tire size ISUZU KB P190 2007 Workshop Repair Manual

[x] Cancel search | Manufacturer: ISUZU, Model Year: 2007, Model line: KB P190, Model: ISUZU KB P190 2007Pages: 6020, PDF Size: 70.23 MB

Page 406 of 6020

3E-2 WHEELS AND TIRES

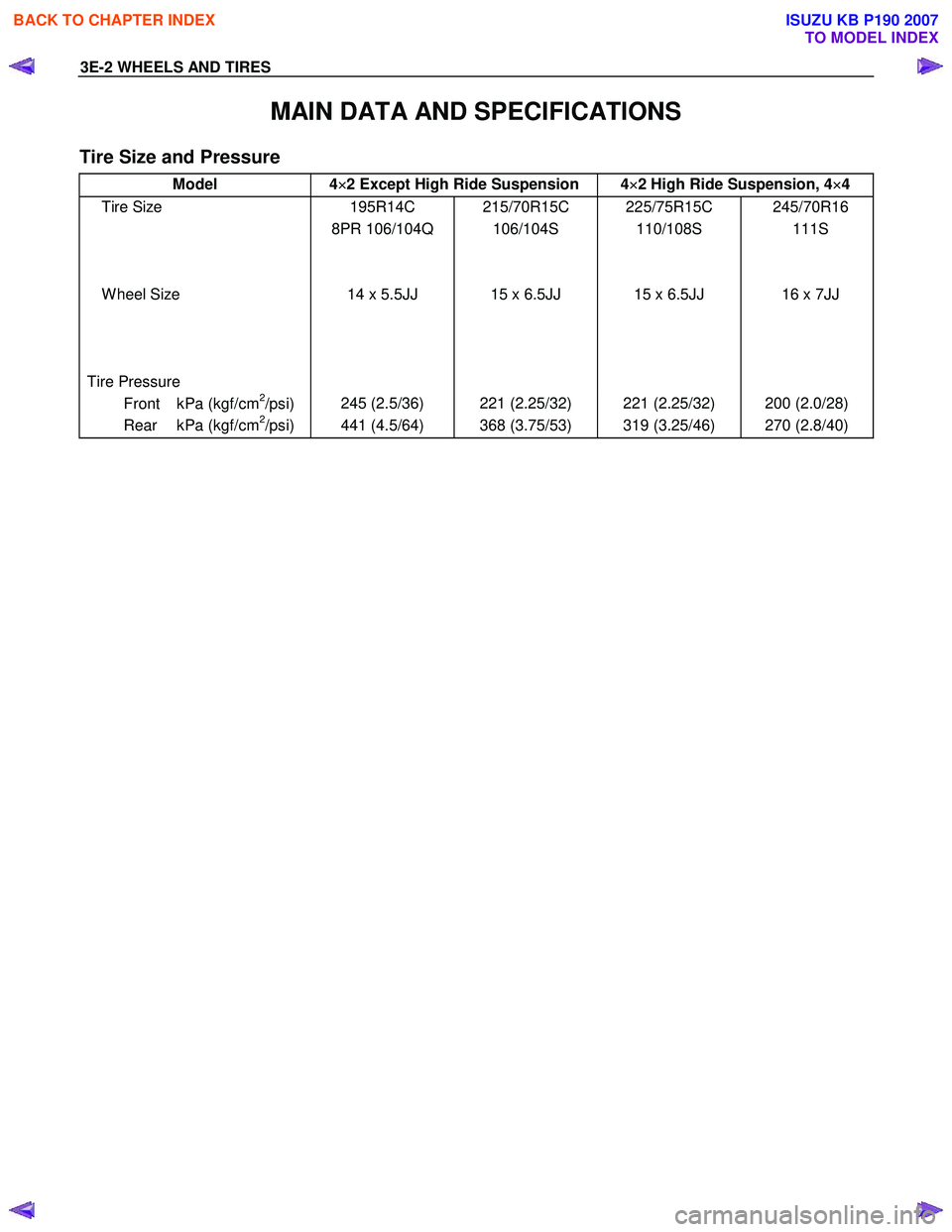

MAIN DATA AND SPECIFICATIONS

Tire Size and Pressure

Model 4×

××

×

2 Except High Ride Suspension 4×

××

×

2 High Ride Suspension, 4 ×

××

×

4

Tire Size

W heel Size

195R14C

8PR 106/104Q

14 x 5.5JJ

215/70R15C

106/104S

15 x 6.5JJ

225/75R15C

110/108S

15 x 6.5JJ

245/70R16

111S

16 x 7JJ

Tire Pressure

Front kPa (kgf/cm2/psi)

Rear kPa (kgf/cm2/psi) 245 (2.5/36)

441 (4.5/64) 221 (2.25/32)

368 (3.75/53) 221 (2.25/32)

319 (3.25/46) 200 (2.0/28)

270 (2.8/40)

