relay ISUZU TROOPER 1998 Service Repair Manual

[x] Cancel search | Manufacturer: ISUZU, Model Year: 1998, Model line: TROOPER, Model: ISUZU TROOPER 1998Pages: 3573, PDF Size: 60.36 MB

Page 1720 of 3573

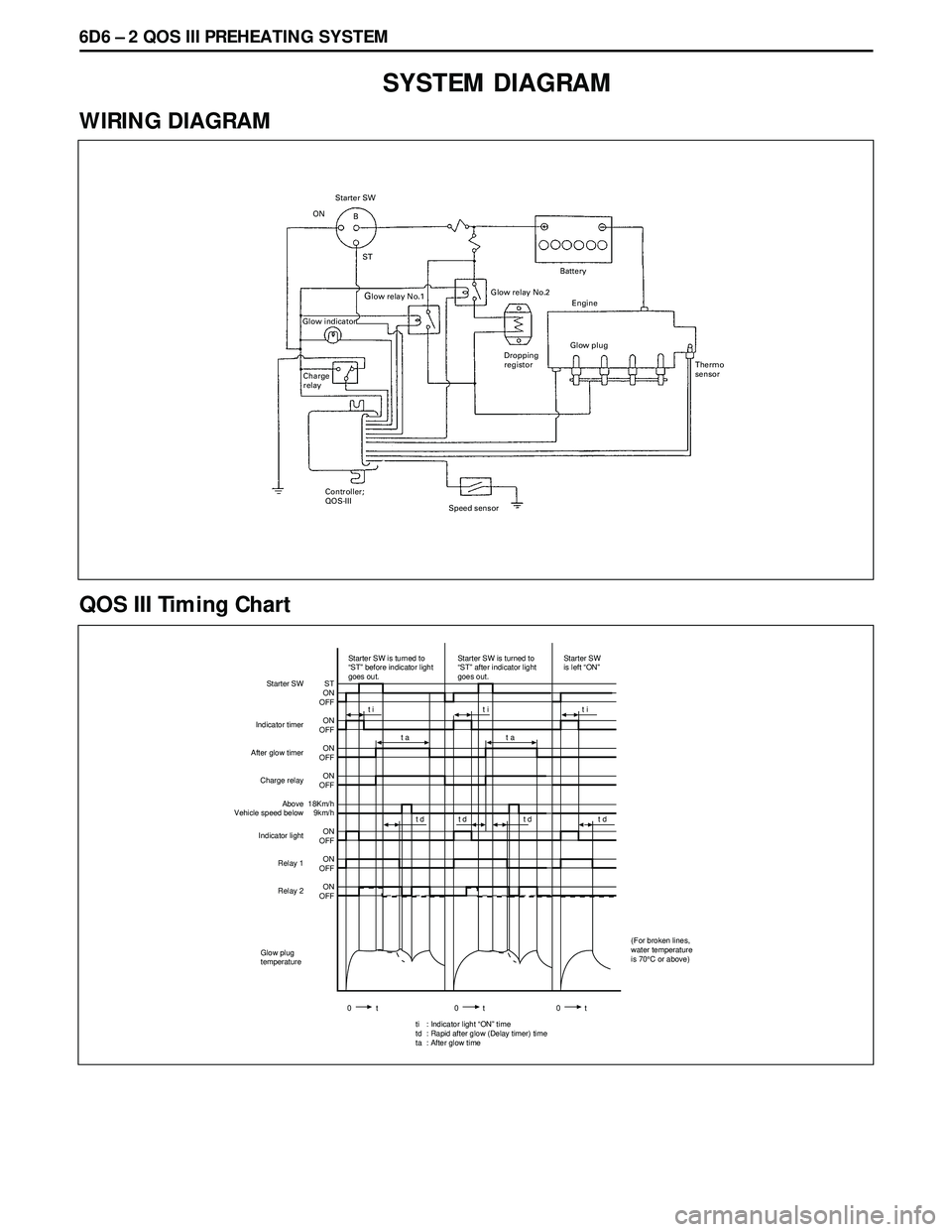

6D6 Ð 2 QOS III PREHEATING SYSTEM

SYSTEM DIAGRAM

WIRING DIAGRAM

ON

B

ST

Glow relay No.1 Starter SW

Battery

Engine Glow relay No.2

Glow indicator

Charge

relayGlow plug

Thermo

sensor

Controller;

