inflation pressure ISUZU KB P190 2007 Workshop Repair Manual

[x] Cancel search | Manufacturer: ISUZU, Model Year: 2007, Model line: KB P190, Model: ISUZU KB P190 2007Pages: 6020, PDF Size: 70.23 MB

Page 251 of 6020

FRONT ALIGNMENT 3A-3

Inspection

Before making any adjustments affecting caster, camber or

toe-in, the following front end inspection should be made.

1. Inspect the tires for proper inflation pressure. Refer to

Main Data and Specifications in W heel and Tire System section.

2. Make sure that the vehicle is in an unladen condition (W ith no passengers or loading).

3. Make sure that the spare tire is installed at the normal position.

4. Inspect the front wheel bearings for proper adjustment. Refer to Front Hub and Disc Overhaul in Suspension

section.

5. Inspect the ball joints and tie rod ends. If excessive looseness is noted, correct before adjusting. Refer to

Steering Linkage in this section.

6. Inspect the wheel and tires for run-out. Refer to W heel Replacement in W heel and Tire System section.

7. Inspect the trim height. If not within specifications, the correction must be made before adjusting caster.

8. Inspect the steering unit for looseness at the frame.

9. Inspect shock absorbers for leaks or any noticeable noise. Refer to Shock Absorber in Suspension section.

10. Inspect the control arms or stabilizer bar attachment fo

r

looseness. Refer to Suspension section.

