mirror ISUZU KB P190 2007 Workshop Repair Manual

[x] Cancel search | Manufacturer: ISUZU, Model Year: 2007, Model line: KB P190, Model: ISUZU KB P190 2007Pages: 6020, PDF Size: 70.23 MB

Page 2519 of 6020

Engine Mechanical – V6 Page 6A1–40

Cause Correction

W orn valve guides and or valve stems. Inspect and repair valves and valve guides as required,

refer to 3.22 Cylinder Head Assembly.

W orn or damaged valve stem oil seal. Replace valve stem oil seals as required, refer to 3.22

Cylinder Head Assembly.

Piston rings broken, worn or not seated correctly. Allowing adequate time for the piston rings to seat correctly,

replace piston rings as required, refer to 4.5 Pistons, Pins,

Rings, Connecting Rods and Big-end Bearings.

Piston rings incorrectly installed or not matched to cylinder

bore oversize. Replace piston rings as required, refer to 4.5 Pistons, Pins,

Rings, Connecting Rods and Big-end Bearings.

2.18 Engine Oil Leak Diagnosis

Introduction

It is important to correctly identify the source of an engine oil leak. For example, a power steering fluid leak or spillage

during servicing can travel across the valley area of the engine and run-out the weep hole, which is located at the back of

the cylinder block. Failure to correctly identify the source of an engine oil leak can lead to unnecessary replacement of

engine components.

Most fluid leaks can be repaired by repairing or replacing the faulty component or resealing the gasket surface. However,

once a leak is identified it is important to determine and repair the cause as well as the leak itself.

Locating and Identifying the Leak

Inspect the leaking fluid and determine whether it is engine oil, transmission fluid, power steering fluid, brake fluid or

some other fluid. If unsure of the source of the leaking lubricant, a quick check of fluid levels should indicate where the

fluid is coming from, as one or more fluid level should be low.

Visual Inspection

Once the type of leaking fluid has been determined, a visual inspection of the affected system should be performed.

W hen performing the visual inspection:

1 Bring the vehicle to the normal operating temperature.

2 Park the vehicle over a large sheet of paper or other clean surface.

3 Leave the vehicle idling for 2-3 minutes, then check for dripping fluid.

4 If required, identify the type of fluid leaking and the approximate location of the leak.

5 Visually inspect the suspected area. A small mirror may assist viewing areas that are difficult to see normally.

6 Check for leaks at all sealing surfaces and fittings.

7 Check for any cracked or damaged components.

8 If the leak cannot be located, completely clean the entire engine and surrounding components, drive the vehicle at normal operating temperature for several kilometres and then repeat Steps 3 to 8.

9 If the leak still cannot be located, proceed with either the Powder Method or Black Light and Dye Method as outlined below.

Powder Method

1 Completely clean the entire engine and surrounding components.

2 Apply an aerosol type powder (e.g. foot powder) to the suspected area.

3 Operate the vehicle at normal operating temperature and at varying speeds for several kilometres.

4 Identify the source of the leak from the discoloration of the powder around the suspect components.

5 If required, use a small mirror to assist in viewing areas that are difficult to see normally.

6 Refer to Possible Causes for Engine Oil Leaks in this Section, and repair or replace components as required.

Black Light and Dye Method

A black light and die kit Tool No. J28428-E or a commercially available equivalent is available to technicians to aid in

engine oil leak diagnosis. W hen using a black light and die kit for the first time, it is recommended the technician read the

manufacturers instructions prior to using the kit.

1 Add the specified amount of dye, as per manufacturers instructions, into the engine or suspected source of the oil leak.

2 Operate the vehicle at normal operating temperature and at varying speeds for several kilometres.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 2825 of 6020

Engine Mechanical – V6 Page 6A1–48

Page 6A1–48

2.18 Engine Oil Leak Diagnosis

Introduction

It is important to correctly identify the source of an engine oil leak. For example, a power steering fluid leak or spillage

during servicing can travel across the va lley area of the engine and run-out the weep hole, which is located at the back of

the cylinder block. Failure to correctly identify the source of an engine oil leak can lead to unnecessary replacement of

engine components.

Most fluid leaks can be repaired by repairi ng or replacing the faulty component or resealing the gasket surface. However,

once a leak is identified it is im portant to determine and repair the c ause as well as the leak itself.

