key ISUZU KB P190 2007 Workshop Manual PDF

[x] Cancel search | Manufacturer: ISUZU, Model Year: 2007, Model line: KB P190, Model: ISUZU KB P190 2007Pages: 6020, PDF Size: 70.23 MB

Page 1967 of 6020

6E-350 ENGINE CONTROL SYSTEM (4JK1/4JJ1)

• The hardware key is plugged into the computerport.

• Vehicle system voltage: - There are no charging system concerns. Allcharging system concerns must be repaired

before programming the ECM.

- The battery voltage is greater than 12 volts but less than 16 volts. The battery must be fully

charged before programming the ECM.

- A battery charger is NOT connected to the vehicles battery. Incorrect system voltage or

voltage fluctuations from a battery charger may

cause programming failure or ECM damage.

- Turn OFF or disable any system that may put a load on the vehicles battery. Turn OFF or

disable systems such as:

◊ Heating, ventilation, and air conditioning

(HVAC) systems

◊ Headlights

◊ Room lights

◊ Accessory equipment

• The ignition switch is in the proper position. The scan tool prompts you to turn ON the ignition, with

the engine OFF. DO NOT change the position of

the ignition switch during the programming

procedure unless instructed to do so.

• All tool connections are secure: - The RS-232 cable

- The connection at the DLC

- The voltage supply circuits

• DO NOT disturb the tool harnesses while programming. If an interruption occurs during the

programming procedure, programming failure or

ECM damage may occur.

• If you are performing the Pass-Thru programming procedure using a notebook computer without the

power cord, ensure that the internal battery is fully

charged.

Service Programming System (SPS)

(Remote Procedure)

Notice: Some module will not accept SPS remote

procedure using 10MB PCMCIA card. In such case,

use 32MB PCMCIA card or SPS pass-thru procedure.

The Remote SPS method is a three-step process that

involves the following procedures:

1. Connecting the scan tool to the vehicle and obtaining the information from the ECM.

2. Connecting the scan tool to the terminal and downloading a new calibration file from the

terminal into the scan tool memory.

3. Reconnecting the scan tool to the vehicle and uploading the new calibration file into the ECM. Performing the Remote Procedure

1. Connect a scan tool to the vehicle and obtain the ECM information using the following procedure:

Notice: Ensure the ECM is installed in the vehicle and

the battery is fully charged before programming.

a. Install a scan tool.

b. Turn ON the ignition, with the engine OFF.

c. Select Service Programming System (SPS) > Request Info.

d. If there is already stored in the scan tool, the existing data is displayed on the screen. The

scan tool asks user to keep existing data "Keep

Data" or "Continue" to request new vehicle

information from the ECM. If there is no data in

the scan tool, it will immediately start vehicle

identification.

e. Select the vehicle description by following the on-screen instructions based on stamped VIN

or affixed VIN plate on the vehicle.

f. During obtaining information, the scan tool is receiving information from all modules at the

same time. But only ECM information is

displayed on the screen.

g. Turn OFF all accessories and press "Okay".

h. Verify that the correct VIN is displayed on the scan tool. If the VIN is incorrect or no VIN,

record the correct VIN.

2. Turn OFF the ignition.

3. Turn OFF the scan tool and disconnect from the vehicle.

4. Transfer the data from the terminal to the scan tool using the following procedure:

Notice: The TIS supports service programming with

the Tech 2 scan tool only.

a. Connect the scan tool to the terminal.

b. Launch the TIS application.

c. Select the Service Programming System at the main screen.

d. Highlight the following information on the Select Diagnostic Tool and Programming Process

screen, then click "Next".

• Select Diagnostic Tool - Tech 2

• Select Programming Process - Identify whether an existing ECM is being

reprogrammed or an ECM is being replaced

with a new one

• Select ECU Location - Vehicle

e. Verify the connections on the Preparing for Communication screen, then click "Next".

f. Verify the VIN on the Validate Vehicle Identification Number (VIN) screen, then click

"Next".

