engine remove ISUZU TF SERIES 2004 Workshop Manual

[x] Cancel search | Manufacturer: ISUZU, Model Year: 2004, Model line: TF SERIES, Model: ISUZU TF SERIES 2004Pages: 4264, PDF Size: 72.63 MB

Page 1776 of 4264

6E–404 4JA1/4JH1 ENGINE DRIVEABILITY AND EMISSIONS

20 Substitute a known good MAF & IAT sensor assembly

and recheck.

Was the problem solved?—Go to Step 21Go to Step 31

21 Replace the MAF & IAT sensor assembly.

Is the action complete?—Veri fy repai r—

22 1. Using the Tech 2, ignition “On” and engine “Off”.

2. Monitor the “Pedal/Throttle Position” and “Idle

Switch” in the data display.

Does the Tech 2 indicate correct “Pedal/Throttle

Position” from 0% to 100% and correct “Idle Switch”

status depending on accelerator pedal operation?—Go to Step 27Go to Step 23

23 1. Using the Tech 2, ignition “On” and engine “Off”.

2. Monitor the “Pedal/Throttle Position” and “Idle

Switch” in the data display.

3. Adjust the accelerator cable or TPS within 0% to

100%.

Was the problem solved?—Verify repair Go to Step 24

24 Check the TPS harness for the following conditions.

Check for poor connector connection.

Check for misrouted harness.

Check for any accessory parts which may cause

electric interference.

If a problem is found, repair as necessary.

Was a problem found? —Verify repair Go to Step 25

25 Substitute a known good TPS and recheck.

Was the problem solved?—Go to Step 26Go to Step 31

26 Replace the TPS.

Is the action complete?—Veri fy repai r—

27 Remove the injection nozzles from the engine and

check for the following conditions.

Improper splay condition.

Operating pressure is incorrect.

If a problem is found, repair as necessary.

Was the problem found?

—Replace the

injection nozzle

and verify repair Go to Step 28 Step Action Value(s) Yes No

1st Stage 2nd Sta ge

4JA1-TCApproximatly

19.0 MpaApprox ima tly

33.5 Mpa

4JH1-TCApproximatly

19.5 MpaApprox ima tly

33.8 Mpa

Page 1779 of 4264

4JA1/4JH1 ENGINE DRIVEABILITY AND EMISSIONS 6E–407

EXCESSIVE WHITE SMOKE

Step Action Value(s) Yes No

1Was the “On-Board Diagnostic (OBD) System Check”

performed?

—Go to Step 2Go to On Board

Diagnostic

(OBD) System

Check

2 1. Perform a bulletin search.

2. If a bulletin that addresses the symptom is found,

correct the condition as instructed in the bulletin.

Was a bulletin found that addresses the symptom?—Verify repair Go to Step 3

3 Was a visually/physical check performed?

—Go to Step 4Go to Visual /

physical Check

4 Is the customer using the incorrect fuel type? Diesel fuel

onlyReplace with

diesel fuel Go to Step 5

5 Check the engine coolant consumption to verify that it

leaks to combustion chamber or ex haust through the

gasket.

Was a problem found?—Verify repair Go to Step 6

6 Check the ECM & PSG grounds to verify that they are

clean and tight. Refer to the ECM wiring diagrams.

Was a problem found?—Verify repair Go to Step 7

7 1. Using the Tech 2, display the ECT sensor and IAT

sensor value.

2. Check the displayed value.

Does the Tech 2 indicate correct temperature

depending on engine condition?

If a problem is found, repair as necessary.

Was the problem found?—Verify repair Go to Step 8

8 1. Using the Tech 2, display the FT sensor value.

2. Check the displayed value.

Does the Tech 2 indicate correct temperature

depending on engine condition?

If a problem is found, repair as necessary.

Was the problem found?—Go to Step 30Go to Step 9

9 1. Using the Tech 2, ignition “On” and engine “Run”.

2. Monitor the “Mass Air Flow” in the data display.

Does the Tech 2 indicate correct “Mass Air Flow”

depending on accelerator pedal operation? —Go to Step 14Go to Step 10

10 Remove the MAF & IAT sensor assembly and check

for the following conditions.

Objects blocking at the MAF sensor element.

If a problem is found, repair as necessary.

Was the problem found?—Verify repair Go to Step 11

11 Check the MAF sensor harness for the following

conditions.

Check for poor connector connection.

Check for misrouted harness.

Check for any accessory parts which may cause

electric interference.

If a problem is found, repair as necessary.

Was a problem found? —Verify repair Go to Step 12

Page 1780 of 4264

6E–408 4JA1/4JH1 ENGINE DRIVEABILITY AND EMISSIONS

12 Substitute a known good MAF & IAT sensor assembly

and recheck.

