lock ISUZU KB P190 2007 Workshop Repair Manual

[x] Cancel search | Manufacturer: ISUZU, Model Year: 2007, Model line: KB P190, Model: ISUZU KB P190 2007Pages: 6020, PDF Size: 70.23 MB

Page 4380 of 6020

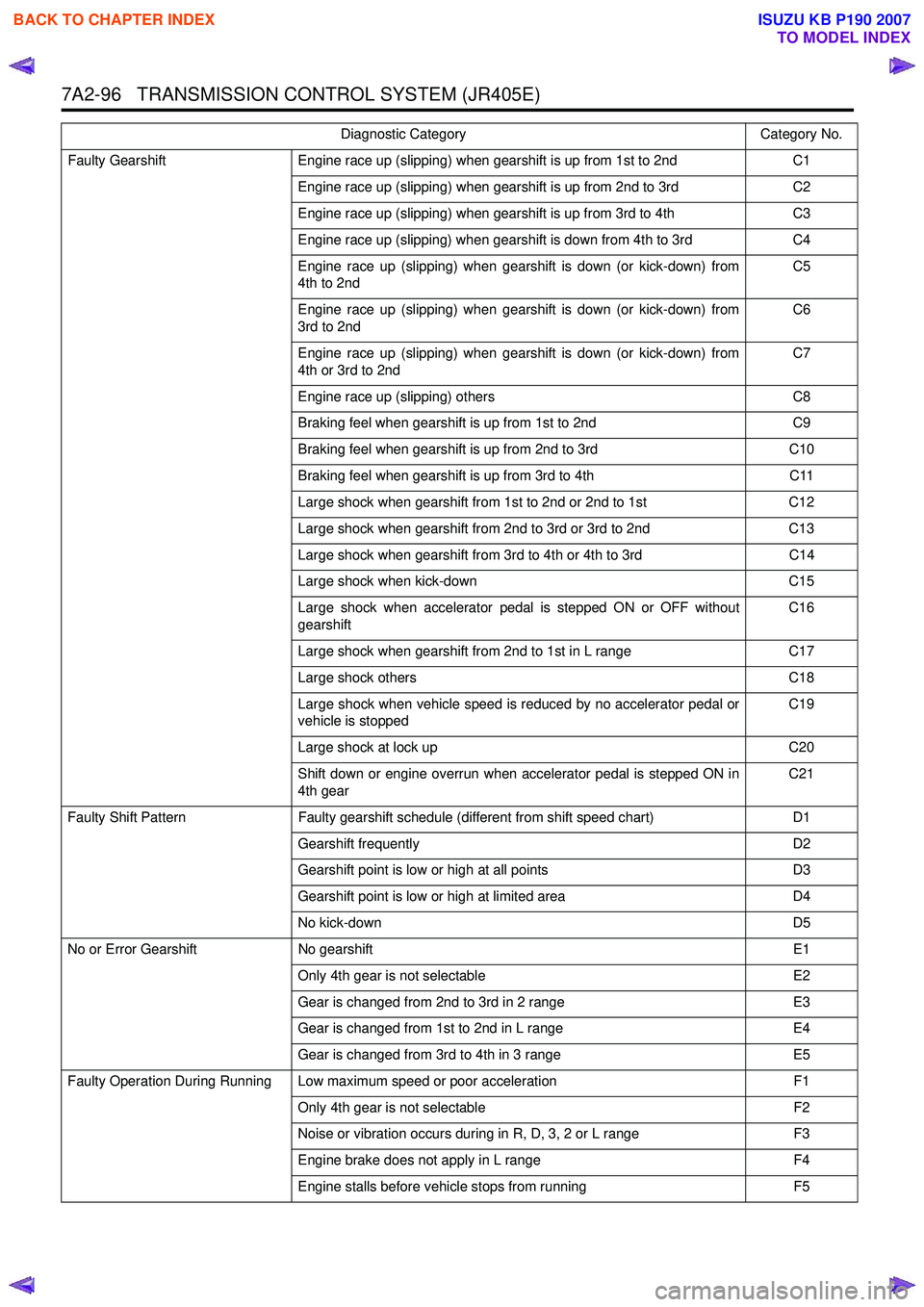

7A2-96 TRANSMISSION CONTROL SYSTEM (JR405E)