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 409 of 6020

WHEELS AND TIRES 3E-5

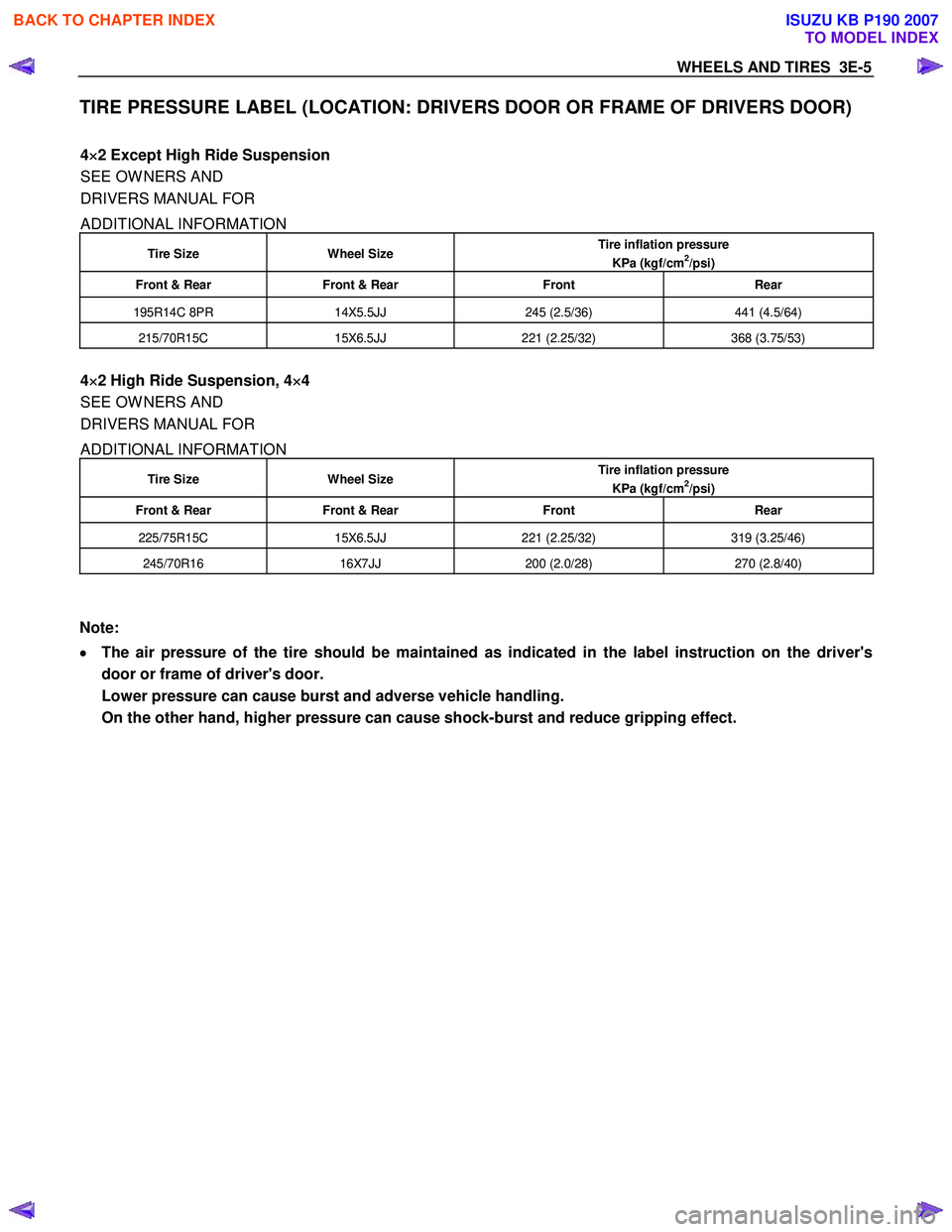

TIRE PRESSURE LABEL (LOCATION: DRIVERS DOOR OR FRAME OF DRIVERS DOOR)

4 ×

××

×

2 Except High Ride Suspension

SEE OW NERS AND

DRIVERS MANUAL FOR

ADDITIONAL INFORMATION

Tire Size Wheel Size Tire inflation pressure

KPa (kgf/cm

2/psi)

Front & Rear Front & Rear Front Rear

195R14C 8PR 14X5.5JJ 245 (2.5/36) 441 (4.5/64)

215/70R15C 15X6.5JJ 221 (2.25/32) 368 (3.75/53)

4 ×

××

×

2 High Ride Suspension, 4 ×

××

×

4

SEE OW NERS AND

DRIVERS MANUAL FOR

ADDITIONAL INFORMATION

Tire Size Wheel Size Tire inflation pressure

KPa (kgf/cm

2/psi)

Front & Rear Front & Rear Front Rear

225/75R15C 15X6.5JJ 221 (2.25/32) 319 (3.25/46)

245/70R16 16X7JJ 200 (2.0/28) 270 (2.8/40)

Note:

•

••

•

The air pressure of the tire should be maintained as indicated in the label instruction on the driver's

door or frame of driver's door.

Lower pressure can cause burst and adverse vehicle handling.

On the other hand, higher pressure can cause shock-burst and reduce gripping effect.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 657 of 6020

5A-64 BRAKE CONTROL SYSTEM

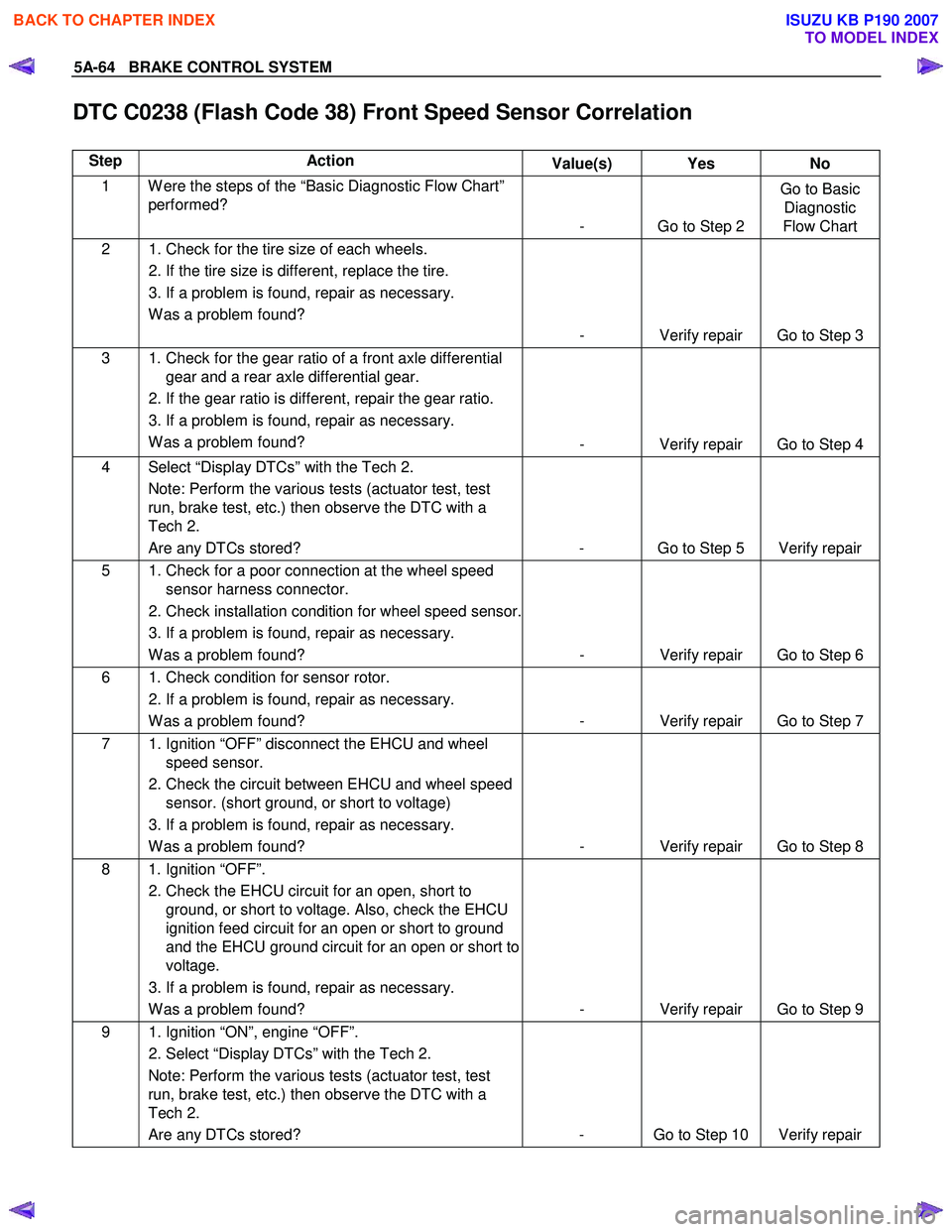

DTC C0238 (Flash Code 38) Front Speed Sensor Correlation

Step Action Value(s) Yes No

1 W ere the steps of the “Basic Diagnostic Flow Chart”

performed?

- Go to Step 2 Go to Basic

Diagnostic

Flow Chart

2 1. Check for the tire size of each wheels.

2. If the tire size is different, replace the tire.

3. If a problem is found, repair as necessary. W as a problem found? - Verify repair Go to Step 3

3 1. Check for the gear ratio of a front axle differential gear and a rear axle differential gear.

2. If the gear ratio is different, repair the gear ratio.

3. If a problem is found, repair as necessary. W as a problem found? - Verify repair Go to Step 4

4 Select “Display DTCs” with the Tech 2.

Note: Perform the various tests (actuator test, test

run, brake test, etc.) then observe the DTC with a

Tech 2.

Are any DTCs stored? - Go to Step 5 Verify repair

5 1. Check for a poor connection at the wheel speed sensor harness connector.