Was the problem solved?—Go to Step 13Go to Step 30

13 Replace the MAF & IAT sensor assembly.

Is the action complete?—Veri fy repai r—

14 1. Using the Tech 2, ignition “On” and engine “Run”.

2. Monitor the “Glow Time Relay” in the data display.

Does the Tech 2 indicate correct “Glow Time Relay”

status depending on the time from engine “Run”?

If a problem is found, repair as necessary.

Was the problem found?—Go to Step 30Go to Step 15

15 1. Using the Tech 2, ignition “On” and engine “Run”.

2. Monitor the “Glow Time Relay” in the data display

and then, does the supply voltage correctly supply

to the glow plug?

—Go to Step 16Repair voltage

supply circuit

and verify repair

16 Check the glow plugs for continuity.

If a problem is found, repair as necessary.

Was a problem found?

—Verify repair Go to Step 17

17 Remove the CKP sensor from the flywheel housing

and check for the following conditions.

Objects sticking the CKP sensor.

Objects sticking the CKP sensor pulser.

If a problem is found, repair as necessary.

Was the problem found? —Verify repair Go to Step 18

18 Check the CKP sensor harness for the following

conditions.

Check for poor connector connection.

Check for misrouted harness.

Check for any accessory parts which may cause

electric interference.

If a problem is found, repair as necessary.

Was a problem found? —Verify repair Go to Step 19 Step Action Value(s) Yes No

Page 1782 of 4264

6E–410 4JA1/4JH1 ENGINE DRIVEABILITY AND EMISSIONS

25 Remove the eye bolt with gauze filter from the

injection pump and check for the following conditions.

Objects blocking at the gauze filter. Check for a

condition that causes contaminated fuel, such as

the customer is using an aftermarket fuel filter or

ex tended maintenance interval.

Check for a condition that causes fuel wax ing or

icing, such as the customer is using an incorrect

fuel type in winter season or water mix ed with the

fuel.

If a problem is found, repair as necessary.

Was the problem found?

—Replace the

eye bolt with

gauze filter and

verify repair Go to Step 26

26 Remove the injection nozzles from the engine and

check for the following conditions.

Improper splay condition.

Operating pressure is incorrect.

If a problem is found, repair as necessary.

Was the problem found?

—Replace the

injection nozzle

and verify repair Go to Step 27 Step Action Value(s) Yes No

1st Stage 2nd Sta ge

4JA1-TCApproximatly

19.0 MpaApprox ima tly

33.5 Mpa

4JH1-TCApproximatly

19.5 MpaApprox ima tly

33.8 Mpa

Page 1786 of 4264

6E–414 4JA1/4JH1 ENGINE DRIVEABILITY AND EMISSIONS

10 Remove the MAF & IAT sensor assembly and check

for the following conditions.

Objects blocking at the MAF sensor element.

If a problem is found, repair as necessary.

Was the problem found?—Verify repair Go to Step 11

11 Check the MAF sensor harness for the following

conditions.

Check for poor connector connection.

Check for misrouted harness.

Check for any accessory parts which may cause

electric interference.

If a problem is found, repair as necessary.

Was a problem found? —Verify repair Go to Step 12

12 Substitute a known good MAF & IAT sensor assembly

and recheck.

