ISUZU TFS SERIES 1997 Workshop Manual

TFS SERIES 1997

ISUZU

ISUZU

https://www.carmanualsonline.info/img/61/57182/w960_57182-0.png

ISUZU TFS SERIES 1997 Workshop Manual

Page 24 of 1600

4B-28 REAR AXLE

Differential cage

Check the ring gear the side gear fitting faces and the cross pin

hole for scores or roughness. Correct as necessary. Slight

scores or roughness may be corrected with an oil stone or fine

sand paper.

Friction disc and plate assembly.

Check the parts for damage or other abnormal conditions.

Check the friction plate for distortion.

Limit mm(in) 0.07 (0.0027)

Check the friction plate for wear.

Limit (A - B) mm(in) 0.1 (0.0039)

Note : A = Non-sliding face thickness

B = Sliding face thickness

Check the friction disc for distortion.

Limit mm(in) 0.07 (0.0027)

Page 48 of 1600

4B-52 REAR AXLE

TROUBLESHOOTING

Refer to this Section to quickly diagnose and repair rear axle problems.

Each troubleshooting chart has three headings arranged from left to right.

(1) Checkpoint (2) Trouble Cause (3) Countermeasure

This Section is divided into five sub-sections:

1. Abnormal Rear Axle Noise

1) Noise when the engine is driving the vehicle

2) Noise when the vehicle is coasting

3) Intermittent noise

4) Noise when the vehicle is turning

5) Constant noise

2. Vibration

3. Oil Leakage

1) Differential carrier leakage

2) Axle case leakage

3) Axle case to inside hub leakage

4) Axle case to inside brake drum leakage

4. Power Not Being Transmitted to the Wheels (Propeller Shaft Operation is Normal)

Page 49 of 1600

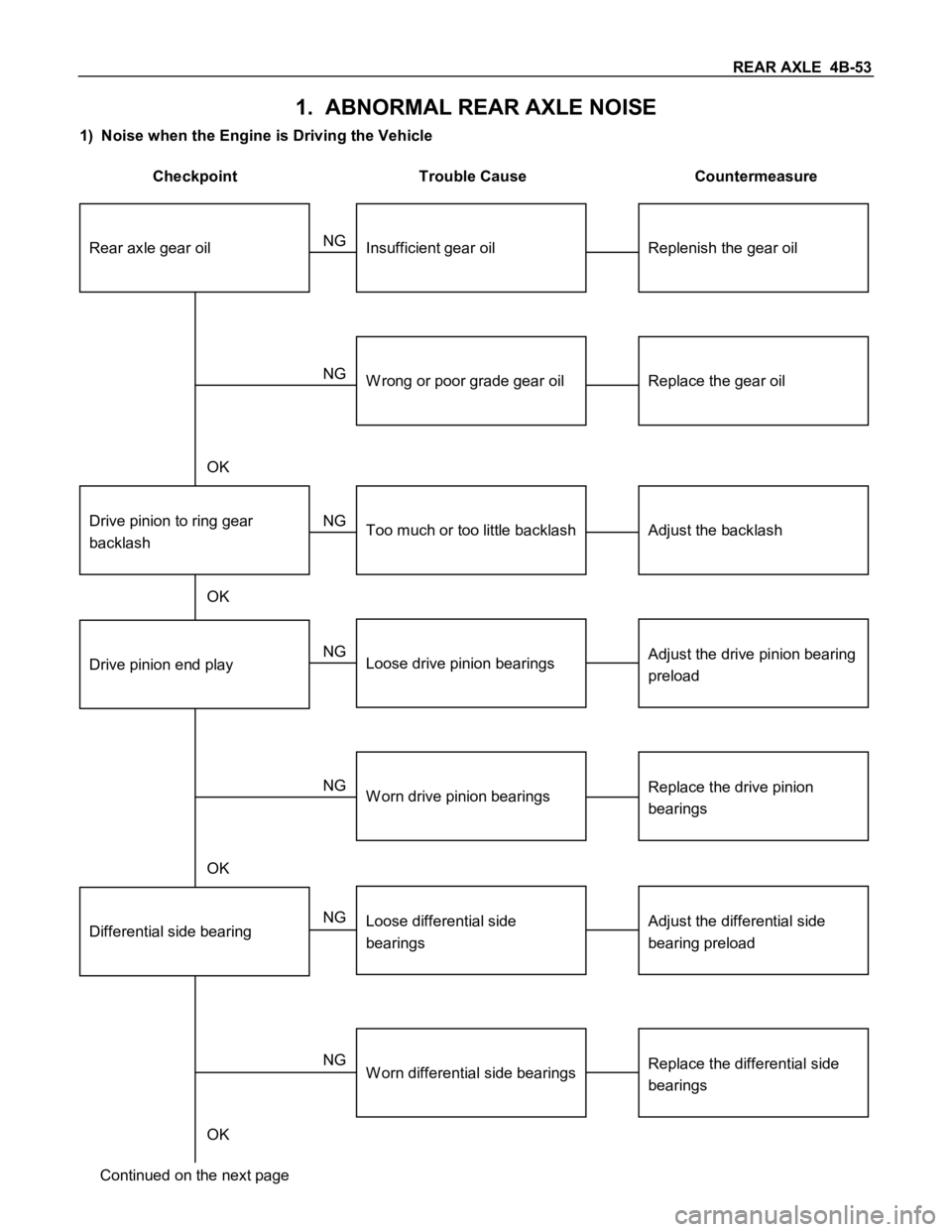

REAR AXLE 4B-53

1. ABNORMAL REAR AXLE NOISE

1) Noise when the Engine is Driving the Vehicle

Checkpoint Trouble Cause Countermeasure

Replenish the gear oilInsufficient gear oil NG

Differential side bearingAdjust the differential side

bearing preload

Replace the drive pinion

bearings

Adjust the drive pinion bearing

preload

Replace the gear oil

Loose differential side

bearings

W orn drive pinion bearings

Loose drive pinion bearings

W rong or poor grade gear oil

Drive pinion to ring gear

backlash

Drive pinion end play

Adjust the backlashToo much or too little backlash

Continued on the next pageOK OK

NG NG NG NG NG

OK

OK

Rear axle gear oil

Replace the differential side