Locating and Identifying the Leak

Inspect the leaking fluid and determine whet her it is engine oil, transmission fluid, power steering fluid, brake fluid or

some other fluid. If unsure of the source of the leaking lubricant, a quick check of fluid levels should indicate where the

fluid is coming from, as one or more fluid level should be low.

Visual Inspection

Once the type of leaking fluid has been determined, a visual inspection of the affected system should be performed.

When performing the visual inspection:

1 Bring the vehicle to the normal operating temperature.

2 Park the vehicle over a large s heet of paper or other clean surface.

3 Leave the vehicle idling for 2-3 minut es, then check for dripping fluid.

4 If required, identify the type of fluid leak ing and the approximate location of the leak.

5 Visually inspect the suspected area. A small mirror may assist viewing areas that are difficult to see normally.

6 Check for leaks at all sealing surfaces and fittings.

7 Check for any cracked or damaged components.

8 If the leak cannot be located, completely clean the entire engine and surrounding components, drive the vehicle at

normal operating temperature for several k ilometres and then repeat Steps 3 to 8.

9 If the leak still cannot be located, proceed with either the Powder Method or Black Light and Dye Method as

outlined below.

Powder Method

1 Completely clean the entir e engine and surrounding components.

2 Apply an aerosol type powder (e.g. f oot powder) to the suspected area.

3 Operate the vehicle at normal operating temperature and at varying speeds for several kilometres.

4 Identify the source of the leak from the discoloration of the powder around the suspect components.

5 If required, use a small mirror to assist in vi ewing areas that are difficult to see normally.

6 Refer to Possible Causes for Engine Oil Leaks in this Section, and repair or replace components as required.

Black Light and Dye Method

A black light and die kit Tool No. J28428-E or a commercially av ailable equivalent is available to technicians to aid in

engine oil leak diagnosis. When using a black light and die kit fo r the first time, it is recommended the technician read the

manufacturers instructions prior to using the kit.

1 Add the specified amount of dye, as per manufacturers instructions, into the engine or suspected source of the oil

leak.

2 Operate the vehicle at normal operating temperature and at varying speeds for several kilometres.

3 With the vehicle parked on a flat leve l surface, aim the black light at the suspected component/s. The dyed fluid will

appear as a yellow path leading to the oil leak source

4 Refer to Possible Causes for Engine Oil Leaks in this Section, and repair or replace components as required.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3800 of 6020