11. Inspect the front end alignment using alignment equipment. Follow the manufacturer’s instructions.

12. Park the vehicle on a level surface.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 261 of 6020

FRONT ALIGNMENT 3A-13

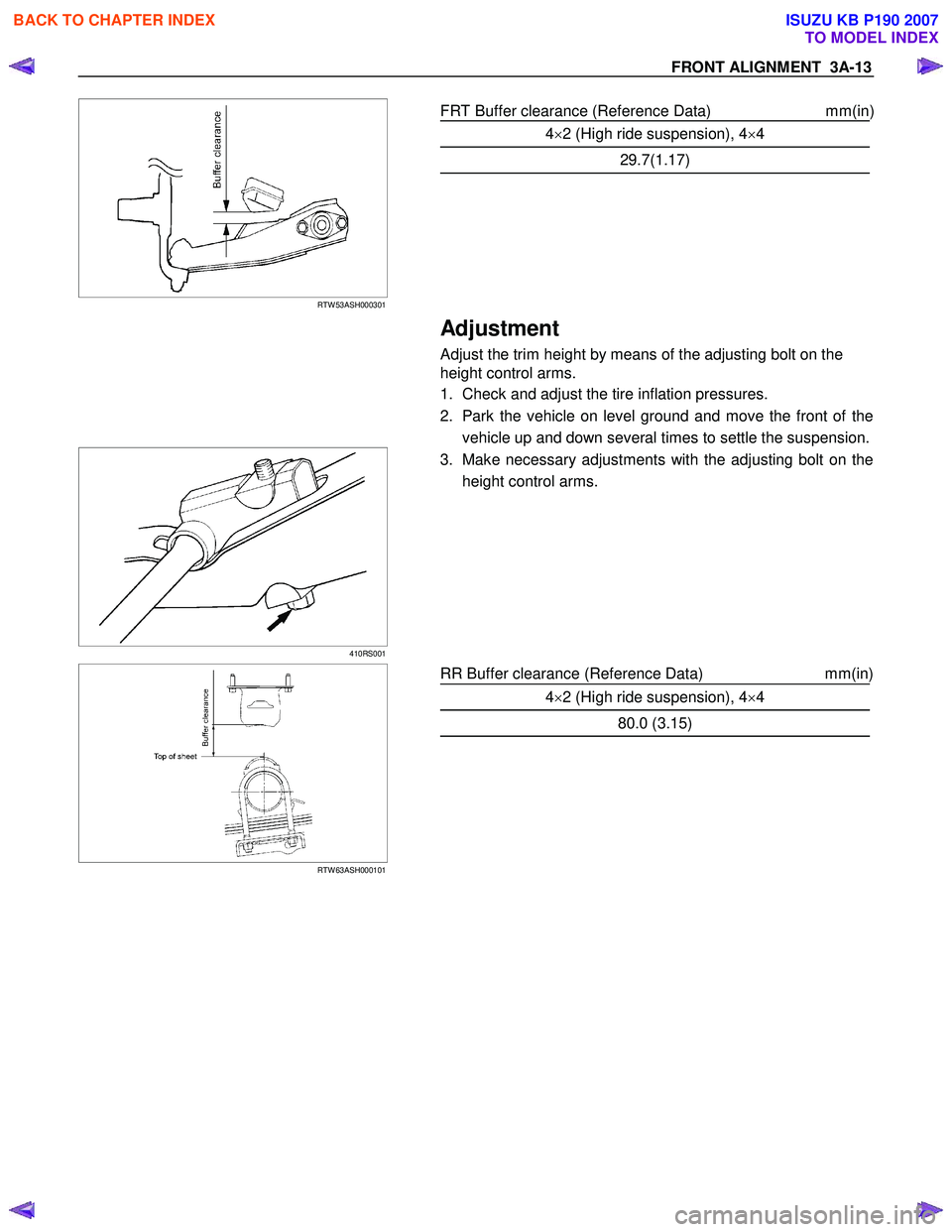

RTW 53ASH000301

FRT Buffer clearance (Reference Data) mm(in)

4×2 (High ride suspension), 4 ×4

29.7(1.17)

Adjustment

Adjust the trim height by means of the adjusting bolt on the

height control arms.

1. Check and adjust the tire inflation pressures.

2. Park the vehicle on level ground and move the front of the vehicle up and down several times to settle the suspension.

410RS001

3. Make necessary adjustments with the adjusting bolt on the

height control arms.

RTW 63ASH000101

RR Buffer clearance (Reference Data)

mm(in)

4×2 (High ride suspension), 4 ×4

80.0 (3.15)

