content ISUZU TF SERIES 2004 Repair Manual

[x] Cancel search | Manufacturer: ISUZU, Model Year: 2004, Model line: TF SERIES, Model: ISUZU TF SERIES 2004Pages: 4264, PDF Size: 72.63 MB

Page 2782 of 4264

6E–206 ENGINE DRIVEABILITY AND EMISSIONS

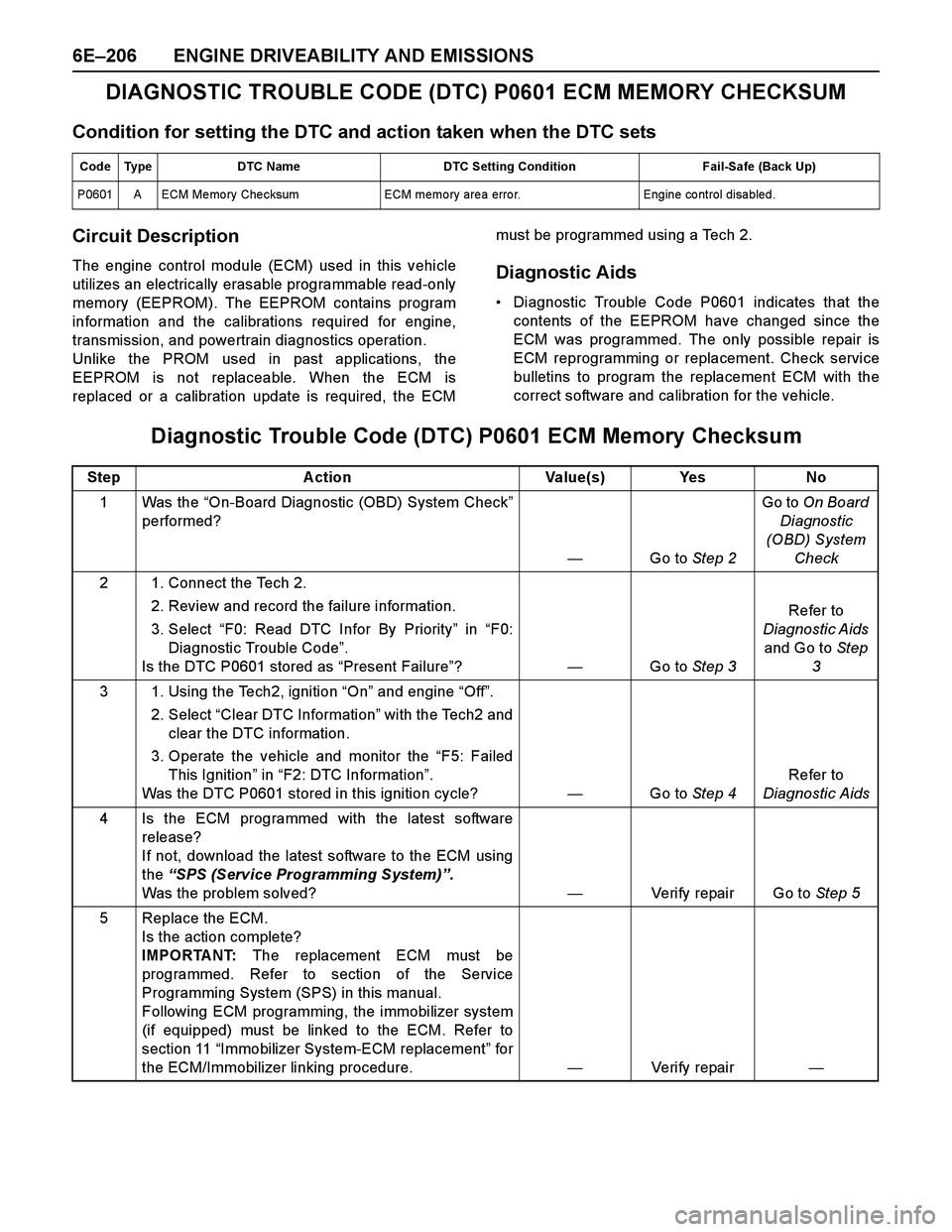

DIAGNOSTIC TROUBLE CODE (DTC) P0601 ECM MEMORY CHECKSUM

Condition for setting the DTC and action taken when the DTC sets

Circuit Description

The engine control module (ECM) used in this vehicle

utilizes an electrically erasable programmable read-only

memory (EEPROM). The EEPROM contains program

information and the calibrations required for engine,

transmission, and powertrain diagnostics operation.