Automatic Transmission – 4L60E – Electrical Diagnosis Page 7C2–14

3 Tech 2 Information

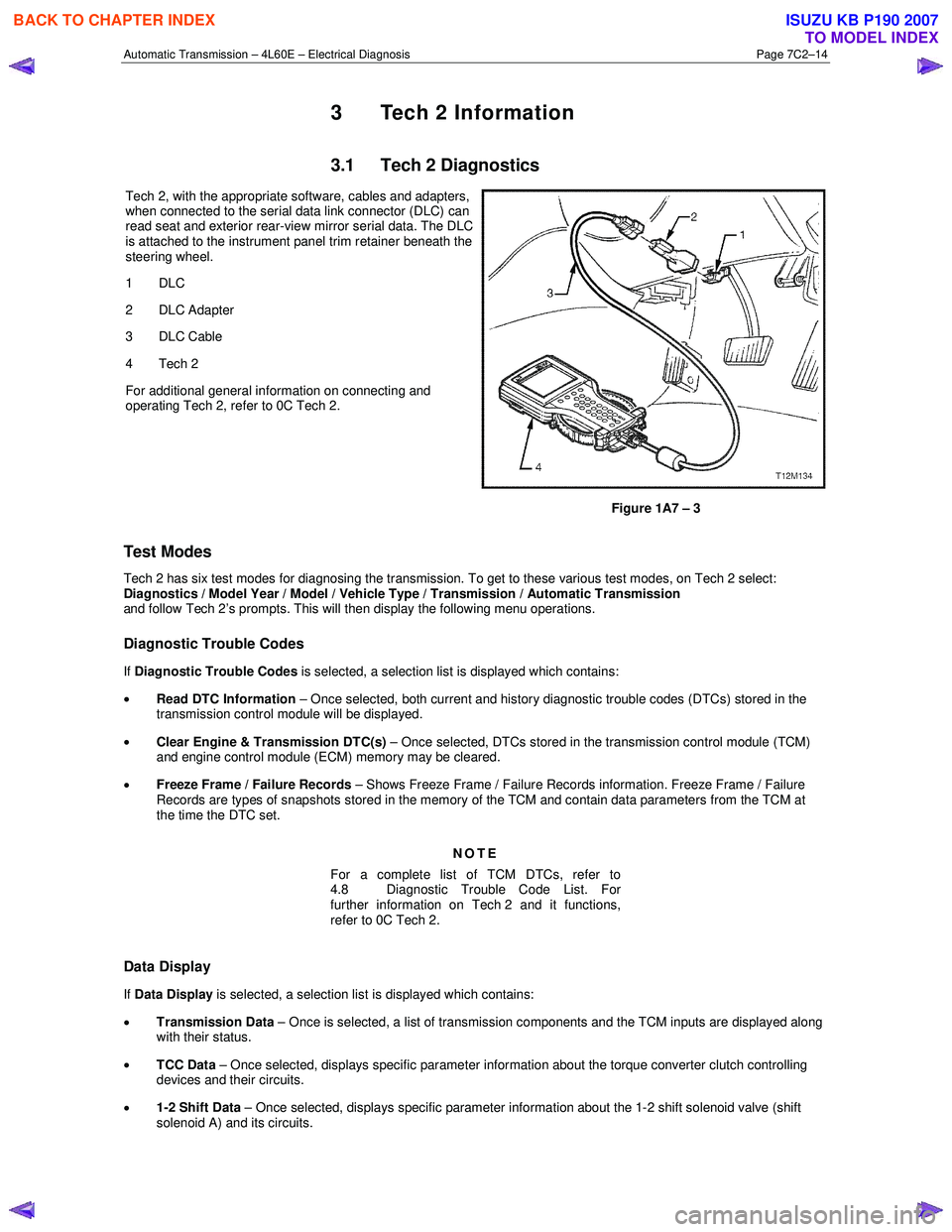

3.1 Tech 2 Diagnostics

Tech 2, with the appropriate software, cables and adapters,

when connected to the serial data link connector (DLC) can

read seat and exterior rear-view mirror serial data. The DLC

is attached to the instrument panel trim retainer beneath the

steering wheel.

1 DLC

2 DLC Adapter

3 DLC Cable

4 Tech 2

For additional general information on connecting and

operating Tech 2, refer to 0C Tech 2.

Figure 1A7 – 3

Test Modes

Tech 2 has six test modes for diagnosing the transmission. To get to these various test modes, on Tech 2 select:

Diagnostics / Model Year / Model / Vehicle Type / Transmission / Automatic Transmission

and follow Tech 2’s prompts. This will then display the following menu operations.

Diagnostic Trouble Codes

If Diagnostic Trouble Codes is selected, a selection list is displayed which contains:

• Read DTC Information – Once selected, both current and history diagnostic trouble codes (DTCs) stored in the

transmission control module will be displayed.

• Clear Engine & Transmission DTC(s) – Once selected, DTCs stored in the transmission control module (TCM)

and engine control module (ECM) memory may be cleared.

• Freeze Frame / Failure Records – Shows Freeze Frame / Failure Records information. Freeze Frame / Failure

Records are types of snapshots stored in the memory of the TCM and contain data parameters from the TCM at

the time the DTC set.

NOTE

For a complete list of TCM DTCs, refer to

4.8 Diagnostic Trouble Code List. For

further information on Tech 2 and it functions,

refer to 0C Tech 2.

Data Display

If Data Display is selected, a selection list is displayed which contains:

• Transmission Data – Once is selected, a list of transmission components and the TCM inputs are displayed along

with their status.

• TCC Data – Once selected, displays specific parameter information about the torque converter clutch controlling

devices and their circuits.

