Circuit ISUZU KB P190 2007 Workshop Repair Manual

[x] Cancel search | Manufacturer: ISUZU, Model Year: 2007, Model line: KB P190, Model: ISUZU KB P190 2007Pages: 6020, PDF Size: 70.23 MB

Page 3377 of 6020

Engine Management – V6 – Diagnostics Page 6C1-2–99

Test Description

The following numbers refer to the step numbers in the diagnostic table:

3 Determines if there is a fault condition in the ignition voltage supply circuit. The fuel injectors for each bank of the engine are fused separately. If all DTCs for a single bank are set, there may be a fault in one of the ignition supply

circuits.

5 Verifies the ECM is sending control voltage to the fuel injector.

6 Tests if the feed back voltage circuit within the ECM is providing the correct voltage.

DTC P0201 to P0206, P0261, P0262, P0264, P0265, P0267, P0268, P0270, P0271, P0273,

P0274, P0276 and P0277 Diagnostic Table

Step Action Yes No

1 Has the Diagnostic System Check been performed?

Go to Step 2 Refer to

4.4 Diagnostic

System Check in this Section

2 1 Switch off the ignition for 30 seconds.

2 Start the engine.

3 Using Tech 2, select the DTC display function.

Does DTC P0201, P0202, P0203, P0204, P0205, P0206, P0261,

P0262, P0264, P0265, P0267, P0268, P0270, P0271, P0273, P0274,

P0276 or P0277 set? Go to Step 3 Refer to Additional

Information in this DTC

3 1 Disconnect the fuel injector interconnect harness connector.

Refer to 6C1-3 Engine Management – V6 – Service Operations.

2 Switch on the ignition with the engine not running.

3 Connect a test lamp between the ignition voltage circuit of the appropriate fuel injector, ECM side of the interconnect

connector, and the ECM housing.

Does the test lamp illuminate? Go to Step 4 Go to Step 5

4 1 Switch on the ignition with the engine not running.

2 Using a digital multimeter, measure the voltage between the appropriate fuel injector control circuit, ECM side of the

interconnect connector, and the ECM housing.

Does the multimeter display 2.6 – 4.6 mV? Go to Step 7 Go to Step 6

5 Repair the open circuit or short to ground fault condition in the ignition

voltage circuit of the appropriate fuel injector. Refer to 8A Electrical -

Body and Chassis for information on electrical wiring repair

procedures.

W as the repair completed? Go to Step 10 —

6 Test the control circuit of the appropriate fuel injector, between the

interconnect connector and the ECM, for a high resistance, open

circuit, short to ground or short to voltage fault condition. Refer to 8A

Electrical - Body and Chassis for information on electrical fault

diagnosis.

W as any fault found and rectified? Go to Step 10 Go to Step 9

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3378 of 6020

Engine Management – V6 – Diagnostics Page 6C1-2–100

Step Action Yes No

7 1 Remove the upper intake manifold. Refer to 6A1-Engine

Mechanical – V6.

2 Test the control circuit and the ignition voltage circuit of the appropriate fuel injector, between the interconnect connector

and the appropriate fuel injector connector, for a high

resistance, open circuit, short to ground or short to voltage fault

condition. Refer to 8A Electrical - Body and Chassis for

information on electrical fault diagnosis.

W as any fault found and rectified? Go to Step 10 Go to Step 8

8 Replace the appropriate fuel injector. Refer to 6C1-3 Engine

Management – V6 – Service Operations.

W as the repair completed? Go to Step 10 —

9 Replace the ECM. Refer to 6C1-3 Engine Management – V6 –

Service Operations.

W as the repair completed? Go to Step 10 —

10 1 Using Tech 2, clear the DTCs.

2 Switch off the ignition for 30 seconds.

3 Start the engine.

4 Operate the vehicle within the conditions for running the DTC.

Does any of the fuel injector control circuit DTCs fail this ignition

cycle? Go to Step 2 Go to Step 11

11 Using Tech 2, select the DTC display function.

Does Tech 2 display any DTCs? Go to the

appropriate DTC

Table in this Section System OK

When all diagnosis and repairs are completed, check the system for correct operation.