Faulty GearshiftEngine race up (slipping) when gearshift is up from 1st to 2nd C1

Engine race up (slipping) when gearshift is up from 2nd to 3rd C2

Engine race up (slipping) when gearshift is up from 3rd to 4th C3

Engine race up (slipping) when gearshift is down from 4th to 3rd C4

Engine race up (slipping) when gearshift is down (or kick-down) from

4th to 2nd C5

Engine race up (slipping) when gearshift is down (or kick-down) from

3rd to 2nd C6

Engine race up (slipping) when gearshift is down (or kick-down) from

4th or 3rd to 2nd C7

Engine race up (slipping) others C8

Braking feel when gearshift is up from 1st to 2nd C9

Braking feel when gearshift is up from 2nd to 3rd C10

Braking feel when gearshift is up from 3rd to 4th C11

Large shock when gearshift from 1st to 2nd or 2nd to 1st C12

Large shock when gearshift from 2nd to 3rd or 3rd to 2nd C13

Large shock when gearshift from 3rd to 4th or 4th to 3rd C14

Large shock when kick-down C15

Large shock when accelerator pedal is stepped ON or OFF without

gearshift C16

Large shock when gearshift from 2nd to 1st in L range C17

Large shock others C18

Large shock when vehicle speed is reduced by no accelerator pedal or

vehicle is stopped C19

Large shock at lock up C20

Shift down or engine overrun when accelerator pedal is stepped ON in

4th gear C21

Faulty Shift Pattern Faulty gearshift schedule (different from shift speed chart) D1

Gearshift frequently D2

Gearshift point is low or high at all points D3

Gearshift point is low or high at limited area D4

No kick-down D5

No or Error Gearshift No gearshift E1

Only 4th gear is not selectable E2

Gear is changed from 2nd to 3rd in 2 range E3

Gear is changed from 1st to 2nd in L range E4

Gear is changed from 3rd to 4th in 3 range E5

Faulty Operation During Running Low maximum speed or poor acceleration F1

Only 4th gear is not selectable F2

Noise or vibration occurs during in R, D, 3, 2 or L range F3

Engine brake does not apply in L range F4

Engine stalls before vehicle stops from running F5

Diagnostic Category

Category No.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 4381 of 6020

TRANSMISSION CONTROL SYSTEM (JR405E) 7A2-97

Faulty Operation in Stopping Vehicle moves in P range or parking is not disengaged in other than Prange G1