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 1981 of 6020

6E-364 ENGINE CONTROL SYSTEM (4JK1/4JJ1)

Fuel Injection System Description

Fuel Injection Quantity Control

This control determines the fuel injection quantity by

adding coolant temperature, fuel temperature, intake

air temperature, barometric pressure, mass air flow and

some switch inputs information corrections to the basic

injection quantity is calculated by the ECM based on

the engine operating conditions (engine speed,

accelerator pedal pressing amount and boost pressure

sensor). More fuel rate indicates if the engine load is

increased as the accelerator pedal is stepped on at

constant engine speed.

Combined with high pressure injection of atomized fuel,

this control improves exhaust gas and ensures proper

fuel consumption. Compared with conventional

mechanical governors, an electronic control system

provides higher degree of freedom of fuel injection

quantity control, thereby presenting high accelerator

response (acceleration feeling and pressing feeling).

Starting Injection Quantity Control

At the engine starting (after the key switch is turned to

the START position to start the engine, up to return of

key switch to the ON position), optimum fuel injection

quantity is controlled based on the information on the

engine speed and coolant temperature. At low

temperature, the fuel injection quantity increases.

When the engine started completely, this boosted

quantity mode at the starting is cancelled and normal

running mode is restored.

Idle Speed Control

A control is made so as to achieve stable idling speed

at all time regardless of engine secular changes or

engine condition variations. The ECM sets target idling

speed and controls the fuel injection quantity according

to the engine conditions (actual engine speed, coolant

temperature and engine load) to follow actual engine

speed to the target idling speed so as to ensure stable

idling speed.

Idle Vibration Control

A control is made so as to reduce the engine vibration

caused by torque variations between cylinders due to

variations in fuel injection quantity of each cylinder or

injector performance. The ECM corrects the injection

quantity between cylinders based on the revolution

signals from the crankshaft position (CKP) sensor.

