check engine ISUZU KB P190 2007 Workshop Repair Manual

[x] Cancel search | Manufacturer: ISUZU, Model Year: 2007, Model line: KB P190, Model: ISUZU KB P190 2007Pages: 6020, PDF Size: 70.23 MB

Page 2357 of 6020

ENGINE DRIVEABILITY AND EMISSIONS 6E–187

mating, broken locks, improperly formed or damaged

terminals, and poor terminal-to-wire connections.

• Damaged harness - Inspect the wiring harness for damage; Open circuits, shorts to ground, or shorts to

Voltage. If the harness appears to be OK, observe the Tech 2 display related to DTC P0351 or P0352

while moving the connector and wiring related to the

ignition system. A change in the display will indicate

the location of the fault.

Diagnostic Trouble Code (DTC) P0351 Ignition 1 Control Circuit

Diagnostic Trouble Code (DTC) P0352 Ignition 2 Control Circuit

Step Action Value(s) Yes No

1 Was the “On-Board Diagnostic (OBD) System Check” performed?

—Go to Step 2Go to

On Board

Diagnostic

(OBD) System Check

2 1. Connect the Tech 2. 2. Review and record the failure information.

3. Select “F0: Read DTC Infor By Priority” in “F0: Diagnostic Trouble Code”.

Is the DTC P0351 or P0352 stored as “Present

Failure”? — Go to Step 3Refer to

Diagnostic Aids and Go to Step

3

3 1. Using the Tech2, ignition “On” and engine “Off”. 2. Select “Clear DTC Information” with the Tech2 andclear the DTC information.

3. Operate the vehicle and monitor the “F5: Failed This Ignition” in “F2: DTC Information”.

Was the DTC P0351 or P0352 stored in this ignition

cycle? — Go to Step 4Refer to

Diagnostic Aids and Go to Step

4

4 Check for poor/faulty connection at the ignition coil module or ECM connector. If a poor/faulty connection

is found, repair as necessary.

Was the problem found?

— Verify repair Go to Step 5

5 Visually check the ignition coil module. Was the problem found? — Go to Step 12Go to Step 6

19 18

E-60(J1) E-18

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 2358 of 6020

6E–188 ENGINE DRIVEABILITY AND EMISSIONS

6 Using the DVM and check the ignition coil modulesignal circuit for the affected coil.

1. Ignition “On”, engine “Off”.

2. Disconnect the ignition coil module connector.

3. Check the circuit for short to battery voltage circuit for the affected coil.

Was the DVM indicated battery voltage?

—Repair faulty

harness and verify repair Go to Step 7

Step Action Value(s) Yes No

E-181

11

1 Coil 2

V

E-183

33

3

Coil 1

V

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 2359 of 6020

ENGINE DRIVEABILITY AND EMISSIONS 6E–189

7 Using the DVM and check the ignition coil signalcircuit for the affected coil.

Breaker box is available:

1. Ignition “Off”, engine “Off”.

2. Install the breaker box as type A. (ECM disconnected) Refer to 6E-88 page.

3. Disconnect the ignition coil module connector.

4. Check the circuit for open or short to ground circuit for the affected coil.

Was the problem found?

Breaker box is not available: 1. Ignition “Off”, engine “Off”.

2. Disconnect the ignition coil module connector and ECM connector.

3. Check the circuit for open or short to ground circuit for the affected coil.

Was the problem found?

—Repair faulty

harness and verify repair Go to Step 8

Step Action Value(s) Yes No

J1-18Breaker BoxE-181Coil 2

ΩΩ

J1-19Breaker BoxE-183Coil 1

ΩΩ

E-181

Coil 2

ΩΩ

E-60(J1)1

8

E-183

Coi l 1

ΩΩ

E-60(J1)19

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 2360 of 6020

6E–190 ENGINE DRIVEABILITY AND EMISSIONS

8 Using the DVM and check the ignition coil modulepower supply circuit.

1. Ignition “On”, engine “Off”.

2. Disconnect the ignition coil module connector.

3. Check the circuit for open circuit.

Was the DVM indicated specified value?

10 - 14.5V Go to Step 10Go to Step 9

9 Repair the open or short to ground circuit between the “IGN. Coil” fuse (15A) and ignition coil module.

Is the action complete? — Verify repair —

10 Replace the ignition coil module. Was the problem solved? — Verify repair Go to Step 11

11 Is the ECM programmed with the latest software release?

If not, download the latest software to the ECM using

the “SPS (Service Programming System)”.