QOS-III

Speed sensorDropping

registor

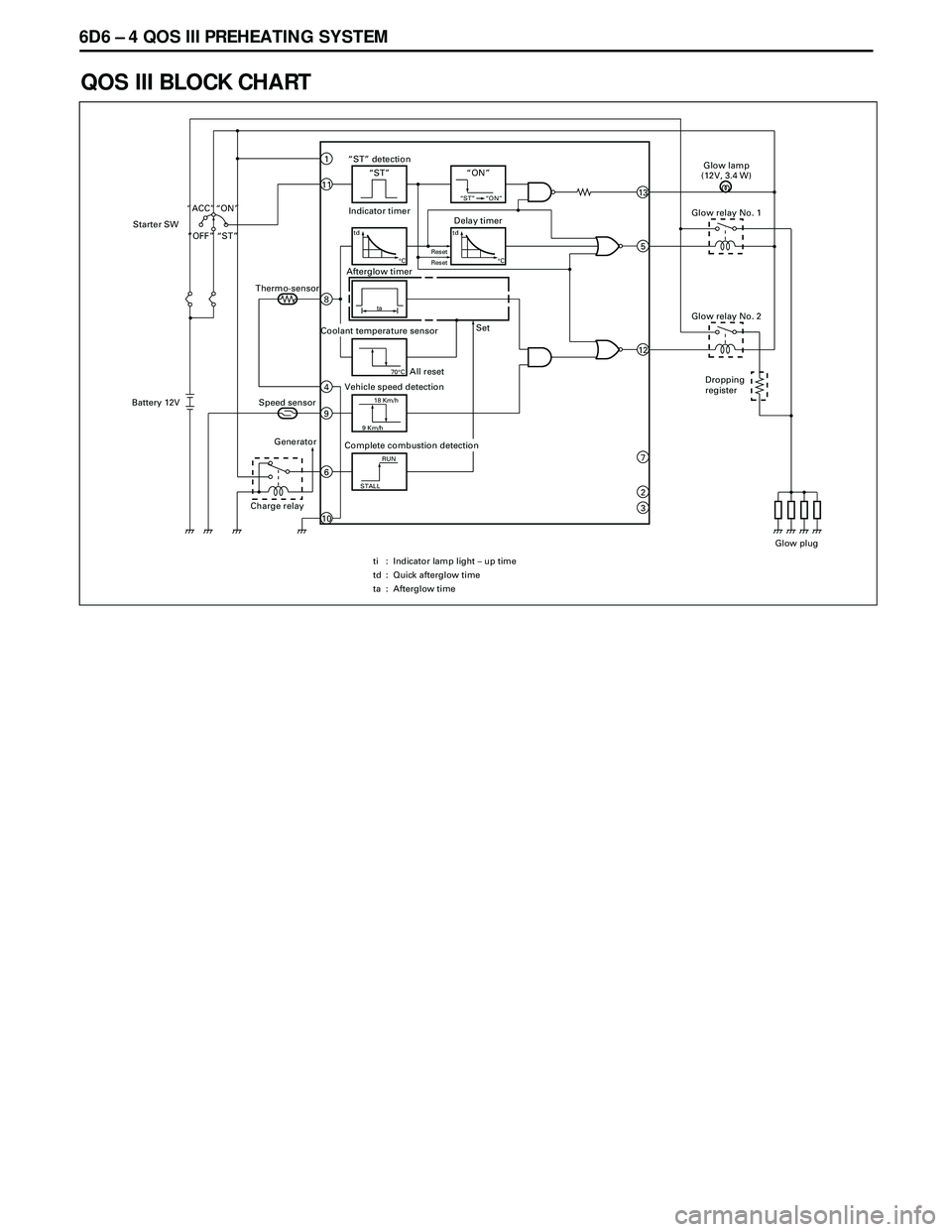

QOS III Timing Chart

ST

ON

OFF

ON

OFF

ON

OFF

ON

OFF

18Km/h

9km/h

ON

OFF

ON

OFF

ON

OFF Starter SW

Starter SW is turned to

“ST” before indicator light

goes out.Starter SW is turned to

“ST” after indicator light

goes out.Starter SW

is left “ON”

Indicator timer

After glow timer

Charge relay

Indicator light

Relay 1

Relay 2Above

Vehicle speed below

t i t i t i

t a t a

t d t d t d t d

Glow plug

temperature

0t 0t 0t

: Indicator light “ON” time

: Rapid after glow (Delay timer) time

: After glow time

ti

td

ta

(For broken lines,

water temperature

is 70¡C or above)

Page 1722 of 3573

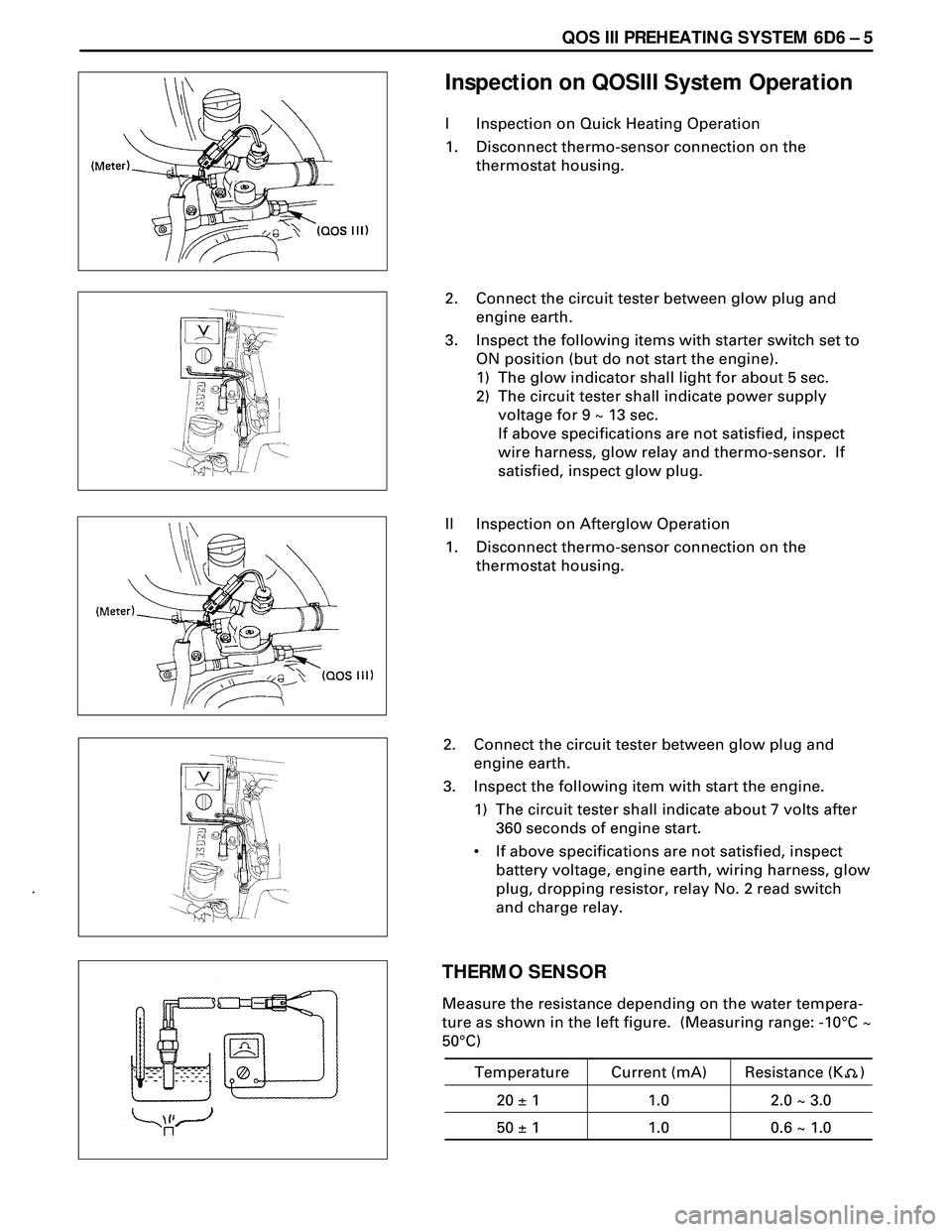

6D6 Ð 4 QOS III PREHEATING SYSTEM

QOS III BLOCK CHART

“ST” detection“ST”