Normal range of correction quantity between cylinders

is within ±5 mm

3.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 2129 of 6020

ENGINE FUEL (C24SE) 6C-11

140R100028

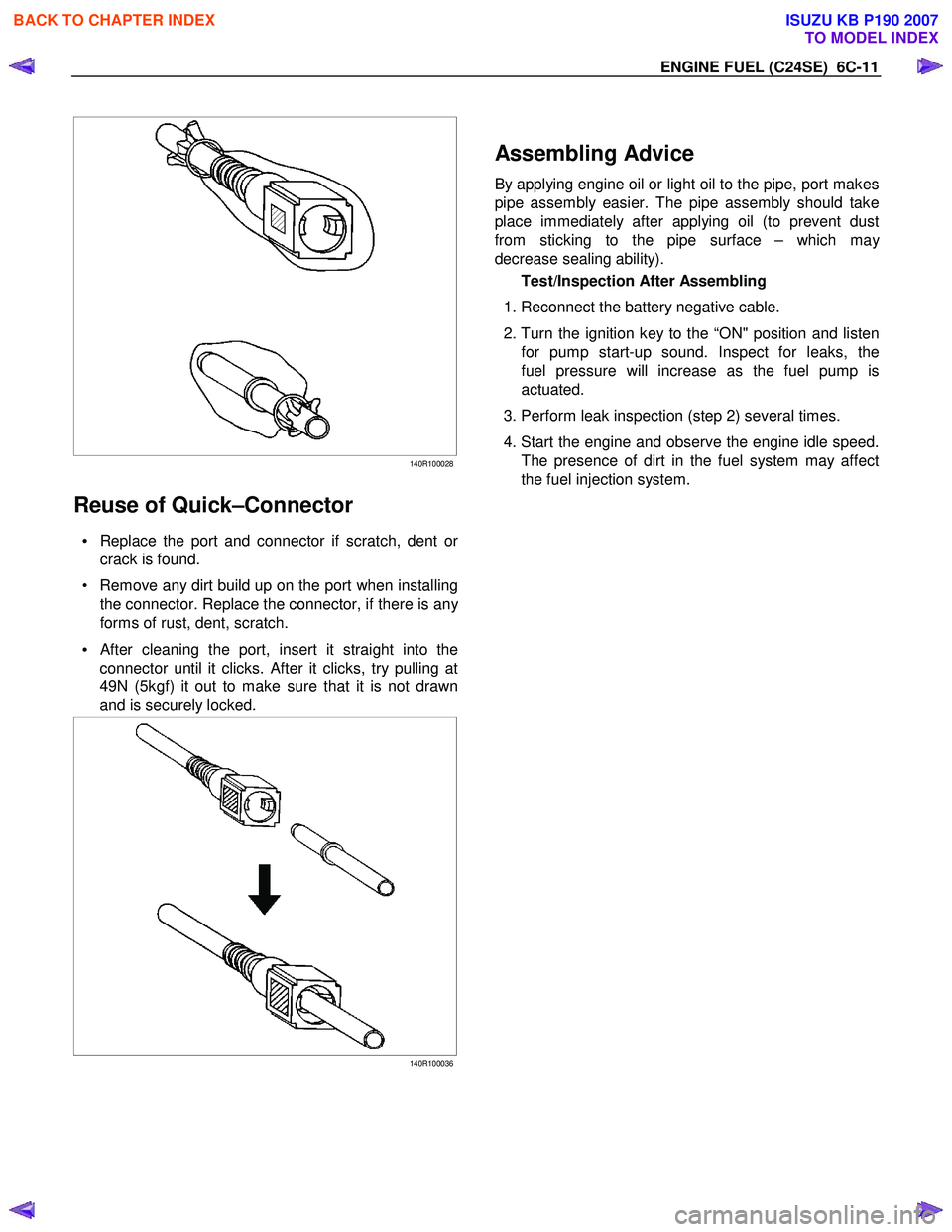

Reuse of Quick–Connector

• Replace the port and connector if scratch, dent or

crack is found.

• Remove any dirt build up on the port when installing the connector. Replace the connector, if there is an

y

forms of rust, dent, scratch.

•

After cleaning the port, insert it straight into the

connector until it clicks. After it clicks, try pulling at

49N (5kgf) it out to make sure that it is not drawn

and is securely locked.

140R100036

Assembling Advice

By applying engine oil or light oil to the pipe, port makes

pipe assembly easier. The pipe assembly should take

place immediately after applying oil (to prevent dust

from sticking to the pipe surface – which ma

y

decrease sealing ability).

Test/Inspection After Assembling

1. Reconnect the battery negative cable.

2. Turn the ignition key to the “ON" position and listen

for pump start-up sound. Inspect for leaks, the

fuel pressure will increase as the fuel pump is

actuated.

3. Perform leak inspection (step 2) several times.

4. Start the engine and observe the engine idle speed.

The presence of dirt in the fuel system may affect

the fuel injection system.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 2162 of 6020

6D3-14 STARTING AND CHARGING SYSTEM

7. To remove the pulley, mount an 8mm Allen key in the vice

with the short end upwards, place a 24mm ring spanner on

the puley nut, position the internal hexagon of the roto

r

shaft onto the Allen ken, loosen the nut and remove the

pulley.

Note: the pulley has an integral boss which locks up against

the bearing,

therefore no thrust collar is provided.

8. Removing the rotor assembly. Remove the four retaining screws from the drive end housing, withdraw the roto

r

complete with the bearing.

Note: the rotor must not be pressed from the drive end housing

using a press as the bearing retaining plate and drive end

housing will be damaged or distorted. Parts removed in this

way must be replaced if the integrity of the generator is to be

maintained.

9. Remove the drive end bearing from the rotor shaft using a

chuck type puler, take care not to distort the fan assembl

y

during this process.

10. Remove the slipring end bearing using the same meghod as in 9.

Clean

Thoroughly clean all components except the rotor and stator

with an approved cleaning agent. Ensure that all traced of oil

and dirt are removed. If an abrasive cleaner is used to remove

scale and paint from the housings take care not to abrade the

bearing and mounting spigot surfaces. The rotor and stator

must be cleaned with compressed air only, the use of solvents

could cause damage to the insulating materials.