Was the problem solved? — Verify repair Go to Step 12

12 Replace the ECM. Is the action complete?

IMPORTANT: The replacement ECM must be

programmed. Refer to section of the Service

Programming System (SPS) in this manual.

Following ECM programming, the immobilizer system

(if equipped) must be linked to the ECM. Refer to

section 11 “Immobilizer System-ECM replacement” for

the ECM/Immobilizer linking procedure. — Verify repair —

Step

Action Value(s) Yes No

V

E-18

2

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 2361 of 6020

ENGINE DRIVEABILITY AND EMISSIONS 6E–191

DIAGNOSTIC TROUBLE CODE (DTC) P0443 EVAPORATIVE (EVAP) EMISSION CONTROL SYSTEM PURGE CONTROL CIRCUIT

Condition for setting the DTC and action taken when the DTC sets

Circuit Description

The Engine Control Module (ECM) controls the

Evaporative Emission (EVAP) Canister Purge Solenoid

Valve through the use of a control (ground) circuit. If the

ECM commands the Purge solenoid to maximum duty

cycle (100%) but the voltage remains High (12 Volts);

or, if the ECM commands the Purge solenoid to

minimum duty cycle (0%) but the voltage remains Low

(0 volts), then DTC P0443 will set.

Diagnostic Aids

• Poor connections, or a damaged harness - Inspect the harness connectors for: backed-out terminals,

improper mating or damaged terminals. Also check

for open circuits, shorts to ground, and shorts to

voltage.

Code Type DTC Name DTC Setting Condition Fail-Safe (Back Up)

P0443 B EVAP Emission Control System Purge Control Circuit EVAP purge solenoid circuit open, short to

ground or short to voltage circuit. No fail-safe function.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 2362 of 6020

6E–192 ENGINE DRIVEABILITY AND EMISSIONS

Diagnostic Trouble Code (DTC) P0443

EVAP Emission Control System Purge Control Circuit

Step Action Value(s) Yes No

1 Was the “On-Board Diagnostic (OBD) System Check” performed?

—Go to Step 2Go to

On Board

Diagnostic

(OBD) System Check

2 1. Connect the Tech 2. 2. Review and record the failure information.

3. Select “F0: Read DTC Infor By Priority” in “F0: Diagnostic Trouble Code”.

Is the DTC P0443 stored as “Present Failure”? — Go to Step 3Refer to

Diagnostic Aids and Go to Step

3

3 1. Using the Tech2, ignition “On” and engine “Off”. 2. Select “Clear DTC Information” with the Tech2 andclear the DTC information.

3. Operate the vehicle and monitor the “F5: Failed This Ignition” in “F2: DTC Information”.

Was the DTC P0443 stored in this ignition cycle? — Go to Step 4Refer to

Diagnostic Aids and Go to Step

4

4 Check for poor/faulty connection at the purge solenoid valve or ECM connector. If a poor/faulty connection is

found, repair as necessary.

Was the problem found?

— Verify repair Go to Step 5

5 Using the DVM and check the purge solenoid valve. 1. Ignition “Off”, engine “Off”.

2. Disconnect purge solenoid valve connector.

3. Measure the resistance of purge solenoid valve coil.

Does the tester indicate standard resistance?

25 - 30Ω at

20°C Go to Step 6Go to Step 9

5

E-60(J1)

E-66

21

EVAP Purge Solenoid

Ω

12

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 2363 of 6020

ENGINE DRIVEABILITY AND EMISSIONS 6E–193

6 Using the DVM and check the purge solenoid valvepower supply circuit.

1. Ignition “On”, engine “Off”.

2. Disconnect the purge solenoid valve connector.

3. Check the circuit for open circuit.

Was the DVM indicated specified value?

10 - 14.5V Go to Step 8Go to Step 7

7 Repair the open or short to ground circuit between the “Engine” fuse (15A) and purge solenoid valve.

Is the action complete? — Verify repair -

8 Using the DVM and check the purge solenoid valve solenoid signal circuit.

Breaker box is available:

1. Ignition “Off”, engine “Off”.

2. Install the breaker box as type A. (ECM disconnected) Refer to 6E-88 page.

3. Disconnect the purge solenoid valve connector.

4. Check the circuit for open or short to ground circuit.

Was the problem found?