7.15 DTC P0219

DTC Descriptor

This diagnostic procedure supports DTC P0219 – Engine Overspeed Condition.

Circuit Description

The ECM continually monitors the engines operating environment. A engine over-speed condition DTC sets if the ECM

detects an engine speed in excess of 7200 RPM.

NOTE

An over-speed condition will occur when a low

gear on a manual transmission vehicle has been

selected whilst the vehicle is travelling at high

road speed. This DTC will not set if the engine is

free-revved as the ECM will limit engine speed.

Conditions for Running the DTC

DTC P0219 runs continuously when the following conditions are met:

• The vehicle is fitted with a manual transmission

• The engine is running.

• The ignition voltage is between 10.0 – 16.0 V.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3379 of 6020

Engine Management – V6 – Diagnostics Page 6C1-2–101

Conditions for Setting the DTC

The ECM detects an engine speed in excess of 7200 RPM for 1 second or longer.

Conditions for Clearing the DTC

The engine over-speed DTC is a Type C DTC. Refer to 1.4 Diagnostic Trouble Codes in this Section, for action

taken when Type C DTCs set and conditions for clearing Type C DTCs.

Additional Information

• For an intermittent fault condition, refer to 5.2 Intermittent Fault Conditions in this Section.

• Since fault condition in a wiring connector may trigger DTCs, always test the connectors related to this diagnostic

procedure for shorted terminals or poor wiring connection before replacing any component. Refer to 8A Electrical -

Body and Chassis for information on electrical fault diagnosis.

• To assist diagnosis, refer to 3 W iring Diagrams and Connector Charts in this Section, for the system wiring

diagram and connector charts.

DTC P0219 Diagnostic Table

Step Action Yes No

1 Has the diagnostic system check been performed?

Go to Step 2 Refer to

4.4 Diagnostic System Check in this Section

2 1 Switch off the ignition for 30 seconds.

2 Operate the vehicle within the conditions for running the DTC.

5 Using Tech 2, select the DTC display function.

Does DTC P0219 fail this ignition cycle? Go to Step 3 Refer to Additional

Information in this DTC

3 Replace the ECM. Refer to 6C1-3 Engine Management – V6 –

Service Operations.

W as the repair completed? Go to Step 4 —

4 1 Using Tech 2, clear the DTCs.

2 Switch off the ignition for 30 seconds.

3 Start the engine.

4 Operate the vehicle within the conditions for running the DTC.

Does DTC P0219 fail this ignition cycle? Go to Step 2 Go to Step 5

5 Using Tech 2, select the DTC display function.

Are there any DTCs displayed? Go to the

appropriate DTC

Table in this Section System OK

When all diagnosis and repairs are completed, check the system for correct operation.

7.16 DTC P0300

DTC Descriptor

This diagnostic procedure supports the following DTC:

DTC P0300 Engine Misfire Detected.

Circuit Description

The engine control module (ECM) uses information from the crankshaft position (CKP) sensor and the camshaft position

(CMP) sensors to determine when an engine misfire is occurring. By monitoring variations in the crankshaft rotation

speed for each cylinder, the ECM is able to detect individual misfire events. A misfire rate that is high enough can cause