Inspection

1. Rectifier assembly

The following test equipment is required.

The recitifier assembly is not repairable and must be replaced

if a faulty diode is detected during inspection.

(a)

Adiode tester where the DC output at the test probes does

not exceed 14 volts or in the case of AC testers 12 volts

RMS. This is to ensue that when inspection rectifiers fitted

with zener power diodes the forward and reverse checks

are completer and are not masked by the diode turning on

due to the zener breakdown voltage.

(b) A zenere diode tester with a DC output in excess of 30 volts, the tester should also incorporate internal current

limiting set to 5 Ma. to prevent high currents during

inspection.

(c) Diodes can be destroyed during service due to high temperature and overload, open circuits are usually a result

of excessive voltage.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 2166 of 6020

6D3-18 STARTING AND CHARGING SYSTEM

Reassembly

Generator

(a) Press new bearing onto slipring end of the rotor taking care to aplly the force to the bearing inner race only, otherwise

the bearing will be noisy and it's life will be shortened.

(b) Fit a new bearing to the drive end housing, fit the bearing plate, and four retaining screws, press the rotor into the

bearing, using a support tool to take the thrust against the

bearing inner.

The support is fitted from the pulley side of the bearing. In this way the thrust is not taken by the drive end housing.

(c) To fit pulley, mount an 8mm Allen key in the vice with the short end upwards, place a 24mm ring spanner on the shaft

nut, position the internal hexagon of the rotor shaft onto the

Allen key, tighten the nut to the required torque(See torque

chart)

(d) Inspect the bearing support ring for signs of damage, if in doubt replace the ring by pressing it into the housing b

y

hand, do not use excessive force.

(e) To refit the rectifier, fit new mica washers to the positive heatsink B+ bolt and retaining screw each washer must

have heatsink compound applied to both surfaces before

fitting.

Fit the three retaining screws to the rectifier then install into slipring end housing. Tighten the B+ bolt to the reuired

torque.

(f) To refit the stator, make sure the spigot surface are clean and free from damage, fit the stator into the slipring end

housing noting the correct lead connection positioning. Fit

the stator leads into the wire loops in the recrifier. Using a

pair of pliers squeeze the loop to retain the stator lead prior

to soldering. Repeat for each lead in turn, solder the leads

into position using 60/40 resin cored solder. Make sure the

leads will be clear of the internal fan when the rotor is

assmebled into the stator.

(g) Carefully install the rotor into the stator/slipring end housing assembly, noting the alignment of the housings and through

bolt holes. Fit the through bolts making sure the stator is

seated correctly, tighten the through bolts to the correct

torque setting (uneven torque can produce magnetic noise

levels above normal).

(h) Fitting the regulator. Compress the brushes into the brush holder by hand, slip the regulator through the opening in the

rear of the slipring end housing until the brushes come in

contact with the slipring. Press the regulator towards the

slipring until the holes are aligned then fit the retaining

screws and tighten.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 2212 of 6020

6E–42 ENGINE DRIVEABILITY AND EMISSIONS

ECM CONNECTOR PIN ASSIGNMENT & OUTPUT SIGNAL

Connector J1 Port: View Looking Into ECM Case

1

17 16

32

PIN16

PIN1

PIN17 PIN32

Pin

No. B/

Box

No. Pin Function

Wire

Color Signal or Continuity

ECM

Connection Tester Position

Key SW Off Key SW

On Engine

Idle Engine

2000rpm Range (+) (-)

J1-1 J1-1 Ground BLK/

WHT Continuity

with

ground -

- - Disconnect ΩJ1-1 GND

J1-2 J1-2 Ground BLK/

WHT Continuity

with

ground -

- - Disconnect ΩJ1-2 GND

J1-3 J1-3 Knock Sensor Signal YEL Less than 1V--- ----

J1-4 J1-4 No Connection - --- - -- - -

J1-5 J1-5 Canister Purge Solenoid Valve RED/

YEL Less than

1V Wave form G or 12-14V

Connect DC V J1-5 GND

J1-6 J1-6 Crankshaft Position (CKP) Sensor (Ground) RED Approx.

