ISUZU TFS SERIES 1997 Repair Manual

TFS SERIES 1997

ISUZU

ISUZU

https://www.carmanualsonline.info/img/61/57182/w960_57182-0.png

ISUZU TFS SERIES 1997 Repair Manual

Page 374 of 1600

5-46 BRAKES

MASTER CYLINDER

REMOVAL AND INSTALLATION

BRAKE PEDAL ASSEMBLY

This illustration based on the LHD model.

Removal Steps

1. Brake line

2. Nut ; master cylinder to vacuum servo

3. Master cylinder assembly

Installation Steps

3. Master cylinder assembly

2. Nut ; master cylinder to vacuum servo

1. Brake line

Important Operation - Removal

1. Brake Line

Be very careful not to spill brake fluid on the painted surface.

Damage to the painted surface will result.

Important Operation - Installation

2. Nut ; Master Cylinder to Vacuum Servo

Torque N

m (kgfm/lbft)

1.0 - 1.6 (7 - 12 / 9.8 - 16)

1. Brake Line

Torque N

m (kgfm/lbft)

0.9 - 1.5 (6.5 - 11 / 8.8 - 15)

Page 375 of 1600

BRAKES 5-47

DISASSEMBLY

Disassembly Steps

1. Dust seal

2. Screw

3. Reservoir ; fluid, brake

4. Grommet

5. Ring ; snap

6. Bolt ; stopper7. Gasket

8. Piston assembly ; primary and spring

9. Piston assembly ; secondary and spring

10. Cover ; fluid reservoir

11. Seal

12. Cylinder assembly ; brake, master

Page 376 of 1600

5-48 BRAKES

Important Operations

When disassembling, inspecting or reassembling the master

cylinder assembly, take care not to bring the parts into contact

with mineral oil or dust. Wash the piston cups only with brake

fluid. Do not use gasoline or other mineral-base cleaning

solvents.

5. Ring ; Snap

Remove the snap ring from the cylinder body with pushing in

the primary and secondary pistons.

6. Bolt ; Stopper

Push in the primary and secondary pistons and remove the

stopper bolt completery from the cylinder body, then remove

the primary and secondary piston assemblies.

8. Piston Assembly ; Primary and Spring

9. Piston Assembly ; Secondary and Spring

Don’t remove the spring from the piston.

Page 377 of 1600

BRAKES 5-49

INSPECTION AND REPAIR

Make necessary correction or parts replacement if wear damage or any other abnormal conditions are found

through inspection.

Cylinder inside face

Piston

Piston cap

Piston cap spacer

Return port

Return spring

Visual Check

Inspect the following parts for wear, distortion, cuts, nicks,

corrosion, or other abnormal conditions.

Master Cylinder Bore Diameter

Standard mm(in)

23.81 (0.938)

Clearance between the Master Cylinder

and the Piston

Measure the outer diameter of the piston assembly at the

portions shown in the left figure.

mm(in)

Standard Limit

0.04 - 0.125

(0.00158 - 0.00493)0.15 (0.00591)

Note:

If the clearance deviates from the range shown above,

replace the master cylinder and the piston assembly

together.

Page 378 of 1600

5-50 BRAKES

Return Port

Check the return port for obstructions and if necessary, clean

with a tag wire.

Blow away foreign matter with compressed air.

Primary Piston

After reassembly, push in the primary piston to see that returns

smoothly.

Repeat the test two or three times to see that brake fluid is

forced out from the front and rear outlets.

Page 379 of 1600

BRAKES 5-51

REASSEMBLY

; Repair Kit

Reassembly Steps

1. Cylinder assembly ; brake, master

2. Piston assembly ; secondary and spring

3. Piston assembly ; primary and spring

4. Ring ; snap

5. Gasket

6. Bolt ; stopper

7. Grommet

8. Reservoir ; fluid, brake

9. Screw

10. Seal

11. Cover ; fluid reservoir

12. Dust seal

Important Operations

1. Cylinder Assembly ; Brake, Master

Lubricate the master cylinder bore with clean rubber

grease.(arrowed portion)

Page 380 of 1600

5-52 BRAKES

2. Piston Assembly ; Secondary and Spring

3. Piston Assembly ; Primary and Spring

Lubricate the piston cups on the primary piston assemblies with

rubber grease.

Take care not to scratch the piston cup when installing the

piston assemblies.

Note:

Don't remove the spring from the piston.

6. Bolt ; Stopper

Depress the primary piston and install the piston stopper bolt

with a new gasket.

Torque N

m(kgfm/lbft)

6.9 - 8.8 (0.7 - 0.9 / 5.1 - 6.5)

7. Grommet

Lubricate the new grommets with clean rubber grease.

Insert the grommets, with the flared side up, into the cylinder

body.

Apply rubber grease to the dust seal portion.

(The portion indicated by the arrows in the left diagram.)

9. Screw

Torque N

m(kgfm/lbft)

1.0 - 2.0 (0.01 - 0.20 / 0.7 - 1.5)

12.Dust Seal

Install the dust seal so that its groove faces downward.