• 1-2 Shift Data – Once selected, displays specific parameter information about the 1-2 shift solenoid valve (shift

solenoid A) and its circuits.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 4941 of 6020

ELECTRICAL-BODY AND CHASSIS 8A-3

PAGE

Power Window ............................................................................................................8A- 41 5

Audio, Clock and Cigarette Lighter ...........................................................................8A- 440

Power Door Mirror ......................................................................................................8A- 464

Rear Defogger .............................................................................................................8A- 480

Supplemental Restraint System (SRS)-Air Bag ........................................................8A- 491

Transfer Case Control Module ...................................................................................8A- 498

Anti-Lock Brake System .............................................................................................8A- 514

Immobilizer ..................................................................................................................8 A- 519

Keyless Entry ..............................................................................................................8A- 529

Data Link Connector ...................................................................................................8A- 553

Anti Theft ..................................................................................................................... .8A- 561

Key Inter Lock .............................................................................................................8A- 588

DRM ........................................................................................................................... ...8A- 592

Trailer Hitch ................................................................................................................. 8A- 595

Power Train Interface Module (PIM) ..........................................................................8A- 600

Connector List ................................................................................................................ .8A- 606

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 4962 of 6020

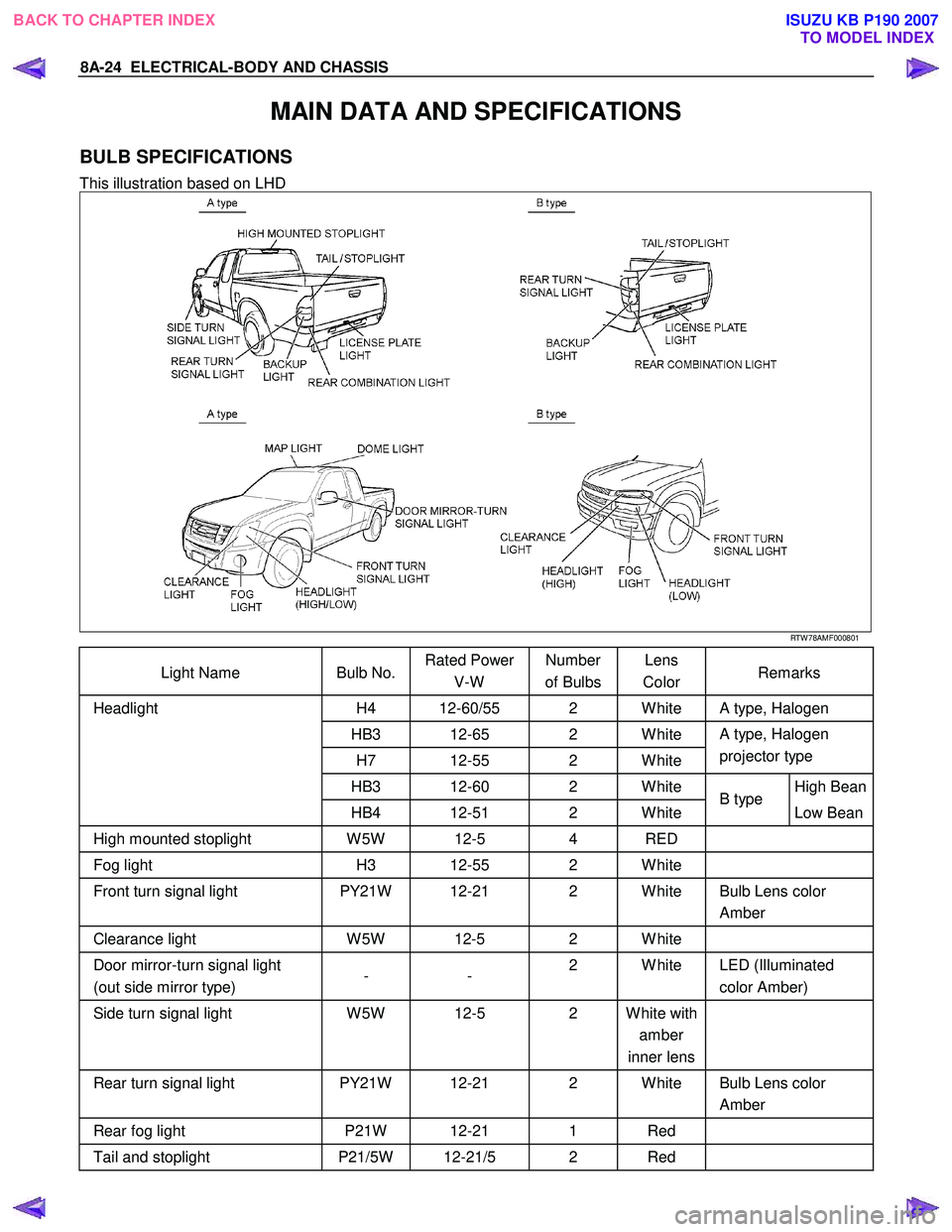

8A-24 ELECTRICAL-BODY AND CHASSIS

MAIN DATA AND SPECIFICATIONS

BULB SPECIFICATIONS

This illustration based on LHD

RTW 78AMF000801

Light Name Bulb No. Rated Power

V-W Number

of Bulbs Lens

Color Remarks

H4 12-60/55 2 W hite A type, Halogen

HB3 12-65 2 W hite

H7 12-55 2 W hite A type, Halogen

projector type

HB3 12-60 2 W hite High Bean

Headlight

HB4 12-51 2 W hite B type

Low Bean

High mounted stoplight W 5W 12-5 4 RED

Fog light H3 12-55 2 W hite

Front turn signal light PY21W 12-21 2 W hite Bulb Lens color

Amber

Clearance light W 5W 12-5 2 W hite

Door mirror-turn signal light

(out side mirror type) - -

2 W hite LED (Illuminated

color Amber)

