clutch ISUZU KB P190 2007 Workshop Manual Online

[x] Cancel search | Manufacturer: ISUZU, Model Year: 2007, Model line: KB P190, Model: ISUZU KB P190 2007Pages: 6020, PDF Size: 70.23 MB

Page 1472 of 6020

6A-112 ENGINE MECHANICAL (4JK1/4JJ1)

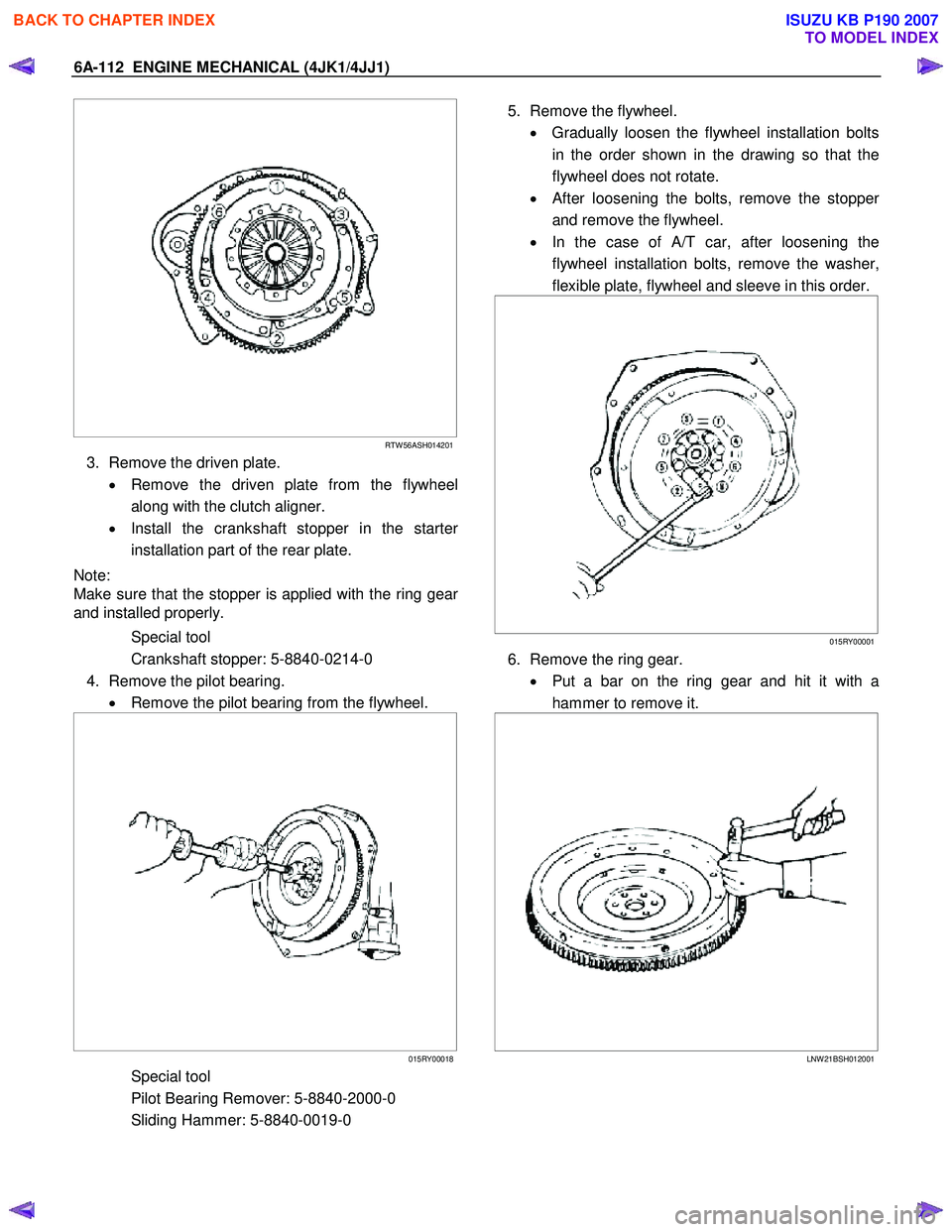

RTW 56ASH014201

3. Remove the driven plate.

• Remove the driven plate from the flywheel

along with the clutch aligner.