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 404 of 6020

3D-20 REAR SUSPENSION

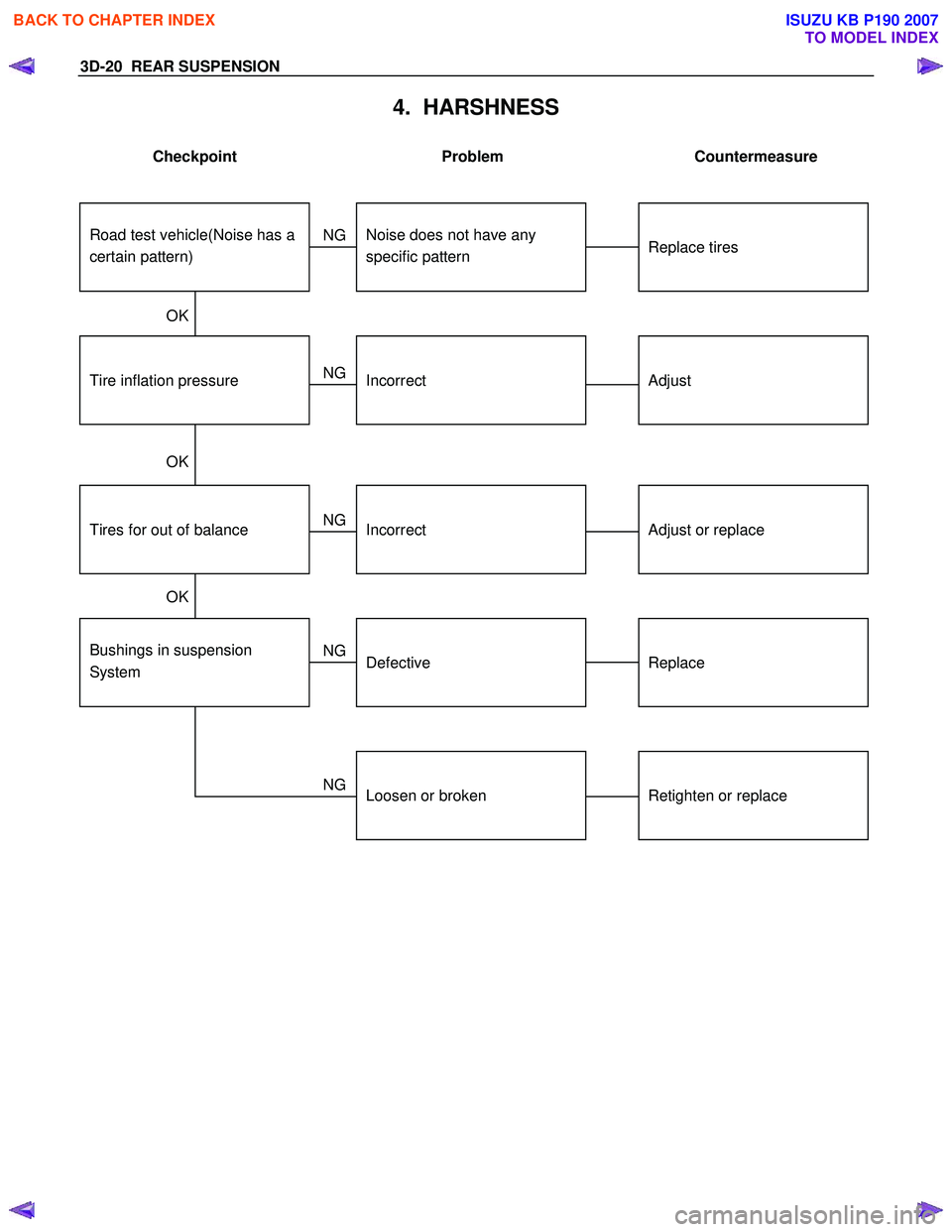

4. HARSHNESS

Checkpoint Problem Countermeasure

Bushings in suspension

System

Tire inflation pressure

Retighten or replace

Replace

Adjust

Loosen or broken

Defective

Incorrect

Tires for out of balance

Adjust or replace

Replace tires

Incorrect

Noise does not have any

specific pattern

OK NG

NG

NG

NG

NG

OK

OK Road test vehicle(Noise has a

certain pattern)