Large creeping force G2

Small creeping force G3

Large noise during idle with vehicle stop G4

Faulty Lock Up Judder Occurs at Lock Up H1

Large Shock at Lock Up H2

Lock Up Point is High or Low H3

No Lock Up No Lock Up I1

Transmission Fluid Leak Transmission fluid leaks from breather J1

Transmission fluid leaks between engine and converter housing J2

Transmission fluid leaks between converter housing and transmission

case J3

Transmission fluid leaks between transmission case and extension

housing J4

Transmission fluid leaks from oil pan J5

Transmission fluid leaks from manual shaft oil seal J6

Transmission fluid leaks from oil cooler pipe joint J7

Others Transmission overheat Z1

Mode lamp (power drive or 3rd start) does not turn On Z2

Mode lamp (power drive or 3rd start) does not turn Off Z3

A/T oil temperature lamp turns On Z4

Selector lever feeling is faulty Z5

Poor fuel consumption Z6

Shift indicator is faulty Z7

Abnormal smell Z8

Transmission fluid quantity is low or high Z9

Transmission fluid quantity is low or high Z10

Abnormal transmission fluid pressure Z11

Diagnostic Category

Category No.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 4383 of 6020

TRANSMISSION CONTROL SYSTEM (JR405E) 7A2-99

C1

Engine race up (slipping) when gearshift is

up from 1st to 2nd

C2

Engine race up (slipping) when gearshift is

up from 2nd to 3rd

C3

Engine race up (slipping) when gearshift is

up from 3rd to 4th

C4

Engine race up (slipping) when gearshift is

down from 4th to 3rd

C5

Engine race up (slipping) when gearshift is

down (or kick-down) from 4th to 2nd

C6

Engine race up (slipping) when gearshift is

down (or kick-down) from 3rd to 2nd

C7

Engine race up (slipping) when gearshift is

down (or kick-down) from 4th or 3rd to 2nd

C8 Engine race up (slipping) othersC9

Braking feel when gearshift is up from 1st to

2nd

C10

Braking feel when gearshift is up from 2nd to

3rd

C11

Braking feel when gearshift is up from 3rd to

4th

C12

Large shock when gearshift from 1st to 2nd

or 2nd to 1st

C13

Large shock when gearshift from 2nd to 3rd

or 3rd to 2nd

C14

Large shock when gearshift from 3rd to 4th

or 4th to 3rd

C15 Large shock when kick-downC16

Large shock when accelerator pedal is

stepped ON or OFF without gearshift

C17

Large shock when gearshift from 2nd to 1st

in L range

C18 Large shock othersC19

Large shock when vehicle speed is reduced

by no accelerator pedal or vehicle is stopped

C20 Large shock at lock upC21

Shift down or engine overrun when

accelerator pedal is stepped ON in 4th gear

Error, open or short circuit

Error, open or short circuit

Error, open or short circuit

Error, open or short circuit

Open or short circuit

Open or short circuit

Open or short circuit

Error, open or short circuit

Open or short circuit

Open or short circuit

Open or short circuit

Open or short circuit

Open or short circuit

Open or short circuit

Open or short circuit

Open or short circuit

Open or short circuit

Open or short circuit

Out of standard value

Faulty operation

Faulty operation

Faulty operation

Faulty operation

Faulty operation

Faulty operation

Faulty operation

Clogged passage

Clogged passage

Clogged passage

Clogged passage

Clogged passage

Clogged passage

Clogged passage

Slip

Seizure

Faulty operation

Separation

Faulty operation

Engine speed signal

Accelerator pedal position signal

Input shaft speed sensor

Output shaft speed sensor

Power drive or 3rd start switch

Transmission range switch

TCM power or ground

Transmission fluid temperature sensor

Pressure control solenoid

Torque converter clutch solenoid

Low & reverse brake solenoid

2-4 brake solenoid

High clutch solenoid

Low clutch solenoid

Ground return circuit

Low & reverse brake fluid pressure switch

2-4 brake fluid pressure switch

High clutch fluid pressure switch

Transmission fluid quantity

Control spool valve

High clutch solenoid accumulator

Low clutch solenoid accumulator

Low & reverse brake solenoid accumulator

2-4 brake solenoid accumulator

High clutch accumulator

2-4 brake accumulator

Pressure control solenoid hydraulic circuit

Torque converter clutch hydraulic circuit

High clutch solenoid hydraulic circuit

Low clutch solenoid hydraulic circuit

Low & reverse brake solenoid hydraulic circuit

2-4 brake solenoid hydraulic circuit

Oil cooler

Torque converter

Clutch (brake)