• Install the crankshaft stopper in the starte

r

installation part of the rear plate.

Note:

Make sure that the stopper is applied with the ring gea

r

and installed properly.

Special tool

Crankshaft stopper: 5-8840-0214-0

4. Remove the pilot bearing. • Remove the pilot bearing from the flywheel.

015RY00018

Special tool

Pilot Bearing Remover: 5-8840-2000-0

Sliding Hammer: 5-8840-0019-0

5. Remove the flywheel.

• Gradually loosen the flywheel installation bolts

in the order shown in the drawing so that the

flywheel does not rotate.

•

After loosening the bolts, remove the stopper

and remove the flywheel.

• In the case of A/T car, after loosening the

flywheel installation bolts, remove the washer,

flexible plate, flywheel and sleeve in this order.

015RY00001

6. Remove the ring gear.

• Put a bar on the ring gear and hit it with a

hammer to remove it.

LNW 21BSH012001

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 1473 of 6020

ENGINE MECHANICAL (4JK1/4JJ1) 6A-113

Inspection

1. Visual inspection

• Inspect the flywheel friction surface for cracks

and damages, and replace it if it has

abnormality.

• Inspect the tooth part of the ring gear, replace

the ring gear if it has damage or serious wear.

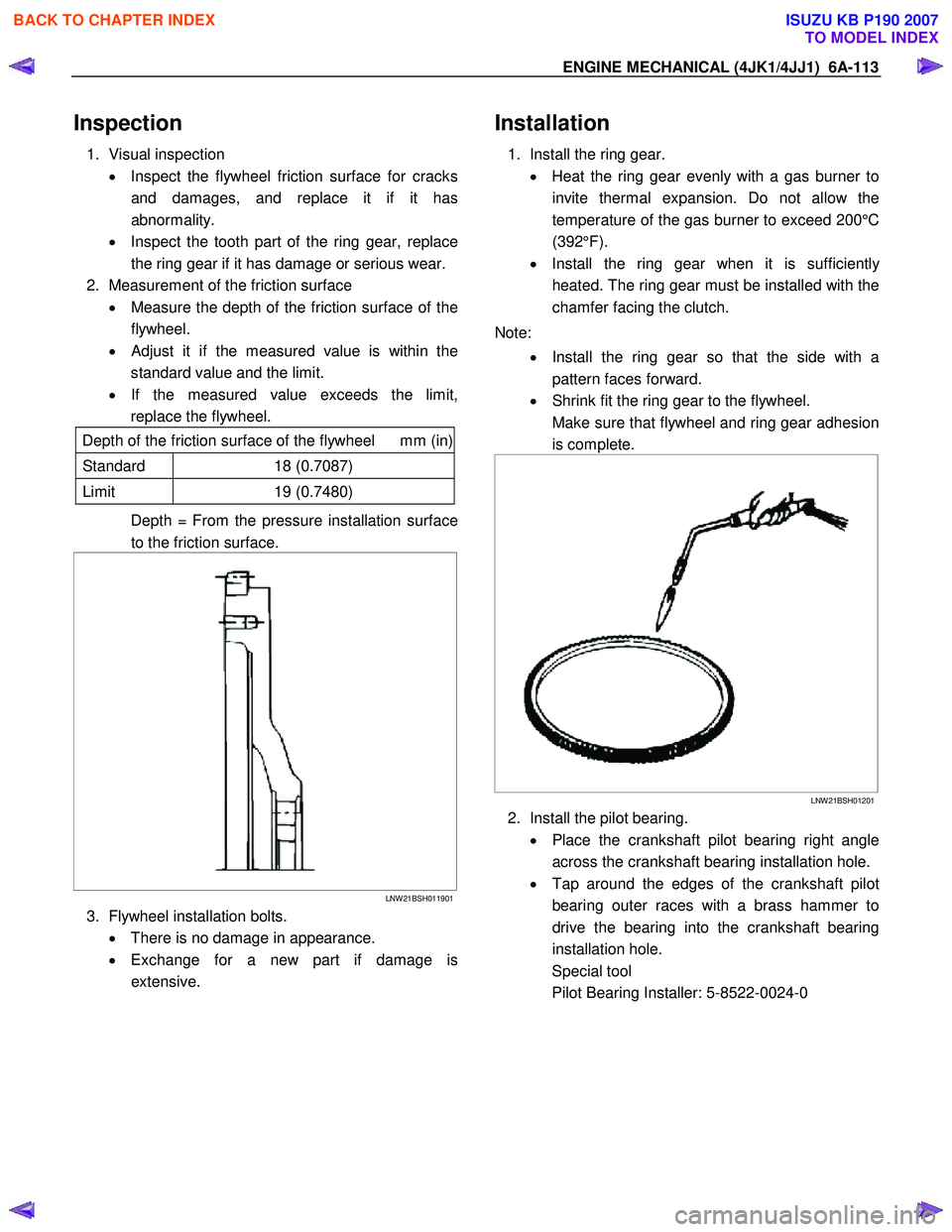

2. Measurement of the friction surface • Measure the depth of the friction surface of the

flywheel.

•

Adjust it if the measured value is within the

standard value and the limit.

• If the measured value exceeds the limit,

replace the flywheel.

Depth of the friction surface of the flywheel mm (in)

Standard 18 (0.7087)

Limit 19 (0.7480)

Depth = From the pressure installation surface

to the friction surface.

LNW 21BSH011901

3. Flywheel installation bolts.

• There is no damage in appearance.

• Exchange for a new part if damage is

extensive.

