ISUZU TROOPER 1998 Service Repair Manual

TROOPER 1998

ISUZU

ISUZU

https://www.carmanualsonline.info/img/61/57184/w960_57184-0.png

ISUZU TROOPER 1998 Service Repair Manual

Trending: ECO mode, Coolant system, maintenance, fuel type, coolant temperature, oil filter, catalytic converter

Page 1701 of 3573

STARTING SYSTEM 6D2 Ð 7

INSPECTION AND REPAIR

Repair or replace necessary parts if extreme wear or

damage is found during inspection.

Armature

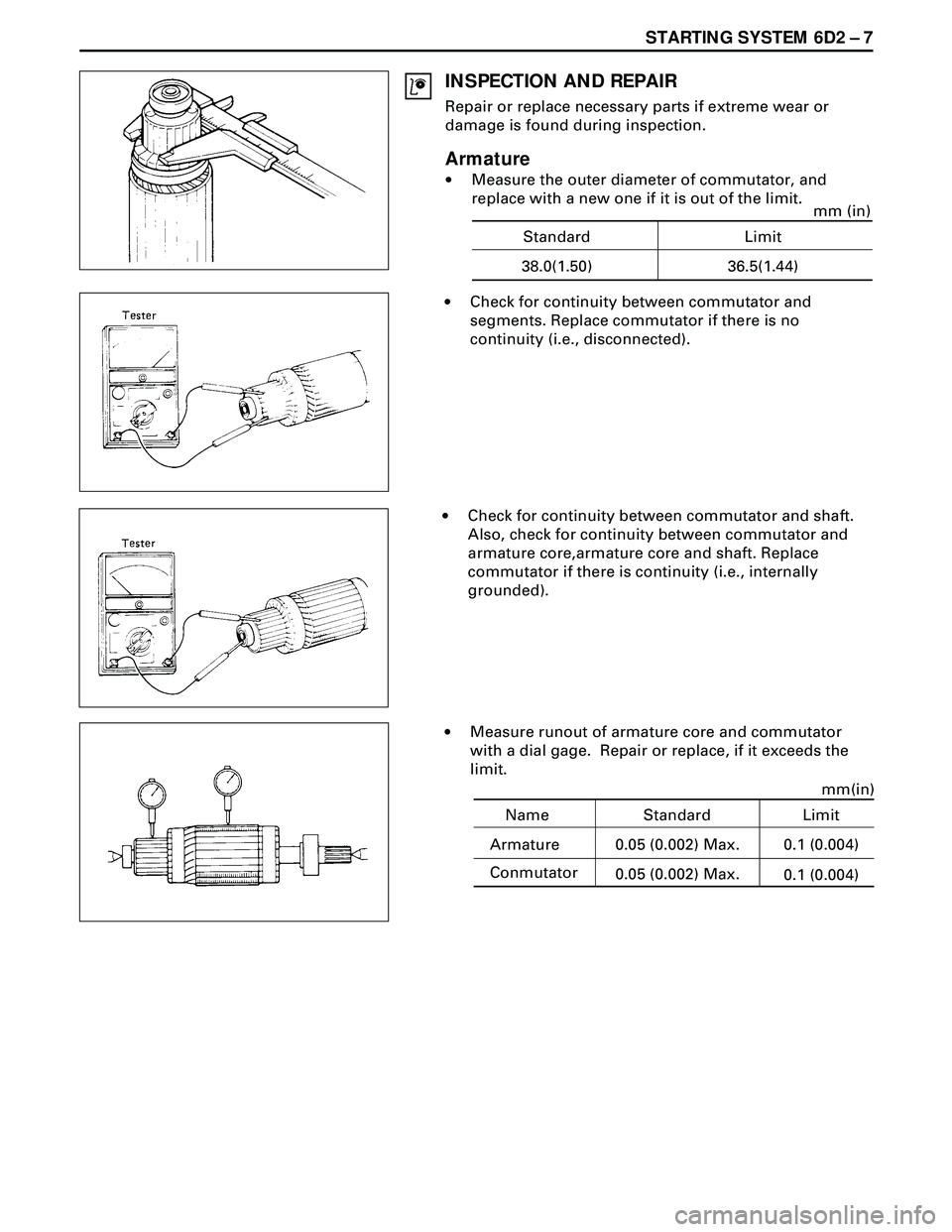

·Measure the outer diameter of commutator, and

replace with a new one if it is out of the limit.

·Check for continuity between commutator and

segments. Replace commutator if there is no

continuity (i.e., disconnected).

·Check for continuity between commutator and shaft.

Also, check for continuity between commutator and

armature core,armature core and shaft. Replace

commutator if there is continuity (i.e., internally

grounded).

