engine ISUZU TF SERIES 2004 Manual Online

[x] Cancel search | Manufacturer: ISUZU, Model Year: 2004, Model line: TF SERIES, Model: ISUZU TF SERIES 2004Pages: 4264, PDF Size: 72.63 MB

Page 1091 of 4264

ELECTRICAL-BODY AND CHASSIS 8A-433

No. Connector face No. Connector face

H-1

White

Battery (+) ~ Engine room H-10

WhiteINST ~ Front Door-RH

H-2

NOT USED H-11

NOT USED

H-3

(6VE1,

4JH1-TC)

White Battery (+) ~ Engine room H-12

BlackINST ~ Roof

H-4

(C24SE)

White Engine room ~ Mission H-13

WhiteINST ~ Door -LH

H-4

(6VE1,

4JA1-TC,

4JH1-TC)

White

Engine ~ Engine room H-14

WhiteRear body ~ Rear door-LH

H-5

NOT USED H-15

White

Engine room ~ Chassis

H-6

White

Engine room ~ INST H-16

WhiteRear body ~ Rear door-RH

H-7

White

Engine room ~ INST H-17

WhiteChassis ~ License plate lamp

H-8

NOT USED H-18

White

Engine room ~ INST

H-9

Blue

Engine room ~ Chassis H-19

~

H-21 NOT USED

Page 1092 of 4264

8A-434 ELECTRICAL-BODY AND CHASSIS

No. Connector face No. Connector face

H-22

(6VE1)

(4JH1-TC)

White Engine ~ Engine room C H-31

(C24SE)

Engine room ~ Mission

H-23

(6VE1)

(4JH1-TC)

White Engine ~ Engine room B H-32

(C24SE)

(6VE1)

Engine room ~ Rear body

H-23

(4JA1-L)

White Engine room B ~ T/misson H-33

(4JH1-TC)

Engine ~ Engine room

H-24

Black

INST ~ Front door-RH H-34

(C24SE)

Engine ~ Engine room

H-25

Black

INST ~ Front door-LH H-35

Trailer

H-26

White

INST ~ Rear body

H-27

Black

INST ~ Rear body

H-28

White

Sub harness connector

H-29

(C24SE)

Battery(+) ~ Engine room

H-30

(6VE1)

(4JH1-TC)

Engine room ~ INST

Page 1095 of 4264

ELECTRICAL-BODY AND CHASSIS 8A-437

No. Connector face No. Connector face

P-1

Silver

Battery (+) P-9

SilverACG (B)

P-2

Silver

Relay & Fuse box P-10

SilverEngine ground

P-3

Brown

Starter (S) P-11

SilverFuse & relay box

P-4

Silver

Starter (B) P-12

NOT USED

P-4

Silver

Starter (B) P-13

Gray Shift on the fly actuator

P-5

Silver

Battery (-) P-14

WhiteFuse & relay box

P-6

Silver

Body earth (Ground) P-15

Silver2nd battery (+)

P-7

NOT USED P-16

Silver

2nd battey (-)

P-8

(C24SE)

(4JH1-TC

Green ACG (L)

P-8

(6VE1)

White ACG (L)

Page 1115 of 4264

CRUISE CONTROL SYSTEM 8B-17

DTC 2–1 Signal of Vehicle Speed Malfunction

Step Action Value(s) YES NO

1 Check the DTC for engine.

Is the vehicle speed sensor DTC set?

—

Go to DTC for

engine

Go to Step 2

2 Check continuity between harness side connector

E–44 terminal 3 and connector C–120 terminal 9.

Is there continuity between terminals?

—

Go to Step 3

Replace open

circuit

3 Check the continuity between harness side

connector E–44 terminal 3 and ground, connector

C–120 terminal 9 and ground.

Are the results same as specified in the value(s)

column?