Installation

1. Install the ring gear.

• Heat the ring gear evenly with a gas burner to

invite thermal expansion. Do not allow the

temperature of the gas burner to exceed 200°C

(392°F).

• Install the ring gear when it is sufficientl

y

heated. The ring gear must be installed with the

chamfer facing the clutch.

Note: • Install the ring gear so that the side with a

pattern faces forward.

• Shrink fit the ring gear to the flywheel.

Make sure that flywheel and ring gear adhesion is complete.

LNW 21BSH01201

2. Install the pilot bearing.

• Place the crankshaft pilot bearing right angle

across the crankshaft bearing installation hole.

• Tap around the edges of the crankshaft pilot

bearing outer races with a brass hammer to

drive the bearing into the crankshaft bearing

installation hole.

Special tool

Pilot Bearing Installer: 5-8522-0024-0

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 1474 of 6020

6A-114 ENGINE MECHANICAL (4JK1/4JJ1)

015RY00010

3. Install the flywheel.

• Install the flywheel of the crankshaft, tighten

them in the order shown in the illustration.

•

Apply molybdenum disulfide on the screw part

and setting face of the bolt.

• Install the crankshaft stopper on the starte

r

installation part of the rear plate.

Tightening torque: 1st step = 59 N ⋅

⋅⋅

⋅

m (6.0 kg ⋅

⋅⋅

⋅

m / 43 lb ft)

2nd step = 60° - 90° (degrees)

Special tool

Crankshaft stopper: 5-8840-0214-0

015RY00001

4. Install the driven plate.

• Use a clutch aligner to install the driven plate

on the flywheel.

LNW 21BSH002601

Legend

1. Clutch Aligner

5. Install the clutch pressure plate.

• Install the pressure plate on the flywheel so that

the installation hole of the pressure plate

matches with the dowel pins of the flywheel.

• Tighten the pressure plate in the order shown

in the illustration.