2. Check installation condition for wheel speed sensor.

3. If a problem is found, repair as necessary. W as a problem found? - Verify repair Go to Step 6

6 1. Check condition for sensor rotor.

2. If a problem is found, repair as necessary. W as a problem found? - Verify repair Go to Step 7

7 1. Ignition “OFF” disconnect the EHCU and wheel

speed sensor.

2. Check the circuit between EHCU and wheel speed sensor. (short ground, or short to voltage)

3. If a problem is found, repair as necessary. W as a problem found? - Verify repair Go to Step 8

8 1. Ignition “OFF”.

2. Check the EHCU circuit for an open, short to ground, or short to voltage. Also, check the EHCU

ignition feed circuit for an open or short to ground

and the EHCU ground circuit for an open or short to

voltage.

3. If a problem is found, repair as necessary. W as a problem found? - Verify repair Go to Step 9

9 1. Ignition “ON”, engine “OFF”.

2. Select “Display DTCs” with the Tech 2. Note: Perform the various tests (actuator test, test

run, brake test, etc.) then observe the DTC with a

Tech 2.

Are any DTCs stored? - Go to Step 10 Verify repair

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 726 of 6020

BRAKES 5C-27

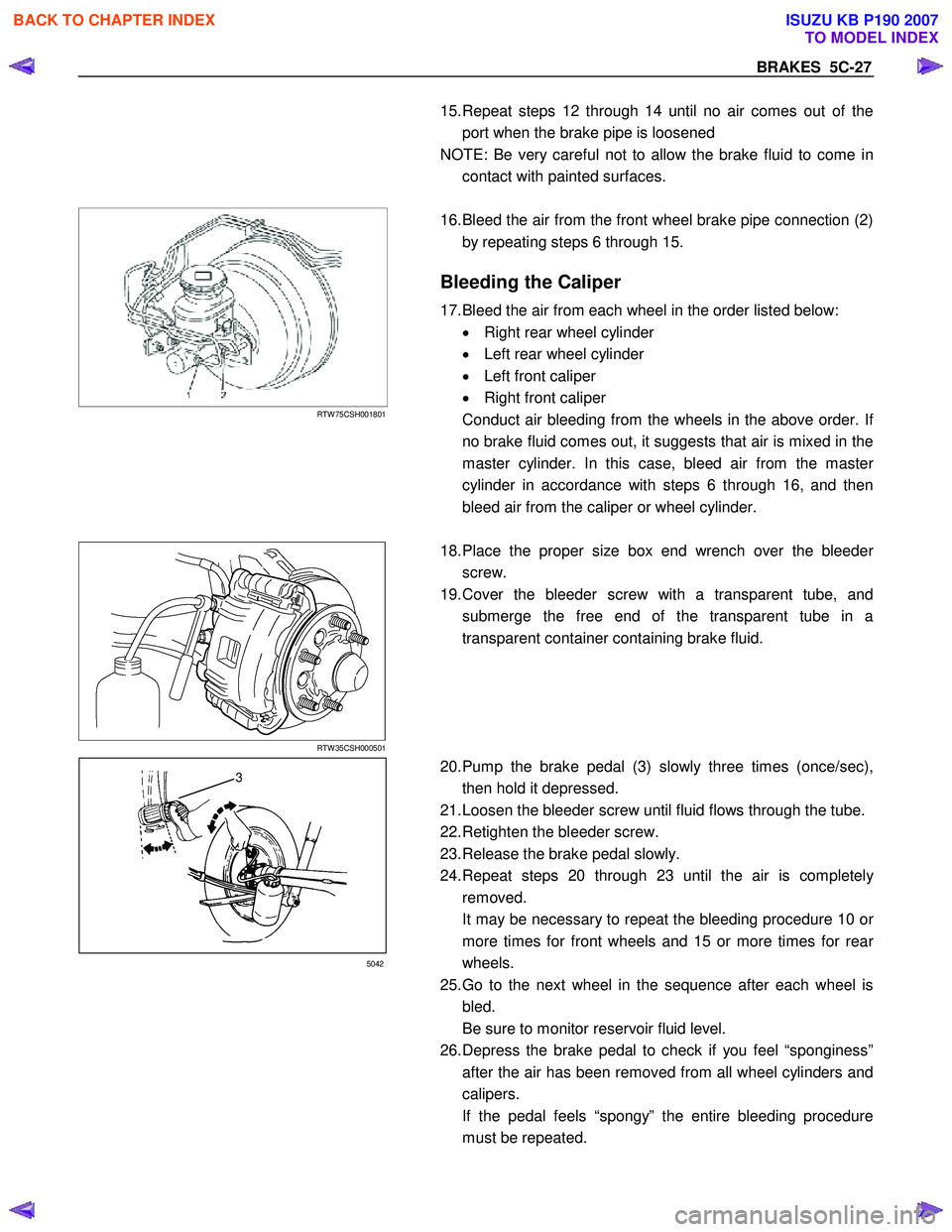

15. Repeat steps 12 through 14 until no air comes out of the

port when the brake pipe is loosened

NOTE: Be very careful not to allow the brake fluid to come in contact with painted surfaces.

RTW 75CSH001801

16. Bleed the air from the front wheel brake pipe connection (2)

by repeating steps 6 through 15.

Bleeding the Caliper

17. Bleed the air from each wheel in the order listed below: • Right rear wheel cylinder

• Left rear wheel cylinder

• Left front caliper

• Right front caliper

Conduct air bleeding from the wheels in the above order. I

f

no brake fluid comes out, it suggests that air is mixed in the

master cylinder. In this case, bleed air from the maste

r

cylinder in accordance with steps 6 through 16, and then

bleed air from the caliper or wheel cylinder.

RTW 35CSH000501

18. Place the proper size box end wrench over the bleeder

screw.

19. Cover the bleeder screw with a transparent tube, and submerge the free end of the transparent tube in a

transparent container containing brake fluid.

3

5042

20. Pump the brake pedal (3) slowly three times (once/sec),

then hold it depressed.

21. Loosen the bleeder screw until fluid flows through the tube.

22. Retighten the bleeder screw.

23. Release the brake pedal slowly.

24. Repeat steps 20 through 23 until the air is completel

y

removed.

It may be necessary to repeat the bleeding procedure 10 o

r

more times for front wheels and 15 or more times for rear

wheels.

25. Go to the next wheel in the sequence after each wheel is bled.

Be sure to monitor reservoir fluid level.

26. Depress the brake pedal to check if you feel “sponginess” after the air has been removed from all wheel cylinders and

calipers.