Torque converter clutch piston

Hydraulic control

Powertrain

Diagnostic category

Possible causes

Electrical

Disordered selector lever cable

Disordered transmission range switch

Faulty line pressure

Faulty engine idle speed

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 4384 of 6020

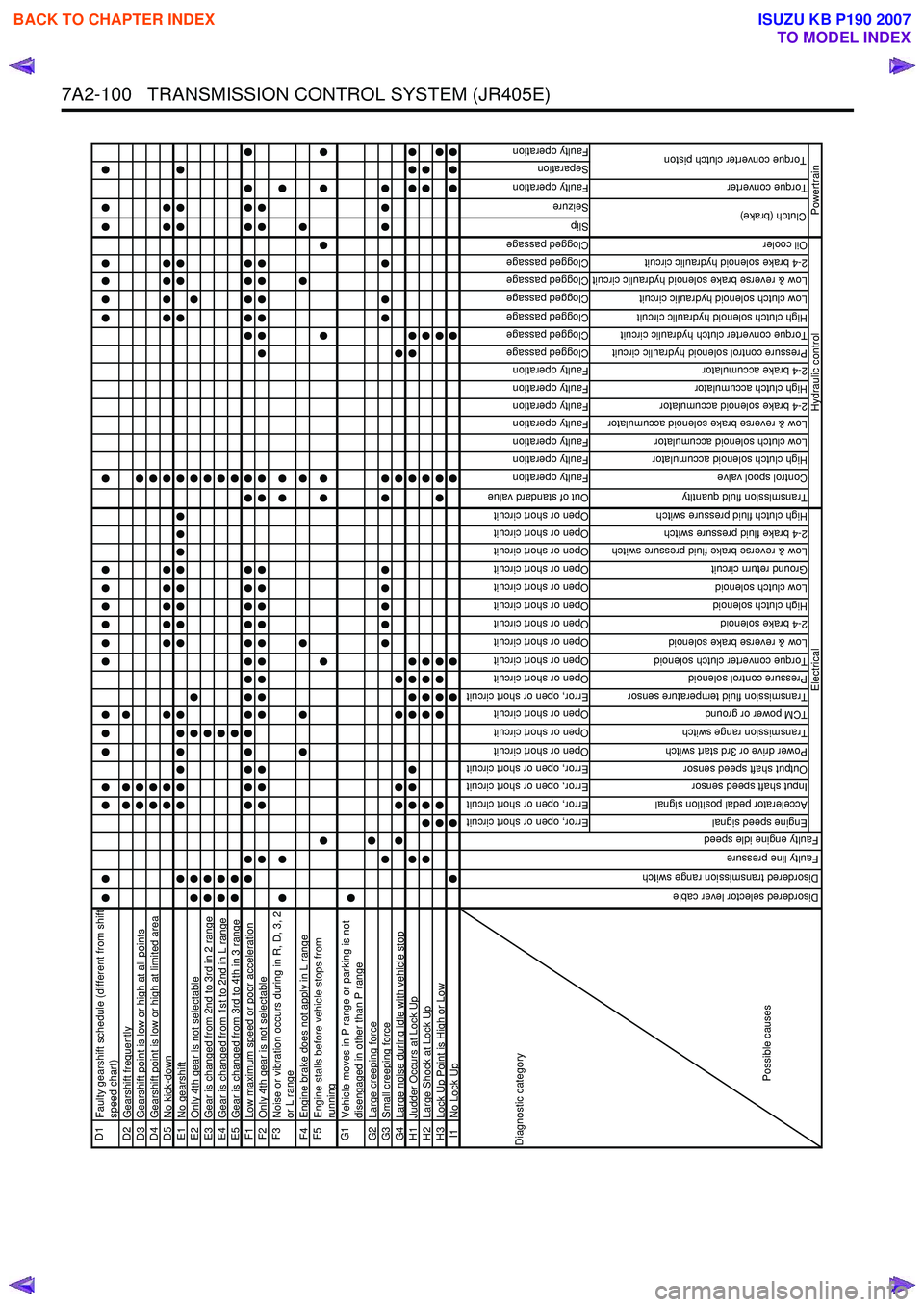

7A2-100 TRANSMISSION CONTROL SYSTEM (JR405E)

D1

Faulty gearshift schedule (different from shift

speed chart)

D2 Gearshift frequentlyD3Gearshift point is low or high at all pointsD4Gearshift point is low or high at limited areaD5No kick-downE1No gearshiftE2Only 4th gear is not selectableE3Gear is changed from 2nd to 3rd in 2 rangeE4Gear is changed from 1st to 2nd in L rangeE5Gear is changed from 3rd to 4th in 3 rangeF1Low maximum speed or poor accelerationF2Only 4th gear is not selectableF3

Noise or vibration occurs during in R, D, 3, 2

or L range

F4 Engine brake does not apply in L rangeF5

Engine stalls before vehicle stops from

running

G1

Vehicle moves in P range or parking is not

disengaged in other than P range

G2 Large creeping forceG3Small creeping forceG4Large noise during idle with vehicle stopH1Judder Occurs at Lock UpH2Large Shock at Lock UpH3Lock Up Point is High or LowI1No Lock Up