Tightening torque: 18 N ⋅

⋅⋅

⋅

m (1.8 kg ⋅

⋅⋅

⋅

m / 13 lb ft)

RTW 56ASH023301

6. Install the transmission assembly.

Refer to removal procedure for “TRANSMISSION”.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 1483 of 6020

ENGINE MECHANICAL (4JK1/4JJ1) 6A-123

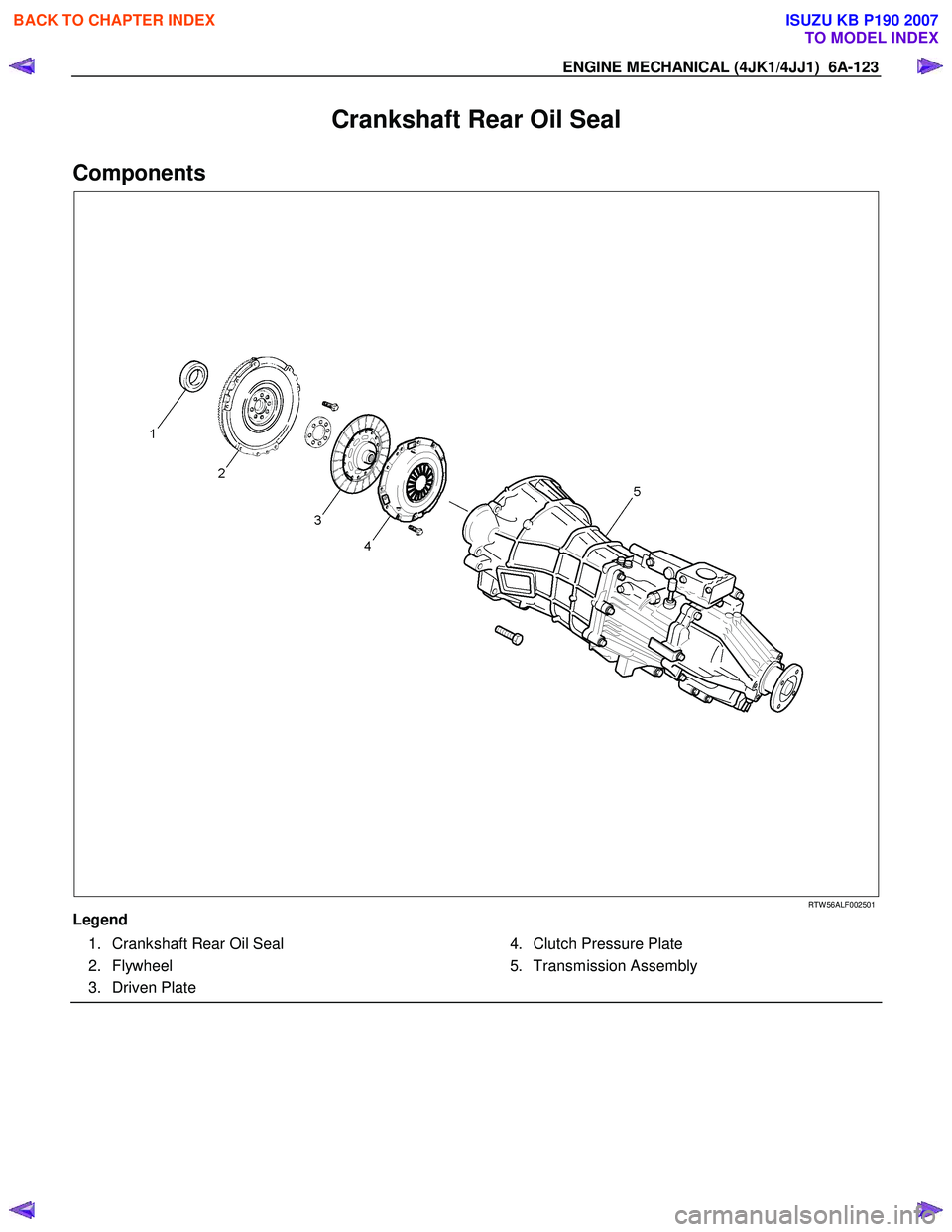

Crankshaft Rear Oil Seal

Components

RTW 56ALF002501

Legend 1. Crankshaft Rear Oil Seal

2. Flywheel

3. Driven Plate 4. Clutch Pressure Plate

5. Transmission Assembly

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 1516 of 6020

6A-156 ENGINE MECHANICAL (4JK1/4JJ1)

Oil Pump

Components

RTW 66AMF000701

Legend 1. Bolt 2. Oil Pump Assembly

Removal

1. Drain the engine coolant.

2. Remove the radiator upper hose.

3. Remove the upper fan shroud.

4. Remove the fan and fan clutch. • Loosen the fan clutch nuts.

• Remove the fan together with the fan clutch.