Was the problem solved?—Go to Step 13Go to Step 21

13 Replace the MAF & IAT sensor assembly.

Is the action complete?—Veri fy repai r—

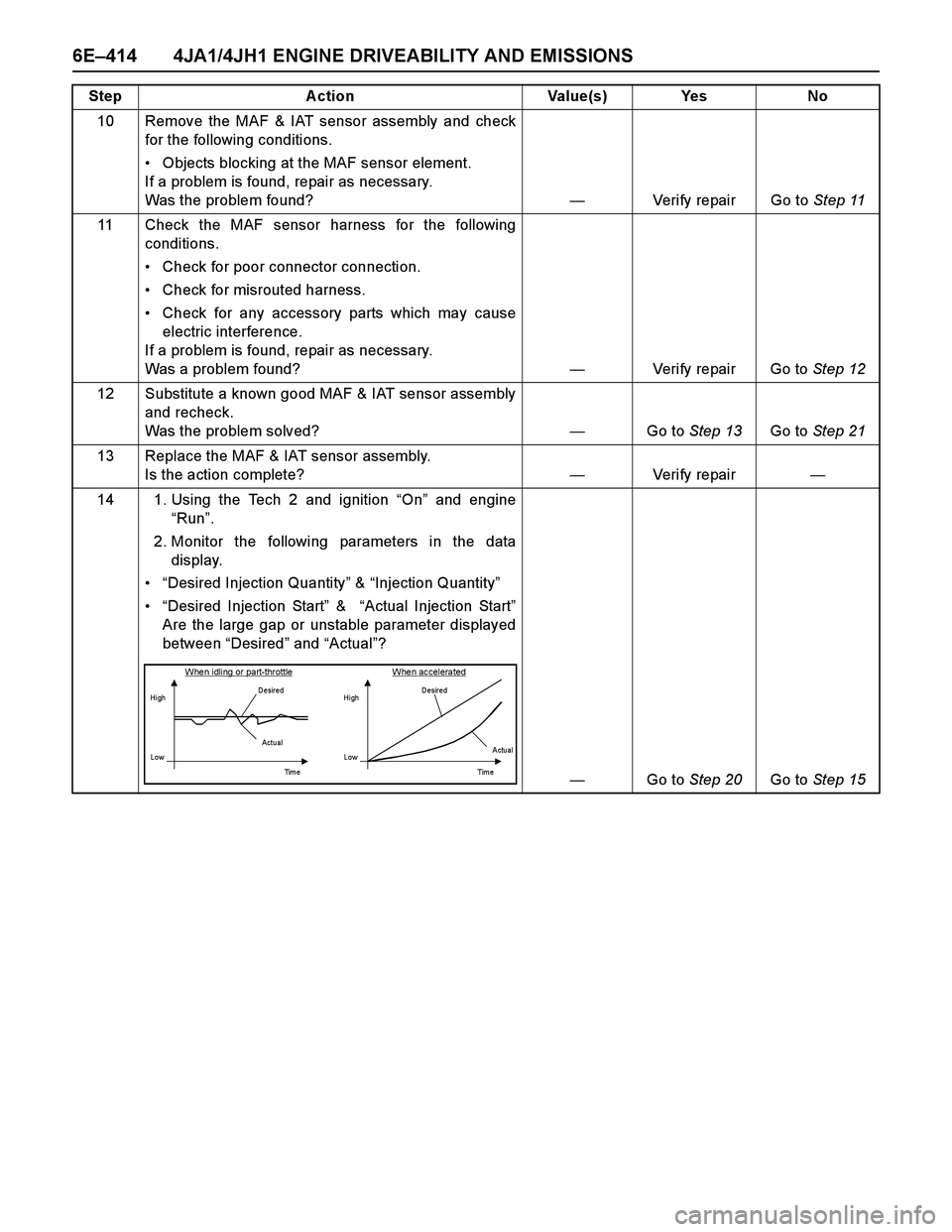

14 1. Using the Tech 2 and ignition “On” and engine

“Run”.

2. Monitor the following parameters in the data

display.

“Desired Injection Quantity” & “Injection Quantity”

“Desired Injection Start” & “Actual Injection Start”

Are the large gap or unstable parameter displayed

between “Desired” and “Actual”?