Error, open or short circuit

Error, open or short circuit

Error, open or short circuit

Error, open or short circuit

Open or short circuit

Open or short circuit

Open or short circuit

Error, open or short circuit

Open or short circuit

Open or short circuit

Open or short circuit

Open or short circuit

Open or short circuit

Open or short circuit

Open or short circuit

Open or short circuit

Open or short circuit

Open or short circuit

Out of standard value

Faulty operation

Faulty operation

Faulty operation

Faulty operation

Faulty operation

Faulty operation

Faulty operation

Clogged passage

Clogged passage

Clogged passage

Clogged passage

Clogged passage

Clogged passage

Clogged passage

Slip

Seizure

Faulty operation

Separation

Faulty operation

Engine speed signal

Accelerator pedal position signal

Input shaft speed sensor

Output shaft speed sensor

Power drive or 3rd start switch

Transmission range switch

TCM power or ground

Transmission fluid temperature sensor

Pressure control solenoid

Torque converter clutch solenoid

Low & reverse brake solenoid

2-4 brake solenoid

High clutch solenoid

Low clutch solenoid

Ground return circuit

Low & reverse brake fluid pressure switch

2-4 brake fluid pressure switch

High clutch fluid pressure switch

Transmission fluid quantity

Control spool valve

High clutch solenoid accumulator

Low clutch solenoid accumulator

Low & reverse brake solenoid accumulator

2-4 brake solenoid accumulator

High clutch accumulator

2-4 brake accumulator

Pressure control solenoid hydraulic circuit

Torque converter clutch hydraulic circuit

High clutch solenoid hydraulic circuit

Low clutch solenoid hydraulic circuit

Low & reverse brake solenoid hydraulic circuit

2-4 brake solenoid hydraulic circuit

Oil cooler

Torque converter

Diagnostic category

Possible causes

Electrical

Disordered selector lever cable

Disordered transmission range switch

Faulty line pressure

Faulty engine idle speed

Clutch (brake)

Torque converter clutch piston

Hydraulic control

Powertrain

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 4390 of 6020

7A2-106 TRANSMISSION CONTROL SYSTEM (JR405E)

B5: Engine Stalls When Selector Lever is Changed from N to R, D, 3, 2 or L Range

B6: Engine Does Not Crank in P or N Range

B7: Engine Cranks in other than P or N Range

B8: Extended Time Lag When Selector Lever is Changed from N to D

Checks Action

Definition:

The engine stalls when selector lever is changed from N or P position to a run position during engine idling.

Diagnosis Hints • As the correct cause is attributable to the engine, faulty idle up, insufficient

engine output, etc. are suspected.

• As this is a cause of the transmission, faulty torque converter clutch (TCC) piston is suspected.

• If the transmission fluid through resistance increases due to clogged oil cooler or some other reason, or if the transmission fluid level decreases, the TCC piston

works causing the engine stall.

Transmission Fluid Checks Inspect the transmission fluid for the following conditions. If the transmission fluid is

extremely blacked, contaminated or smells burnt, slipping of clutch is suspected.

• Low quantity

• Contamination

• Smell

Line Pressure Checks Inspect the line pressure in forward ranges for a possible dropped pressure. Refer to

Line Pressure Test in Test Instruction section.

Stall Speed Checks Inspect the stall speed in forward ranges. Refer to Stall Test in Test Instruction

section.

Control Valve Body Checks Inspect the valve body for the following conditions.

• Faulty operation

• Sticking lock up spool valve

• Sticking TCC solenoid valve. Perform function check. Refer to On-Vehicle Service section.

• Clogged hydraulic circuit

Additional Checks • Inspect the engine for proper outputs. Refer to appropriate inspection chart in

engine section.

• Inspect the engine for proper idle speed.

Checks Action

Definition: • The engine starter does not run even though the P or N range.

• The engine starter runs even though the R, D, 3, 2 or L range.

Transmission Range Switch & Selector

Lever Cable Checks Inspect the transmission range switch and selector lever cable for misadjusting or

disordering. Refer to On-Vehicle Service section.

Checks Action

Definition:

The shift time lag is longer than the standard value when the selector lever is changed from N to D.

Transmission Fluid Checks Inspect the transmission fluid for low quantity.