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3383 of 6020

Engine Management – V6 – Diagnostics Page 6C1-2–105

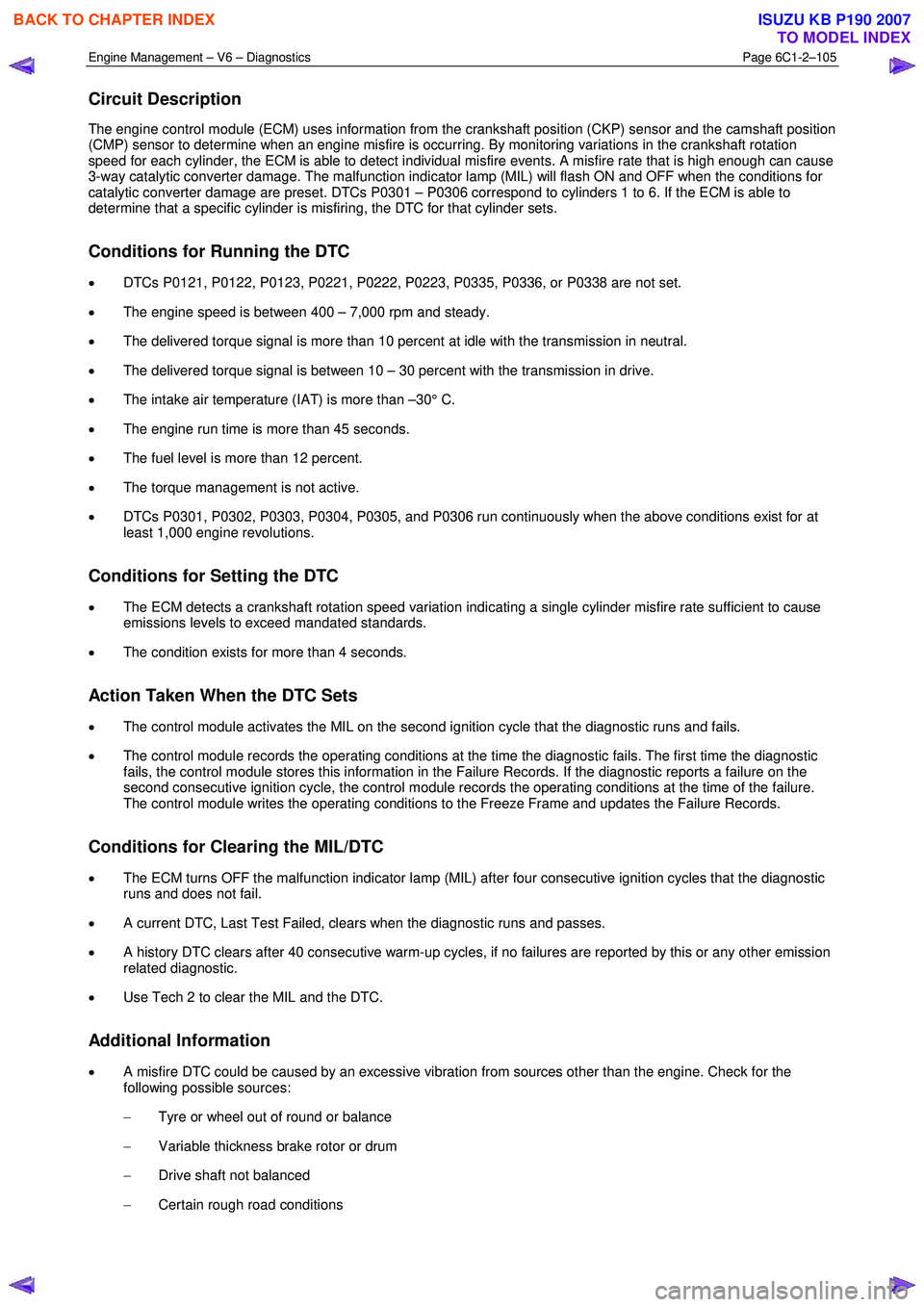

Circuit Description

The engine control module (ECM) uses information from the crankshaft position (CKP) sensor and the camshaft position

(CMP) sensor to determine when an engine misfire is occurring. By monitoring variations in the crankshaft rotation

speed for each cylinder, the ECM is able to detect individual misfire events. A misfire rate that is high enough can cause

3-way catalytic converter damage. The malfunction indicator lamp (MIL) will flash ON and OFF when the conditions for

catalytic converter damage are preset. DTCs P0301 – P0306 correspond to cylinders 1 to 6. If the ECM is able to

determine that a specific cylinder is misfiring, the DTC for that cylinder sets.