bearingsW orn differential side bearings NG

Page 53 of 1600

REAR AXLE 4B-57

5) Constant Noise

Checkpoint Trouble Cause Countermeasure

Replace the rear axle shaftBent rear axle shaft NG

Replace the side bearing

Replace the drive pinion

bearing

Replace the drive pinion and

the ring gear as a set

Replace the drive pinion and

the ring gear as a set

Flat spot on the side bearing

oil seal

BearingFlat spot on the drive pinion

Flat spot on the gear teeth

pilot bearing wear

Drive pinionFlat spot on the drive pinion

gear teeth

Ring gear

Replace the drive pinion and

the ring gear as a setW orn pinion splines oil seal

NG NG NG NG NG

OK OK

OK

Rear axle shaft

Page 55 of 1600

REAR AXLE 4B-59

3. OIL LEAKAGE

1) Differential Carrier Leakage

Checkpoint Trouble Cause Countermeasure

Correct the oil levelToo much gear oil NG

Reapply the liquid gasket

and/or tighten the lock nut to

the specified torque

Reapply the liquid gasket

Tighten the bolts to the

specified torque

Replace the oil seal

Ring gear thrust boltLoose lock nut and/or liquid

Liquid gasket seal bed

Loose bolts

Oil sealW orn or defective oil seal

Differential carrier

Clean the air breatherAir breatherClogged air breather

NG NG NG NG NG

OK OK OK

OK

Gear oil level

Page 56 of 1600

4B-60 REAR AXLE

2) Axle Case Leakage

Checkpoint Trouble Cause Countermeasure

Tighten the drain plug and/or

replace the gasket(s)Loose drain plug and/or

defective gasket(s) NG

Reapply the liquid gasket

Tighten the bolts to the

specified torque

Clean the air breather

Liquid gasket seal bad

Loose bolts

Air breatherClogged air breather

Differential carrier

Replace the axle caseAxle caseCracked axle case

NG NG NG NG

OK OK

OK

Oil filler and drain plug

Page 57 of 1600

REAR AXLE 4B-61

3) Axle Case to Inside Brake Drum Leakage

Checkpoint Trouble Cause Countermeasure

Replace the oil sealW orn or defective oil seal NGOil seal

Page 81 of 1600

4C1-18 FRONT WHEEL DRIVE

INSPECTION AND REPAIR

Make all necessary adjustments, repairs, and part replacements if wear, damage, or other problems are discovered

during inspection.

BJ assembly

DOJ case, ball, ball guide, ball retainer

Bellows

Bearing

Dust seal, oil seal

Visual Check

Inspect the following parts for wear, damage, or other

abnormal conditions.