Line Pressure Checks Inspect the line pressure in D range for a possible dropped pressure. Refer to Line

Pressure Test in Test Instruction section.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 4394 of 6020

7A2-110 TRANSMISSION CONTROL SYSTEM (JR405E)

C12: Large Shock When Gearshift from 1st to 2nd or 2nd to 1st

C13: Large Shock When Gearshift from 2nd to 3rd or 3rd to 2nd

C14: Large Shock When Gearshift from 3rd to 4th or 4th to 3rd

C15: Large Shock When Kick-down

C16: Large Shock When Accelerator Pedal is Stepped ON or OFF without Gearshift

C17: Large Shock When Gearshift from 2nd to 1st in L Range

C18: Large Shock Others

C19: Large Shock When Vehicle Speed is Reduced by No Accelerator Pedal or Vehicle is Stopped

C20: Large Shock at Lock Up

C21: Shift Down or Engine Overrun When Accelerator Pedal is Stepped ON in 4th Gear

D1: Faulty Gearshift Schedule (Different from Shift Speed Chart)

Checks Action

Definition: • A large shock is felt when the accelerator pedal is stepped on for acceleration and the gear is shifted up or down.

• A large shock is felt when the accelerator pedal is stepped on for kick-down.

• A large shock is felt when the accelerator pedal is not stepped on.

• A large shock is felt when the selector lever is selected in L range.

Diagnosis Hints The same causes as in category No. “C1 - C8: Engine Race Up (Slipping)” are

suspected.

Checks Action

Definition:

A large shock is felt at lock up.

Diagnosis Hints Incorrect input signals or faulty operation of torque converter clutch is suspected.

Refer to category No. “I1: No Lock Up.”

Checks Action

Definition:

Shift down or engine overrun occurs above than kick-down area.

Diagnosis Hints The same causes as in category No. “C1 - C8: Engine Race Up (Slipping)” are

suspected.

Checks Action

Definition:

Faulty gearshift schedule, it is differ from the shift speed chart.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 4401 of 6020

TRANSMISSION CONTROL SYSTEM (JR405E) 7A2-117

H1: Judder Occurs at Lock Up

H2: Large Shock at Lock Up

H3: Lock Up Point is High or Low

I1: No Lock Up

Diagnosis Hints • Causes such as the solenoid operating sound or a faulty oil pump are

suspected.

• Distinguishing is possible by stopping the solenoid operation temporarily, checking the correlation for the former case and, changing

the line pressure and confirming the correlation with noise.

• As a matter of course, noise other than the transmission may be generated around the engine, and should be checked carefully.

Notice: When the noise is generated only at the time of a gear shift, it may

be the sound of transmission fluid flowing or gear noise. If the sound varies

depending on the gear speed to be shifted, it may be the gear noise

generated from the planetary gear and its components. If the sound varies

depending on the vehicle speed, it may be the gear noise of the output

system, or the gear noise of the input system or a faulty torque converter.

Checks

Action

Checks Action

Definition:

Judder occurs when lock up area.

Diagnosis Hints Slip due to burning of the torque converter clutch (TCC) facing or insufficient

engagement due to dropped working pressure are suspected. Refer to

category No. “l1: No Lock Up “.

Notice: When the TCC facing has burnt, foreign material mixed in the oil

cooler is suspected. In such a case, inspect the oil cooler circuit for clogging

of the oil cooler.

Checks Action

Definition: • A large shock is felt at lock up.

• Lock up point is excessively high or low.

Diagnosis Hints Incorrect input signals or faulty operation of torque converter clutch (TCC) is

suspected. Refer to category No. “I1: No Lock Up”.

Checks Action

Definition:

Lock up is not performed even though lock up control conditions being satisfied.

Diagnosis Hints • Monitor the signal to the torque converter clutch (TCC) solenoid valve

while carrying out a running test.

• When the transmission fluid temperature is lower than 20 °C (68 °F),

lock up control is inhibited.

• When the output signal to the TCC solenoid valve is sent correctly, causing no lock up, clogged hydraulic circuits or malfunction of the TCC

piston may be suspected.

• Even with the lock up area, the output signal to the TCC solenoid valve is not sent, a fault of the transmission fluid temperature (TFT) sensor

controlling the lock up may be suspected.

Notice: When the TCC facing has burnt, foreign material mixed in the oil

cooler is suspected. In such a case, inspect the oil cooler circuit for clogging

of the oil cooler.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 4409 of 6020

TRANSMISSION CONTROL SYSTEM (JR405E) 7A2-125

Road Test

Road Test Procedure

*1: Shifting at high vehicle speed, the transmission may

hold the gear position until vehicle speed gets down to

prevent engine overruning.

Notice: Perform this test at the normal transmission

fluid temperature between 50 to 80 °C (122 to 176 °F).