Conditions for Running the DTC

• DTCs P0121, P0122, P0123, P0221, P0222, P0223, P0335, P0336, or P0338 are not set.

• The engine speed is between 400 – 7,000 rpm and steady.

• The delivered torque signal is more than 10 percent at idle with the transmission in neutral.

• The delivered torque signal is between 10 – 30 percent with the transmission in drive.

• The intake air temperature (IAT) is more than –30° C.

• The engine run time is more than 45 seconds.

• The fuel level is more than 12 percent.

• The torque management is not active.

• DTCs P0301, P0302, P0303, P0304, P0305, and P0306 run continuously when the above conditions exist for at

least 1,000 engine revolutions.

Conditions for Setting the DTC

• The ECM detects a crankshaft rotation speed variation indicating a single cylinder misfire rate sufficient to cause

emissions levels to exceed mandated standards.

• The condition exists for more than 4 seconds.

Action Taken When the DTC Sets

• The control module activates the MIL on the second ignition cycle that the diagnostic runs and fails.

• The control module records the operating conditions at the time the diagnostic fails. The first time the diagnostic

fails, the control module stores this information in the Failure Records. If the diagnostic reports a failure on the

second consecutive ignition cycle, the control module records the operating conditions at the time of the failure.

The control module writes the operating conditions to the Freeze Frame and updates the Failure Records.

Conditions for Clearing the MIL/DTC

• The ECM turns OFF the malfunction indicator lamp (MIL) after four consecutive ignition cycles that the diagnostic

runs and does not fail.

• A current DTC, Last Test Failed, clears when the diagnostic runs and passes.

• A history DTC clears after 40 consecutive warm-up cycles, if no failures are reported by this or any other emission

related diagnostic.

• Use Tech 2 to clear the MIL and the DTC.

Additional Information

• A misfire DTC could be caused by an excessive vibration from sources other than the engine. Check for the

following possible sources:

− Tyre or wheel out of round or balance

− Variable thickness brake rotor or drum

− Drive shaft not balanced

− Certain rough road conditions

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3385 of 6020

Engine Management – V6 – Diagnostics Page 6C1-2–107

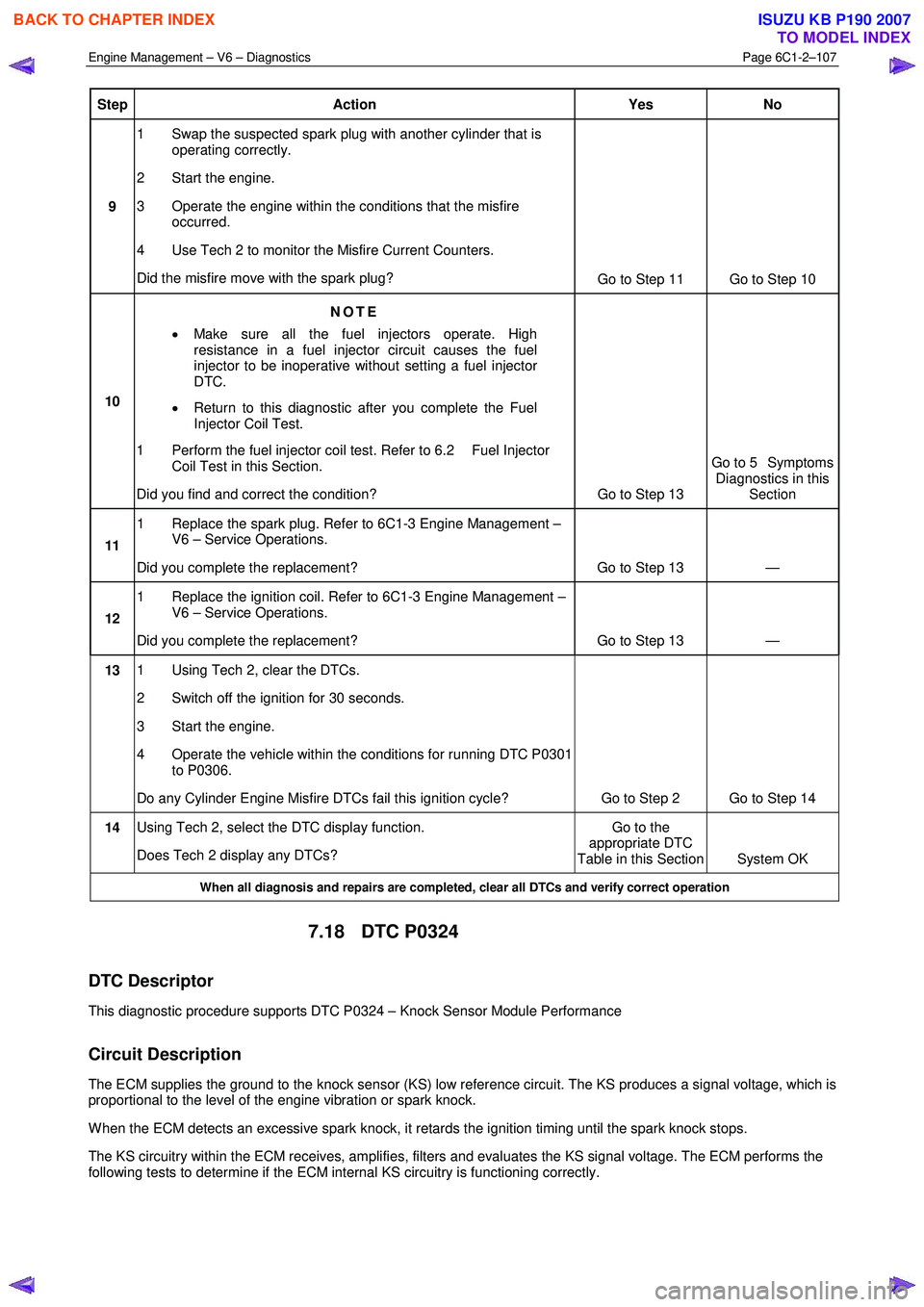

Step Action Yes No

9 1 Swap the suspected spark plug with another cylinder that is

operating correctly.

2 Start the engine.

3 Operate the engine within the conditions that the misfire occurred.

4 Use Tech 2 to monitor the Misfire Current Counters.

Did the misfire move with the spark plug? Go to Step 11 Go to Step 10

10 NOTE

• Make sure all the fuel injectors operate. High

resistance in a fuel injector circuit causes the fuel

injector to be inoperative without setting a fuel injector

DTC.

• Return to this diagnostic after you complete the Fuel

Injector Coil Test.

1 Perform the fuel injector coil test. Refer to 6.2 Fuel Injector Coil Test in this Section.

Did you find and correct the condition? Go to Step 13 Go to 5 Symptoms

Diagnostics in this Section

11 1 Replace the spark plug. Refer to 6C1-3 Engine Management –

V6 – Service Operations.

Did you complete the replacement? Go to Step 13 —

12 1 Replace the ignition coil. Refer to 6C1-3 Engine Management –

V6 – Service Operations.

Did you complete the replacement? Go to Step 13 —

13 1 Using Tech 2, clear the DTCs.

2 Switch off the ignition for 30 seconds.

3 Start the engine.

4 Operate the vehicle within the conditions for running DTC P0301 to P0306.

Do any Cylinder Engine Misfire DTCs fail this ignition cycle? Go to Step 2 Go to Step 14

14 Using Tech 2, select the DTC display function.

Does Tech 2 display any DTCs? Go to the

appropriate DTC

Table in this Section System OK

When all diagnosis and repairs are completed, clear all DTCs and verify correct operation

7.18 DTC P0324

DTC Descriptor

This diagnostic procedure supports DTC P0324 – Knock Sensor Module Performance

Circuit Description

The ECM supplies the ground to the knock sensor (KS) low reference circuit. The KS produces a signal voltage, which is

proportional to the level of the engine vibration or spark knock.

W hen the ECM detects an excessive spark knock, it retards the ignition timing until the spark knock stops.