Side turn signal light W 5W 12-5 2 W hite with

amber

inner lens

Rear turn signal light

PY21W 12-21 2 W hite Bulb Lens color

Amber

Rear fog light P21W 12-21 1 Red

Tail and stoplight P21/5W 12-21/5 2 Red

BACK TO CHAPTER INDEX

TO MODEL INDEXISUZU KB P190 2007

Page 5174 of 6020

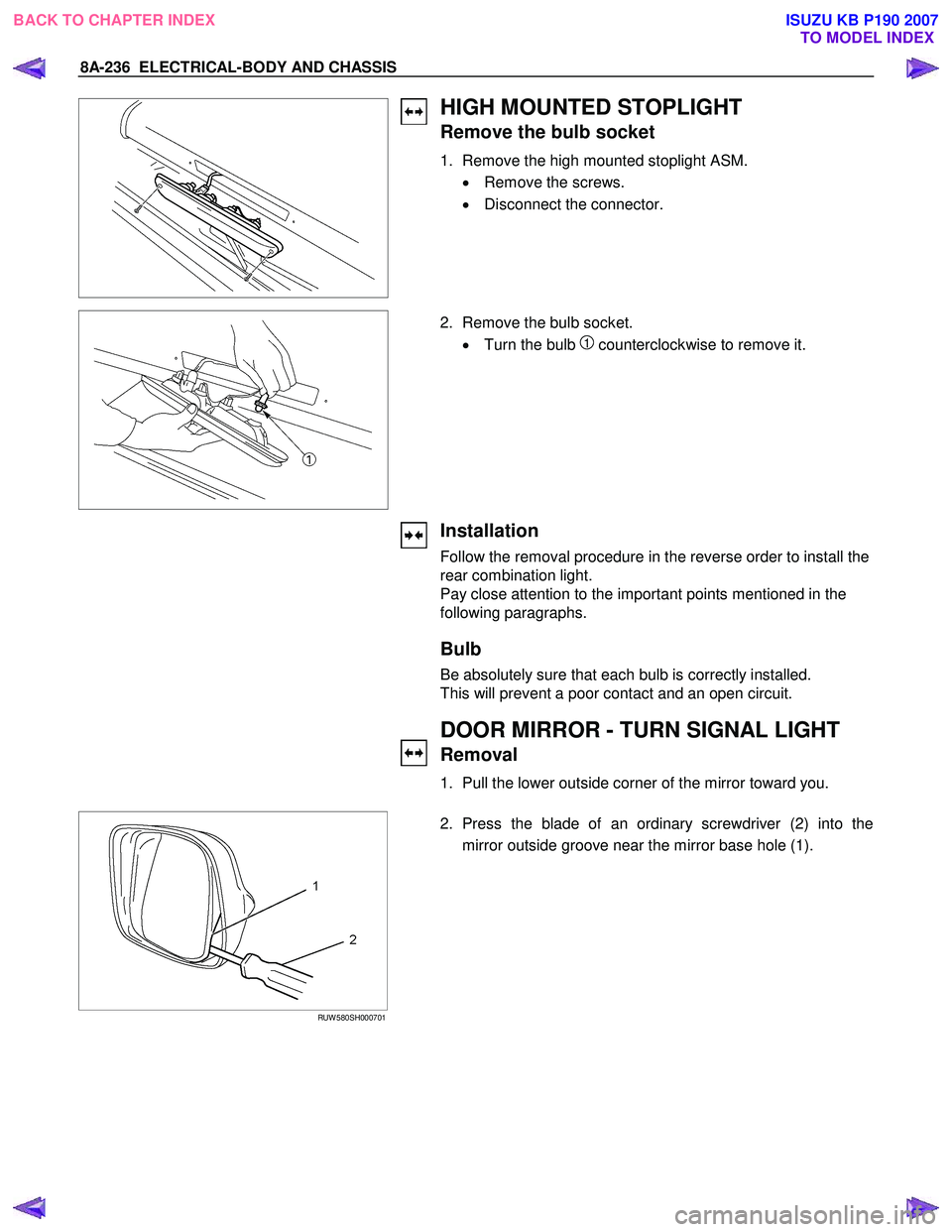

8A-236 ELECTRICAL-BODY AND CHASSIS

HIGH MOUNTED STOPLIGHT

Remove the bulb socket

1. Remove the high mounted stoplight ASM. • Remove the screws.

• Disconnect the connector.

2. Remove the bulb socket.

• Turn the bulb

1 counterclockwise to remove it.

Installation

Follow the removal procedure in the reverse order to install the

rear combination light.

Pay close attention to the important points mentioned in the

following paragraphs.

Bulb

Be absolutely sure that each bulb is correctly installed.

This will prevent a poor contact and an open circuit.

DOOR MIRROR - TURN SIGNAL LIGHT

Removal

1. Pull the lower outside corner of the mirror toward you.

RUW 580SH000701

2. Press the blade of an ordinary screwdriver (2) into the

mirror outside groove near the mirror base hole (1).