If the pedal feels “spongy” the entire bleeding procedure must be repeated.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 1300 of 6020

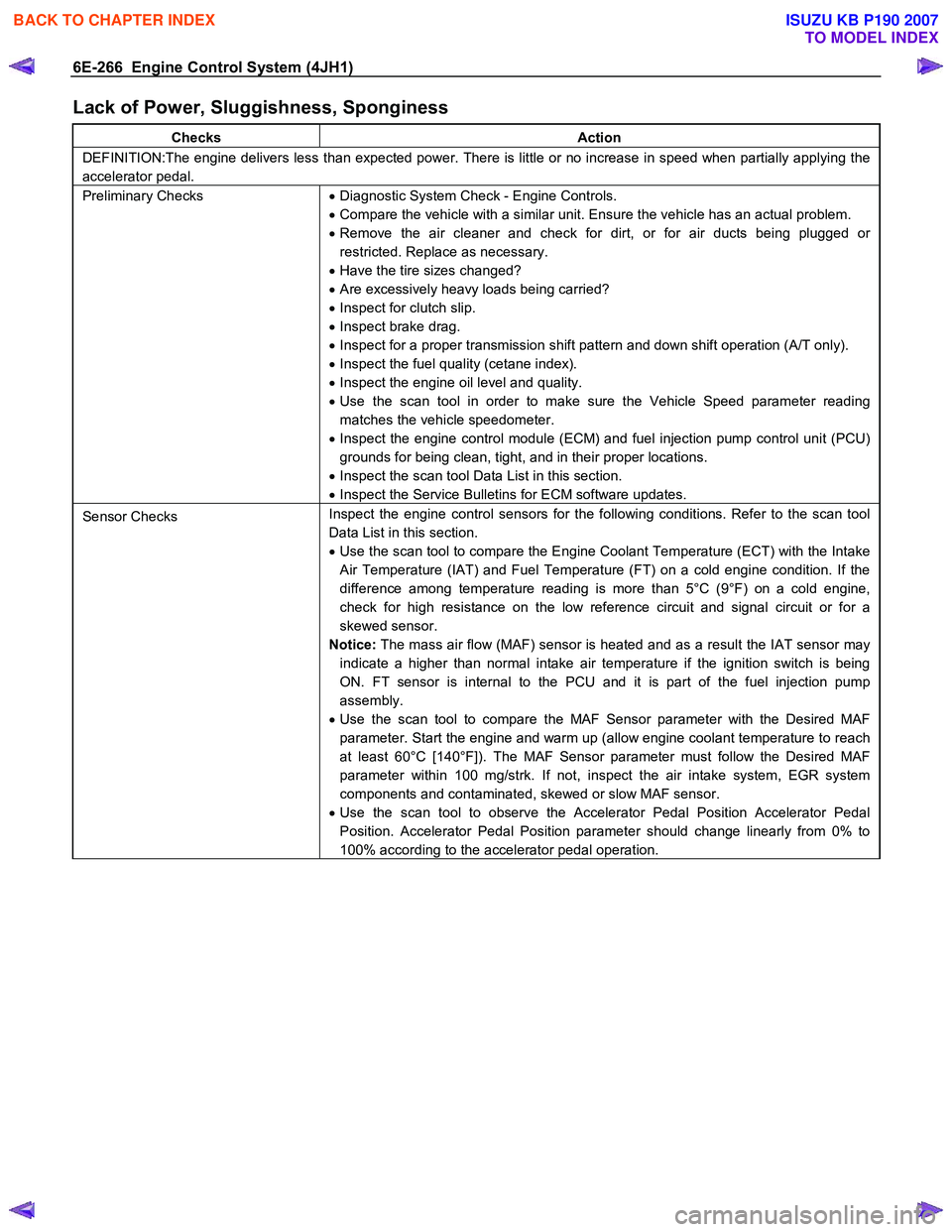

6E-266 Engine Control System (4JH1)

Lack of Power, Sluggishness, Sponginess

Checks Action

DEFINITION:The engine delivers less than expected power. There is little or no increase in speed when partially applying the

accelerator pedal.

Preliminary Checks • Diagnostic System Check - Engine Controls.

• Compare the vehicle with a similar unit. Ensure the vehicle has an actual problem.

• Remove the air cleaner and check for dirt, or for air ducts being plugged or

restricted. Replace as necessary.

• Have the tire sizes changed?

• Are excessively heavy loads being carried?

• Inspect for clutch slip.

• Inspect brake drag.

• Inspect for a proper transmission shift pattern and down shift operation (A/T only).

• Inspect the fuel quality (cetane index).

• Inspect the engine oil level and quality.

• Use the scan tool in order to make sure the Vehicle Speed parameter reading

matches the vehicle speedometer.

• Inspect the engine control module (ECM) and fuel injection pump control unit (PCU)

grounds for being clean, tight, and in their proper locations.

• Inspect the scan tool Data List in this section.

• Inspect the Service Bulletins for ECM software updates.

Sensor Checks Inspect the engine control sensors for the following conditions. Refer to the scan tool

Data List in this section.

• Use the scan tool to compare the Engine Coolant Temperature (ECT) with the Intake

Air Temperature (IAT) and Fuel Temperature (FT) on a cold engine condition. If the

difference among temperature reading is more than 5°C (9°F) on a cold engine,

check for high resistance on the low reference circuit and signal circuit or for a

skewed sensor.

Notice: The mass air flow (MAF) sensor is heated and as a result the IAT sensor may

indicate a higher than normal intake air temperature if the ignition switch is being

ON. FT sensor is internal to the PCU and it is part of the fuel injection pump

assembly.

• Use the scan tool to compare the MAF Sensor parameter with the Desired MAF

parameter. Start the engine and warm up (allow engine coolant temperature to reach

at least 60°C [140°F]). The MAF Sensor parameter must follow the Desired MAF

parameter within 100 mg/strk. If not, inspect the air intake system, EGR system

components and contaminated, skewed or slow MAF sensor.

• Use the scan tool to observe the Accelerator Pedal Position Accelerator Pedal

Position. Accelerator Pedal Position parameter should change linearly from 0% to

100% according to the accelerator pedal operation.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 1305 of 6020