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 409 of 6020

WHEELS AND TIRES 3E-5

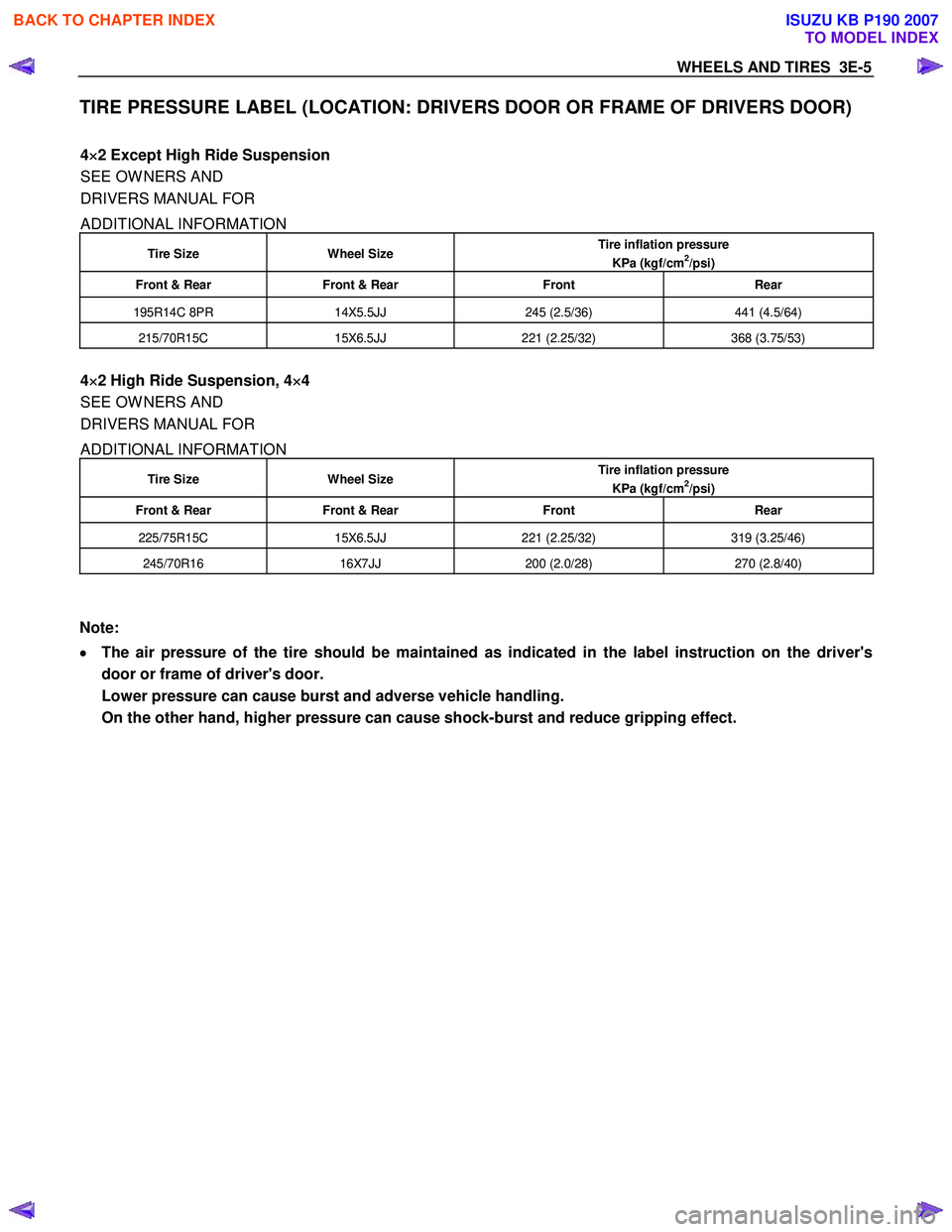

TIRE PRESSURE LABEL (LOCATION: DRIVERS DOOR OR FRAME OF DRIVERS DOOR)

4 ×

××

×

2 Except High Ride Suspension

SEE OW NERS AND

DRIVERS MANUAL FOR

ADDITIONAL INFORMATION

Tire Size Wheel Size Tire inflation pressure

KPa (kgf/cm

2/psi)

Front & Rear Front & Rear Front Rear

195R14C 8PR 14X5.5JJ 245 (2.5/36) 441 (4.5/64)

215/70R15C 15X6.5JJ 221 (2.25/32) 368 (3.75/53)

4 ×

××

×

2 High Ride Suspension, 4 ×

××

×

4

SEE OW NERS AND

DRIVERS MANUAL FOR

ADDITIONAL INFORMATION

Tire Size Wheel Size Tire inflation pressure

KPa (kgf/cm

2/psi)

Front & Rear Front & Rear Front Rear

225/75R15C 15X6.5JJ 221 (2.25/32) 319 (3.25/46)

245/70R16 16X7JJ 200 (2.0/28) 270 (2.8/40)

Note:

•

••

•

The air pressure of the tire should be maintained as indicated in the label instruction on the driver's

door or frame of driver's door.

Lower pressure can cause burst and adverse vehicle handling.