Indicator timer

11

1“ON”

“ST” “ON”13

tdDelay timer

¡C

td

¡CResetReset5

ta

Afterglow timer

Coolant temperature sensor

70¡CAll reset

12

Vehicle speed detection

9 Km/h18 Km/h

Complete combustion detection

STALLRUN

Set 8

4

9

6

10

Thermo-sensor

Speed sensor

Generator

Charge relay

Glow relay No. 1

Glow lamp

(12V, 3.4 W)

Glow relay No. 2

Glow plug

Battery 12VStarter SW

“OFF” “ST” “ACC” “ON”

: Indicator lamp light – up time

: Quick afterglow time

: Afterglow time ti

td

ta7

2

3

Dropping

register

Page 1723 of 3573

QOS III PREHEATING SYSTEM 6D6 Ð 5

Inspection on QOSIII System Operation

I Inspection on Quick Heating Operation

1. Disconnect thermo-sensor connection on the

thermostat housing.

2. Connect the circuit tester between glow plug and

engine earth.

3. Inspect the following items with starter switch set to

ON position (but do not start the engine).

1) The glow indicator shall light for about 5 sec.

2) The circuit tester shall indicate power supply

voltage for 9 ~ 13 sec.

If above specifications are not satisfied, inspect

wire harness, glow relay and thermo-sensor. If

satisfied, inspect glow plug.

II Inspection on Afterglow Operation

1. Disconnect thermo-sensor connection on the

thermostat housing.

2. Connect the circuit tester between glow plug and

engine earth.

3. Inspect the following item with start the engine.

1) The circuit tester shall indicate about 7 volts after

360 seconds of engine start.

¥ If above specifications are not satisfied, inspect

battery voltage, engine earth, wiring harness, glow

plug, dropping resistor, relay No. 2 read switch

and charge relay.

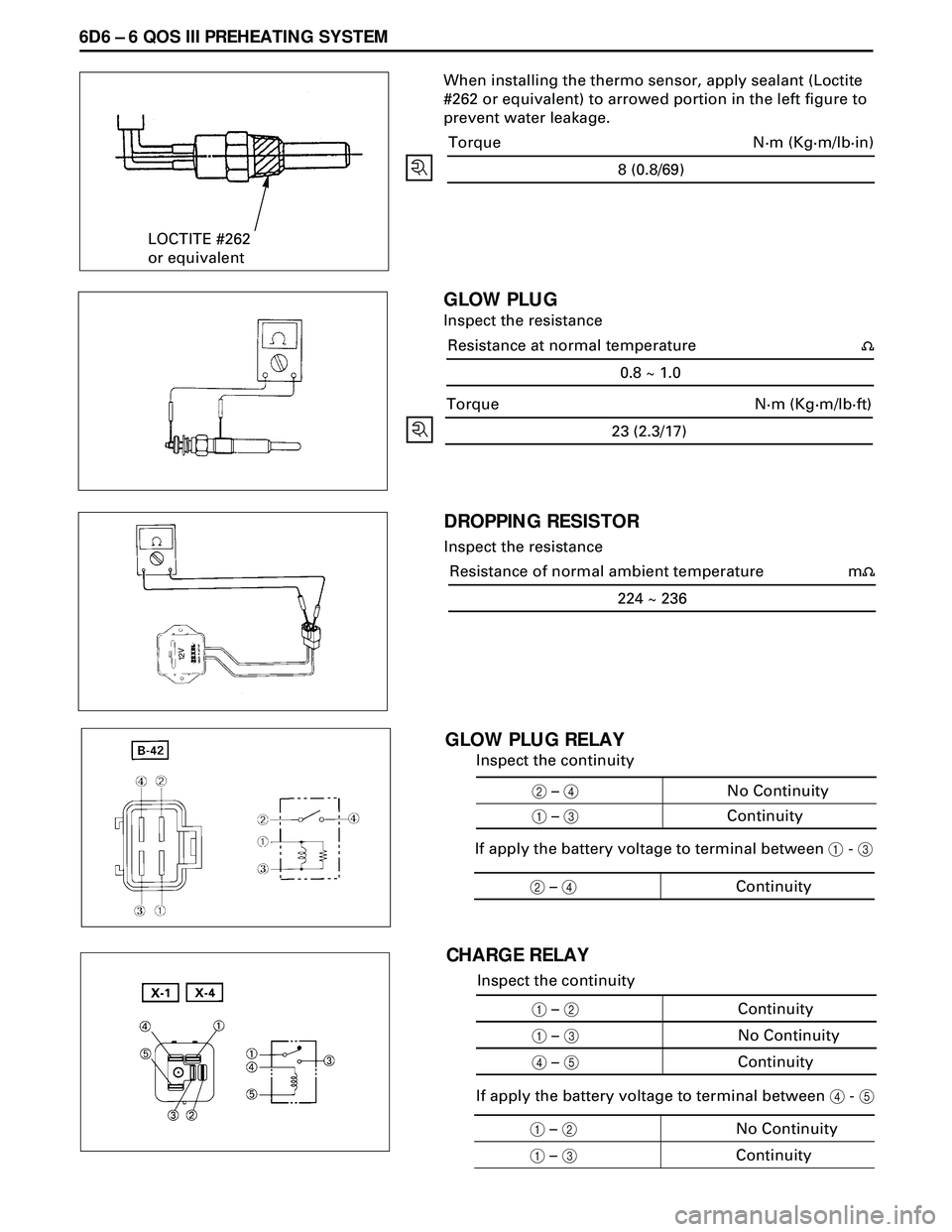

THERMO SENSOR

Measure the resistance depending on the water tempera-

ture as shown in the left figure. (Measuring range: -10¡C ~

50¡C)

Current (mA)

20 ± 1 1.0

50 ± 1Resistance (K )

1.0

2.0 ~ 3.0

0.6 ~ 1.0 Temperature

Page 1724 of 3573

6D6 Ð 6 QOS III PREHEATING SYSTEM

8 (0.8/69)

Torque N·m (Kg·m/lb·in)

23 (2.3/17)

Torque N·m (Kg·m/lb·ft)

0.8 ~ 1.0

Resistance at normal temperature

LOCTITE #262

or equivalentWhen installing the thermo sensor, apply sealant (Loctite

#262 or equivalent) to arrowed portion in the left figure to

prevent water leakage.