Page 381 of 1600

BRAKES 5-53

VACUUM SERVO

REMOVAL AND INSTALLATION

Removal Steps

1. Clamp ; vacuum hose

2. Vacuum hose

3. Brake line

4. Return spring ; brake pedal

5. Snap pin

6. Pin ; push rod to brake pedal

7. Vacuum servo to dash panel and pedal

mounting bracket

8. Maser cylinder assembly

9. Vacuum servo assembly

Installation Steps

9. Vacuum servo assembly

8. Maser cylinder assembly

7. Vacuum servo to dash panel and pedal

mounting bracket

6. Pin ; push rod to brake pedal

5. Snap pin

4. Return spring ; brake pedal

3. Brake line

2. Vacuum hose

1. Clamp ; vacuum hose

Page 382 of 1600

5-54 BRAKES

Important Operation - Removal

3. Brake Line

When handling, be careful not to spill brake fluid over the

painted surfaces, as damage to the paint finish will result.

Important Operation - Installation

8. Master Cylinder Assembly

Check the distance from the flange face of the vacuum servo

to the end of the push rod before installation of the master

cylinder.

Projection (A) mm(in)

18.0 - 18.2 (0.709 - 0.717)

If the measured distance deviates from the specified range,

make an adjustment with the lock nut

1 at the end of the push

rod.

Torque N

m(kgfm/lbft)

15 - 25 (1.5 - 2.5 / 11 - 18)

7. Vacuum Servo to Dash Panel and Pedal Mounting

Bracket

Torque N

m(kgfm/lbft)

22 - 31 (2.2 - 3.2 / 16 - 23)

Apply sealer to the dashboard fitting face.

3. Brake Line

Torque N

m(kgfm/lbft)

9 - 15 (0.9 - 1.5 / 6.5 - 11)

Page 383 of 1600

BRAKES 5-55

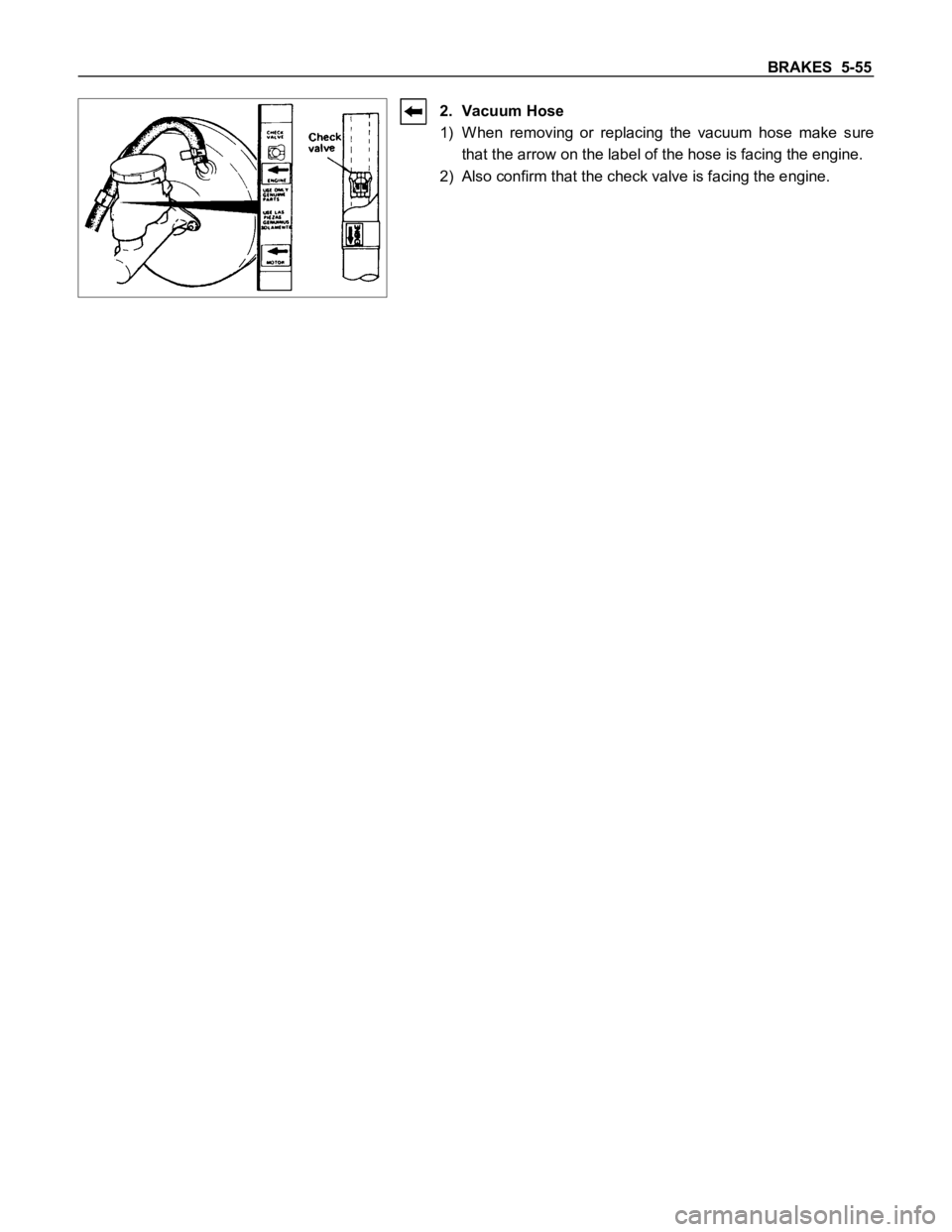

2. Vacuum Hose

1) W hen removing or replacing the vacuum hose make sure

that the arrow on the label of the hose is facing the engine.

2) Also confirm that the check valve is facing the engine.