Unlike the PROM used in past applications, the

EEPROM is not replaceable. When the ECM is

replaced or a calibration update is required, the ECMmust be programmed using a Tech 2.Diagnostic Aids

Diagnostic Trouble Code P0601 indicates that the

contents of the EEPROM have changed since the

ECM was programmed. The only possible repair is

ECM reprogramming or replacement. Check service

bulletins to program the replacement ECM with the

correct software and calibration for the vehicle.

Diagnostic Trouble Code (DTC) P0601 ECM Memory Checksum

Code Type DTC Name DTC Setting Condition Fail-Safe (Back Up)

P0601 A ECM Me mo ry Che cksum ECM memo ry are a erro r. Engine co ntrol disabled.

Step A ction Value(s) Yes No

1 Was the “On-Board Diagnostic (OBD) System Check”

performed?

—Go to Step 2Go to On Board

Diagnostic

(OBD) System

Check

2 1. Connect the Tech 2.

2. Review and record the failure information.

3. Select “F0: Read DTC Infor By Priority” in “F0:

Diagnostic Trouble Code”.

Is the DTC P0601 stored as “Present Failure”?—Go to Step 3Refer to

Diagnostic Aids

and Go to Step

3

3 1. Using the Tech2, ignition “On” and engine “Off”.

2. Select “Clear DTC Information” with the Tech2 and

clear the DTC information.

3. Operate the vehicle and monitor the “F5: Failed

This Ignition” in “F2: DTC Information”.

Was the DTC P0601 stored in this ignition cycle?—Go to Step 4Refer to

Diagnostic Aids

4 Is the ECM programmed with the latest software

release?

If not, download the latest software to the ECM using

the “SPS (Service Programming System)”.

Was the problem solved?—Verify repair Go to Step 5

5 Replace the ECM.

Is the action complete?

IMPORTANT: The replacement ECM must be

programmed. Refer to section of the Service

Programming System (SPS) in this manual.

Following ECM programming, the immobilizer system

(if equipped) must be linked to the ECM. Refer to

section 11 “Immobilizer System-ECM replacement” for

the ECM/Immobilizer linking procedure.—Veri fy repai r—

Page 2808 of 4264

6E–232 ENGINE DRIVEABILITY AND EMISSIONS

SYMPTOM DIAGNOSIS

PRELIMINARY CHECKS

Before using this section, perform the “On-Board

Diagnostic (OBD) System Check” and verify all of the

following items:

The engine control module (ECM) and malfunction

indicator lamp (MIL = Check Engine Lamp) are

operating correctly.

There are no Diagnostic Trouble Code(s) stored.

Tech 2 data is within normal operating range. Refer to

Typical Scan Data Values.

Verify the customer complaint and locate the correct

symptom in the table of contents. Perform the

procedure included in the symptom chart.

VISUAL/PHYSICAL CHECK

Several of the symptom procedures call for a careful

visual/physical check. This can lead to correcting a

problem without further checks and can save valuable

time. This check should include the following items:

ECM grounds for cleanliness, tightness and proper

location.

Vacuum hoses for splits, kinks, and proper

connection, shown on the “Emission Control System

Schematics”. Check thoroughly for any type of leak or

restriction.

Air intake ducts for collapsed or damaged areas.

Air leaks at throttle body mounting area, manifold

absolute pressure (MAP) sensor and intake manifold

sealing surfaces.

Ignition wires for cracking, harness, and carbon

tracking.

Wiring for proper connections, pinches and cuts.

INTERMITTENT

Important: An intermittent problem may or may not turn

on the malfunction indicator lamp (MIL) or store a

Diagnostic Trouble Code. Do NOT use the Diagnostic

Trouble Code (DTC) charts for intermittent problems.

The fault must be present to locate the problem.

Most intermittent problems are cased by faulty electrical

connections or wiring. Perform a careful visual/physical

check for the following conditions.

Poor mating of the connector halves or a terminal not

fully seated in the connector (backed out).

Improperly formed or damaged terminal.

All connector terminals in the problem circuit should

be carefully checked for proper contact tension.