On the other hand, higher pressure can cause shock-burst and reduce gripping effect.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 2008 of 6020

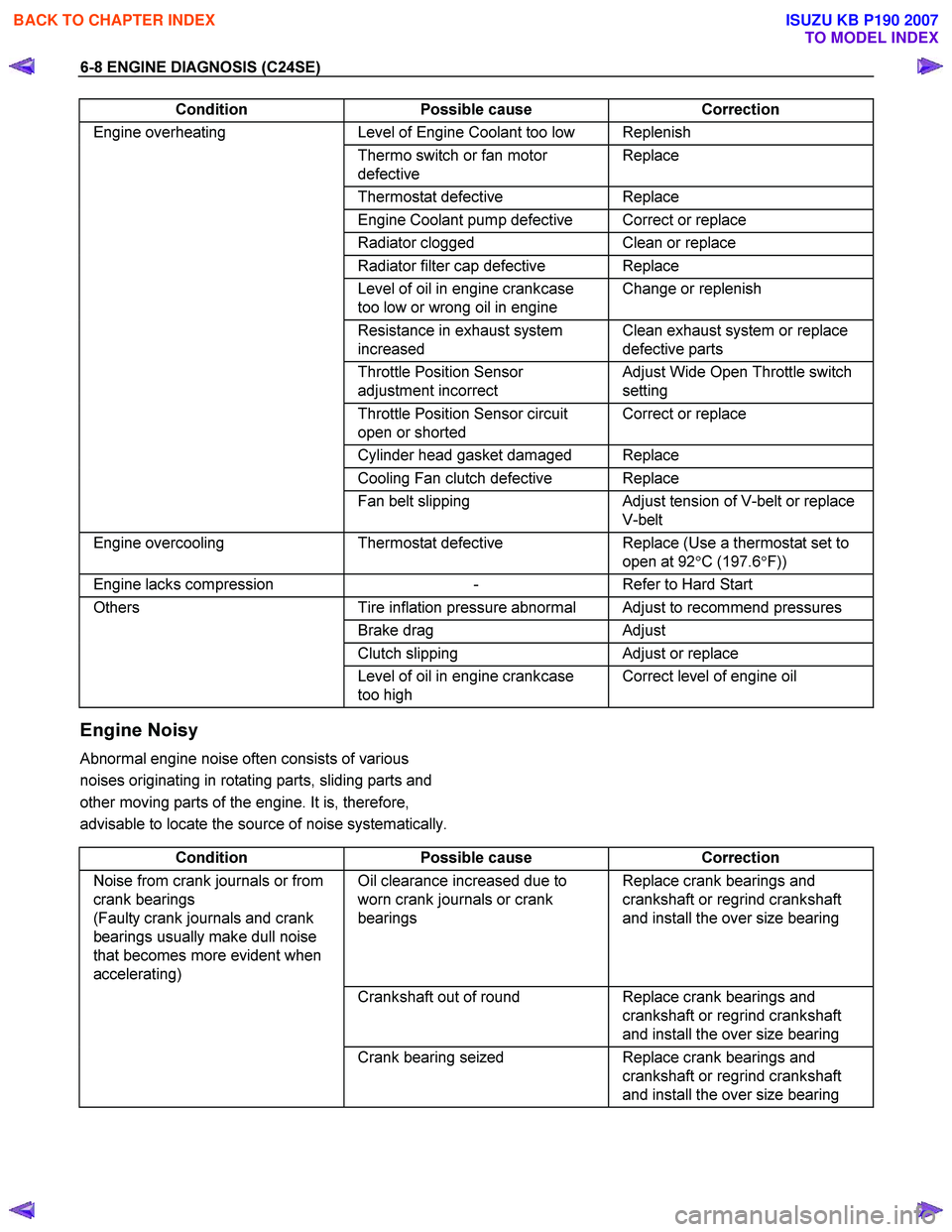

6-8 ENGINE DIAGNOSIS (C24SE)