The KS circuitry within the ECM receives, amplifies, filters and evaluates the KS signal voltage. The ECM performs the

following tests to determine if the ECM internal KS circuitry is functioning correctly.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3386 of 6020

Engine Management – V6 – Diagnostics Page 6C1-2–108

Test One

The ECM performs the following:

1 Turns off the knock sensor signal circuits.

2 Applies different test signals to the ECM internal KS circuitry.

3 Verifies each test signal output response is within range.

4 If the ECM detects any of the tested signals are not within the normal range, DTC P0324 sets.

Test Two

The ECM performs the following:

1 Turns off the knock sensor signal circuits.

2 Tests for any output response when no test signals are applied.

3 If the ECM detects an output response, DTC P0324 sets.

Test Three

1 Turns off the knock sensor signal circuits.

2 Generates an internal test pulse then monitors the return signal.

3 If the return test pulse is less than a calibrated threshold, DTC P0324 sets.

DTC P0324 sets if the ECM detects an incorrect response to the ECM internal KS circuitry tests.

Conditions for Running the DTC

Condition One

Runs continuously once the following conditions are met:

• The ECM is controlling the ignition spark.

• The engine speed is less than 2,300 rpm and steady.

• The volumetric efficiency is steady.

Condition Two

Runs continuously once the following conditions are met:

• The ECM is controlling the ignition spark.

• The engine speed is 1,000 – 4,000 rpm

• The engine coolant temperature is greater than 60 ° C.

• The volumetric efficiency is steady.

Condition Three

Runs continuously once the following conditions are met:

• The ECM is controlling the ignition spark.

• The engine speed is less than 2,300 rpm and steady.

• The engine coolant temperature is greater than 40 ° C.

• The volumetric efficiency is steady.

Conditions for Setting the DTC

The ECM detects an incorrect response to an internal ECM KS circuitry test.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3387 of 6020

Engine Management – V6 – Diagnostics Page 6C1-2–109

Conditions for Clearing the DTC

DTC P0324 – Knock Sensor (KS) Module Performance is a Type B DTC. Refer to 1.4 Diagnostic Trouble Codes in

this Section, for action taken when a Type B DTC sets and conditions for clearing Type B DTC.

Additional Information

• Refer to 6C1-1 Engine Management – V6 – General Information for details of the knock sensor (KS) system

operation.

• The ECM turns off the KS signal circuits when performing the ECM internal KS circuitry tests. DTC P0324 sets if

there is a fault condition in the internal ECM KS circuitry. Therefore, the KS and the KS signal circuits are not

tested in DTC P0324 Diagnostic Table.

• For an intermittent fault condition, refer to 5.2 Intermittent Fault Conditions in this Section.

• Since fault condition in a wiring connector may trigger DTCs, always test the connectors related to this diagnostic

procedure for shorted terminals or poor wiring connection before replacing any component. Refer to 8A Electrical -

Body and Chassis for information on electrical fault diagnosis.

• To assist diagnosis, refer to 3 W iring Diagrams and Connector Charts in this Section, for the system wiring

diagram and connector charts.

Test Description

The following number refers to the step number in the diagnostic table:

3 A crankshaft sensor DTC may trigger DTC P0324.

DTC P0324 Diagnostic Table

Step Action Yes No

1 Has the Diagnostic System Check been performed?

Go to Step 2 Refer to

4.4 Diagnostic System Check in this Section

2 1 Switch off the ignition for 30 seconds.

2 Operate the vehicle within the conditions for running the DTC.

3 Using Tech 2, select the DTC display function.

Does DTC P0324 fail this ignition cycle? Go to Step 3 Refer to Additional

Information in this DTC

3 Are DTCs relating to the CKP Sensor Circuit also set? Refer to

7.20 DTC P0335, P0336, P0337 or P0338 in this Section Go to Step 4

4 Replace the ECM. Refer to 6C1-3 Engine Management – V6 –

Service Operations.