Take care not to damage the radiator core.

5. Remove the fan drive belt and pulley. • Loosen the tension adjust bolt on the generato

r

and A/C.

• Remove the fan drive belt with the fan pulley.

6. Remove the lower fan shroud.

7. Disconnect the power steering pump. • Disconnect the bracket of the power steering oil

hose clip (1).

LTW 56ASH000101

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 1520 of 6020

6A-160 ENGINE MECHANICAL (4JK1/4JJ1)

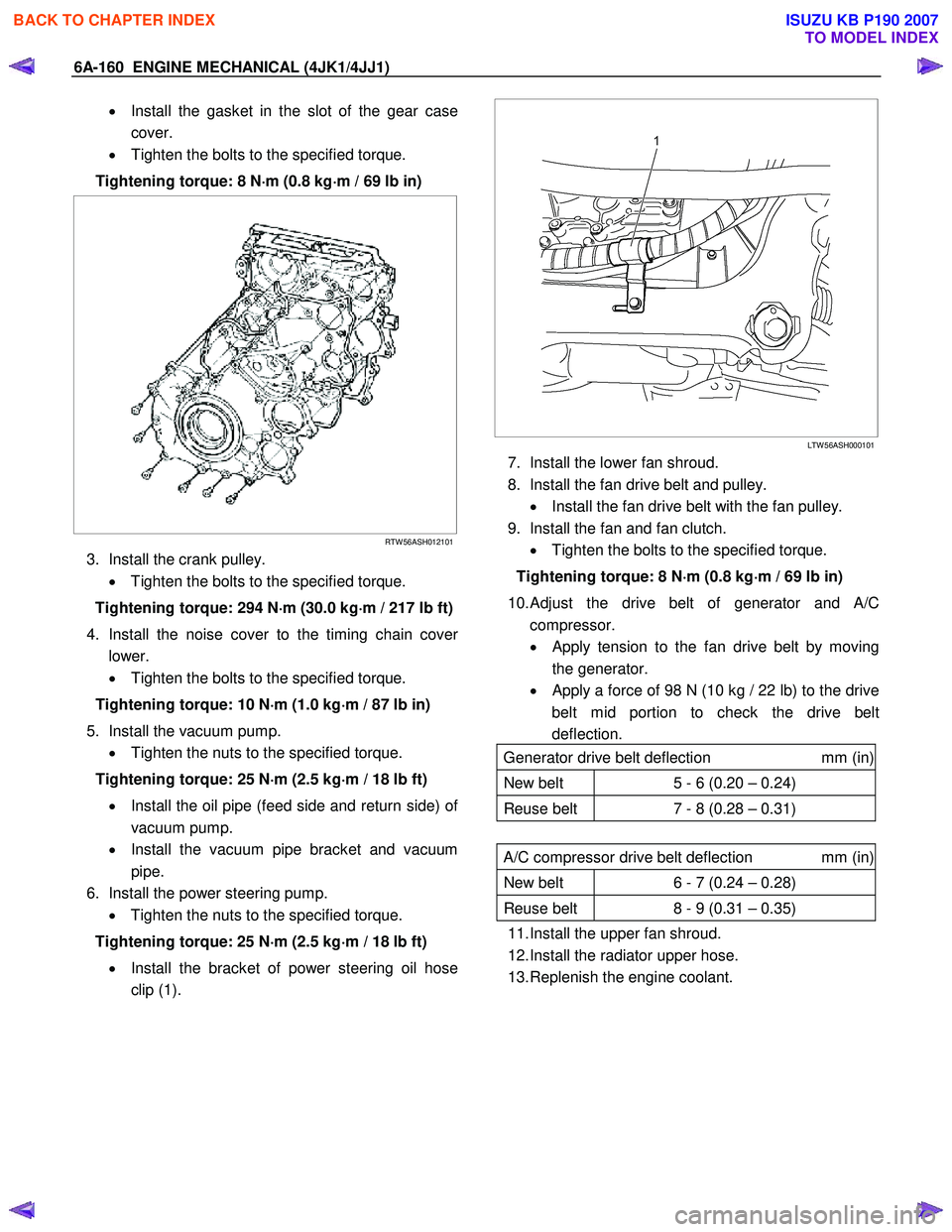

• Install the gasket in the slot of the gear case

cover.