Condition Possible cause Correction

Engine overheating Level of Engine Coolant too low Replenish

Thermo switch or fan motor

defective Replace

Thermostat

defective Replace

Engine Coolant pump defective Correct or replace

Radiator clogged Clean or replace

Radiator filter cap defective Replace

Level of oil in engine crankcase

too low or wrong oil in engine Change or replenish

Resistance in exhaust system

increased Clean exhaust system or replace

defective parts

Throttle Position Sensor

adjustment incorrect Adjust Wide Open Throttle switch

setting

Throttle Position Sensor circuit

open or shorted Correct or replace

Cylinder head gasket damaged Replace

Cooling Fan clutch defective Replace

Fan belt slipping Adjust tension of V-belt or replace

V-belt

Engine overcooling Thermostat defective Replace (Use a thermostat set to

open at 92 °C (197.6 °F))

Engine lacks compression - Refer to Hard Start

Others Tire inflation pressure abnormal Adjust to recommend pressures

Brake drag Adjust

Clutch slipping Adjust or replace

Level of oil in engine crankcase

too high Correct level of engine oil

Engine Noisy

Abnormal engine noise often consists of various

noises originating in rotating parts, sliding parts and

other moving parts of the engine. It is, therefore,

advisable to locate the source of noise systematically.

Condition Possible cause Correction

Noise from crank journals or from

crank bearings

(Faulty crank journals and crank

bearings usually make dull noise

that becomes more evident when

accelerating) Oil clearance increased due to

worn crank journals or crank

bearings Replace crank bearings and

crankshaft or regrind crankshaft

and install the over size bearing