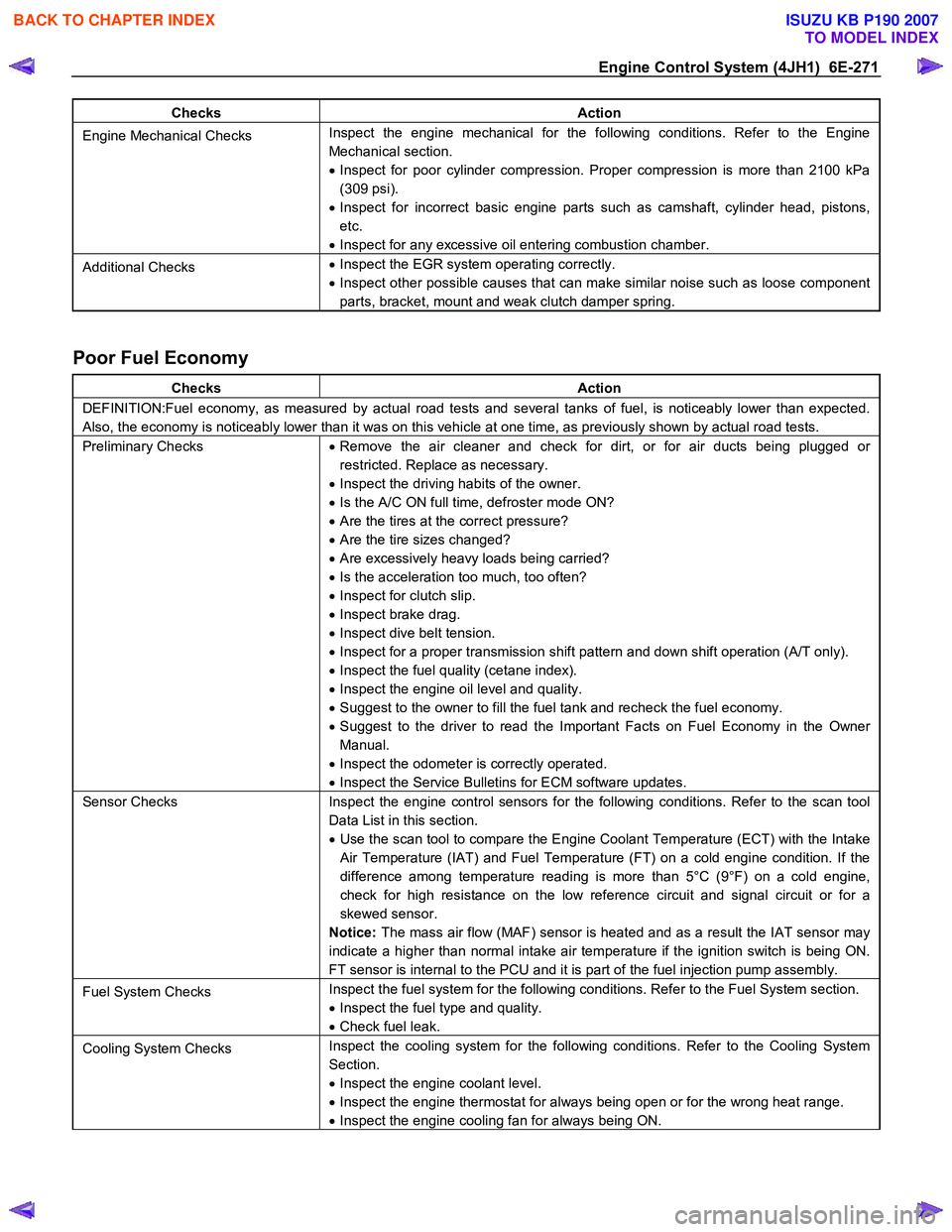

Engine Control System (4JH1) 6E-271

Checks Action

Engine Mechanical Checks Inspect the engine mechanical for the following conditions. Refer to the Engine

Mechanical section.

• Inspect for poor cylinder compression. Proper compression is more than 2100 kPa

(309 psi).

• Inspect for incorrect basic engine parts such as camshaft, cylinder head, pistons,

etc.

• Inspect for any excessive oil entering combustion chamber.

Additional Checks •

Inspect the EGR system operating correctly.

• Inspect other possible causes that can make similar noise such as loose component

parts, bracket, mount and weak clutch damper spring.

Poor Fuel Economy

Checks Action

DEFINITION:Fuel economy, as measured by actual road tests and several tanks of fuel, is noticeably lower than expected.

Also, the economy is noticeably lower than it was on this vehicle at one time, as previously shown by actual road tests.

Preliminary Checks • Remove the air cleaner and check for dirt, or for air ducts being plugged or

restricted. Replace as necessary.

• Inspect the driving habits of the owner.

• Is the A/C ON full time, defroster mode ON?

• Are the tires at the correct pressure?

• Are the tire sizes changed?

• Are excessively heavy loads being carried?

• Is the acceleration too much, too often?

• Inspect for clutch slip.

• Inspect brake drag.

• Inspect dive belt tension.

• Inspect for a proper transmission shift pattern and down shift operation (A/T only).

• Inspect the fuel quality (cetane index).

• Inspect the engine oil level and quality.

• Suggest to the owner to fill the fuel tank and recheck the fuel economy.

• Suggest to the driver to read the Important Facts on Fuel Economy in the Owner

Manual.

• Inspect the odometer is correctly operated.

• Inspect the Service Bulletins for ECM software updates.

Sensor Checks Inspect the engine control sensors for the following conditions. Refer to the scan tool

Data List in this section.

• Use the scan tool to compare the Engine Coolant Temperature (ECT) with the Intake

Air Temperature (IAT) and Fuel Temperature (FT) on a cold engine condition. If the

difference among temperature reading is more than 5°C (9°F) on a cold engine,

check for high resistance on the low reference circuit and signal circuit or for a

skewed sensor.

Notice: The mass air flow (MAF) sensor is heated and as a result the IAT sensor may

indicate a higher than normal intake air temperature if the ignition switch is being ON.

FT sensor is internal to the PCU and it is part of the fuel injection pump assembly.

Fuel System Checks Inspect the fuel system for the following conditions. Refer to the Fuel System section.

• Inspect the fuel type and quality.

• Check fuel leak.

Cooling System Checks Inspect the cooling system for the following conditions. Refer to the Cooling System

Section.

• Inspect the engine coolant level.

• Inspect the engine thermostat for always being open or for the wrong heat range.

• Inspect the engine cooling fan for always being ON.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 1953 of 6020

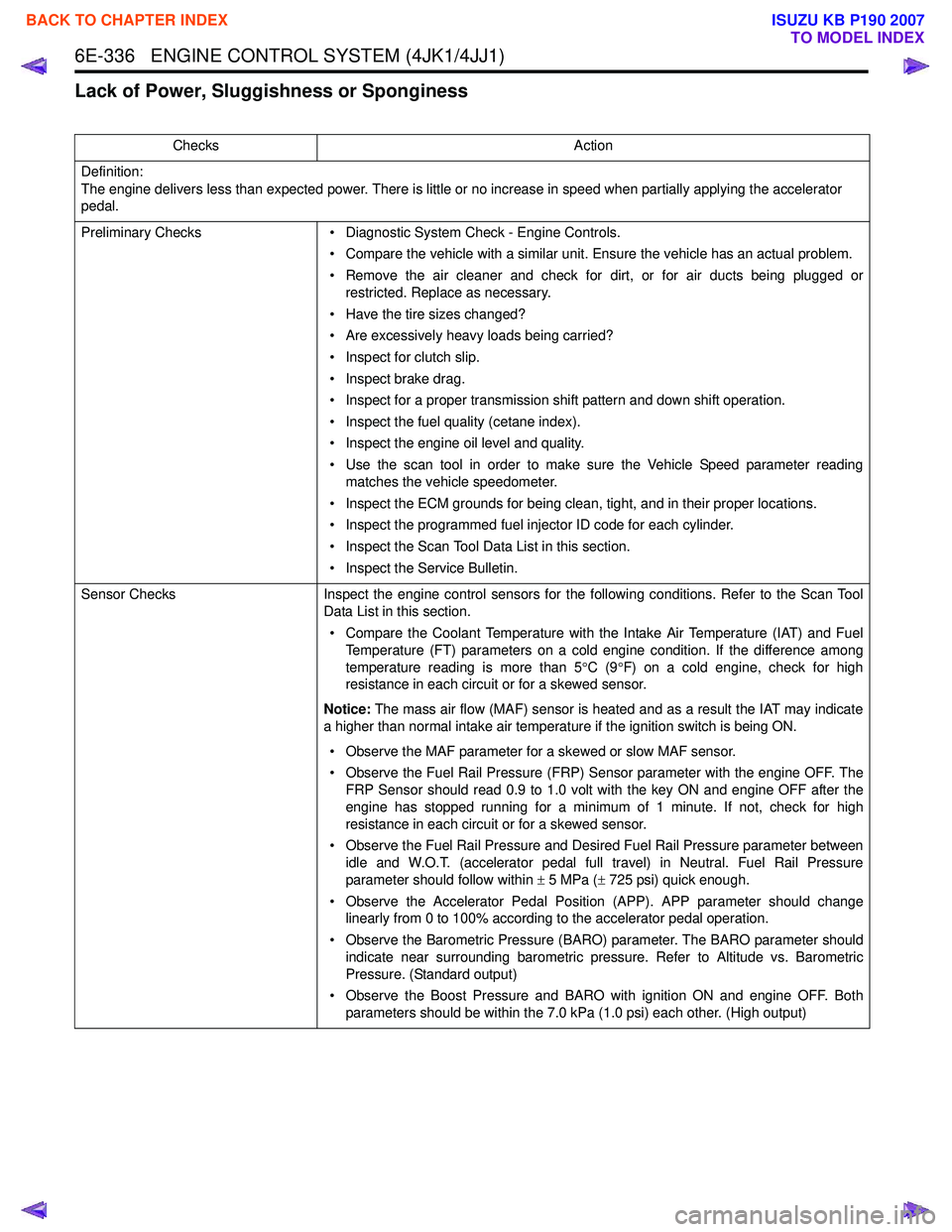

6E-336 ENGINE CONTROL SYSTEM (4JK1/4JJ1)

Lack of Power, Sluggishness or Sponginess

ChecksAction

Definition:

The engine delivers less than expected power. There is little or no increase in speed when partially applying the accelerator

pedal.