No continuity

Replace the

control unit

Repair short

circuit

Page 1119 of 4264

WORKSHOP MANUAL

TF SERIES

ENGINE

4JA1/4JH1-TC

SECTION 6

Page 1121 of 4264

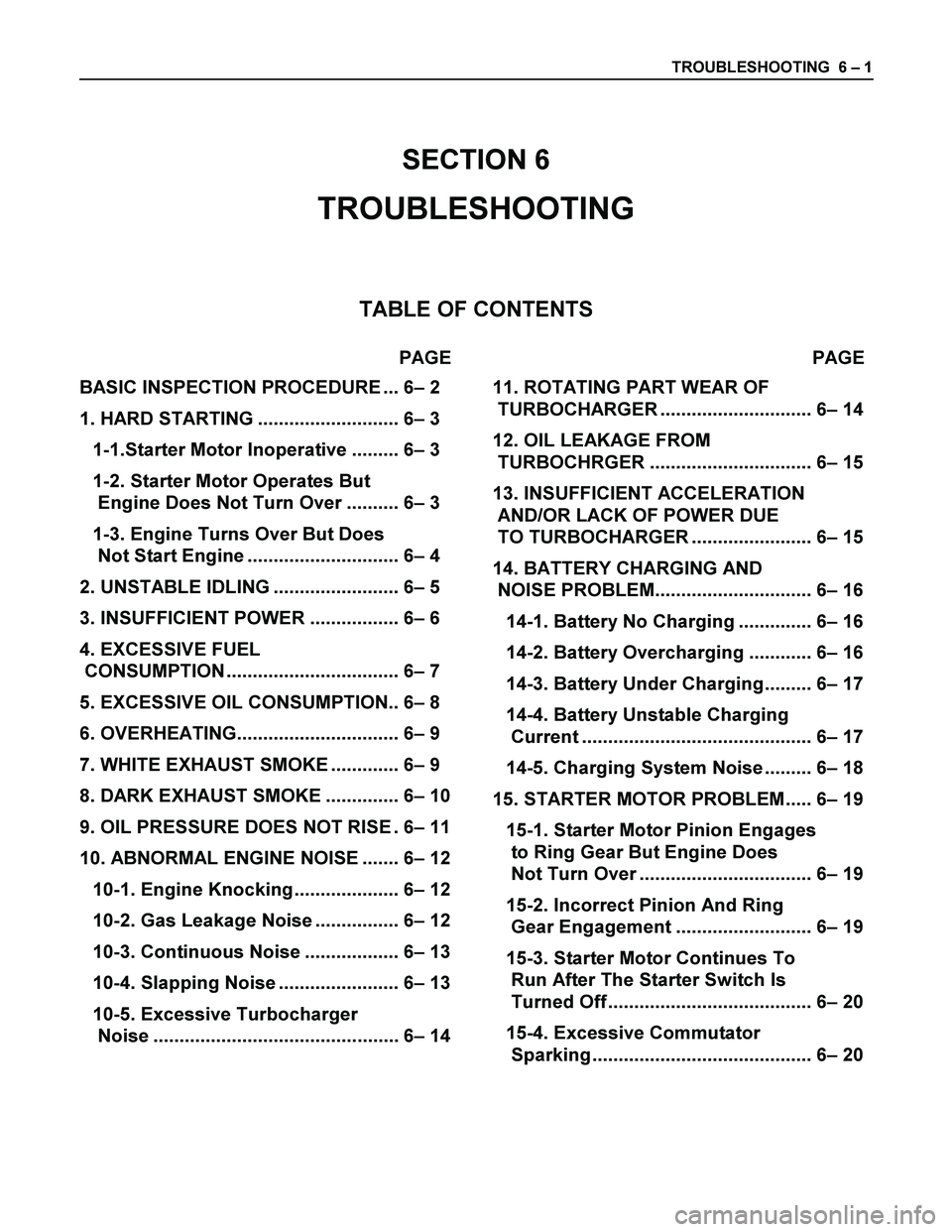

TROUBLESHOOTING 6 – 1

SECTION 6

TROUBLESHOOTING

TABLE OF CONTENTS

PAGE PAGE

BASIC INSPECTION PROCEDURE ... 6– 2

1. HARD STARTING ........................... 6– 3

1-1.Starter Motor Inoperative ......... 6– 3

1-2. Starter Motor Operates But

Engine Does Not Turn Over .......... 6– 3

1-3. Engine Turns Over But Does

Not Start Engine ............................. 6– 4

2. UNSTABLE IDLING ........................ 6– 5

3. INSUFFICIENT POWER ................. 6– 6

4. EXCESSIVE FUEL

CONSUMPTION ................................. 6– 7

5. EXCESSIVE OIL CONSUMPTION.. 6– 8

6. OVERHEATING............................... 6– 9

7. WHITE EXHAUST SMOKE ............. 6– 9

8. DARK EXHAUST SMOKE .............. 6– 10

9. OIL PRESSURE DOES NOT RISE . 6– 11

10. ABNORMAL ENGINE NOISE ....... 6– 12

10-1. Engine Knocking.................... 6– 12

10-2. Gas Leakage Noise ................ 6– 12

10-3. Continuous Noise .................. 6– 13

10-4. Slapping Noise ....................... 6– 13

10-5. Excessive Turbocharger