·Measure runout of armature core and commutator

with a dial gage. Repair or replace, if it exceeds the

limit.

Name Standard

Armature 0.05 (0.002) Max.mm(in)

Conmutator

0.05 (0.002) Max.0.1 (0.004)

0.1 (0.004)

Limit

Standard Limit

38.0(1.50) 36.5(1.44)mm (in)

Page 1702 of 3573

6D2 Ð 8 STARTING SYSTEM

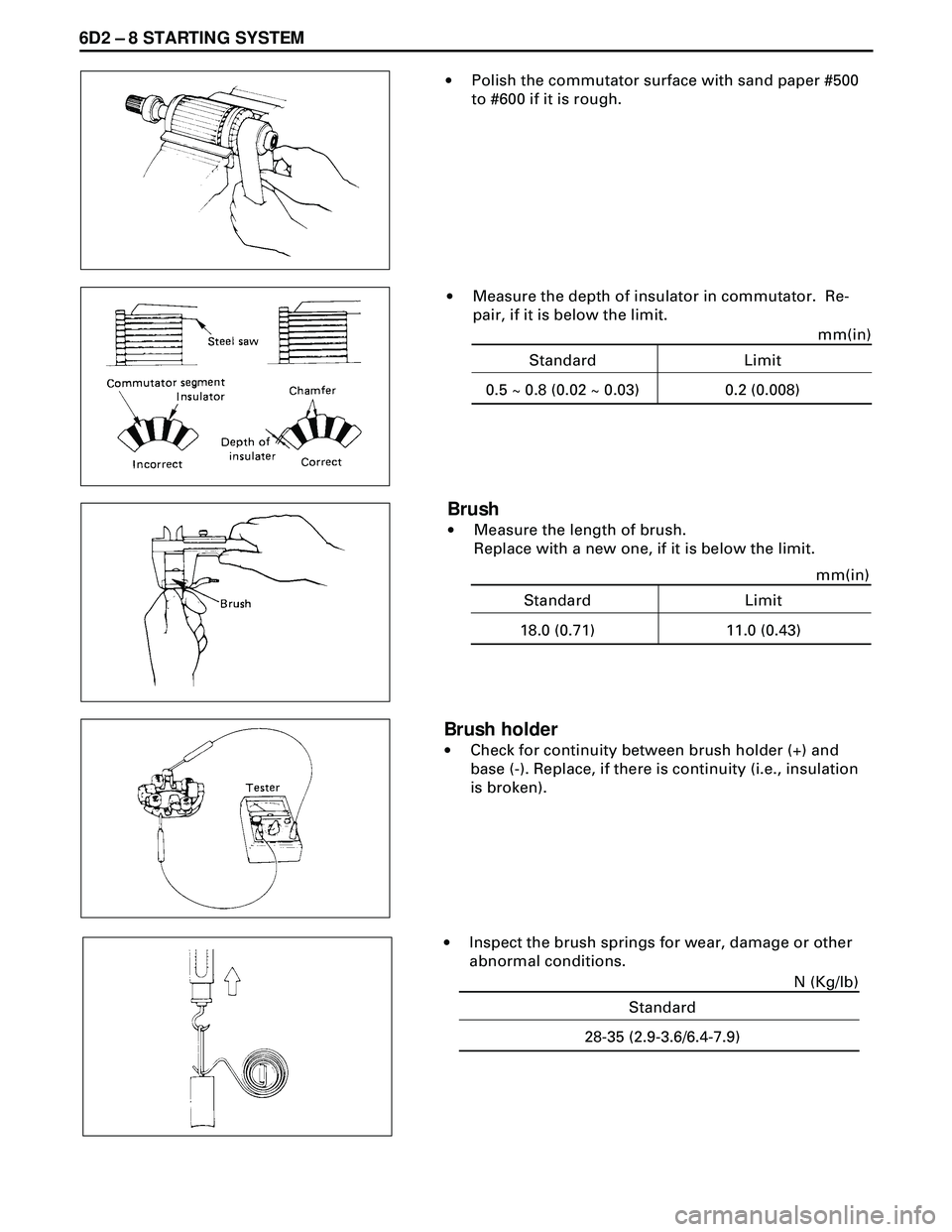

·Polish the commutator surface with sand paper #500

to #600 if it is rough.

·Measure the depth of insulator in commutator. Re-

pair, if it is below the limit.

Brush

·Measure the length of brush.

Replace with a new one, if it is below the limit.

Brush holder

·Check for continuity between brush holder (+) and

base (-). Replace, if there is continuity (i.e., insulation

is broken).

·Inspect the brush springs for wear, damage or other

abnormal conditions.