Preliminary Checks • Diagnostic System Check - Engine Controls.

• Compare the vehicle with a similar unit. Ensure the vehicle has an actual problem.

• Remove the air cleaner and check for dirt, or for air ducts being plugged or restricted. Replace as necessary.

• Have the tire sizes changed?

• Are excessively heavy loads being carried?

• Inspect for clutch slip.

• Inspect brake drag.

• Inspect for a proper transmission shift pattern and down shift operation.

• Inspect the fuel quality (cetane index).

• Inspect the engine oil level and quality.

• Use the scan tool in order to make sure the Vehicle Speed parameter reading matches the vehicle speedometer.

• Inspect the ECM grounds for being clean, tight, and in their proper locations.

• Inspect the programmed fuel injector ID code for each cylinder.

• Inspect the Scan Tool Data List in this section.

• Inspect the Service Bulletin.

Sensor Checks Inspect the engine control sensors for the following conditions. Refer to the Scan Tool

Data List in this section.

• Compare the Coolant Temperature with the Intake Air Temperature (IAT) and Fuel Temperature (FT) parameters on a cold engine condition. If the difference among

temperature reading is more than 5 °C (9 °F) on a cold engine, check for high

resistance in each circuit or for a skewed sensor.

Notice: The mass air flow (MAF) sensor is heated and as a result the IAT may indicate

a higher than normal intake air temperature if the ignition switch is being ON.

• Observe the MAF parameter for a skewed or slow MAF sensor.

• Observe the Fuel Rail Pressure (FRP) Sensor parameter with the engine OFF. The FRP Sensor should read 0.9 to 1.0 volt with the key ON and engine OFF after the

engine has stopped running for a minimum of 1 minute. If not, check for high

resistance in each circuit or for a skewed sensor.

• Observe the Fuel Rail Pressure and Desired Fuel Rail Pressure parameter between idle and W.O.T. (accelerator pedal full travel) in Neutral. Fuel Rail Pressure

parameter should follow within ± 5 MPa ( ± 725 psi) quick enough.

• Observe the Accelerator Pedal Position (APP). APP parameter should change linearly from 0 to 100% according to the accelerator pedal operation.

• Observe the Barometric Pressure (BARO) parameter. The BARO parameter should indicate near surrounding barometric pressure. Refer to Altitude vs. Barometric

Pressure. (Standard output)

• Observe the Boost Pressure and BARO with ignition ON and engine OFF. Both parameters should be within the 7.0 kPa (1.0 psi) each other. (High output)

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 1958 of 6020

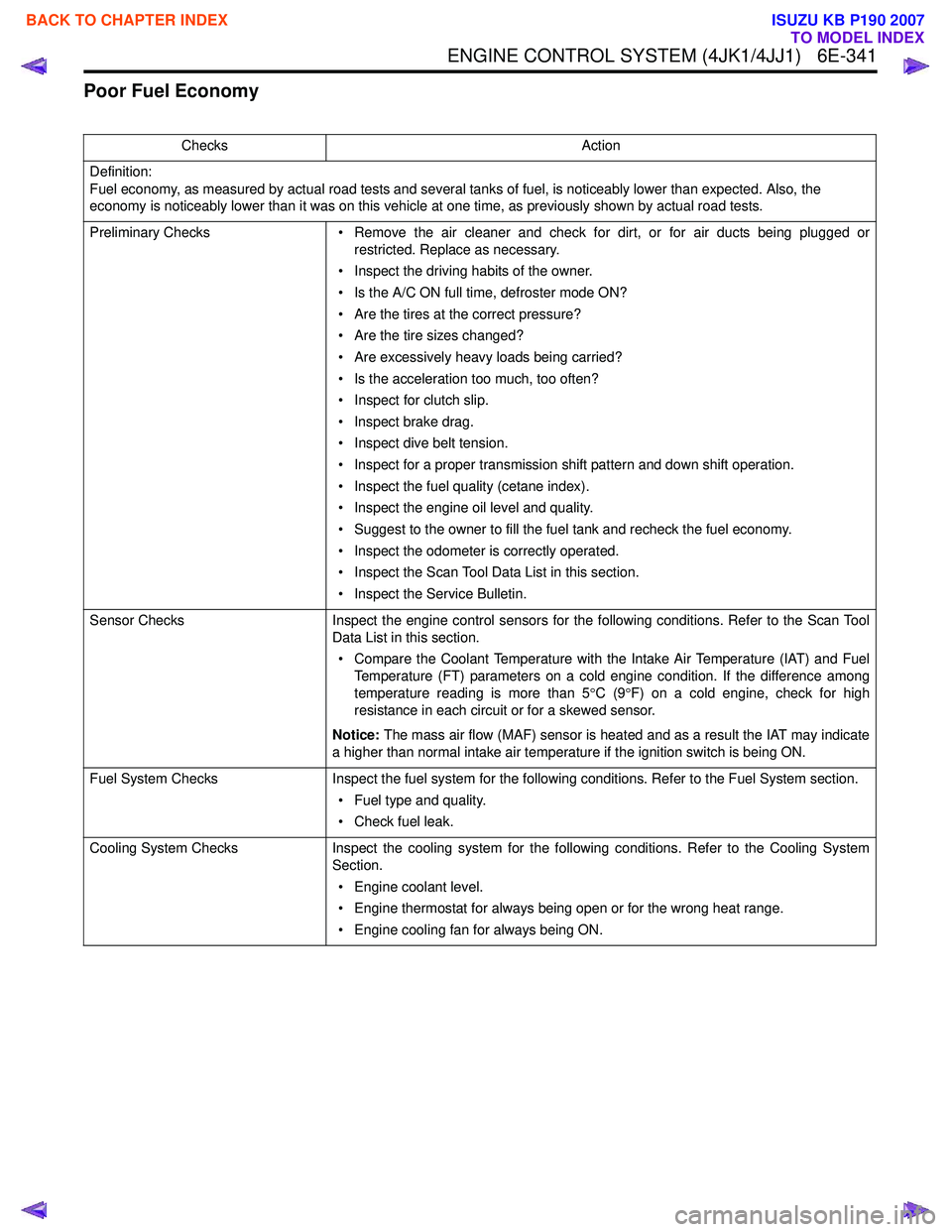

ENGINE CONTROL SYSTEM (4JK1/4JJ1) 6E-341

Poor Fuel Economy

ChecksAction

Definition:

Fuel economy, as measured by actual road tests and several tanks of fuel, is noticeably lower than expected. Also, the

economy is noticeably lower than it was on this vehicle at one time, as previously shown by actual road tests.