• Tighten the bolts to the specified torque.

Tightening torque: 8 N ⋅

⋅⋅

⋅

m (0.8 kg ⋅

⋅⋅

⋅

m / 69 lb in)

RTW 56ASH012101

3. Install the crank pulley.

• Tighten the bolts to the specified torque.

Tightening torque: 294 N ⋅

⋅⋅

⋅

m (30.0 kg ⋅

⋅⋅

⋅

m / 217 lb ft)

4. Install the noise cover to the timing chain cove

r

lower.

• Tighten the bolts to the specified torque.

Tightening torque: 10 N ⋅

⋅⋅

⋅

m (1.0 kg ⋅

⋅⋅

⋅

m / 87 lb in)

5. Install the vacuum pump. • Tighten the nuts to the specified torque.

Tightening torque: 25 N ⋅

⋅⋅

⋅

m (2.5 kg ⋅

⋅⋅

⋅

m / 18 lb ft)

• Install the oil pipe (feed side and return side) o

f

vacuum pump.

• Install the vacuum pipe bracket and vacuum

pipe.

6. Install the power steering pump. • Tighten the nuts to the specified torque.

Tightening torque: 25 N ⋅

⋅⋅

⋅

m (2.5 kg ⋅

⋅⋅

⋅

m / 18 lb ft)

• Install the bracket of power steering oil hose

clip (1).

LTW 56ASH000101

7. Install the lower fan shroud.

8. Install the fan drive belt and pulley. • Install the fan drive belt with the fan pulley.

9. Install the fan and fan clutch. • Tighten the bolts to the specified torque.

Tightening torque: 8 N ⋅

⋅⋅

⋅

m (0.8 kg ⋅

⋅⋅

⋅

m / 69 lb in)

10.

Adjust the drive belt of generator and A/C

compressor.

• Apply tension to the fan drive belt by moving

the generator.

•

Apply a force of 98 N (10 kg / 22 lb) to the drive

belt mid portion to check the drive belt

deflection.

Generator drive belt deflection mm (in)

New belt 5 - 6 (0.20 – 0.24)

Reuse belt 7 - 8 (0.28 – 0.31)

A/C compressor drive belt deflection mm (in)

New belt 6 - 7 (0.24 – 0.28)

Reuse belt 8 - 9 (0.31 – 0.35)

11. Install the upper fan shroud.

12. Install the radiator upper hose.

13. Replenish the engine coolant.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 1524 of 6020

ENGINE COOLING (4JK1/4JJ1) 6B-1

SECTION 6B

ENGINE COOLING

TABLE OF CONTENTS

Main Data and Specifications ............................. 6B-2

General Description............................................ 6B-3 Coolant Flow ................................................... 6B-3

W ater Pump .................................................... 6B-4

Thermostat ...................................................... 6B-4

Radiator ........................................................... 6B-5

Antifreeze Solution .......................................... 6B-5

Diagnosis............................................................ 6B-6

Draining and Refilling Cooling System ............... 6B-7

W ater Pump ....................................................... 6B-8 Removal .......................................................... 6B-8

Inspection and Repair ..................................... 6B-9

Installation ....................................................... 6B-9

Thermostat ......................................................... 6B-11 Removal .......................................................... 6B-11

Inspection and Repair ..................................... 6B-11

Operating Test of Thermostat ......................... 6B-11

Installation ....................................................... 6B-12

Radiator .............................................................. 6B-13 Radiator and Associated Parts........................ 6B-13

Removal .......................................................... 6B-14

Inspection and Repair ..................................... 6B-15

Radiator Cap ................................................... 6B-15

Radiator Core .................................................. 6B-15

Flushing the Radiator ...................................... 6B-15

Cooling System Leakage Check ..................... 6B-15

Installation ....................................................... 6B-16

Engine Coolant Change .................................. 6B-16

Fan Clutch with Cooling Fan .............................. 6B-17 Inspection and Repair ..................................... 6B-17

Special Tools................................................... 6B-18

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 1531 of 6020

6B-8 ENGINE COOLING (4JK1/4JJ1)

Water Pump

Read this Section carefully before performing any

removal and installation procedure. This Section gives

you important points as well as the order of operation.