Crankshaft out of round Replace crank bearings and

crankshaft or regrind crankshaft

and install the over size bearing

Crank bearing seized Replace crank bearings and

crankshaft or regrind crankshaft

and install the over size bearing

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 5111 of 6020

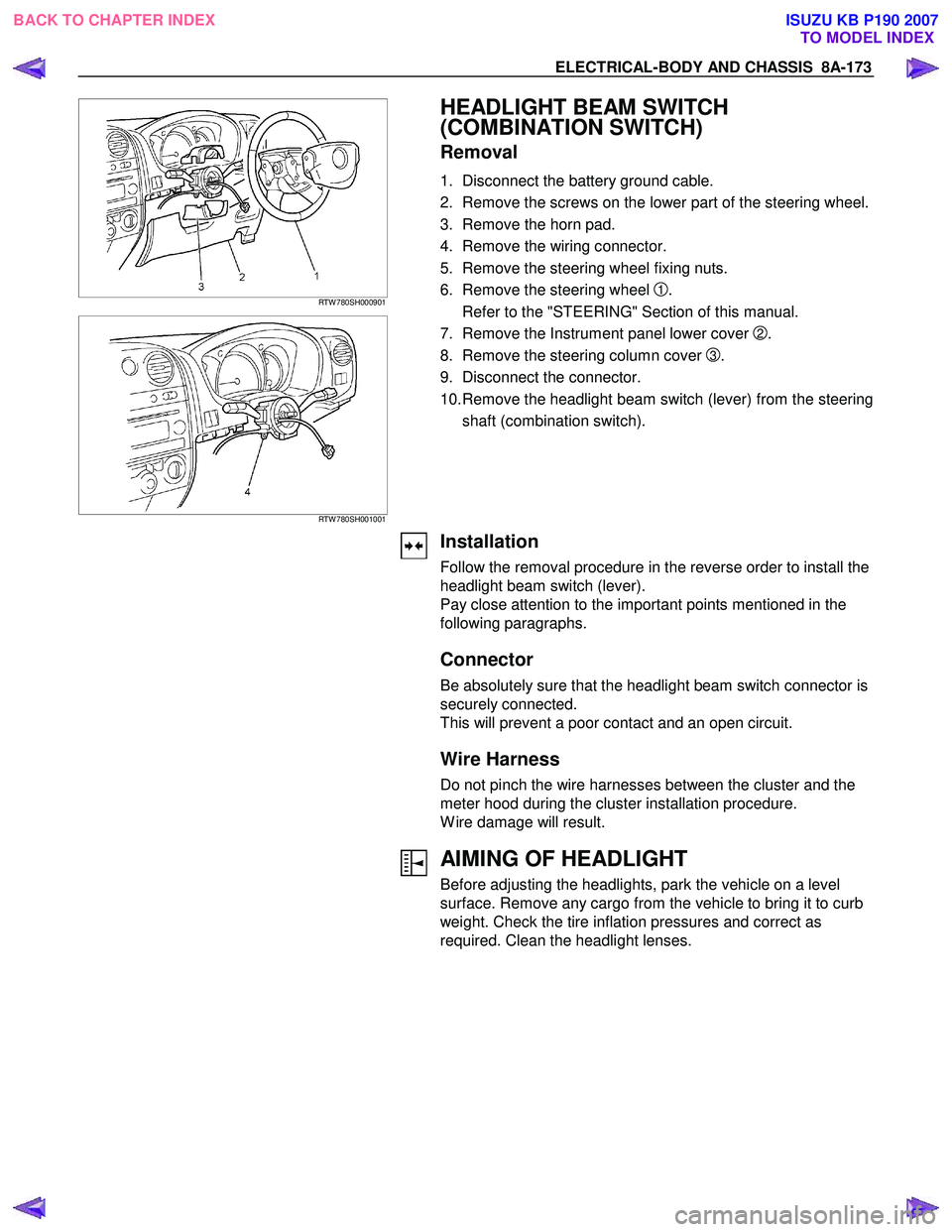

ELECTRICAL-BODY AND CHASSIS 8A-173

RTW 780SH000901

RTW 780SH001001

HEADLIGHT BEAM SWITCH

(COMBINATION SWITCH)

Removal

1. Disconnect the battery ground cable.

2. Remove the screws on the lower part of the steering wheel.

3. Remove the horn pad.

4. Remove the wiring connector.

5. Remove the steering wheel fixing nuts.

6. Remove the steering wheel

1.

Refer to the "STEERING" Section of this manual.

7. Remove the Instrument panel lower cover

2.

8. Remove the steering column cover

3.

9. Disconnect the connector.

10. Remove the headlight beam switch (lever) from the steering shaft (combination switch).

Installation

Follow the removal procedure in the reverse order to install the

headlight beam switch (lever).

Pay close attention to the important points mentioned in the

following paragraphs.

Connector

Be absolutely sure that the headlight beam switch connector is

securely connected.

This will prevent a poor contact and an open circuit.

Wire Harness

Do not pinch the wire harnesses between the cluster and the

meter hood during the cluster installation procedure.

W ire damage will result.

AIMING OF HEADLIGHT

Before adjusting the headlights, park the vehicle on a level

surface. Remove any cargo from the vehicle to bring it to curb

weight. Check the tire inflation pressures and correct as

required. Clean the headlight lenses.