Standard Limit

0.5 ~ 0.8 (0.02 ~ 0.03) 0.2 (0.008)mm(in)

Standard Limit

18.0 (0.71) 11.0 (0.43)mm(in)

Standard

28-35 (2.9-3.6/6.4-7.9)N (Kg/lb)

Page 1703 of 3573

STARTING SYSTEM 6D2 Ð 9

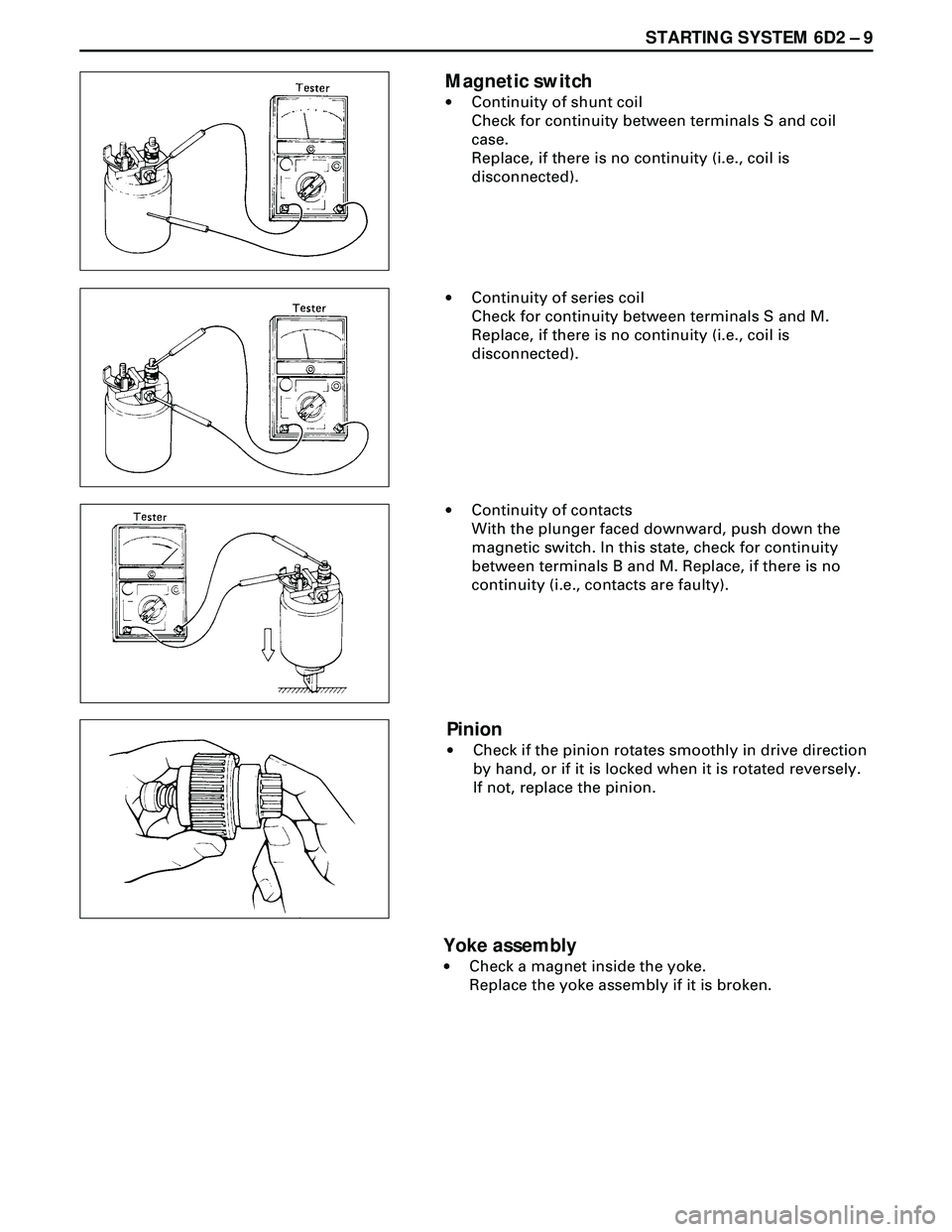

Magnetic switch

·Continuity of shunt coil

Check for continuity between terminals S and coil

case.

Replace, if there is no continuity (i.e., coil is

disconnected).

·Continuity of series coil

Check for continuity between terminals S and M.

Replace, if there is no continuity (i.e., coil is

disconnected).

Pinion

·Check if the pinion rotates smoothly in drive direction

by hand, or if it is locked when it is rotated reversely.

If not, replace the pinion.

Yoke assembly

·Check a magnet inside the yoke.

Replace the yoke assembly if it is broken. ·Continuity of contacts

With the plunger faced downward, push down the

magnetic switch. In this state, check for continuity

between terminals B and M. Replace, if there is no

continuity (i.e., contacts are faulty).