Drive the vehicle on level ground so as not to change to

up slope mode and down slope mode.

1. D range road test in normal and power drive mode. • Select into the D range and hold the accelerator pedal constant at the 50% and 100% accelerator

pedal position.

• 1 to 2, 2 to 3, 3 to 4 upshift and lock up should take place, and shift points should match those shown

in the shift speed chart.

• Also check to see that downshift is made from 4 to 3, 3 to 2 and 2 to 1 point is within the limits shown

in the shift speed chart.

2. 3 range road test in normal and power drive mode. • Select into the 3 range and hold the accelerator pedal constant at the 50% and 100% accelerator

pedal position.

• 1 to 2, 2 to 3 upshift and lock up should take place, and shift points should match those shown in the

shift speed chart.

• While running in the 3 range, does not upshift from 3 to 4.

3. 2 range road test in normal mode. • Select into the 2 range and hold the accelerator

pedal constant at the 50% and 100% accelerator

pedal position.

• 1 to 2 upshift should take place, and shift points should match those shown in the shift speed chart.

• While running in the 2 range, does not upshift from 2 to 3 or 3 to 4, and lock-up does not operate.

4. L range road test in normal mode.

• While running in the L range, does not upshift from 1 to 2, 2 to 3 or 3 to 4, and lock-up does not

operate.

5. R range road test. • Select into the R range and check for slipping.

6. P range road test. • Stop the vehicle on a grade and release the park brake after selecting into the P range. Then check

to see that the parking lock pawl holds the vehicle

in place.

Diagnosis 1. If there is no 1 to 2 upshift.• Faulty operation of 2-4 brake

• Faulty operation of 2-4 brake hydraulic circuits

• Sticking of 2-4 brake solenoid valve

• Refer to symptom diagnosis No. D1: Faulty Gear Shifting or DTC P0731 - P0734 Incorrect Gear

Ratio diagnosis.

2. If there is no 2 to 3 upshift.

• Faulty operation of high clutch

• Faulty operation of high clutch hydraulic circuits

• Sticking of high clutch solenoid valve

• Refer to symptom diagnosis No. D1: Faulty Gear Shifting or DTC P0731 - P0734 Incorrect Gear

Ratio diagnosis.

3. If there is no 3 to 4 upshift.

• Faulty operation of 2-4 brake

• Faulty operation of 2-4 brake hydraulic circuits

• Sticking of 2-4 brake solenoid valve

• Refer to symptom diagnosis No. D1: Faulty Gear Shifting or DTC P0731 - P0734 Incorrect Gear

Ratio diagnosis.

4. If there is no lock up in 2nd, 3rd and 4th. • Faulty operation of torque converter clutch (TCC) piston

• Faulty operation of lock up hydraulic circuit

• Sticking of TCC solenoid valve

• Refer to symptom diagnosis No. I1: No Lock-up

5. If there is no reverse. • Faulty operation of reverse clutch

• Faulty operation of reverse clutch hydraulic circuits

• Faulty operation of low & reverse brake hydraulic circuits

Selector lever

position GearshiftSelected gear

position

P

R

N

D

3

2

L 1st

2nd 3rd4th1st

2nd 3rd

4th(*1) 1st

2nd

3rd(*1) 4th(*1) 1st

2nd(*1) 3rd(*1)4th(*1)

Reverse

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 4423 of 6020

TRANSMISSION CONTROL SYSTEM (JR405E) 7A2-139

Repair Instructions

Transmission Controls Module (TCM) Replacement

Description

The following A - C steps provide an overview

procedure to replace and reprogram a TCM. Each A -C

steps is explained further in this section.

A. Replace the old TCM with the new TCM.

B. Program the latest software and calibrations into the

new TCM using the Service Programming System

(SPS) if released. If not released, do not perform this

and skip to Step C.

C. Program the vehicle identification number (VIN) into

the TCM.

A. Removal and Installation

Removal Procedure 1. Disconnect the negative battery cable.

2. Disconnect the TCM harness connectors (1).

3. Loosen nuts (2) and remove the TCM (3) from the bracket (4).

Installation Procedure

Follow the removal steps in the reverse order. Be sure

that the connectors are securely fastened.

B. Programming Software and Calibrations

Program the latest software/ calibrations if released.