0.58kΩ -

- - Disconnect ΩJ1-6 J1-21

J1-7 J1-7 Throttle Position Sensor (TPS) Output

Signal BLU Less than

1V Approx 0.7V Approx

0.8VConnect DC V J1-7 J1-32

J1-8 J1-8 No. 3 Injector GRN/

BLK Less than

1V Wave form E or 12-14V

Connect DC V J1-8 GND

J1-9 J1-9 No. 1 Injector GRN/

WHT Less than

1V Wave form E or 12-14V

Connect DC V J1-9 GND

J1-10 J1-10 No Connection - --- - -- - -

J1-11 J1-11 No. 4 Injector GRN Less than

1V Wave form E or 12-14V

Connect DC V J1-11 GND

J1-12 J1-12 No Connection - --- - -- - -

J1-13 J1-13 Idle Air Control Valve (IACV) Coil B High BLU/

RED Less than

1V Less than 1V / 10-14V

Connect DC V J1-13 GND

J1-14 J1-14 No Connection - --- - -- - -

J1-15 J1-15 Throttle Position Sensor (TPS) Power

Supply RED Less than

1V Approx. 5V

Connect DC V J1-15 J1-32

J1-16 J1-16 MAP Sensor Ground GRN Continuity with

ground -

- - Connect ΩJ1-16 GND

J1-17 J1-17 Ground BLK/

WHT Continuity

with

ground -

- - Connect ΩJ1-17 GND

J1-18 J1-18 Coil Module 2 (No. 2 & 3 Cylinder) BLU -

-Wave form F -- - -

J1-19 J1-19 Coil Module 1 (No. 1 & 4 Cylinder) GRN -

-Wave form F -- - -

J1-20 J1-20 No Connection - --- - -- - -

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 2213 of 6020

ENGINE DRIVEABILITY AND EMISSIONS 6E–43

J1-21 J1-21 Crankshaft Position (CKP) Sensor Signal WHT - - Wave form

or approx. 3.7V Wave form

A or

approx. 7.8V Connect AC V J1-21 J1-6

J1-22 J1-22 No.2 Injector GRN/

WHT Less than

1V Wave form E or 12-14V

Connect DC V J1-22 GND

J1-23 J1-23 No Connection - --- - -- - -

J1-24 J1-24 MAP Sensor Signal GRY Less than 1VApprox.

4.8V Approx.

1.3V Approx.

0.9V Connect DC V J1-24 J1-16

J1-25 J1-25 No Connection - --- - -- - -

J1-26 J1-26 No Connection - --- - -- J1-26 -

J1-27 J1-27 Engine Coolant Temp. (ECT) Sensor Signal GRY Less than

1V

20℃: Approx. 2.4V / 40 ℃: Approx. 1.4V or

4.1V / 60 ℃: Approx. 3.3V / 80 ℃: Approx.

2.5VConnect DC V J1-27 J1-32

J1-28 J1-28 Idle Air Control Valve (IACV) Coil A High BLU Less than

1V Less than 1V / 10-14V

Connect DC V J1-28 GND

J1-29 J1-29 Idle Air Control Valve (IACV) Coil B Low BLU/

BLK Less than

1V Less than 1V / 10-14V

Connect DC V J1-29 GND

J1-30 J1-30 Idle Air Control Valve (IACV) Coil A Low BLU/

WHT Less than

1V Less than 1V / 10-14V

Connect DC V J1-30 GND

J1-31 J1-31 MAP Sensor Power Supply RED Less than

1V Approx.. 5V

Connect DC V J1-31 J1-16

J1-32 J1-32 ECT Sensor, Knock Sensor, Throttle

Position Sensor Ground GRN Continuity

with

ground -

- - Connect ΩJ1-32 GND

Pin

No. B/

Box No. Pin Function

Wire

Color Signal or Continuity

ECM

Connection Tester Position

Key SW Off Key SW

On Engine

Idle Engine

2000rpm Range (+) (-)