—Go to Step 20Go to Step 15 Step Action Value(s) Yes No

When idling or part-throttle When accelerated

HighD esired

Low

Ti m e Actu al

High

LowD esired

Actual

Tim e

Page 1788 of 4264

6E–416 4JA1/4JH1 ENGINE DRIVEABILITY AND EMISSIONS

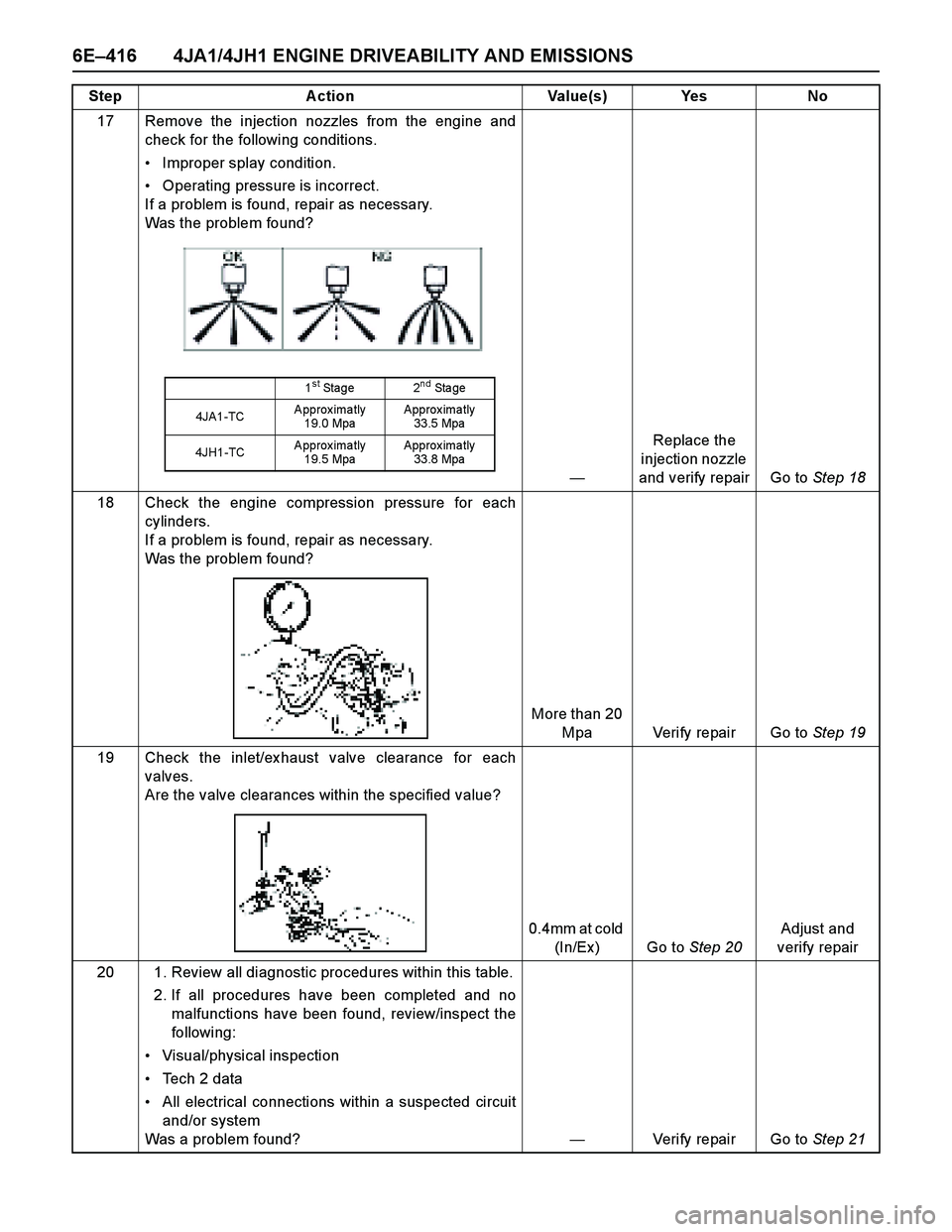

17 Remove the injection nozzles from the engine and

check for the following conditions.

Improper splay condition.

Operating pressure is incorrect.

If a problem is found, repair as necessary.

Was the problem found?

—Replace the

injection nozzle

and verify repair Go to Step 18

18 Check the engine compression pressure for each

cylinders.

If a problem is found, repair as necessary.

Was the problem found?

More than 20

Mpa Verify repair Go to Step 19

19 Check the inlet/ex haust valve clearance for each

valves.

Are the valve clearances within the specified value?

0.4mm at cold

(In/Ex ) Go to Step 20Adjust and

verify repair

20 1. Review all diagnostic procedures within this table.

2. If all procedures have been completed and no

malfunctions have been found, review/inspect the

followi ng:

Visual/physical inspection

Tech 2 data

All electrical connections within a suspected circuit

and/or system

Was a problem found?—Verify repair Go to Step 21 Step Action Value(s) Yes No

1st Stage 2nd Sta ge

4JA1-TCApproximatly

19.0 MpaApprox ima tly

33.5 Mpa

4JH1-TCApproximatly

19.5 MpaApprox ima tly

33.8 Mpa

Page 1790 of 4264

6E–418 4JA1/4JH1 ENGINE DRIVEABILITY AND EMISSIONS

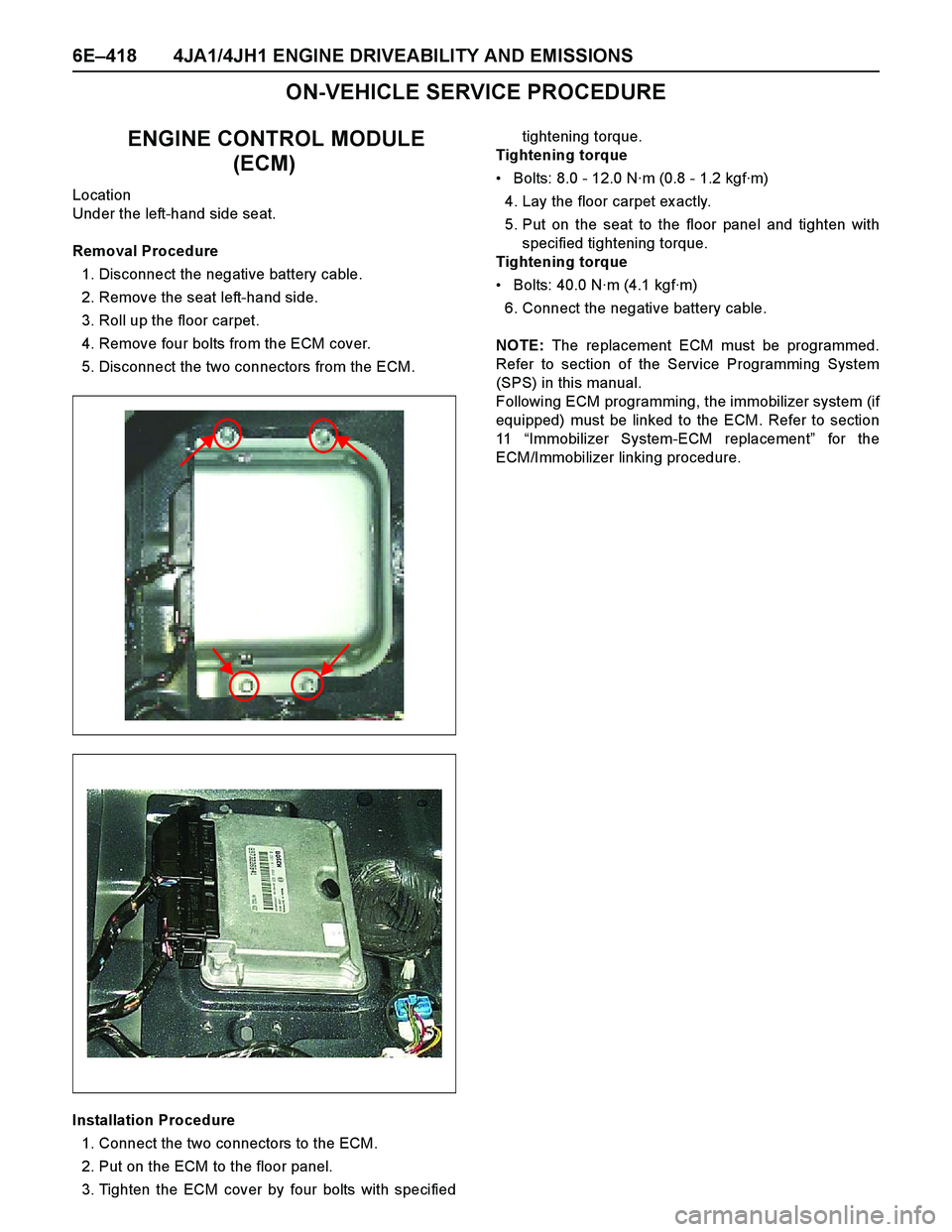

ON-VEHICLE SERVICE PROCEDURE

ENGINE CONTROL MODULE

(ECM)

Location

Under the left-hand side seat.

Removal Procedure

1. Disconnect the negative battery cable.

2. Remove the seat left-hand side.

3. Roll up the floor carpet.

4. Remove four bolts from the ECM cover.

5. Disconnect the two connectors from the ECM.

Installation Procedure

1. Connect the two connectors to the ECM.

2. Put on the ECM to the floor panel.

3. Tighten the ECM cover by four bolts with specifiedtightening torque.

Tightening torque

Bolts: 8.0 - 12.0 N·m (0.8 - 1.2 kgf·m)

4. Lay the floor carpet ex actly.

5. Put on the seat to the floor panel and tighten with

specified tightening torque.

Tightening torque

Bolts: 40.0 N·m (4.1 kgf·m)

6. Connect the negative battery cable.

NOTE: The replacement ECM must be programmed.

Refer to section of the Service Programming System

(SPS) in this manual.

Following ECM programming, the immobilizer system (if

equipped) must be linked to the ECM. Refer to section

11 “Immobilizer System-ECM replacement” for the

ECM/Immobilizer linking procedure.