Be sure that you understand everything in this Section

before you begin.

Removal

1. Remove the engine cover.

2. Radiator Upper Hose a. Partially drain the engine coolant.

b. Remove the radiator upper hose.

RTW 56FSH000101

3. W ater Outlet Pipe

a. Disconnect the turbocharger-cooling pipe from the outlet pipe.

b. Loosen the fixing bolt and remove the wate

r

outlet bolt.

4. Upper Fan Shroud

5. Fan and Fan Clutch a. Loosen the fan clutch nuts.

b. Remove the fan together with the fan clutch. Take care not to damage the radiator core.

6. Fan Drive Belt and Pulley a. Loosen the tension adjust bolt on the generator.

b. Remove the fan drive belt with the fan pulley.

RTW 56ASH025401

7. W ater Pump

a. Remove the water pump bolts and nuts.

b. Remove the water pump.

RTW 56BSH000201

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 1532 of 6020

ENGINE COOLING (4JK1/4JJ1) 6B-9

Inspection and Repair

The water pump is not disassembled type.

Make necessary parts replacement if extreme wear o

r

damage is found during inspection. Should any of the

following problems occur, the entire water pump

assembly must be replaced.

• Cracks in the water pump body.

• Coolant leakage from the sealed unit.

• Excessive radial play or abnormal noise in the fan

center when rotated by hand.

• Excessive thrust play in the fan center (Standard

play: less than 0.2 mm (0.0078 in)).

• Cracks or corrosion in the impeller.

Installation

1. W ater Pump

RTW 56BSH000201

a. Install the water pump with a new gasket.

b. Tighten bolts and nuts to specified torque.

Water Pump Nut/Bolt Torque: 25 N·m (2.5 kg·m /18 lb ft)