GLOW PLUG

Inspect the resistance

No Continuity 2 –4

Continuity 1 –3

Continuity 2 –4

Continuity 1 –2

No Continuity 1 –3

Continuity 4 –5

No Continuity 1 –2

Continuity 1 –3

224 ~ 236

Resistance of normal ambient temperature m

DROPPING RESISTOR

Inspect the resistance

GLOW PLUG RELAY

Inspect the continuity

If apply the battery voltage to terminal between 1 - 3

CHARGE RELAY

Inspect the continuity

If apply the battery voltage to terminal between 4 - 5

Page 1746 of 3573

ENGINE MECHANICAL 6A – 13

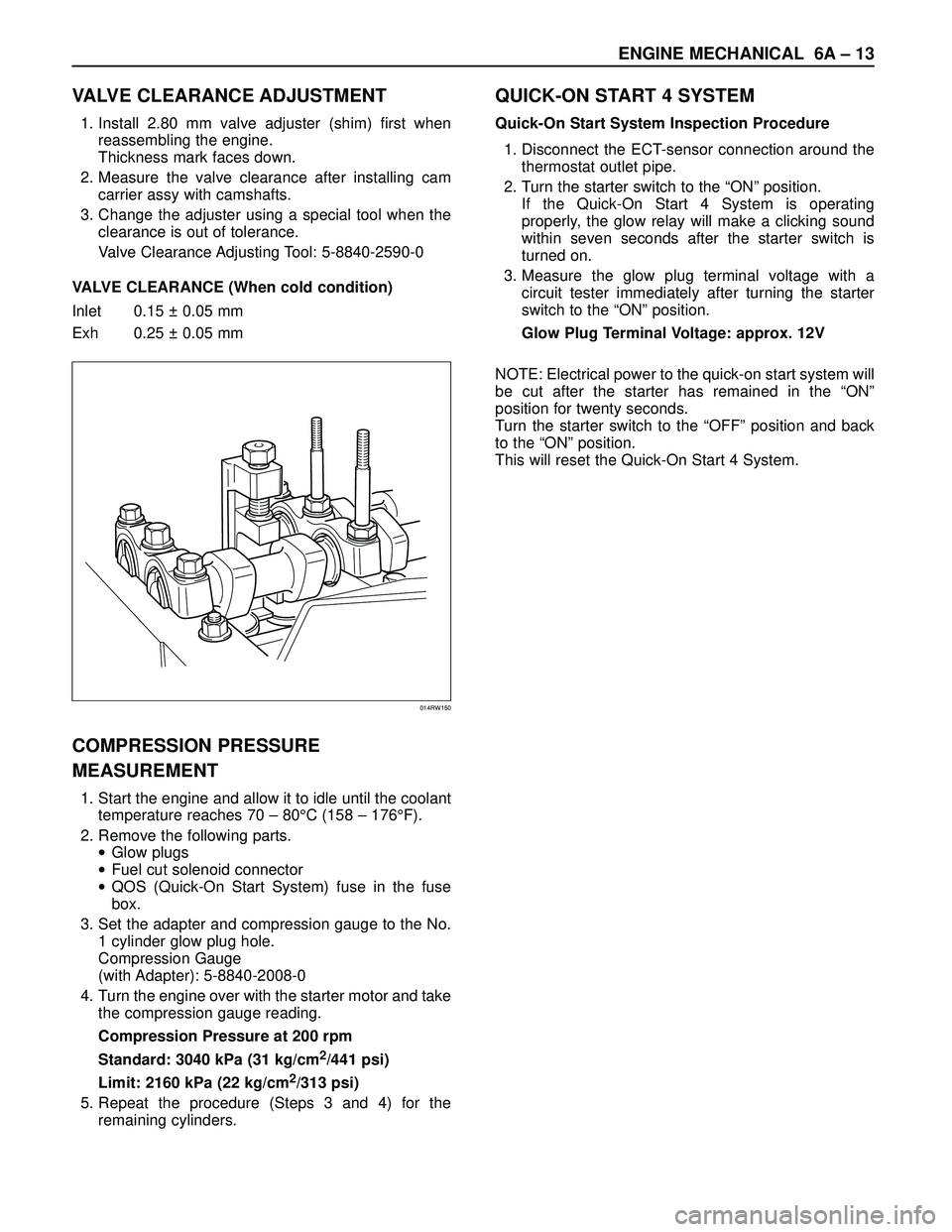

VALVE CLEARANCE ADJUSTMENT

1. Install 2.80 mm valve adjuster (shim) first when

reassembling the engine.

Thickness mark faces down.

2. Measure the valve clearance after installing cam

carrier assy with camshafts.

3. Change the adjuster using a special tool when the

clearance is out of tolerance.

Valve Clearance Adjusting Tool: 5-8840-2590-0

VALVE CLEARANCE (When cold condition)

Inlet 0.15 ± 0.05 mm

Exh 0.25 ± 0.05 mm

COMPRESSION PRESSURE

MEASUREMENT

1. Start the engine and allow it to idle until the coolant

temperature reaches 70 – 80°C (158 – 176°F).

2. Remove the following parts.

•Glow plugs

•Fuel cut solenoid connector

•QOS (Quick-On Start System) fuse in the fuse

box.

3. Set the adapter and compression gauge to the No.

1 cylinder glow plug hole.

Compression Gauge

(with Adapter): 5-8840-2008-0

4. Turn the engine over with the starter motor and take

the compression gauge reading.

Compression Pressure at 200 rpm

Standard: 3040 kPa (31 kg/cm

2/441 psi)

Limit: 2160 kPa (22 kg/cm

2/313 psi)

5. Repeat the procedure (Steps 3 and 4) for the

remaining cylinders.