Preliminary Checks • Remove the air cleaner and check for dirt, or for air ducts being plugged or

restricted. Replace as necessary.

• Inspect the driving habits of the owner.

• Is the A/C ON full time, defroster mode ON?

• Are the tires at the correct pressure?

• Are the tire sizes changed?

• Are excessively heavy loads being carried?

• Is the acceleration too much, too often?

• Inspect for clutch slip.

• Inspect brake drag.

• Inspect dive belt tension.

• Inspect for a proper transmission shift pattern and down shift operation.

• Inspect the fuel quality (cetane index).

• Inspect the engine oil level and quality.

• Suggest to the owner to fill the fuel tank and recheck the fuel economy.

• Inspect the odometer is correctly operated.

• Inspect the Scan Tool Data List in this section.

• Inspect the Service Bulletin.

Sensor Checks Inspect the engine control sensors for the following conditions. Refer to the Scan Tool

Data List in this section.

• Compare the Coolant Temperature with the Intake Air Temperature (IAT) and Fuel Temperature (FT) parameters on a cold engine condition. If the difference among

temperature reading is more than 5 °C (9 °F) on a cold engine, check for high

resistance in each circuit or for a skewed sensor.

Notice: The mass air flow (MAF) sensor is heated and as a result the IAT may indicate

a higher than normal intake air temperature if the ignition switch is being ON.

Fuel System Checks Inspect the fuel system for the following conditions. Refer to the Fuel System section.

• Fuel type and quality.

• Check fuel leak.

Cooling System Checks Inspect the cooling system for the following conditions. Refer to the Cooling System

Section.

• Engine coolant level.

• Engine thermostat for always being open or for the wrong heat range.

• Engine cooling fan for always being ON.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 2008 of 6020

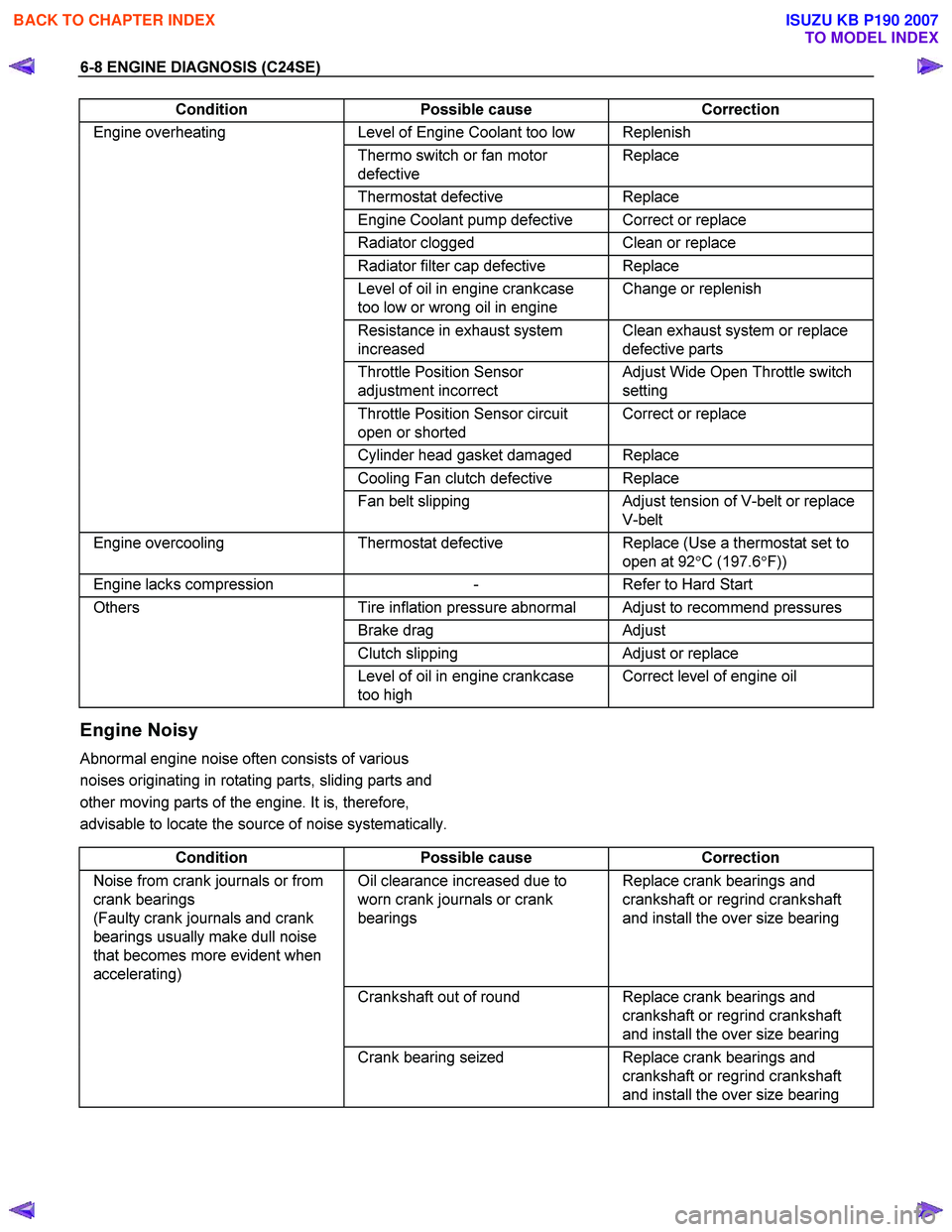

6-8 ENGINE DIAGNOSIS (C24SE)

Condition Possible cause Correction

Engine overheating Level of Engine Coolant too low Replenish

Thermo switch or fan motor

defective Replace

Thermostat

defective Replace

Engine Coolant pump defective Correct or replace

Radiator clogged Clean or replace

Radiator filter cap defective Replace

Level of oil in engine crankcase

too low or wrong oil in engine Change or replenish

Resistance in exhaust system

increased Clean exhaust system or replace

defective parts

Throttle Position Sensor

adjustment incorrect Adjust Wide Open Throttle switch

setting

Throttle Position Sensor circuit

open or shorted Correct or replace

Cylinder head gasket damaged Replace

Cooling Fan clutch defective Replace

Fan belt slipping Adjust tension of V-belt or replace

V-belt

Engine overcooling Thermostat defective Replace (Use a thermostat set to

open at 92 °C (197.6 °F))

Engine lacks compression - Refer to Hard Start

Others Tire inflation pressure abnormal Adjust to recommend pressures

Brake drag Adjust

Clutch slipping Adjust or replace

Level of oil in engine crankcase

too high Correct level of engine oil

Engine Noisy

Abnormal engine noise often consists of various

noises originating in rotating parts, sliding parts and

other moving parts of the engine. It is, therefore,

advisable to locate the source of noise systematically.