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 2214 of 6020

6E–44 ENGINE DRIVEABILITY AND EMISSIONS

Connector J2 Port: View Looking Into ECM Case

1

17 16

32

PIN32

PIN1

PIN17

PIN16

Pin

No. B/

Box No. Pin Function

Wire

Color Signal or Continuity

ECM

Connection Tester Position

Key SW Off Key SW

On Engine

Idle Engine

2000rpm Range (+) (-)

J2-1 J2-1 Intake Air Temp. (IAT) Sensor Ground GRN Continuity

with

ground -

- - Disconnect ΩJ2-1 GND

J2-2 J2-2 Battery Power Supply RED/ WHT10-14V

Connect DC V J2-2 GND

J2-3 J2-3 Ignition Power Supply BLU/ YELLess than

1V 10-14V

Connect DC V J2-3 GND

J2-4 J2-4 To Data Link Connector No. 6 BLU -

-- - -- - -

J2-5 J2-5 No Connection -- - - - -- - -

J2-6 J2-6 Oxygen Sensor (Ground) PNK Continuity

with

ground -

- - Connect ΩJ2-6 GND

J2-7 J2-7 No Connection -- - - - -- - -

J2-8 J2-8 No Connection -- - - - -- - -

J2-9 J2-9 No Connection -- - - - -- - -

J2-10 J2-10 CO Adjust Signal (W/O Catalystic

Converter) YEL -

-- - -- - -

J2-11 J2-11 Fuel Pump Relay GRN/ WHT10-14V

While relay

is activated; 10-14V

Relay is not

activated;

Less than 1V10-14V Connect DC V J2-11 GND

J2-12 J2-12 No Connection -- - - - -- - -

J2-13 J2-13 A/C Compressor Relay GRY/

RED Less than

1V A/C comp. is operated: Less than 1V

A/C comp. is not operated: 10-14V Connect DC V J2-13 GND

J2-14 J2-14 No Connection -- - - - -- - -

J2-15 J2-15 No Connection -- - - - -- - -

J2-16 J2-16 No Connection -- - - - -- - -

J2-17 J2-17 CO Adjust (W/O Catalystic Converter) RED -

-- - -- - -

J2-18 J2-18 Battery Power Supply RED/ WHT10-14V

Connect DC V J2-18 GND

J2-19 J2-19 No Connection -- - - - -- - -

J2-20 J2-20 Power Steering Pressure Switch GRN/

YEL Less than

1V

Pressure switch is turned on: Less than 1VPressure switch is turned off: 10-14VConnect DC V J2-20 GND

J2-21 J2-21 Oxygen Sensor BLU Less than 1VApprox.

0.4V Wave form D or 0.1 -

0.9V Connect DC V J2-21 J2-6

J2-22 J2-22 Intake Air Temp. (IAT) Sensor (Signal) YEL/

GRN Less than

1V

20℃: Approx. 2.9V / 40 ℃: Approx. 1.8V V

/ 60 ℃: Approx. 1.1V / 80 ℃: Approx. 0.6VConnect DC V J2-22 33

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 2215 of 6020

ENGINE DRIVEABILITY AND EMISSIONS 6E–45

J2-23 J2-23 Vehicle Speed Sensor (VSS) Signal

(Immobilizer Control

Unit Terminal B8) WHT -

- Wave form C or Approx.

6.5V at 20km/h Connect AC V J2-23 GND

J2-24 J2-24 No Connection -- - - - -- - -

J2-25 J2-25 Tachometer Output Signal BLK/

RED -

- Wave form Wave form

B or

Approx.