QUICK-ON START 4 SYSTEM

Quick-On Start System Inspection Procedure

1. Disconnect the ECT-sensor connection around the

thermostat outlet pipe.

2. Turn the starter switch to the “ON” position.

If the Quick-On Start 4 System is operating

properly, the glow relay will make a clicking sound

within seven seconds after the starter switch is

turned on.

3. Measure the glow plug terminal voltage with a

circuit tester immediately after turning the starter

switch to the “ON” position.

Glow Plug Terminal Voltage: approx. 12V

NOTE: Electrical power to the quick-on start system will

be cut after the starter has remained in the “ON”

position for twenty seconds.

Turn the starter switch to the “OFF” position and back

to the “ON” position.

This will reset the Quick-On Start 4 System.

014RW150

Page 1872 of 3573

ENGINE ELECTRICAL 6D – 5

STARTING SYTEM

GENERAL DESCRIPTION

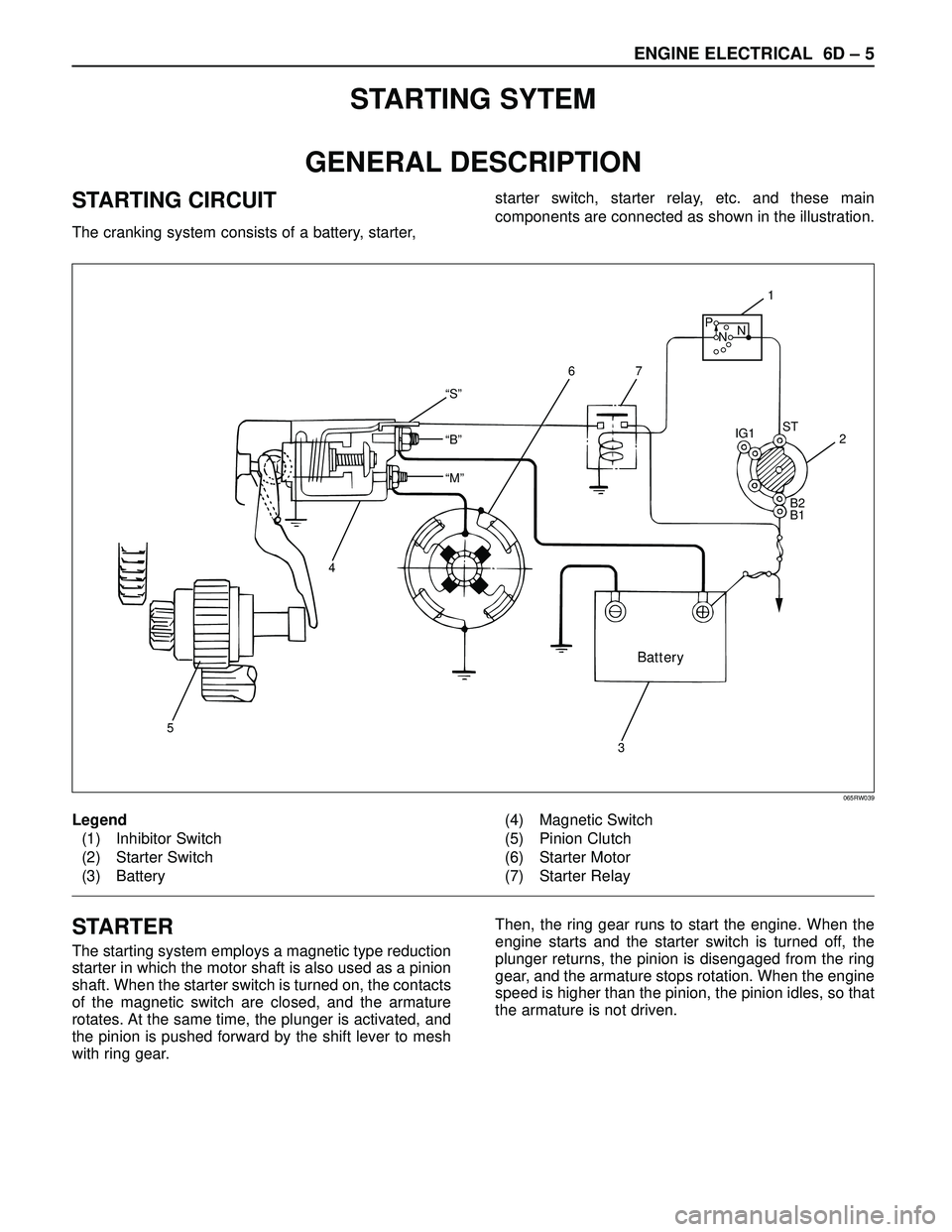

STARTING CIRCUIT

The cranking system consists of a battery, starter, starter switch, starter relay, etc. and these main

components are connected as shown in the illustration.

“S”

“B”

“M”

Battery

5

4

32 IG1ST

B2

B1

1

76

P

NN

Legend

(1) Inhibitor Switch

(2) Starter Switch

(3) Battery(4) Magnetic Switch

(5) Pinion Clutch

(6) Starter Motor

(7) Starter Relay

065RW039

STARTER

The starting system employs a magnetic type reduction

starter in which the motor shaft is also used as a pinion

shaft. When the starter switch is turned on, the contacts

of the magnetic switch are closed, and the armature

rotates. At the same time, the plunger is activated, and

the pinion is pushed forward by the shift lever to mesh

with ring gear.Then, the ring gear runs to start the engine. When the

engine starts and the starter switch is turned off, the

plunger returns, the pinion is disengaged from the ring

gear, and the armature stops rotation. When the engine

speed is higher than the pinion, the pinion idles, so that

the armature is not driven.