Poor terminal-to-wire connection. This requires

removing the terminal form the connector body to

check.

Ignition coils shorted to ground and arcing at ignition

wires or plugs.MIL (Check Engine Lamp) wire to ECM shorted to

ground.

Poor ECM grounds. Refer to the ECM wiring

diagrams.

Road test the vehicle with a Digital Multimeter

connected to a suspected circuit. An abnormal voltage

when the malfunction occurs is a good indication that

there is a fault in the circuit being monitored.

Using Tech 2 to help detect intermittent conditions. The

Tech 2 has several features that can be used to located

an intermittent condition.

An intermittent MIL (Check Engine Lamp) with no stored

Diagnostic Trouble Code may be caused by the

follow ing:

Ignition coil shorted to ground and arcing at ignition

wires or plugs.

MIL (Check Engine Lamp) wire to ECM short to

ground.

Poor ECM grounds. Refer to the ECM wiring

diagrams.

Check for improper installation of electrical options such

as light, cellular phones, etc. Check all wires from ECM

to the ignition control module for poor connections.

Check for an open diode across the A/C compressor

clutch and check for other open diodes (refer to wiring

diagrams in Electrical Diagnosis).

If problem has not been found, refer to ECM connector

symptom tables.

Check the “Broadcast Code” of the ECM, and

compare it with the latest Isuzu service bulletins and/

or Isuzu EEPROM reprogramming equipment to

determine if an update to the ECM’s reprogrammable

memory has been released.

To check the “Broadcast Code”, connect the Tech 2,

then look for “ID info.” then select “Broadcast Code”.

This should display a 4 character code, such as “XBYA”

(ex ample only).

This identifies the contents of the reprogrammable

software and calibration contained in the ECM.

If the “Broadcast Code” is not the most current

available, it is advisable to reprogram the ECM’s

EEPROM memory, which may either help identify a

hard-to find problem or may fix the problem.

The Service Programming System (SPS) will not allow

incorrect software programming or incorrect calibration

changes.

Page 2857 of 4264

ENGINE EXHAUST 6F-1

SECTION 6F

ENGINE EXHAUST

CONTENTS

PAGE

General Description........................................................................................................ 6F- 2

Service Precaution ......................................................................................................... 6F- 4

Exhaust Pipe ................................................................................................................... 6F- 5

Exhaust pipe and Associated parts.......................................................................... 6F- 5

Removal ...................................................................................................................... 6F- 5

Installation .................................................................................................................. 6F- 6

Inspection ................................................................................................................... 6F- 6

Front Exhaust Pipe ......................................................................................................... 6F- 7

Front Exhaust Pipe and Associated Parts ............................................................... 6F- 7

Removal ...................................................................................................................... 6F- 7

Installation .................................................................................................................. 6F- 7

Mid Pipe ........................................................................................................................... 6F- 8

Mid Pipe and associated Parts ................................................................................. 6F- 8

Removal ...................................................................................................................... 6F- 8

Installation .................................................................................................................. 6F- 8

Catalytic Converter (If applicable) ................................................................................. 6F- 9

Catalytic Converter and Associated Parts ............................................................... 6F- 9

Removal ...................................................................................................................... 6F- 9

Installation .................................................................................................................. 6F- 9

3 way Catalytic Converter System ............................................................................ 6F- 10

Exhaust Silencer ............................................................................................................. 6F- 12

Exhaust Silencer and Associated Parts ................................................................... 6F- 12

Removal ...................................................................................................................... 6F- 12

Installation .................................................................................................................. 6F- 13

Main Data and Specifications ........................................................................................ 6F- 14

Torque Specification.................................................................................................. 6F- 15

Page 2873 of 4264

ENGINE LUBRICATION 6G-1

SECTION 6G

ENGINE LUBRICATION

CONTENTS

PAGE

General Description........................................................................................................ 6G- 2

Service Precaution ......................................................................................................... 6G- 3

Oil Pump .......................................................................................................................... 6G- 4

Oil Pump and Associated Parts ................................................................................ 6G- 4

Disassembly ............................................................................................................... 6G- 4

Inspection and Repair................................................................................................ 6G- 5

Reassembly ................................................................................................................ 6G- 5

Oil Pan ............................................................................................................................. 6G- 6