Condition Possible cause Correction

Noise from crank journals or from

crank bearings

(Faulty crank journals and crank

bearings usually make dull noise

that becomes more evident when

accelerating) Oil clearance increased due to

worn crank journals or crank

bearings Replace crank bearings and

crankshaft or regrind crankshaft

and install the over size bearing

Crankshaft out of round Replace crank bearings and

crankshaft or regrind crankshaft

and install the over size bearing

Crank bearing seized Replace crank bearings and

crankshaft or regrind crankshaft

and install the over size bearing

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 2519 of 6020

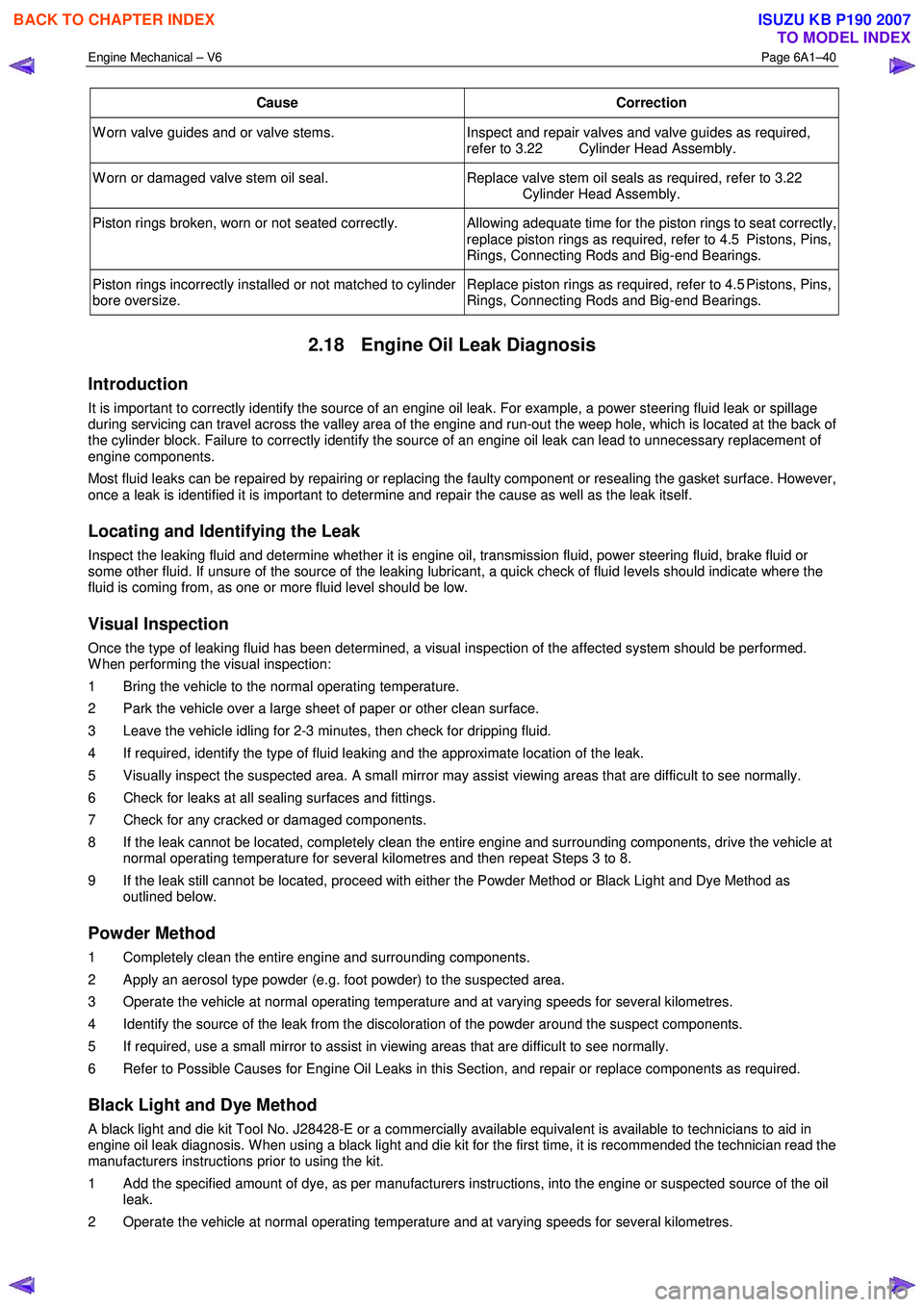

Engine Mechanical – V6 Page 6A1–40

Cause Correction

W orn valve guides and or valve stems. Inspect and repair valves and valve guides as required,

refer to 3.22 Cylinder Head Assembly.

W orn or damaged valve stem oil seal. Replace valve stem oil seals as required, refer to 3.22

Cylinder Head Assembly.

Piston rings broken, worn or not seated correctly. Allowing adequate time for the piston rings to seat correctly,

replace piston rings as required, refer to 4.5 Pistons, Pins,

Rings, Connecting Rods and Big-end Bearings.

Piston rings incorrectly installed or not matched to cylinder

bore oversize. Replace piston rings as required, refer to 4.5 Pistons, Pins,

Rings, Connecting Rods and Big-end Bearings.

2.18 Engine Oil Leak Diagnosis

Introduction

It is important to correctly identify the source of an engine oil leak. For example, a power steering fluid leak or spillage

during servicing can travel across the valley area of the engine and run-out the weep hole, which is located at the back of

the cylinder block. Failure to correctly identify the source of an engine oil leak can lead to unnecessary replacement of

engine components.

Most fluid leaks can be repaired by repairing or replacing the faulty component or resealing the gasket surface. However,

once a leak is identified it is important to determine and repair the cause as well as the leak itself.

Locating and Identifying the Leak

Inspect the leaking fluid and determine whether it is engine oil, transmission fluid, power steering fluid, brake fluid or

some other fluid. If unsure of the source of the leaking lubricant, a quick check of fluid levels should indicate where the

fluid is coming from, as one or more fluid level should be low.

Visual Inspection

Once the type of leaking fluid has been determined, a visual inspection of the affected system should be performed.

W hen performing the visual inspection:

1 Bring the vehicle to the normal operating temperature.

2 Park the vehicle over a large sheet of paper or other clean surface.

3 Leave the vehicle idling for 2-3 minutes, then check for dripping fluid.

4 If required, identify the type of fluid leaking and the approximate location of the leak.

5 Visually inspect the suspected area. A small mirror may assist viewing areas that are difficult to see normally.

6 Check for leaks at all sealing surfaces and fittings.

7 Check for any cracked or damaged components.

8 If the leak cannot be located, completely clean the entire engine and surrounding components, drive the vehicle at normal operating temperature for several kilometres and then repeat Steps 3 to 8.

9 If the leak still cannot be located, proceed with either the Powder Method or Black Light and Dye Method as outlined below.

Powder Method

1 Completely clean the entire engine and surrounding components.

2 Apply an aerosol type powder (e.g. foot powder) to the suspected area.

3 Operate the vehicle at normal operating temperature and at varying speeds for several kilometres.

4 Identify the source of the leak from the discoloration of the powder around the suspect components.

5 If required, use a small mirror to assist in viewing areas that are difficult to see normally.

6 Refer to Possible Causes for Engine Oil Leaks in this Section, and repair or replace components as required.

Black Light and Dye Method

A black light and die kit Tool No. J28428-E or a commercially available equivalent is available to technicians to aid in

engine oil leak diagnosis. W hen using a black light and die kit for the first time, it is recommended the technician read the

manufacturers instructions prior to using the kit.

1 Add the specified amount of dye, as per manufacturers instructions, into the engine or suspected source of the oil leak.

2 Operate the vehicle at normal operating temperature and at varying speeds for several kilometres.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007