Page 1873 of 3573

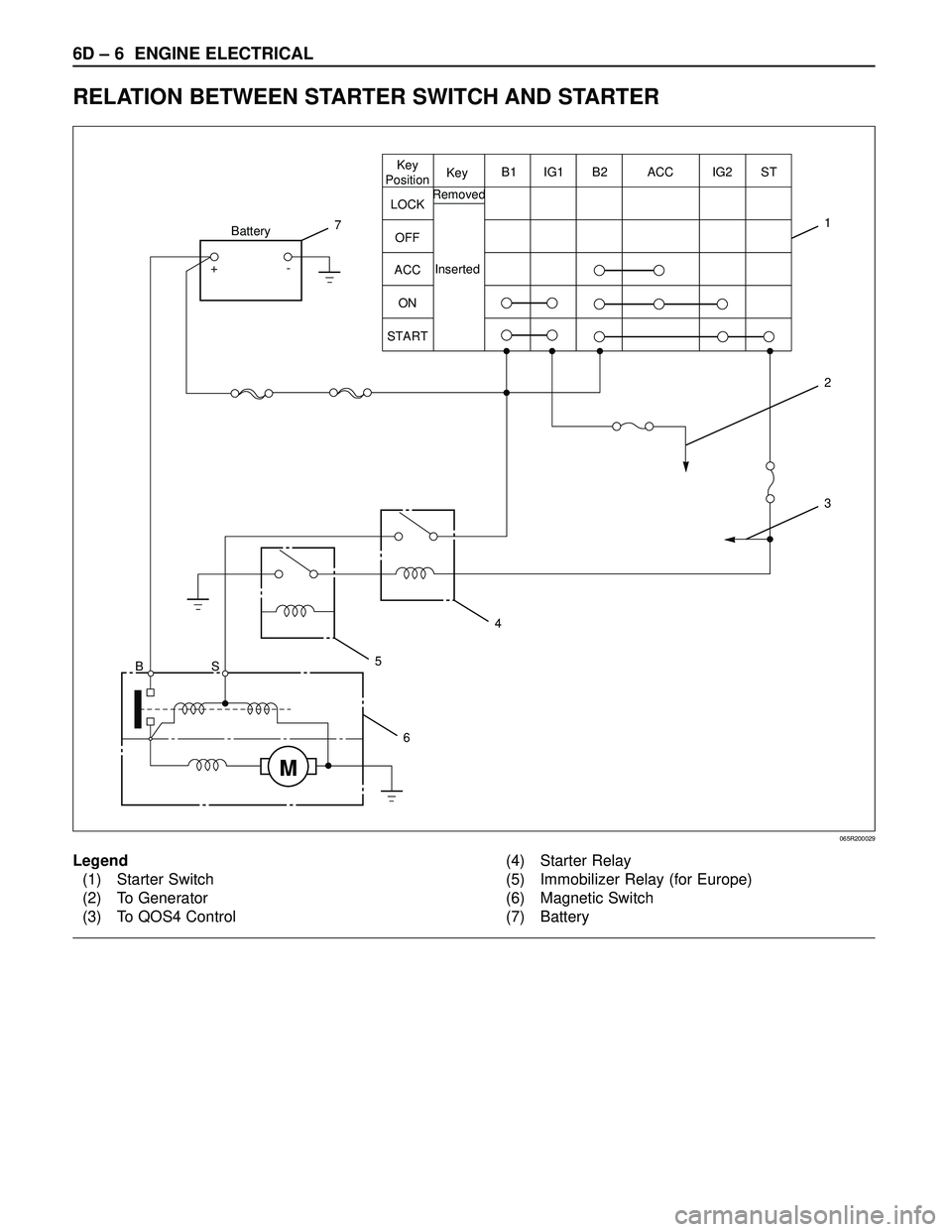

6D – 6 ENGINE ELECTRICAL

RELATION BETWEEN STARTER SWITCH AND STARTER

M

Key

PositionB1 B2 ACCIG1 IG2 ST

LOCKKey

Removed

Inserted OFF

ACC

ON

START

BSBattery

+-

2

17

3

4

5

6

Legend

(1) Starter Switch

(2) To Generator

(3) To QOS4 Control(4) Starter Relay

(5) Immobilizer Relay (for Europe)