Noise ............................................... 6– 14

11. ROTATING PART WEAR OF

TURBOCHARGER ............................. 6– 14

12. OIL LEAKAGE FROM

TURBOCHRGER ............................... 6– 15

13. INSUFFICIENT ACCELERATION

AND/OR LACK OF POWER DUE

TO TURBOCHARGER ....................... 6– 15

14. BATTERY CHARGING AND

NOISE PROBLEM.............................. 6– 16

14-1. Battery No Charging .............. 6– 16

14-2. Battery Overcharging ............ 6– 16

14-3. Battery Under Charging......... 6– 17

14-4. Battery Unstable Charging

Current ............................................ 6– 17

14-5. Charging System Noise ......... 6– 18

15. STARTER MOTOR PROBLEM..... 6– 19

15-1. Starter Motor Pinion Engages

to Ring Gear But Engine Does

Not Turn Over ................................. 6– 19

15-2. Incorrect Pinion And Ring

Gear Engagement .......................... 6– 19

15-3. Starter Motor Continues To

Run After The Starter Switch Is

Turned Off ....................................... 6– 20

15-4. Excessive Commutator

Sparking .......................................... 6– 20

Page 1122 of 4264

6 – 2 TROUBLESHOOTING

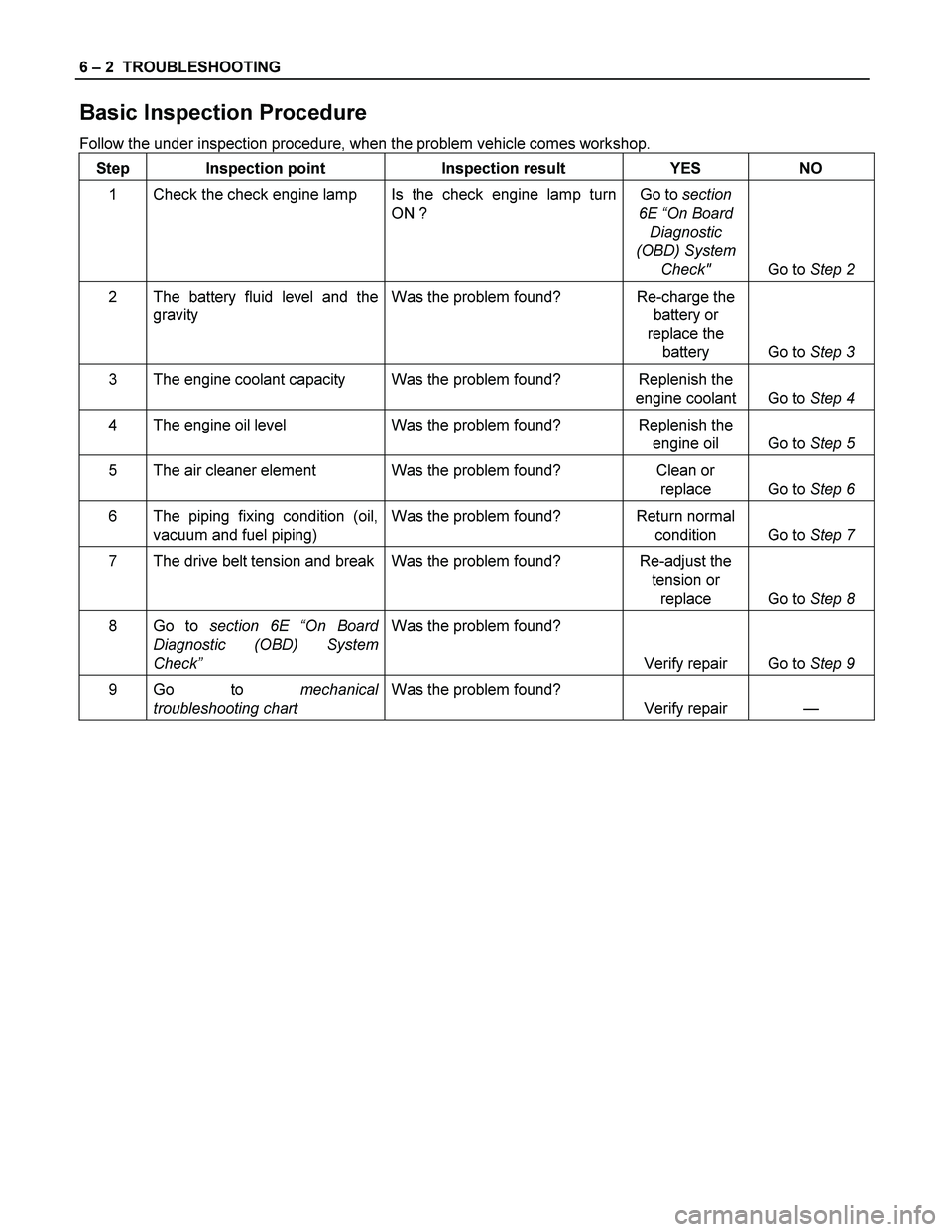

Basic Inspection Procedure

Follow the under inspection procedure, when the problem vehicle comes workshop.

Step Inspection point Inspection result YES NO

1 Check the check engine lamp Is the check engine lamp turn

ON ? Go to section

6E “On Board

Diagnostic

(OBD) System

Check" Go to Step 2

2 The battery fluid level and the

gravity Was the problem found? Re-charge the

battery or

replace the

battery Go to Step 3

3 The engine coolant capacity Was the problem found? Replenish the

engine coolant Go to Step 4

4 The engine oil level Was the problem found? Replenish the

engine oil Go to Step 5

5 The air cleaner element Was the problem found? Clean or

replace Go to Step 6

6 The piping fixing condition (oil,

vacuum and fuel piping) Was the problem found? Return normal

condition Go to Step 7

7 The drive belt tension and break Was the problem found? Re-adjust the

tension or

replace Go to Step 8

8 Go to section 6E “On Board

Diagnostic (OBD) System

Check” Was the problem found?

Verify repair Go to Step 9

9 Go to mechanical

troubleshooting chart Was the problem found?

Verify repair —

Page 1123 of 4264

TROUBLESHOOTING 6 – 3

1. Hard Starting

Inspect the following items before diagnosis.

1. The battery conditions.

The terminal connection condition.

The battery charge condition or battery power weakness.