BACK TO CHAPTER INDEX TO MODEL INDEXISUZU KB P190 2007

Page 5115 of 6020

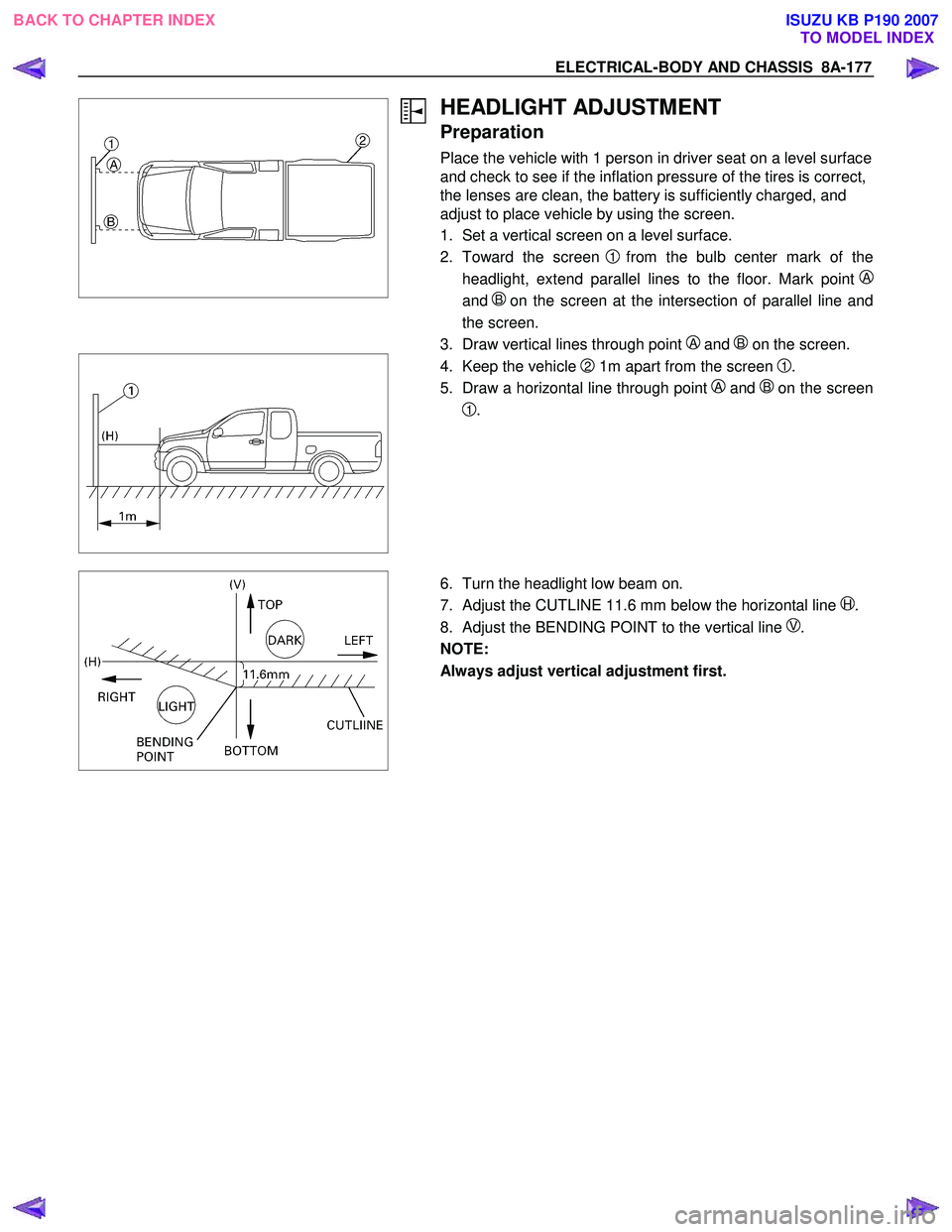

ELECTRICAL-BODY AND CHASSIS 8A-177

HEADLIGHT ADJUSTMENT

Preparation

Place the vehicle with 1 person in driver seat on a level surface

and check to see if the inflation pressure of the tires is correct,

the lenses are clean, the battery is sufficiently charged, and

adjust to place vehicle by using the screen.

1. Set a vertical screen on a level surface.

2. Toward the screen

1from the bulb center mark of the

headlight, extend parallel lines to the floor. Mark point

A

and B on the screen at the intersection of parallel line and

the screen.

3. Draw vertical lines through point

A and B on the screen.

4. Keep the vehicle 2 1m apart from the screen 1.

5. Draw a horizontal line through point

A and Bon the screen

1.

6. Turn the headlight low beam on.

7. Adjust the CUTLINE 11.6 mm below the horizontal line

H.

8. Adjust the BENDING POINT to the vertical line

V.

NOTE:

Always adjust vertical adjustment first.

BACK TO CHAPTER INDEX TO MODEL INDEXISUZU KB P190 2007