(6) Magnetic Switch

(7) Battery

065R200029

Page 1874 of 3573

ENGINE ELECTRICAL 6D – 7

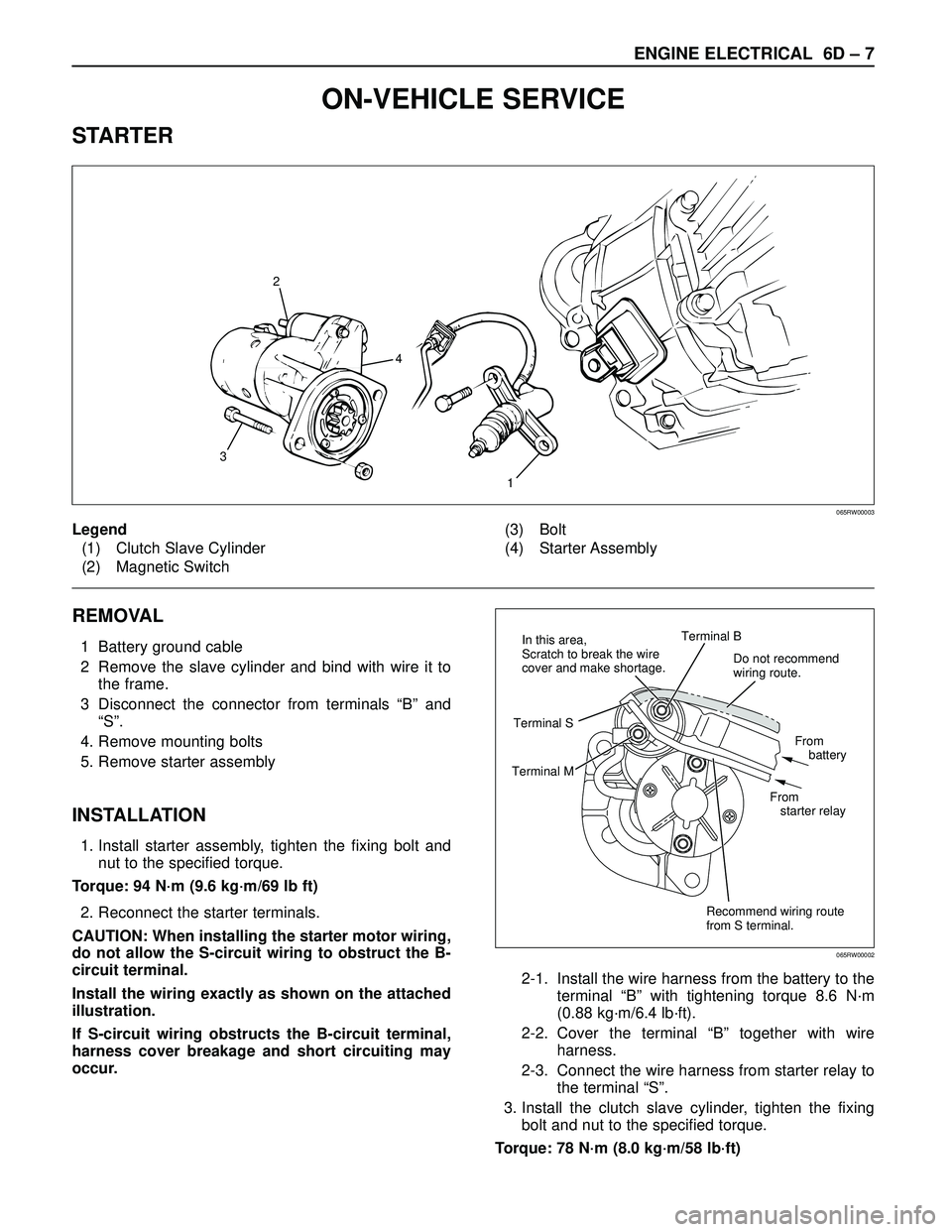

ON-VEHICLE SERVICE

STARTER

REMOVAL

1 Battery ground cable

2 Remove the slave cylinder and bind with wire it to

the frame.

3 Disconnect the connector from terminals “B” and

“S”.

4. Remove mounting bolts

5. Remove starter assembly

INSTALLATION

1. Install starter assembly, tighten the fixing bolt and

nut to the specified torque.

Torque: 94 N·m (9.6 kg·m/69 lb ft)

2. Reconnect the starter terminals.

CAUTION: When installing the starter motor wiring,

do not allow the S-circuit wiring to obstruct the B-

circuit terminal.

Install the wiring exactly as shown on the attached

illustration.

If S-circuit wiring obstructs the B-circuit terminal,

harness cover breakage and short circuiting may

occur.2-1. Install the wire harness from the battery to the

terminal “B” with tightening torque 8.6 N·m

(0.88 kg·m/6.4 lb·ft).

2-2. Cover the terminal “B” together with wire

harness.

2-3. Connect the wire harness from starter relay to

the terminal “S”.

3. Install the clutch slave cylinder, tighten the fixing

bolt and nut to the specified torque.

Torque: 78 N·m (8.0 kg·m/58 lb·ft)

1

32

4

Legend

(1) Clutch Slave Cylinder

(2) Magnetic Switch(3) Bolt

(4) Starter Assembly

065RW00003

Do not recommend

wiring route.

Recommend wiring route

from S terminal.From

battery

From

starter relay Terminal B

Terminal MTerminal SIn this area,

Scratch to break the wire

cover and make shortage.