Page 1791 of 4264

4JA1/4JH1 ENGINE DRIVEABILITY AND EMISSIONS 6E–419

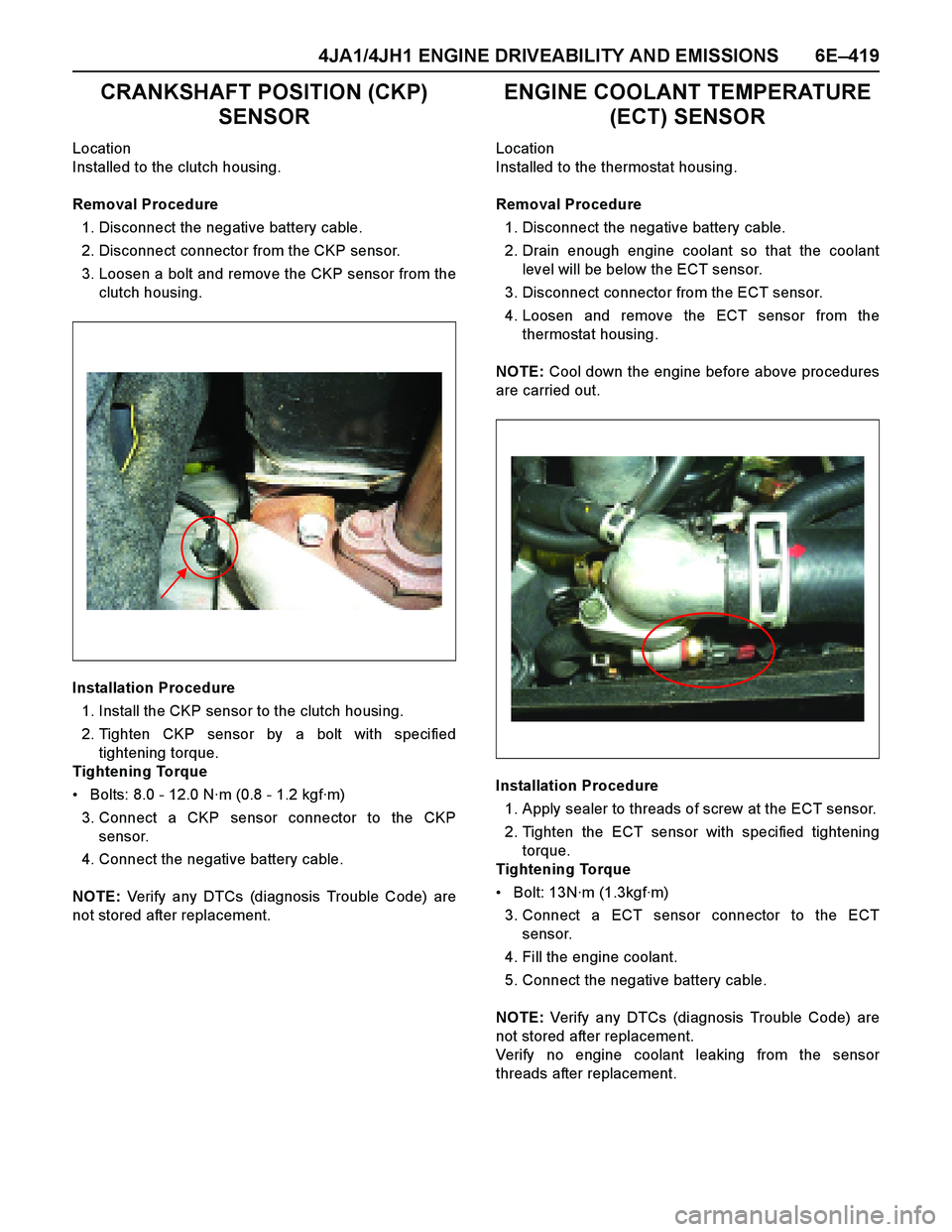

CRANKSHAFT POSITION (CKP)

SENSOR

Location

Installed to the clutch housing.

Removal Procedure

1. Disconnect the negative battery cable.

2. Disconnect connector from the CKP sensor.

3. Loosen a bolt and remove the CKP sensor from the

clutch housing.

Installation Procedure

1. Install the CKP sensor to the clutch housing.

2. Tighten CKP sensor by a bolt with specified

tightening torque.

Tightening Torque

Bolts: 8.0 - 12.0 N·m (0.8 - 1.2 kgf·m)

3. Connect a CKP sensor connector to the CKP

sensor.

4. Connect the negative battery cable.

NOTE: Verify any DTCs (diagnosis Trouble Code) are

not stored after replacement.

ENGINE COOLANT TEMPERATURE

(ECT) SENSOR

Location

Installed to the thermostat housing.

Removal Procedure

1. Disconnect the negative battery cable.

2. Drain enough engine coolant so that the coolant

level will be below the ECT sensor.

3. Disconnect connector from the ECT sensor.

4. Loosen and remove the ECT sensor from the

thermostat housing.

NOTE: Cool down the engine before above procedures

are carried out.

Installation Procedure

1. Apply sealer to threads of screw at the ECT sensor.

2. Tighten the ECT sensor with specified tightening

torque.

Tightening Torque

Bolt: 13N·m (1.3kgf·m)

3. Connect a ECT sensor connector to the ECT

sensor.

4. Fill the engine coolant.

5. Connect the negative battery cable.

NOTE: Verify any DTCs (diagnosis Trouble Code) are

not stored after replacement.

Verify no engine coolant leaking from the sensor

threads after replacement.