Breaker box is not available:

1. Ignition “Off”, engine “Off”.

2. Disconnect the purge solenoid valve connector and ECM connector.

3. Check the circuit for open or short to ground circuit.

Was the problem found?

—Repair faulty

harness and verify repair Go to Step 9

Step Action Value(s) Yes No

V

E-66

2

J1-5Breaker BoxE-66

Ω

1

E-66

E-60(J1)

51

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 2364 of 6020

6E–194 ENGINE DRIVEABILITY AND EMISSIONS

9 Using the DVM and check the purge solenoid valvesignal circuit.

1. Ignition “On”, engine “Off”.

2. Disconnect the purge solenoid valve connector.

3. Check the circuit for short to voltage circuit.

Was the DVM indicated voltage?

—Repair faulty

harness and verify repair Go to Step 10

10 Substitute a known good purge solenoid valve and recheck.

Was the problem solved? — Go to Step 11Go to Step 12

11 Replace the purge solenoid valve. Was the problem solved? — Verify repair Go to Step 12

12 Is the ECM programmed with the latest software release?

If not, download the latest software to the ECM using

the “SPS (Service Programming System)”.

Was the problem solved? — Verify repair Go to Step 13

13 Replace the ECM. Is the action complete?

IMPORTANT: The replacement ECM must be

programmed. Refer to section of the Service

Programming System (SPS) in this manual.

Following ECM programming, the immobilizer system

(if equipped) must be linked to the ECM. Refer to

section 11 “Immobilizer System-ECM replacement” for

the ECM/Immobilizer linking procedure. — Verify repair —

Step

Action Value(s) Yes No

V

E-66

1

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 2366 of 6020

6E–196 ENGINE DRIVEABILITY AND EMISSIONS

Diagnostic Trouble Code (DTC) P0502 Vehicle Speed Sensor Circuit Low Input

StepAction Value(s) Yes No

1 Was the “On-Board Diagnostic (OBD) System Check” performed?

—Go to Step 2Go to

On Board

Diagnostic

(OBD) System Check

2 1. Connect the Tech 2. 2. Review and record the failure information.

3. Select “F0: Read DTC Infor By Priority” in “F0: Diagnostic Trouble Code”.

Is the DTC P0502 stored as “Present Failure”? — Go to Step 3Refer to

Diagnostic Aids and Go to Step

3

3 1. Using the Tech2, ignition “On” and engine “Off”. 2. Select “Clear DTC Information” with the Tech2 andclear the DTC information.

3. Operate the vehicle and monitor the “F5: Failed This Ignition” in “F2: DTC Information”.

Was the DTC P0502 stored in this ignition cycle? — Go to Step 4Refer to

Diagnostic Aids and Go to Step

4

4 Check for poor/faulty connection at the VSS, meter, immobilizer control unit (if equipped), ECM and other

connectors. If a poor/faulty connection is found, repair

the faulty terminal.

Was the problem found?

— Verify repair Go to Step 5

5 Remove the VSS from the housing case and visually check.

Was the problem found? — Go to Step 19Go to Step 6

6 8

23

27

910

C-56(J2)