BACK TO CHAPTER INDEX TO MODEL INDEXISUZU KB P190 2007

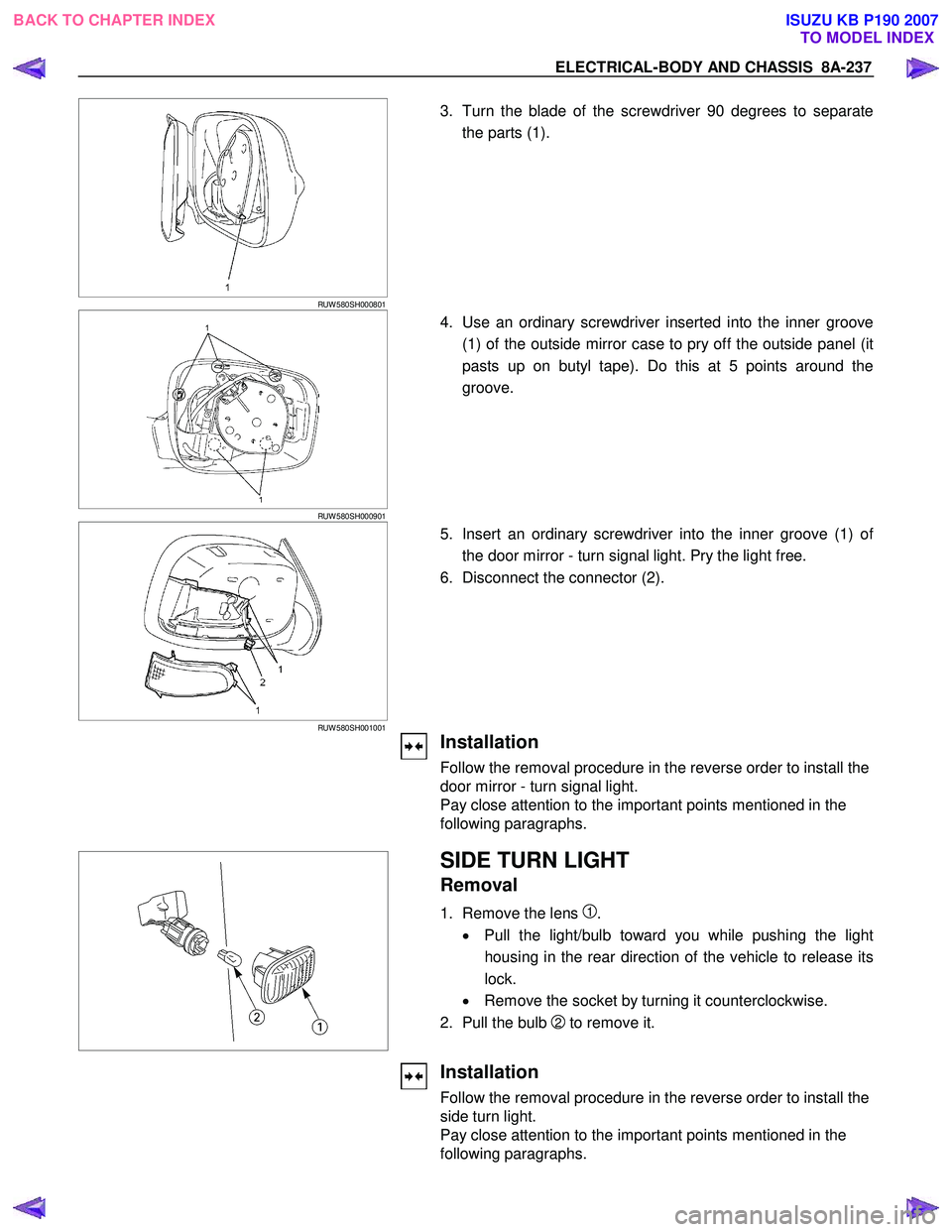

Page 5175 of 6020

ELECTRICAL-BODY AND CHASSIS 8A-237

RUW 580SH000801

3. Turn the blade of the screwdriver 90 degrees to separate

the parts (1).

RUW 580SH000901

4. Use an ordinary screwdriver inserted into the inner groove

(1) of the outside mirror case to pry off the outside panel (it

pasts up on butyl tape). Do this at 5 points around the

groove.

RUW 580SH001001

5. Insert an ordinary screwdriver into the inner groove (1) of

the door mirror - turn signal light. Pry the light free.

6. Disconnect the connector (2).

Installation

Follow the removal procedure in the reverse order to install the

door mirror - turn signal light.

Pay close attention to the important points mentioned in the

following paragraphs.

SIDE TURN LIGHT

Removal

1. Remove the lens 1.

• Pull the light/bulb toward you while pushing the light

housing in the rear direction of the vehicle to release its

lock.

• Remove the socket by turning it counterclockwise.

2. Pull the bulb

2 to remove it.

Installation

Follow the removal procedure in the reverse order to install the

side turn light.

Pay close attention to the important points mentioned in the

following paragraphs.