W as the repair completed? Go to Step 5 —

5 1 Using Tech 2, clear the DTCs.

2 Switch off the ignition for 30 seconds.

3 Start the engine.

4 Operate the vehicle within the conditions for running DTC P0324.

Does DTC P0324 fail this ignition cycle? Go to Step 2 Go to Step 6

6 Using Tech 2, select the DTC display function.

Does Tech 2 display any DTCs? Go to the

appropriate DTC

Table in this Section System OK

When all diagnosis and repairs are completed, check the system for correct operation.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3388 of 6020

Engine Management – V6 – Diagnostics Page 6C1-2–110

7.19 DTC P0327, P0328, P0332 or P0333

DTC Descriptor

This diagnostic procedure supports the following DTCs:

• DTC P0327 – Knock Sensor Circuit Low Frequency (Bank 1)

• DTC P0328 – Knock Sensor Circuit High Frequency (Bank 1)

• DTC P0332 – Knock Sensor Circuit Low Frequency (Bank 2)

• DTC P0333 – Knock Sensor Circuit High Frequency (Bank 2)

Circuit Description

The ECM supplies the ground to the knock sensor (KS) low reference circuit. The KS produces a signal voltage, which is

proportional to the level of the engine vibration or spark knock.

W hen the ECM detects an excessive spark knock, it retards the ignition timing until the spark knock stops.

To differentiate between a normal engine vibration and the vibration created by a spark knock, the ECM samples the KS

signal under different engine speeds and load condition. The ECM uses this samples to determine maximum and

minimum KS signal voltage produced when the engine is running under normal conditions.

A knock sensor circuit DTC sets if the ECM detects the KS signal voltage is outside the normal range.

Conditions for Running the DTC

DTC P0327 and P0332

Run continuously once the following conditions are met:

• DTCs P0324, P0335, P0342 and P0343 ran and passed.

• The ECM controls the ignition spark.

• Engine speed is greater than 2000 rpm and steady.

• The engine coolant temperature is greater than 60ºC.

• The volumetric efficiency is steady.

DTC P0328 or P0333

Run continuously once the following conditions are met:

• The ECM controls the ignition spark.

• Engine speed is greater than 2,000 rpm and steady.

• The engine coolant temperature is greater than 60 °C.

• The volumetric efficiency is steady.

Conditions for Setting the DTC

DTC P0327 and P0332

The ECM detects the KS signal voltage is less than the minimum KS signal normal range for at least 10 seconds.

DTC P0328 and P0333

The ECM detects the KS signal voltage is greater than the maximum KS signal normal range.

Conditions for Clearing DTC

The knock sensor circuit DTCs are Type B DTCs. Refer to 1.4 Diagnostic Trouble Codes in this Section, for action

taken when Type B DTC sets and conditions for clearing Type B DTCs.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3389 of 6020

Engine Management – V6 – Diagnostics Page 6C1-2–111

Additional Information

• Refer to 6C1-1 Engine Management – V6 – General Information for details of the knock sensor (KS) system

operation.

• Preconditions for running knock sensor circuit DTCs requires that DTC P0324 has ran and passed. Therefore, the

diagnostic table for the knock sensor circuit DTCs is developed with the assumption the ECM internal KS circuitry

is functioning correctly.

• Excessive engine mechanical noise or engine knocking condition may trigger knock sensor circuit DTCs.

• The knock sensor must be tightened correctly. Refer to 6C1-3 Engine Management – V6 – Service Operations.

• The mounting between the knock sensor and engine must be free of burrs, casting flash and foreign material.

• The knock sensor head must be clear from hoses, brackets and engine wiring.

• If the knock sensor lead is damaged in any way, the sensor must be replaced.

• Since fault condition in a wiring connector may trigger DTCs, always test the connectors related to this diagnostic

procedure for shorted terminals or poor wiring connection before replacing any component. Refer to 8A Electrical -

Body and Chassis for information on electrical fault diagnosis.

• To assist diagnosis, refer to 3 W iring Diagrams and Connector Charts in this Section, for the system wiring

diagram and connector charts.