2. The fan belt loosen or broken.

3. The main fuse condition (open or not).

4. Fuel quantity level.

1–1 Starter motor inoperative

Step Action Value(s) Yes No

1 Check the starter switch.

Does the starter switch work? —

Go to Step 2 Repair or

replace the

starter switch

2 Check the starter relay.

Does the starter relay work? —

Go to Step 3 Repair or

replace the

starter relay

3 Check the magnetic switch.

Does the magnetic switch work? —

Go to Step 4 Repair or

replace the

magnetic

switch

4 Check the pinion gear condition on the starter motor.

Was the condition normal? —

Go to Step 5 Replace the

pinion gear

5 Check the brush wear or brush spring weakness.

Was the condition normal? —

Replace the

starter motor

assembly Repair or

replace the

brush or brush

spring

1-2 Starter motor operates but engine does not turn over

Step Action Value(s) Yes No

1 Check the engine internal seizure.

Was the engine seized? —

Repair or

replace seized

parts Check other

DTC by Tech

2 and go to

indicated DTC

Page 1124 of 4264

6 – 4 TROUBLESHOOTING

1-3 Engine turn over but does not start engine

Incase of the fuel not being delivered to the injection pump

Step Action Value(s) Yes No

1 Check clogged, damaged the fuel piping or the

connector loosen.

Was any problem found? —

Repair replace

problem parts. Go to Step 2

2 Was the over flow valve on the fuel filter closed? — Repair replace

the over flow

valve Go to Step 3

3 Was the fuel filter element clogged? — Replace the

fuel filter

element Go to Step 4

4 Was the fuel line air bled? — Go to Step 5 Bleed the air

5 Are any DTC stored? — Go to indicated

DTC Solved

Incase of the fuel is being delivered to the injection pump

Step Action Value(s) Yes No

1 Was the water contain in the fuel? — Replace the

fuel Go to Step 2

2 Was the fuel line air bled? — Go to Step 5 Bleed the air

3 Was the injection spray condition complete? —

Go to Step 4 Replace the

injection nozzle

4 Was the injection nozzle injection starting pressure

OK? (See below)

Go to Step 5 Replace the

injection nozzle

5 Was the injection nozzle sticking? — Replace the

injection nozzle Go to Step 6

6 Are any DTC stored? — Go to indicated

DTC Solved

Injection nozzle opening pressure

1st = 19.5 MPa (199 kg/cm2, 2828 psi)