Page 1792 of 4264

6E–420 4JA1/4JH1 ENGINE DRIVEABILITY AND EMISSIONS

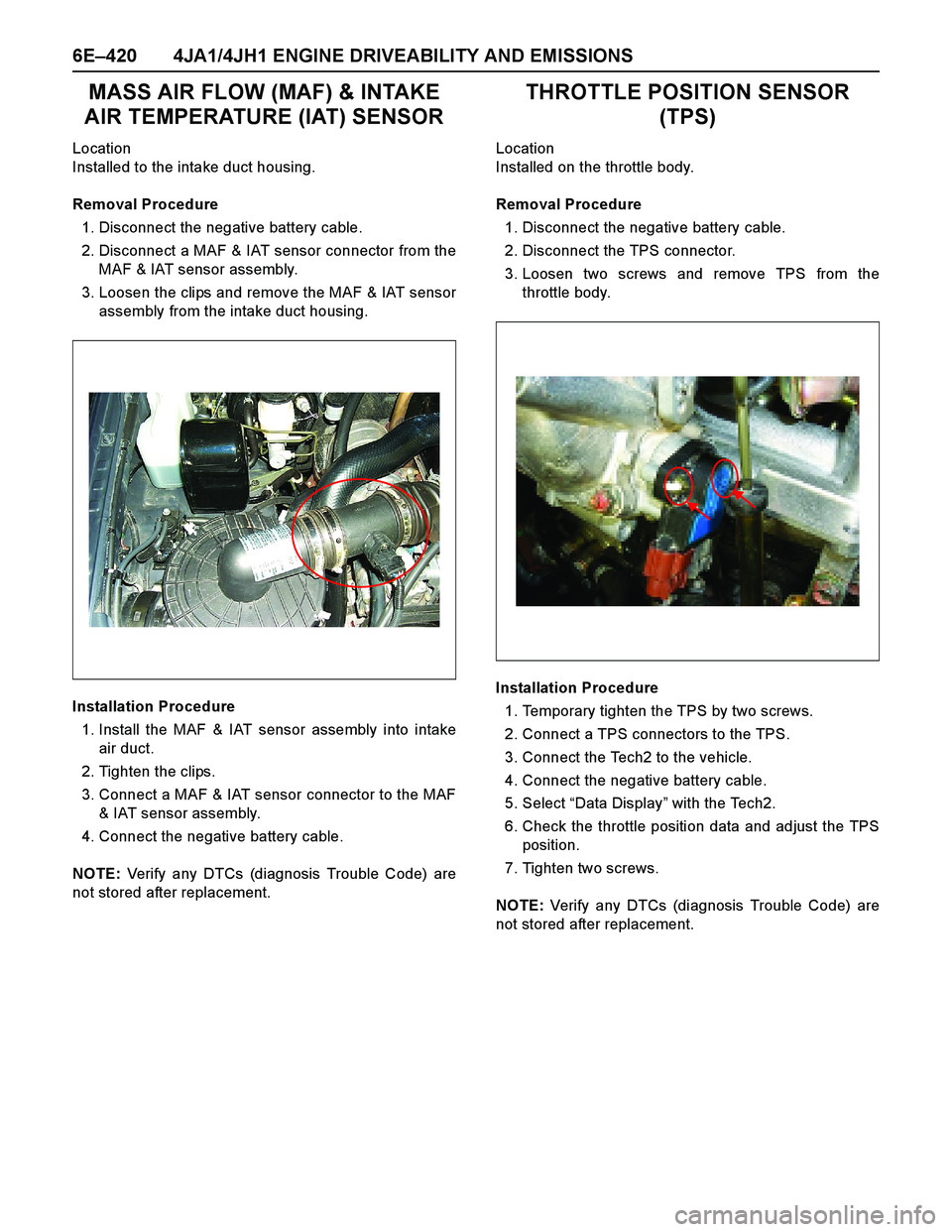

MASS AIR FLOW (MAF) & INTAKE

AIR TEMPERATURE (IAT) SENSOR

Location

Installed to the intake duct housing.

Removal Procedure

1. Disconnect the negative battery cable.

2. Disconnect a MAF & IAT sensor connector from the

MAF & IAT sensor assembly.

3. Loosen the clips and remove the MAF & IAT sensor

assembly from the intake duct housing.

Installation Procedure

1. Install the MAF & IAT sensor assembly into intake

air duct.

2. Tighten the clips.

3. Connect a MAF & IAT sensor connector to the MAF

& IAT sensor assembly.

4. Connect the negative battery cable.

NOTE: Verify any DTCs (diagnosis Trouble Code) are

not stored after replacement.

THROTTLE POSITION SENSOR

(TPS)

Location

Installed on the throttle body.

Removal Procedure

1. Disconnect the negative battery cable.

2. Disconnect the TPS connector.

3. Loosen two screws and remove TPS from the

throttle body.

Installation Procedure

1. Temporary tighten the TPS by two screws.

2. Connect a TPS connectors to the TPS.

3. Connect the Tech2 to the vehicle.

4. Connect the negative battery cable.

5. Select “Data Display” with the Tech2.

6. Check the throttle position data and adjust the TPS

position.