4.5V Connect AC V J2-25 GND

J2-26 J2-26 Thermo Relay GRN/

BLK Less than

1V

A/C request is activated: 10-14V

A/C request is not activated: Less than 1VConnect DC V J2-26 GND

J2-27 J2-27 No Connection - - - - - - - - -

J2-28 J2-28 No Connection - - - - - - - - -

J2-29 J2-29 No Connection -- - - - -- - -

J2-30 J2-30 To Data Link Connector No. 2 GRN -

-- - -- - -

J2-31 J2-31 Oxygen Sensor Heater BLU/ WHTContinuity

with

ground - Wave

Form Wave

Form D Connect

ΩJ2-31 GND

J2-32 J2-32 Check Engine Lamp (Immobilizer Control

Unit Terminal B7) BRN/

YEL Less than

1V Less than

1V Lamp is turned on: Less

than 1V

Lamp is turned off: 10-

14V Connect DC V J2-32 GND

Pin

No. B/

Box No. Pin Function

Wire

Color Signal or Continuity

ECM

Connection Tester Position

Key SW Off Key SW

On Engine

Idle Engine

2000rpm Range (+) (-)

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 2219 of 6020

ENGINE DRIVEABILITY AND EMISSIONS 6E–49

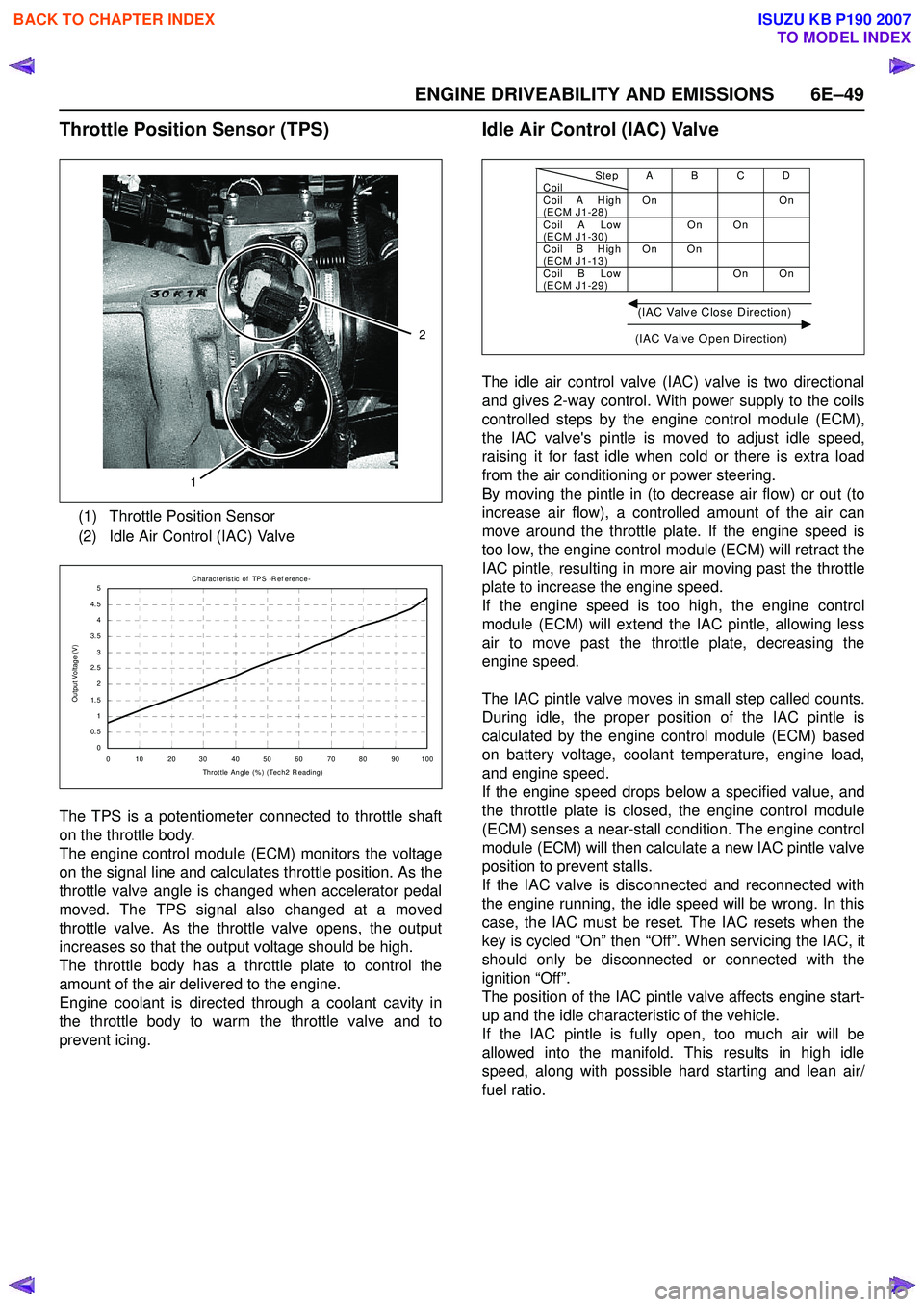

Throttle Position Sensor (TPS)

The TPS is a potentiometer connected to throttle shaft

on the throttle body.

The engine control module (ECM) monitors the voltage

on the signal line and calculates throttle position. As the

throttle valve angle is changed when accelerator pedal

moved. The TPS signal also changed at a moved

throttle valve. As the throttle valve opens, the output

increases so that the output voltage should be high.

The throttle body has a throttle plate to control the

amount of the air delivered to the engine.

Engine coolant is directed through a coolant cavity in

the throttle body to warm the throttle valve and to

prevent icing.

Idle Air Control (IAC) Valve

The idle air control valve (IAC) valve is two directional

and gives 2-way control. With power supply to the coils

controlled steps by the engine control module (ECM),

the IAC valve's pintle is moved to adjust idle speed,

raising it for fast idle when cold or there is extra load

from the air conditioning or power steering.