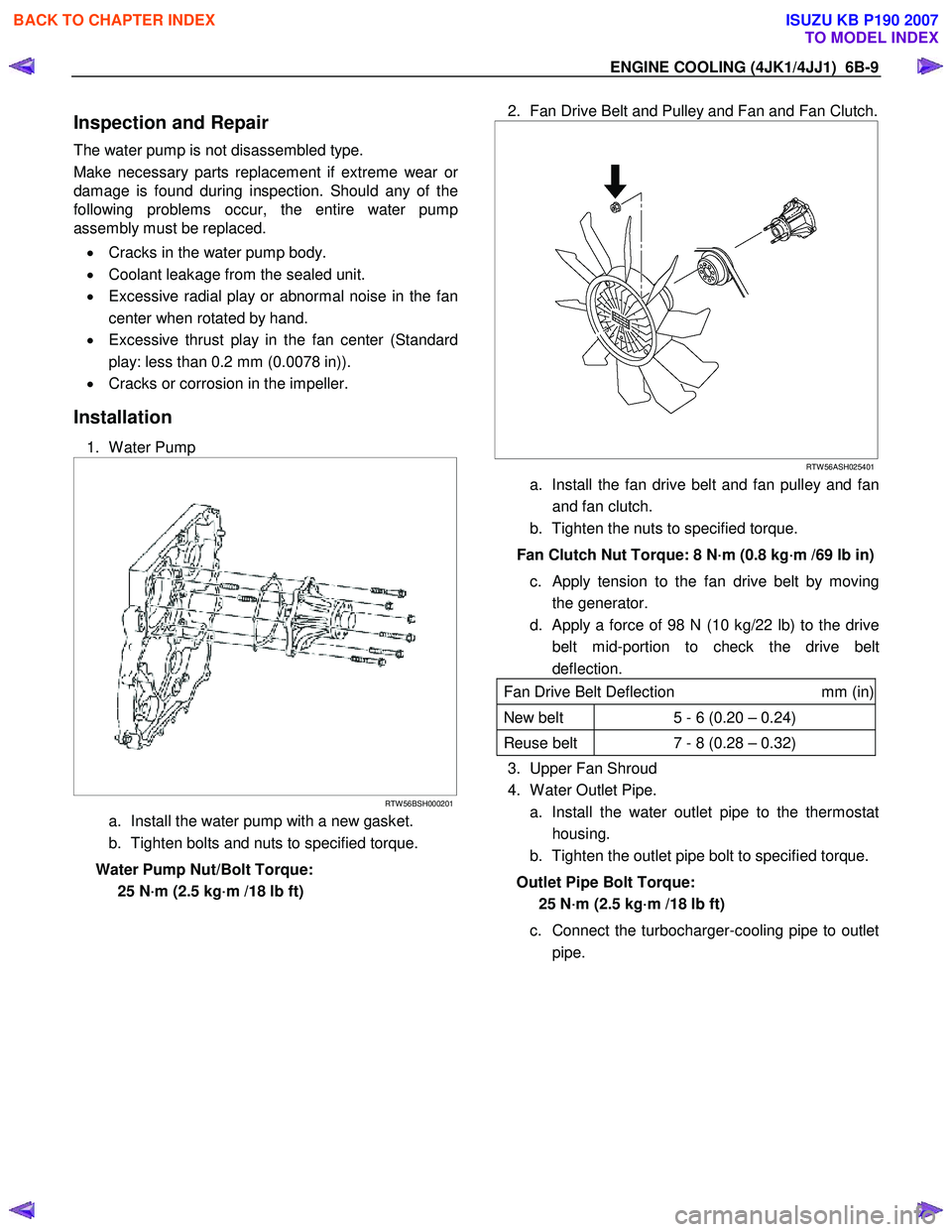

2. Fan Drive Belt and Pulley and Fan and Fan Clutch.

RTW 56ASH025401

a. Install the fan drive belt and fan pulley and fan

and fan clutch.

b. Tighten the nuts to specified torque.

Fan Clutch Nut Torque: 8 N·m (0.8 kg·m /69 lb in) c. Apply tension to the fan drive belt by moving the generator.

d. Apply a force of 98 N (10 kg/22 lb) to the drive belt mid-portion to check the drive belt

deflection.

Fan Drive Belt Deflection mm (in)

New belt 5 - 6 (0.20 – 0.24)

Reuse belt 7 - 8 (0.28 – 0.32)

3. Upper Fan Shroud

4. W ater Outlet Pipe.

a. Install the water outlet pipe to the thermostat housing.

b. Tighten the outlet pipe bolt to specified torque.

Outlet Pipe Bolt Torque: 25 N·m (2.5 kg·m /18 lb ft)

c. Connect the turbocharger-cooling pipe to outlet pipe.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 1540 of 6020

ENGINE COOLING (4JK1/4JJ1) 6B-17

Fan Clutch with Cooling Fan

Inspection and Repair

Make necessary correction or parts replacement if

wear, damage or any other abnormal conditions are

found through inspection.

Visually inspect for damage, leak (silicon grease) o

r

other abnormal conditions.

1. Inspection (on-vehicle) a) Turn the fan clutch by hand when in a lo

w

temperature condition before starting the

engine, and confirm that it can be turned

readily.

b) Start the engine to warm it up until the temperature at the fan clutch portion gets to

around 85°C (185°F). Then stop the engine and

confirm that the fan clutch can be turned with

considerable effort (clutch torque) when turned

by hand.

If the fan clutch rotates more readily, however, this indicates that the silicone grease is leaking

internally.

Replace the fan clutch with a new one.

RTW 56ASH025401

2. Inspection (in unit)

W arm up the bimetal of the fan clutch by using the heat gun until the temperature gets to about 85°C

when measured with the thermistor. Then confirm

that the fan clutch can be turned with considerable

effort (clutch torque).

If the fan clutch rotates more readily at this time, this indicates that the silicone grease is leaking

internally.

Replace the fan clutch with a new one.

033RY00011

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007