Page 90 of 1600

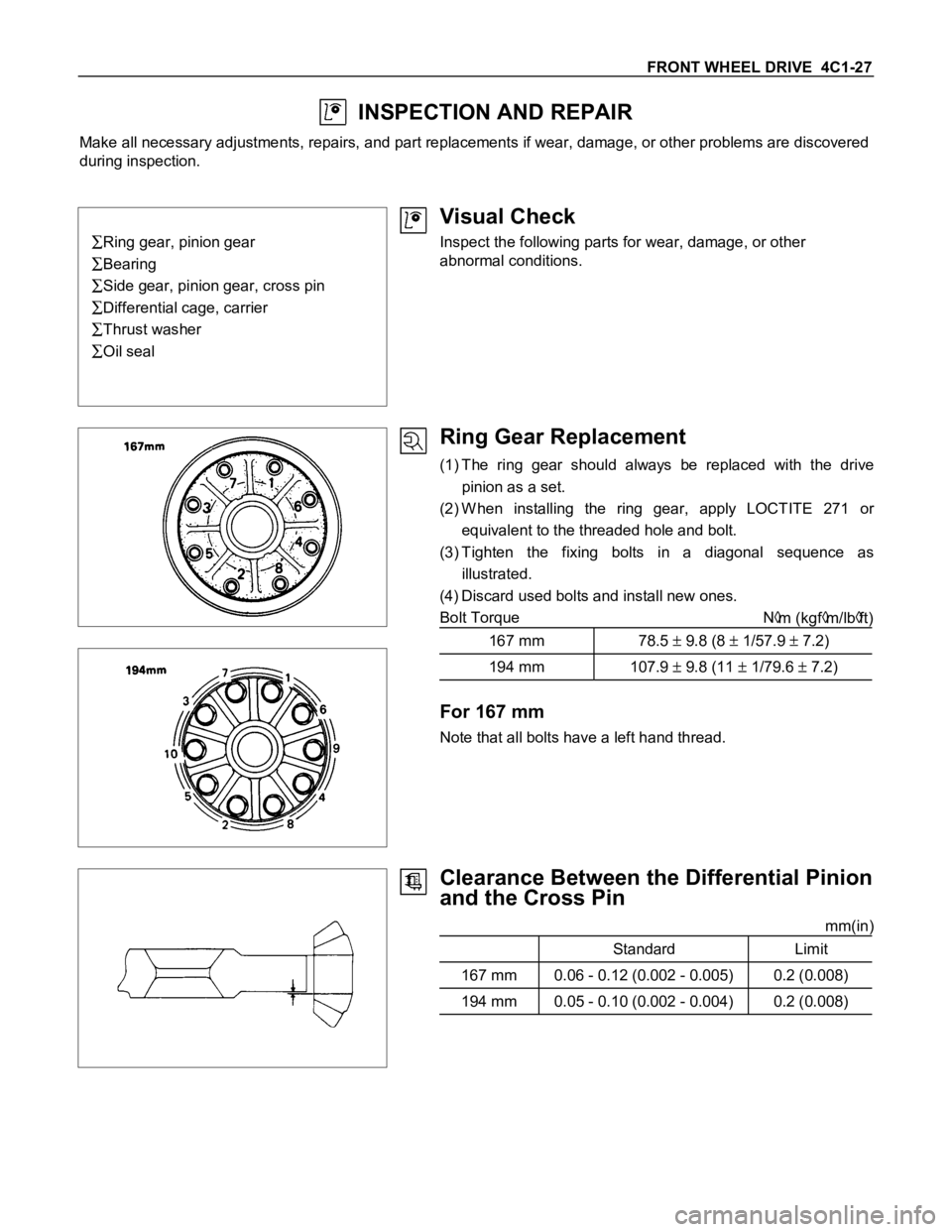

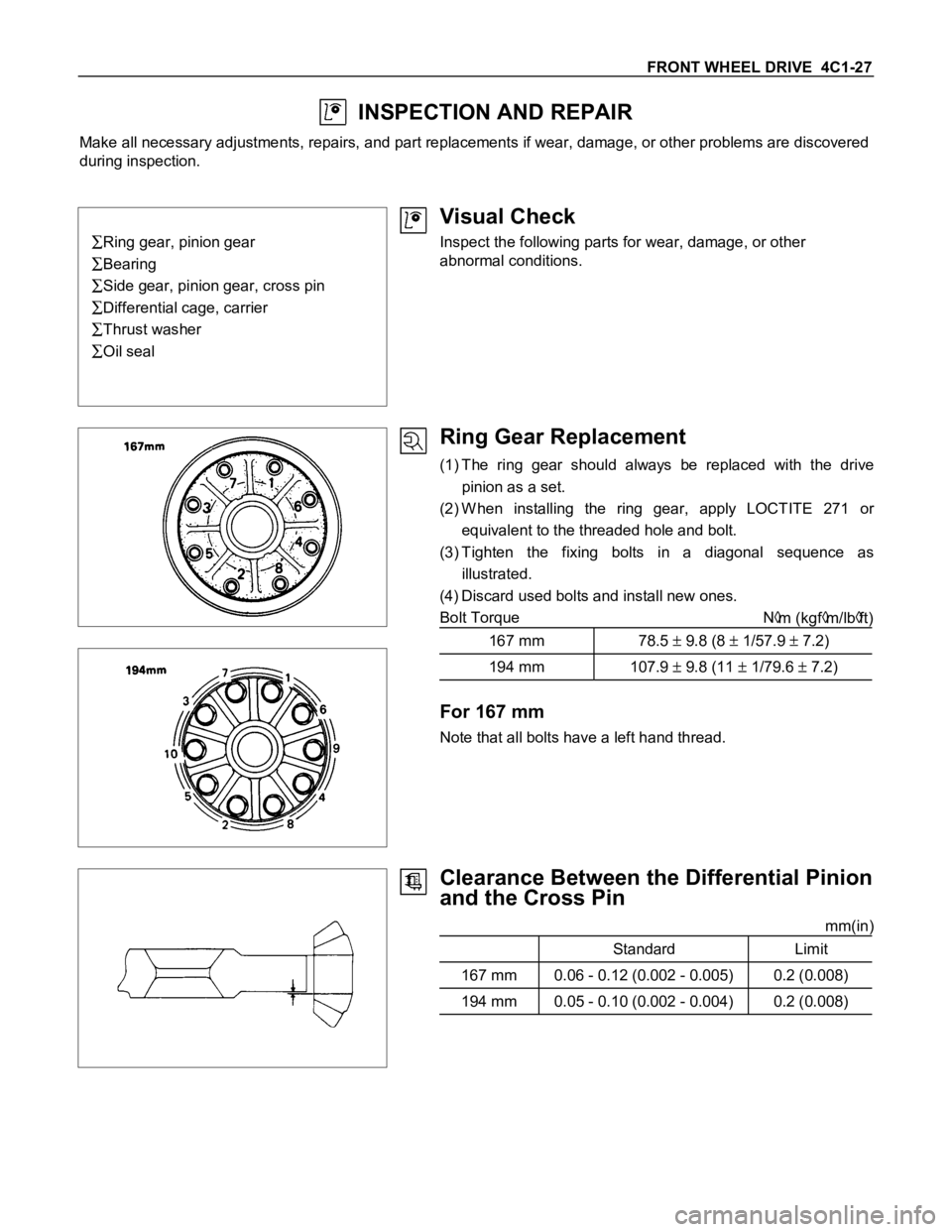

FRONT WHEEL DRIVE 4C1-27

INSPECTION AND REPAIR

Make all necessary adjustments, repairs, and part replacements if wear, damage, or other problems are discovered

during inspection.

Ring gear, pinion gear

Bearing

Side gear, pinion gear, cross pin

Differential cage, carrier

Thrust washer

Oil seal

Visual Check

Inspect the following parts for wear, damage, or other

abnormal conditions.

Ring Gear Replacement

(1) The ring gear should always be replaced with the drive

pinion as a set.

(2) W hen installing the ring gear, apply LOCTITE 271 or

equivalent to the threaded hole and bolt.

(3) Tighten the fixing bolts in a diagonal sequence as

illustrated.

(4) Discard used bolts and install new ones.

Bolt Torque N

m (kgfm/lbft)

167 mm 78.5

9.8 (8 1/57.9 7.2)

194 mm 107.9 9.8 (11 1/79.6 7.2)

For 167 mm

Note that all bolts have a left hand thread.

Clearance Between the Differential Pinion

and the Cross Pin

mm(in)

Standard Limit

167 mm 0.06 - 0.12 (0.002 - 0.005) 0.2 (0.008)

194 mm 0.05 - 0.10 (0.002 - 0.004) 0.2 (0.008)

Page 107 of 1600

4C1-44 FRONT WHEEL DRIVE

INSPECTION AND REPAIR

Make necessary correction or parts replacement if wear, damage or any other abnormal conditions are found

through inspection.

Hub

Hub bearing

Bearing outer race

Disc

Oil seal

Visual Check

Check the following parts for wear, damage or other abnormal

conditions.