Oil Pan and Associated Parts ................................................................................... 6G- 6

Disassembly ............................................................................................................... 6G- 6

Inspection and Repair................................................................................................ 6G- 7

Reassembly ................................................................................................................ 6G- 7

Page 2881 of 4264

ENGINE SPEED CONTROL SYSTEM (C24SE) 6H-1

ENGINE

ENGINE SPEED CONTROL SYSTEM (C24SE)

CONTENTS

Service Precaution............................................... 6H-1

Accelerator Pedal Control Cable...................... 6H-2

Removal.............................................................. 6H-2

Inspection........................................................... 6H-3

Installation.......................................................... 6H-3

Service Precaution

WARNING: THIS VEHICLE HAS A SUPPLEMENTAL

RESTRAINT SYSTEM (SRS). REFER TO THE SRS

COMPONENT AND WIRING LOCATION VIEW IN

ORDER TO DETERMINE WHETHER YOU ARE

PERFORMING SERVICE ON OR NEAR THE SRS

COMPONENTS OR THE SRS WIRING. WHEN YOU

ARE PERFORMING SERVICE ON OR NEAR THE

SRS COMPONENTS OR THE SRS WIRING, REFE

R

TO THE SRS SERVICE INFORMATION. FAILURE TO

FOLLOW WARNINGS COULD RESULT IN

POSSIBLE AIR BAG DEPLOYMENT, PERSONAL

INJURY, OR OTHERWISE UNNEEDED SRS SYSTEM

REPAIRS.

CAUTION: Always use the correct fastener in the

proper location. When you replace a fastener, use

ONLY the exact part number for that application.

ISUZU will call out those fasteners that require a

replacement after removal. ISUZU will also call out

the fasteners that require thread lockers or thread

sealant. UNLESS OTHERWISE SPECIFIED, do not

use supplemental coatings (Paints, greases, o

r

other corrosion inhibitors) on threaded fasteners o

r

fastener joint interfaces. Generally, such coatings

adversely affect the fastener torque and the joint

clamping force, and may damage the fastener.

When you install fasteners, use the correct

tightening sequence and specifications. Following

these instructions can help you avoid damage to

parts and systems.

Page 2885 of 4264

INDUCTION 6J-1

SECTION 6J

INDUCTION

CONTENTS

PAGE

Service Precaution ......................................................................................................... 6J- 2

Air Cleaner Filter ............................................................................................................. 6J- 2

Removal ...................................................................................................................... 6J- 2

Inspection ................................................................................................................... 6J- 2

Installation .................................................................................................................. 6J- 3

Page 2893 of 4264

FRAME AND BUMPER 2A-1

SECTION 2A

FRAME AND BUMPER

TABLE OF CONTENTS

PAGE

Front Bumper ..................................................................................................................... 2A- 2

Rear Step Bumper ............................................................................................................. 2A- 4

Rear Bumper And Rear Guard ASM ................................................................................. 2A- 7

Frame Dimensions............................................................................................................. 2A- 9

Page 2933 of 4264

SHEET METAL 2B-1

SECTION 2B

SHEET METAL

This section includes items of front end sheet metal that are attached by bolts, screws or clips and related

accessory components.

Anticorrosion materials have been applied to the interior surfaces of some metal panels to provide rust resistance.

When servicing these panes, areas on which this material has been disturbed, should be properly recoated with

service-type anticorrosion material.

TABLE OF CONTENTS

PAGE

Engine Hood Assembly ..................................................................................................... 2B- 2

Engine Hood Lock ............................................................................................................. 2B- 5

Front Fender Panel ............................................................................................................ 2B- 7

Radiator Grille .................................................................................................................... 2B- 10

Rear Body ........................................................................................................................... 2B- 11

Body Mounting ................................................................................................................... 2B- 13

Body Dimension.................................................................................................................2B- 19

Page 2973 of 4264

GENERAL INFORMATION 0A-1

SECTION 0A

GENERAL INFORMATION

TABLE OF CONTENTS

PAGE

General Repair Instructions ............................................................................................ 0A- 2

Notes on The Format of this Manual .............................................................................. 0A- 3

Identification .................................................................................................................... 0A- 6

Lifting Instructions .......................................................................................................... 0A- 7

Conversion Table............................................................................................................. 0A- 9

