipped) must be linked to the ECM. Refer to

section 11 “Immobilizer System-ECM replacement” for

the ECM/Immobilizer linking procedure. — Verify repair —

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 2388 of 6020

6E–218 ENGINE DRIVEABILITY AND EMISSIONS

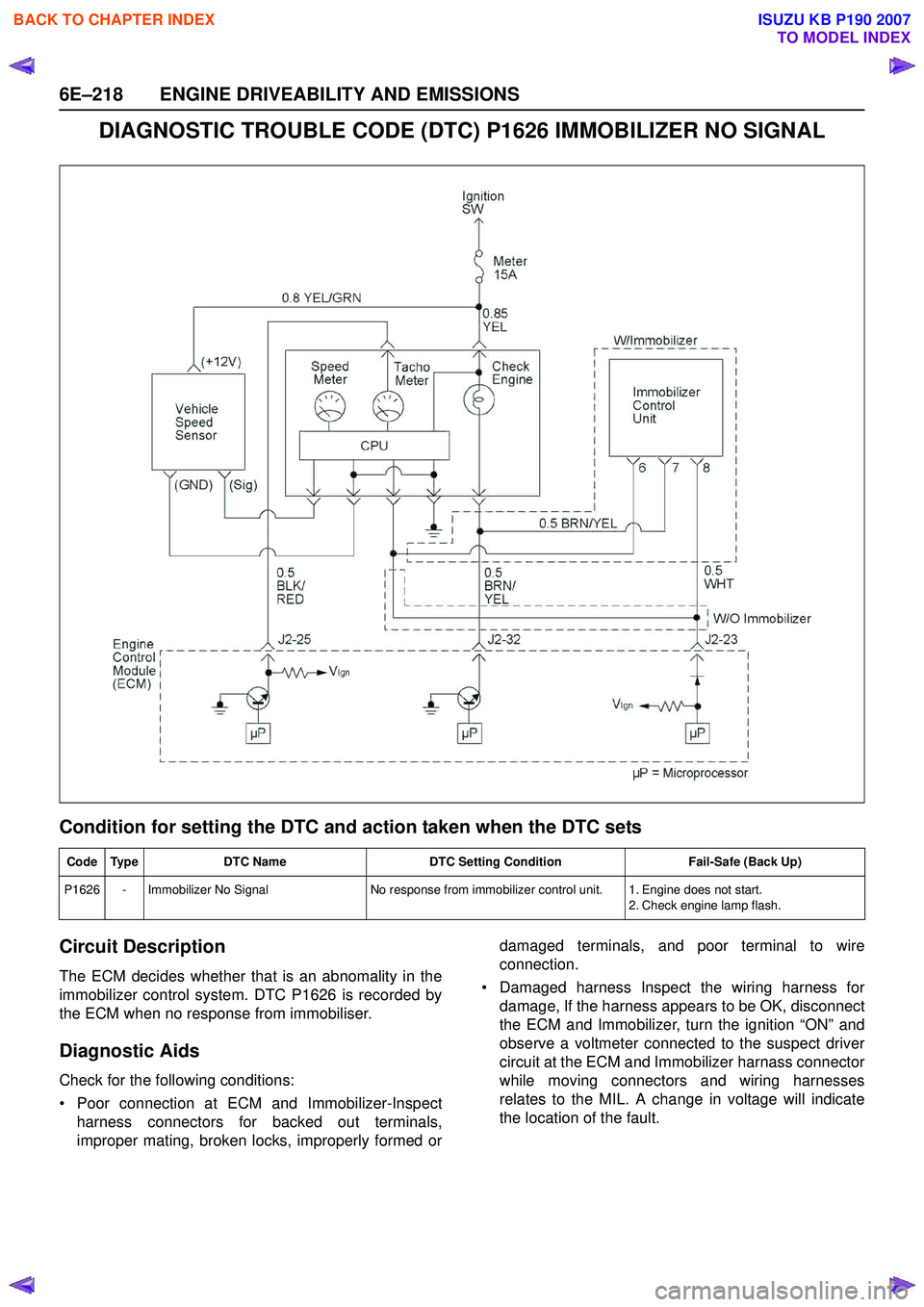

DIAGNOSTIC TROUBLE CODE (DTC) P1626 IMMOBILIZER NO SIGNAL

Condition for setting the DTC and action taken when the DTC sets

Circuit Description

The ECM decides whether that is an abnomality in the

immobilizer control system. DTC P1626 is recorded by

the ECM when no response from immobiliser.

Diagnostic Aids

Check for the following conditions:

• Poor connection at ECM and Immobilizer-Inspect harness connectors for backed out terminals,

improper mating, broken locks, improperly formed or damaged terminals, and poor terminal to wire

connection.

• Damaged harness Inspect the wiring harness for damage, If the harness appears to be OK, disconnect

the ECM and Immobilizer, turn the ignition “ON” and

observe a voltmeter connected to the suspect driver

circuit at the ECM and Immobilizer harnass connector

while moving connectors and wiring harnesses

relates to the MIL. A change in voltage will indicate

the location of the fault.

Code Type DTC Name DTC Setting Condition Fail-Safe (Back Up)

P1626 - Immobilizer No Signal No response from immobilizer control unit. 1. Engine does not start.

2. Check engine lamp flash.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 2389 of 6020

ENGINE DRIVEABILITY AND EMISSIONS 6E–219

Diagnostic Trouble Code (DTC) P1626 Immobilizer No Signal

StepAction Value(s) Yes No

1 Was the “On-Board Diagnostic (OBD) System Check” performed?

—Go to Step 2Go to

On Board

Diagnostic

(OBD) System Check

2 1. Connect the Tech 2. 2. Review and record the failure information.

3. Select “F0: Read DTC Infor By Priority” in “F0: Diagnostic Trouble Code”.

Is the DTC P1626 stored as “Present Failure”? — Go to Step 3Refer to

Diagnostic Aids and Go to Step

3

3 1. Using the Tech2, ignition “On” and engine “Off”. 2. Select “Clear DTC Information” with the Tech2 andclear the DTC information.

3. Operate the vehicle and monitor the “F5: Failed This Ignition” in “F2: DTC Information”.

Was the DTC P1626 stored in this ignition cycle? — Go to Step 4Refer to

Diagnostic Aids and Go to Step

4

4 1. Using the Tech 2, ignition “On” and engine “Off”. 2. Select “Immobilizer” in the system selection menu“Body”.

3. Select “Read DTC Info Ordered By Priority” in the “Diagnositic Trouble Code”.

Was the DTC B0007 stored in this ignition cycle? —Refer to

“Immobilizer Workshop

Manual” & Go to DTC Chart B0007 Go to Step 5

5 Check for poor/faulty connection at the immobilizer control unit connector or ECM connector. If a poor/

faulty connection is found, repair as necessary.

Was the problem found?

— Verify repair Go to Step 6

6 Using the DVM and check the “CHECK ENGINE” lamp circuit.

1. Ignition “Off”, engine “Off”.

2. Disconnect the meter connector and immobilizer control unit connector.

3. Ignition “On”.

4. Check the circuit for short to power supply circuit.

Was the problem found?

—Repair faulty

harness and verify repair Go to Step 7

3223 78

C-56(J2) B-68

VV

B-24

B-68

17

7

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007