By moving the pintle in (to decrease air flow) or out (to

increase air flow), a controlled amount of the air can

move around the throttle plate. If the engine speed is

too low, the engine control module (ECM) will retract the

IAC pintle, resulting in more air moving past the throttle

plate to increase the engine speed.

If the engine speed is too high, the engine control

module (ECM) will extend the IAC pintle, allowing less

air to move past the throttle plate, decreasing the

engine speed.

The IAC pintle valve moves in small step called counts.

During idle, the proper position of the IAC pintle is

calculated by the engine control module (ECM) based

on battery voltage, coolant temperature, engine load,

and engine speed.

If the engine speed drops below a specified value, and

the throttle plate is closed, the engine control module

(ECM) senses a near-stall condition. The engine control

module (ECM) will then calculate a new IAC pintle valve

position to prevent stalls.

If the IAC valve is disconnected and reconnected with

the engine running, the idle speed will be wrong. In this

case, the IAC must be reset. The IAC resets when the

key is cycled “On” then “Off”. When servicing the IAC, it

should only be disconnected or connected with the

ignition “Off”.

The position of the IAC pintle valve affects engine start-

up and the idle characteristic of the vehicle.

If the IAC pintle is fully open, too much air will be

allowed into the manifold. This results in high idle

speed, along with possible hard starting and lean air/

fuel ratio.

(1) Throttle Position Sensor

(2) Idle Air Control (IAC) Valve

1

2

C harac teris t ic of TPS -R ef erenc e-

0

0.5

1

1.5 2

2.5

3

3.5 4

4.5 5

0 10 2030 405060 7080 90100 Throt t le Angle (% ) (Tec h2 R eading)

Output Voltage (V)

StepCoilAB CDCoil A H igh

(ECM J1-28) On On

Coil A Low

(ECM J1-30) On On

Coil B H igh

(ECM J1-13) On On

Coil B Low

(ECM J1-29) On On

(IAC Valve Close Direction)

(IAC Valve Open Direction)

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007