Page 2981 of 4264

GENERAL INFORMATION 0A-9

CONVERSION TABLE

TABLE OF CONTENTS

PAGE

Length ............................................................................................................................... 0A- 9

Area ................................................................................................................................... 0A-11

Volume .............................................................................................................................. 0A-11

Mass.................................................................................................................................. 0A-13

Pressure ........................................................................................................................... 0A-14

Torque............................................................................................................................... 0A-15

Temperature ..................................................................................................................... 0A-16

LENGTH

MILLIMETERS TO INCHES

mm in. mm in. mm in. mm in. 1 0.0394 26 1.0236 51 2.0079 76 2.9921 2 0.0787 27 1.0630 52 2.0472 77 3.0315 3 0.1181 28 1.1024 53 2.0866 78 3.0709 4 0.1575 29 1.1417 54 2.1260 79 3.1102 5 0.1969 30 1.1811 55 2.1654 80 3.1496 6 0.2362 31 1.2205 56 2.2047 81 3.1890 7 0.2756 32 1.2598 57 2.2441 82 3.2283 8 0.3150 33 1.2992 58 2.2835 83 3.2677 9 0.3543 34 1.3386 59 2.3228 84 3.307110 0.3937 35 1.3780 60 2.3622 85 3.346511 0.4331 36 1.4173 61 2.4016 86 3.385812 0.4724 37 1.4567 62 2.4409 87 3.425213 0.5118 38 1.4961 63 2.4803 88 3.464614 0.5512 39 1.5354 64 2.5197 89 3.503915 0.5906 40 1.5748 65 2.5591 90 3.543316 0.6299 41 1.6142 66 2.5984 91 3.582717 0.6693 42 1.6535 67 2.6378 92 3.622018 0.7087 43 1.6929 68 2.6772 93 3.661419 0.7480 44 1.7323 69 2.7165 94 3.700820 0.7874 45 1.7717 70 2.7559 95 3.740221 0.8268 46 1.8110 71 2.7953 96 3.779522 0.8661 47 1.8504 72 2.8346 97 3.818923 0.9055 48 1.8898 73 2.8740 98 3.858324 0.9449 49 1.9291 74 2.9134 99 3.897625 0.9843 50 1.9685 75 2.9528 100 3.9370 101 3.9764 111 4.3701 121 4.7638 131 5.1575102 4.0157 112 4.4094 122 4.8031 132 5.1968103 4.0551 113 4.4488 123 4.8425 133 5.2362104 4.0945 114 4.4882 124 4.8819 134 5.2756105 4.1339 115 4.5276 125 4.9213 135 5.3150106 4.1732 116 4.5669 126 4.9606 136 5.3543107 4.2126 117 4.6063 127 5.0000 137 5.3937108 4.2520 118 4.6457 128 5.0394 138 5.4331109 4.2913 119 4.6850 129 5.0787 139 5.4724

INCHES TO MILLIMETERS

in. mm in. mm 1/64 0.3969 33/64 13.0969 1/32 0.7938 17/32 13.4938 3/64 1.1906 35/64 13.89061/16 1.5875 9/16 14.2875 5/64 1.9844 37/64 14.6844 3/32 2.3813 19/32 15.0813 7/64 2.7781 39/64 15.47811/8 3.1750 5/8 15.8750 9/64 3.5719 41/64 16.2719 5/32 3.9688 21/32 16.6688 11/64 4.3656 43/64 17.06563/16 4.7625 11/16 17.4625 13/64 5.1594 45/64 17.8594 7/32 5.5563 23/32 18.2563 15/64 5.9531 47/64 18.65311/4 6.3500 3/4 19.0500 17/64 6.7469 49/64 19.4469 9/32 7.1438 25/32 19.8438 19/64 7.5406 51/64 20.24065/16 7.9375 13/16 20.6375 21/64 8.3344 53/64 21.0344 11/32 8.7313 27/32 21.4313 23/64 9.1281 55/64 21.82813/8 9.5250 7/8 22.2250 25/64 9.9219 57/64 22.6219 13/32 10.3188 29/32 23.0188 27/64 10.7156 59/64 23.41567/16 11.1125 15/16 23.8125 29/64 11.5094 61/64 24.2094 15/32 11.9063 31/32 24.6063 31/64 12.3031 63/64 25.00311/2 12.7000 1 25.4000