Page 1129 of 4264

TROUBLESHOOTING 6 – 9

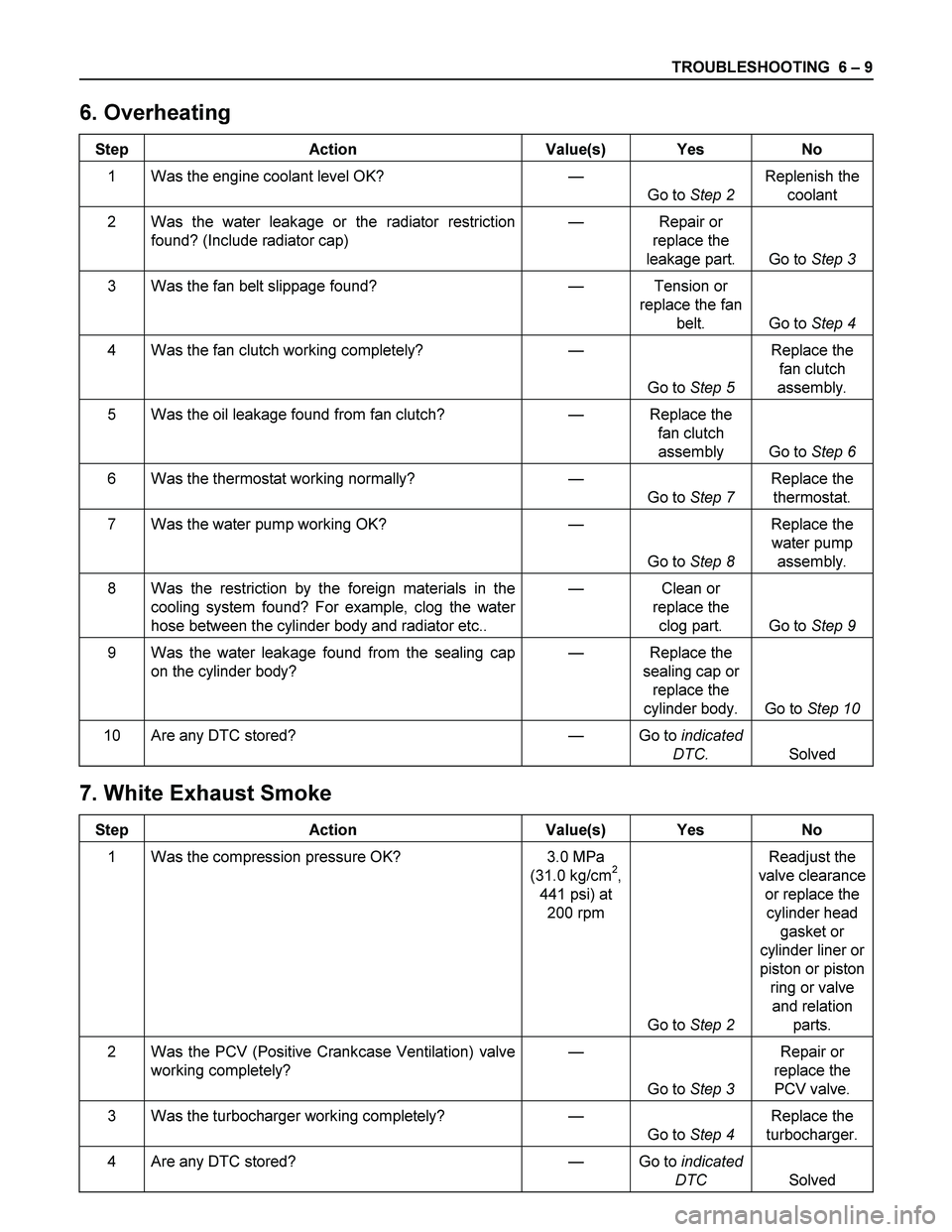

6. Overheating

Step Action Value(s) Yes No

1 Was the engine coolant level OK? —

Go to Step 2 Replenish the

coolant

2 Was the water leakage or the radiator restriction

found? (Include radiator cap) — Repair or

replace the

leakage part. Go to Step 3

3 Was the fan belt slippage found? — Tension or

replace the fan

belt. Go to Step 4

4 Was the fan clutch working completely? —

Go to Step 5 Replace the

fan clutch

assembly.

5 Was the oil leakage found from fan clutch? — Replace the

fan clutch

assembly Go to Step 6

6 Was the thermostat working normally? —

Go to Step 7 Replace the

thermostat.

7 Was the water pump working OK? —

Go to Step 8 Replace the

water pump

assembly.

8 Was the restriction by the foreign materials in the

cooling system found? For example, clog the water

hose between the cylinder body and radiator etc.. — Clean or

replace the

clog part. Go to Step 9

9 Was the water leakage found from the sealing cap

on the cylinder body? — Replace the

sealing cap or

replace the

cylinder body. Go to Step 10

10 Are any DTC stored? — Go to indicated

DTC. Solved

7. White Exhaust Smoke

Step Action Value(s) Yes No

1 Was the compression pressure OK? 3.0 MPa

(31.0 kg/cm2,

441 psi) at

200 rpm

Go to Step 2 Readjust the

valve clearance

or replace the

cylinder head

gasket or

cylinder liner or

piston or piston

ring or valve

and relation

parts.

2 Was the PCV (Positive Crankcase Ventilation) valve

working completely? —

Go to Step 3 Repair or

replace the

PCV valve.

3 Was the turbocharger working completely? —

Go to Step 4 Replace the

turbocharger.

4 Are any DTC stored? — Go to indicated

DTC Solved