B-68

B-24

E-44

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 2367 of 6020

ENGINE DRIVEABILITY AND EMISSIONS 6E–197

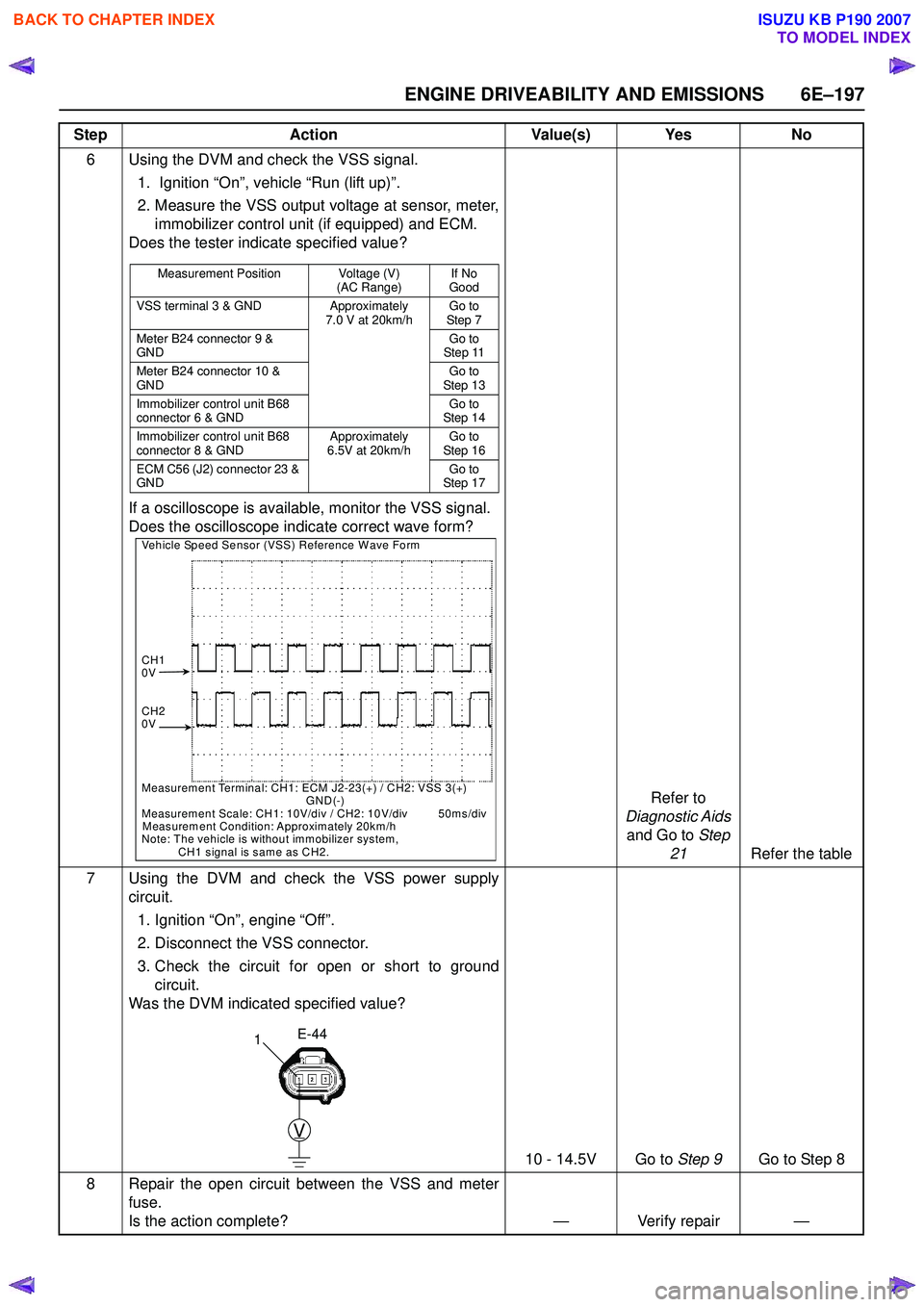

6 Using the DVM and check the VSS signal.1. Ignition “On”, vehicle “Run (lift up)”.

2. Measure the VSS output voltage at sensor, meter, immobilizer control unit (if equipped) and ECM.

Does the tester indicate specified value?

If a oscilloscope is available, monitor the VSS signal.

Does the oscilloscope indicate correct wave form?

Refer to

Diagnostic Aids

and Go to Step

21 Refer the table

7 Using the DVM and check the VSS power supply circuit.

1. Ignition “On”, engine “Off”.

2. Disconnect the VSS connector.

3. Check the circuit for open or short to ground circuit.

Was the DVM indicated specified value?

10 - 14.5V Go to Step 9Go to Step 8

8 Repair the open circuit between the VSS and meter fuse.

Is the action complete? — Verify repair —

Step

Action Value(s) Yes No

Measurement Position Voltage (V)

(AC Range)If No

Good

VSS terminal 3 & GND Approximately 7.0 V at 20km/hGo to

Step 7

Meter B24 connector 9 &

GND Go to

Step 11

Meter B24 connector 10 &

GND Go to

Step 13

Immobilizer control unit B68

connector 6 & GND Go to

Step 14

Immobilizer control unit B68

connector 8 & GND Approximately

6.5V at 20km/h Go to

Step 16

ECM C56 (J2) connector 23 &

GND Go to

Step 17

Vehicle Speed Sensor (VSS) Reference Wave Form

CH1

0V

CH2

0V

Measurement Terminal: CH1: ECM J2-23(+) / CH2: VSS 3(+)

GND(-)

Measurement Scale: CH1: 10V/div / CH2: 10V/div 50ms/div

Measurement Condition: Approximately 20km/h

Note: The vehicle is without immobilizer system,

CH1 signal is same as CH2.

V

E-44

1

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007