065RW00002

Page 1882 of 3573

ENGINE ELECTRICAL 6D – 15

CHARGING SYSTEM

GENERAL DESCRIPTION

GENERATOR

CHARGING CIRCUIT

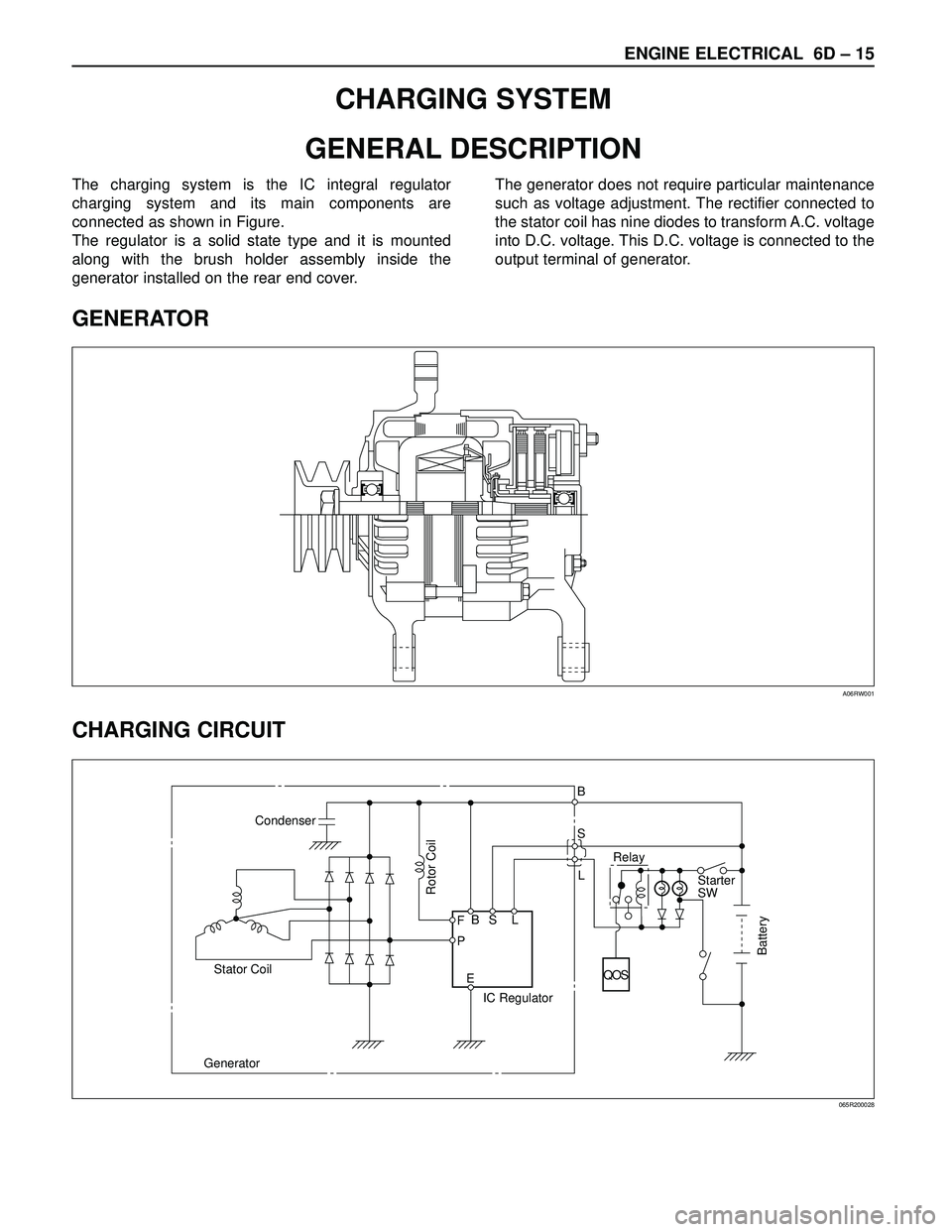

The charging system is the IC integral regulator

charging system and its main components are

connected as shown in Figure.

The regulator is a solid state type and it is mounted

along with the brush holder assembly inside the

generator installed on the rear end cover.The generator does not require particular maintenance

such as voltage adjustment. The rectifier connected to

the stator coil has nine diodes to transform A.C. voltage

into D.C. voltage. This D.C. voltage is connected to the

output terminal of generator.

A06RW001

Condenser

GeneratorStator Coil

IC RegulatorStarter

SW

Rotor Coil

Battery

P F

EBS LRelay B

S

L

QOS

065R200028

Page 1883 of 3573

6D – 16 ENGINE ELECTRICAL

DIAGNOSIS

GENERAL ON-VEHICLE INSPECTION

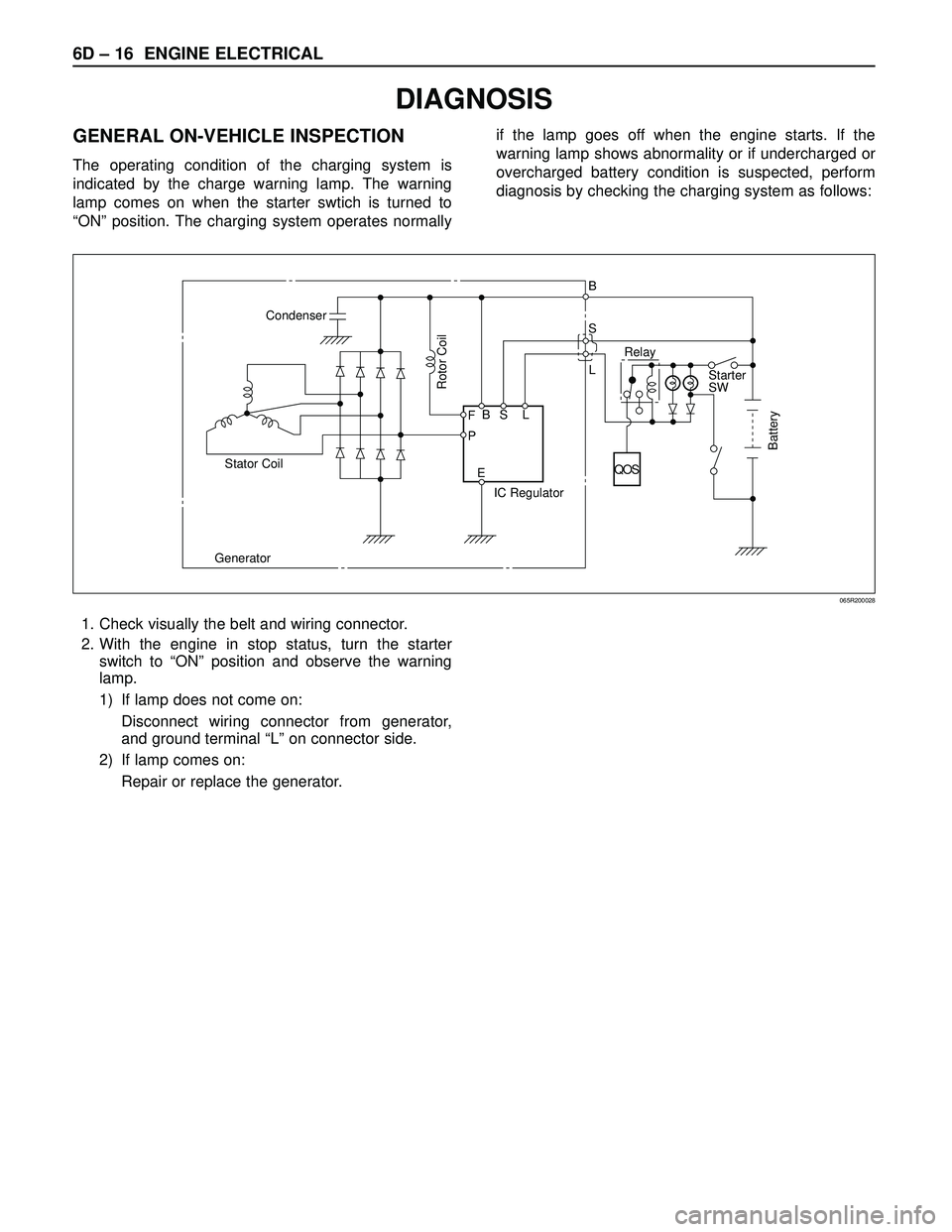

The operating condition of the charging system is

indicated by the charge warning lamp. The warning

lamp comes on when the starter swtich is turned to

“ON” position. The charging system operates normallyif the lamp goes off when the engine starts. If the

warning lamp shows abnormality or if undercharged or

overcharged battery condition is suspected, perform

diagnosis by checking the charging system as follows:

Condenser

GeneratorStator Coil

IC RegulatorStarter

SW

Rotor Coil

Battery

P F

EBS LRelay B

S

L

QOS

065R200028

1. Check visually the belt and wiring connector.

2. With the engine in stop status, turn the starter

switch to “ON” position and observe the warning

lamp.

1) If lamp does not come on:

Disconnect wiring connector from generator,

and ground terminal “L” on connector side.

2) If lamp comes on:

Repair or replace the generator.