BACK TO CHAPTER INDEX TO MODEL INDEXISUZU KB P190 2007

Page 5402 of 6020

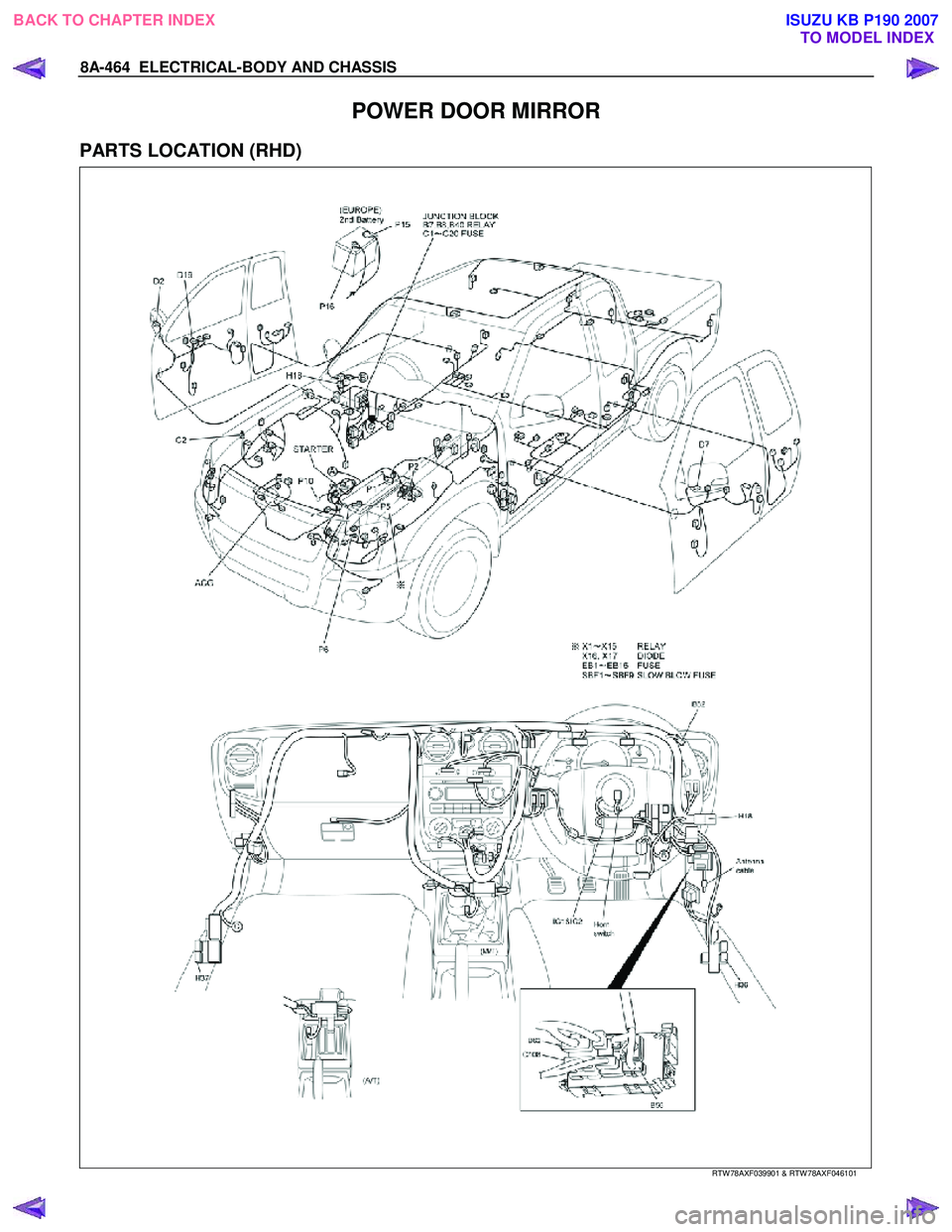

8A-464 ELECTRICAL-BODY AND CHASSIS

POWER DOOR MIRROR

PARTS LOCATION (RHD)

RTW 78AXF039901 & RTW 78AXF046101

BACK TO CHAPTER INDEX

TO MODEL INDEXISUZU KB P190 2007

Page 5410 of 6020

8A-472 ELECTRICAL-BODY AND CHASSIS

TROUBLESHOOTING

QUICK CHART FOR CHECK POINT

Check Point Fuse Door Mirror Door Mirror

Trouble Mode C11

(10A) Control

Switch LH RH

1. Mirrors on the both sides do not operate

2. Mirror on the left (or right) side does not

operate

3. Mirrors on the both sides operate only in

the vertical

(or horizontal) direction

4. Mirror on the left side operates only in

the vertical

(or horizontal) direction

5. Mirror on the right side operates only in

the vertical

(or horizontal) direction

Cable

Harness

BACK TO CHAPTER INDEX

TO MODEL INDEXISUZU KB P190 2007

Page 5411 of 6020

ELECTRICAL-BODY AND CHASSIS 8A-473

DOOR MIRROR CONTROL SWITCH

1. Mirrors on the both sides do not operate

Checkpoint Trouble Cause Countermeasure

Reinstall or replace the fuse

No. C11 (10A)

Poor fuse contact or blown

NG

Repair grounding point

C2

contact

Grounding point

C2

Poor grounding point contact

Repair an open circuit or a

poor connection of the

connectors between the fuse

No. C11 (10A) and 4

D19

Voltage between the door

mirror control SW . harness

side connector terminal

4

D19 and the ground

(Should be battery voltage

present)

Open circuit or poor connector

contact

NG

NG

OK

OK

OK

Fuse No. C11 (10A, Fuse box)

Repair open circuit or

connector contact

Open circuit or poor connector

contact

NG Continuity between the door

mirror control SW harness

side connector terminal

8

D19 and C2

Replace the door mirror

control SW .

Door mirror control SW .

function

SW . malfunction

NG

OK

Repair open circuit or

connector contact

Continuity between 7

D19

and 12

H36 (or 12 H37 )

Open circuit or poor connector

contact

NG

OK

BACK TO CHAPTER INDEX TO MODEL INDEXISUZU KB P190 2007