Test Description

The following numbers refer to the step numbers in the diagnostic table:

3 Identifies engine mechanical fault conditions that may trigger knock sensor circuit DTCs.

4 Identifies KS fault conditions that may trigger knock sensor circuit DTCs.

DTC P0327, P0328, P0332 and P0333 Diagnostic Table

Step Action Yes No

1 Has the Diagnostic System Check been performed?

Go to Step 2 Refer to

4.4 Diagnostic System Check in this Section

2 1 Switch off the ignition for 30 seconds.

2 Operate the vehicle within the conditions for running the DTC.

3 Using Tech 2, select the DTC display function.

Does DTC P0327, P0328, P0332 or P0333 fail this ignition cycle? Go to Step 3 Refer to Additional

Information in this DTC

3 Check the engine for excessive mechanical engine noise or engine

knocking fault condition. Refer to 6A1 Engine Mechanical – V6.

W as any fault found and rectified? Go to Step 7 Go to Step 4

4 Inspect the appropriate KS for the following fault condition. Refer to

6C1-3 Engine Management – V6 – Service Operations.

• incorrect KS attaching bolt torque value,

• burrs, casting flash or foreign material between the knock

sensor and engine,

• hoses, brackets or engine wiring touching the KS, and

• damaged KS wiring harness.

• sensor wiring harness for conditions that may induce

electromagnetic interference. Refer to 5.2 Intermittent Fault

Conditions in this Section.

W as any fault found and rectified? Go to Step 7 Go to Step 5

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3390 of 6020

Engine Management – V6 – Diagnostics Page 6C1-2–112

Step Action Yes No

5 Test the appropriate KS signal circuit and low reference circuit for a

high resistance, open circuit, short to ground or short to voltage or

shorted together fault condition. Refer to 8A Electrical - Body and

Chassis for information on electrical fault diagnosis.

W as any fault found and rectified? Go to Step 7 Go to Step 6

6 Replace the faulty KS. Refer to 6C1-3 Engine Management – V6 –

Service Operations.

W as the repair completed? Go to Step 7 —

7 1 Using Tech 2, clear the DTCs.

2 Switch off the ignition for 30 seconds.

3 Start the engine.

4 Operate the vehicle within the conditions for running the DTC.

Does any of the knock sensor circuit DTCs fail this ignition cycle? Go to Step 2 Go to Step 8

8 Using Tech 2, select the DTC display function.

Does Tech 2 display any DTCs? Go to the

appropriate DTC

Table in this Section System OK

When all diagnosis and repairs are completed, check the system for correct operation.

7.20 DTC P0335, P0336, P0337 or P0338

DTC Descriptors

This diagnostic procedure supports the following DTCs:

• DTC P0335 – Crankshaft Position Sensor Circuit Malfunction

• DTC P0336 – Crankshaft Position Sensor Signal Range / Performance

• DTC P0337 – Crankshaft Position Sensor Circuit Low Duty Cycle

• DTC P0338 – Crankshaft Position Sensor Circuit High Duty Cycle

Circuit Description

The ECM applies the ground to the crankshaft position (CKP) sensor low reference circuit.

The CKP sensor in conjunction with the 58X reluctor wheel generates an AC signal voltage. The amplitude and

frequency of the signal generated is proportional to the engine speed. The ECM uses this signal from the CKP sensor

signal circuit to determine the engine rpm

In addition, the CKP sensor sends a signal to the ECM when piston No. 1 and piston No. 4 are at the top dead centre

position. The ECM monitors both the CKP signal and the camshaft position (CMP) sensor signal to determine the

compression stroke of piston No. 1.

A CKP sensor DTC sets if the ECM detects a fault condition in the CKP sensor signal circuit.

Conditions for Running the DTC

DTC P0335

Runs continuously once the following conditions are met:

• The engine is cranking or running.

• The ECM detects greater than 8 CMP sensor pulses.

DTC P0336

Runs continuously once the following conditions are met:

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007