7. Tighten two screws.

NOTE: Verify any DTCs (diagnosis Trouble Code) are

not stored after replacement.

Page 1793 of 4264

4JA1/4JH1 ENGINE DRIVEABILITY AND EMISSIONS 6E–421

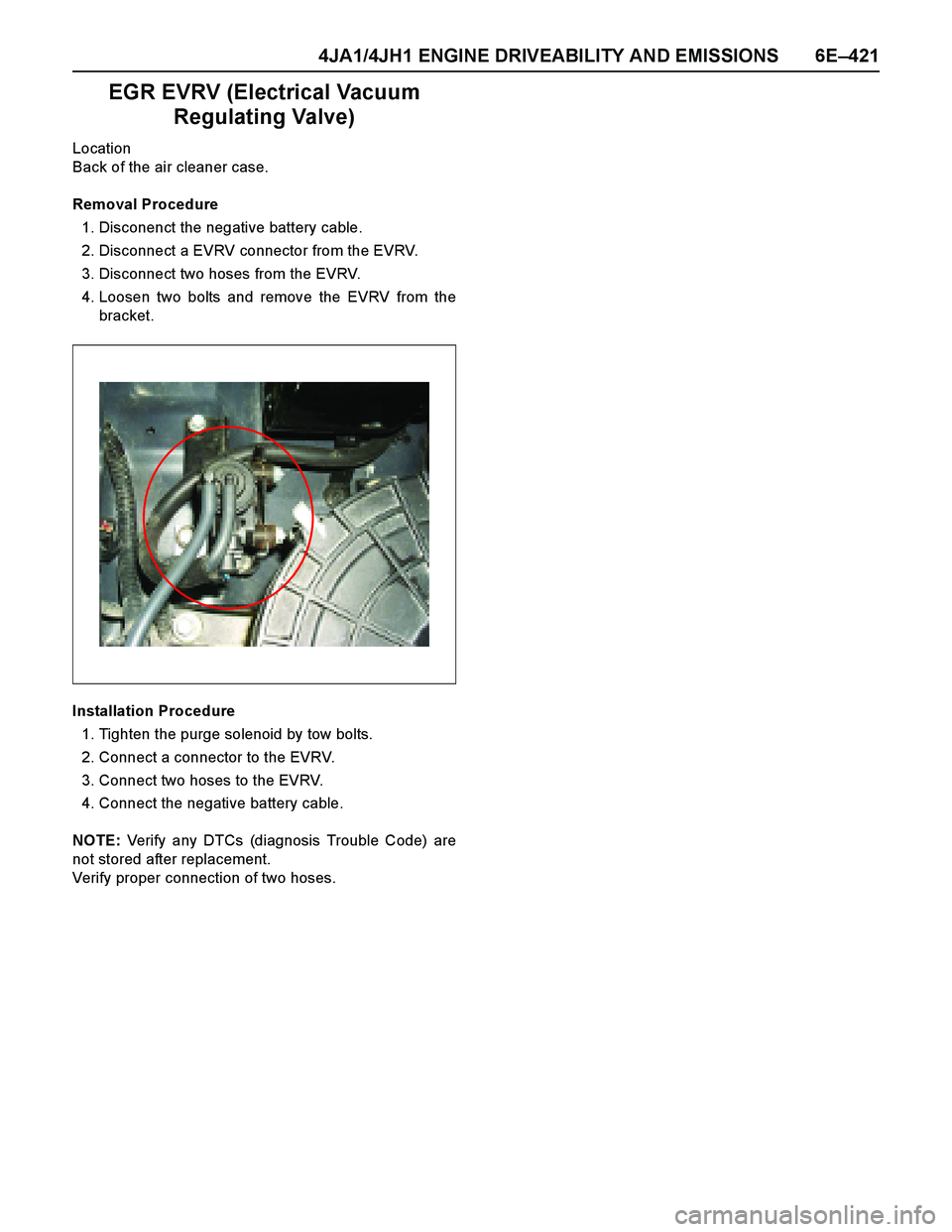

EGR EVRV (Electrical Vacuum

Regulating Valve)

Location

Back of the air cleaner case.

Removal Procedure

1. Disconenct the negative battery cable.

2. Disconnect a EVRV connector from the EVRV.

3. Disconnect two hoses from the EVRV.

4. Loosen two bolts and remove the EVRV from the

bracket.

Installation Procedure

1. Tighten the purge solenoid by tow bolts.

2. Connect a connector to the EVRV.

3. Connect two hoses to the EVRV.

4. Connect the negative battery cable.

NOTE: Verify any DTCs (diagnosis Trouble Code) are

not stored after replacement.

Verify proper connection of two hoses.