Refer to Service Programming System (SPS)

Description and SPS (Remote Procedure) or SPS

(Pass-Thru Procedure) in this section. If not released,

do not perform this and skip to Step C.

C. Programming Vehicle Identification Number

(VIN) Notice:

If you have performed SPS in the previous

step, VIN has prgrommaned already. Programming VIN

is not necessary in this step.

1. Install a scan tool.

2. Turn ON the ignition, with the engine OFF.

3. Select Diagnostics > appropriate vehicle identification > AT JR405E > Programming >

Program VIN.

4. If you installed a new, skip to step 8. If you installed a reused TCM from another vehicle or incorrect

VIN is programmed before, the TCM might be

locked already. In order to get programming

approval, the on-screen displays a message to

user. Get programming approval from the TIS

2000 using the following procedure:

a. Connect a scan tool to the terminal that installed TIS 2000 with the latest software and

the hardware key is plugged into port.

b. Turn ON the scan tool and keep at title screen.

c. Launch the TIS application.

d. Select the Security Access at the main screen.

e. Highlight the “Tech 2" on the Diagnostic Tool Selection screen and click “Next”.

f. Click “Close” on the Security Access Enabled screen.

g. Turn OFF the scan tool.

h. Disconnect the scan tool from the terminal.

5. Install a scan tool to the vehicle.

6. Turn ON the ignition, with the engine OFF.

7. Select Diagnostics > appropriate vehicle identification > AT JR405E > Programming >

Program VIN.

8. Input 17 digits of correct VIN.

9. After complete the programming, turn OFF/ ON the ignition.

10. Select Diagnostics > Lock ECU.

11. Follow the on-screen instructions and turn OFF/ ON the ignition.

Service Programming System (SPS)

Description

The service programming system (SPS) allows a

technician to program a control module through the

data link connector (DLC). The information transfer

circuit that is used at the DLC is the same serial data

circuit used by the scan tool for retrieving DTCs,

displaying data, clearing DTCs etc. This procedure

offers the ability to install software/ calibrations

matched to a particular vehicle.

Most control modules have two types of memory. The

software/ calibrations reside in the flash memory. The

two types of memory are listed below:

1

3 42

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 4428 of 6020

7A2-144 TRANSMISSION CONTROL SYSTEM (JR405E)

The JR405E automatic transmission is electrically

controlled by a transmission control module (TCM).

There are four forward speeds and one reverse speed.

This JR405E automatic transmission employs a clutch

pressure direct control system (Direct Electronic Shift

Control: DESC) using duty cycle type solenoid valves,

which ensure high shift quality. This transmission also

has a learning function and constantly checks the time

of each clutch and brake required for the shift in order

to match this time with the target value for the optimum

shift. The TCM will automatically select the most

appropriate shift points and lock-up points depending

on the accelerator pedal opening, the vehicle speed

and the vehicle load. If any trouble arises in the speed

sensor, solenoid valve, etc., the fail-safe control

function is activated to keep the running performance.

The JR405E automatic transmission consists of the

torque converter, oil pump, input shaft, out put shaft,

planetary gears and valve body. The gear train consists

of two planetary gear sets and three multiple plate

clutches in combination with two multiple plate brakes

and a one-way clutch.

Transmission Component Description

Torque Converter

Legend

1. Pump impeller

2. Turbine runner

3. Stator

4. Converter front cover

5. One-way clutch

6. Torque converter clutch (TCC) piston

7. Torsion damper

The torque converter is a device for transmitting the

engine torque to the transmission. It transmits power by

means of oil when the lock up clutch is disengaged,

and by means of a lock up clutch when it is engaged. The torque converter is of the symmetrical, three-

element, single-stage, two-phase type. As shown in the

picture, the symmetrical three-elements refer to three

elements (components) consisting of impeller (1),

turbine (2) and stator (3) that are arranged

symmetrically. Single-stage means that there is only

one turbine as an output element; two-phase means

that the pump impeller acts as a torque converter when

the turbine speed is comparatively low, and as a fluid

coupling when the speed is high. Lock up refers to a

fixed state of the lock up clutch (=torque converter

clutch (TCC) inside the torque converter and thus

connects the engine directly to the transmission.

Oil Pump

Legend 1. Torque converter

2. Oil pump

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007