Page 1704 of 3573

6D2 Ð 10 STARTING SYSTEM

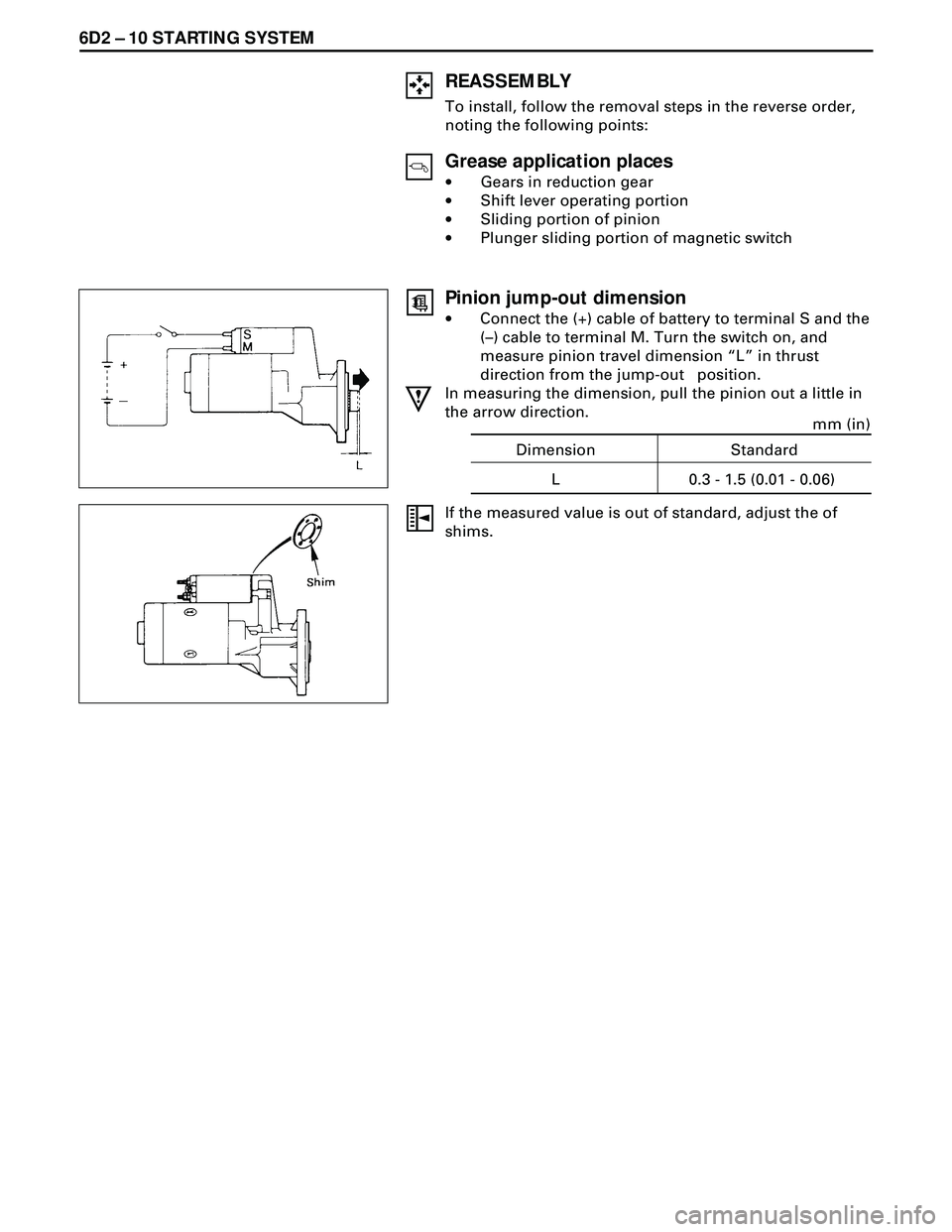

REASSEMBLY

To install, follow the removal steps in the reverse order,

noting the following points:

Grease application places

·Gears in reduction gear

·Shift lever operating portion

·Sliding portion of pinion

·Plunger sliding portion of magnetic switch

Pinion jump-out dimension

·Connect the (+) cable of battery to terminal S and the

(Ð) cable to terminal M. Turn the switch on, and

measure pinion travel dimension ÒLÓ in thrust

direction from the jump-out position.

In measuring the dimension, pull the pinion out a little in

the arrow direction.

If the measured value is out of standard, adjust the of

shims.

Dimension

L 0.3 - 1.5 (0.01 - 0.06)Standard

mm (in)

Page 1705 of 3573

STARTING SYSTEM 6D2 Ð 11

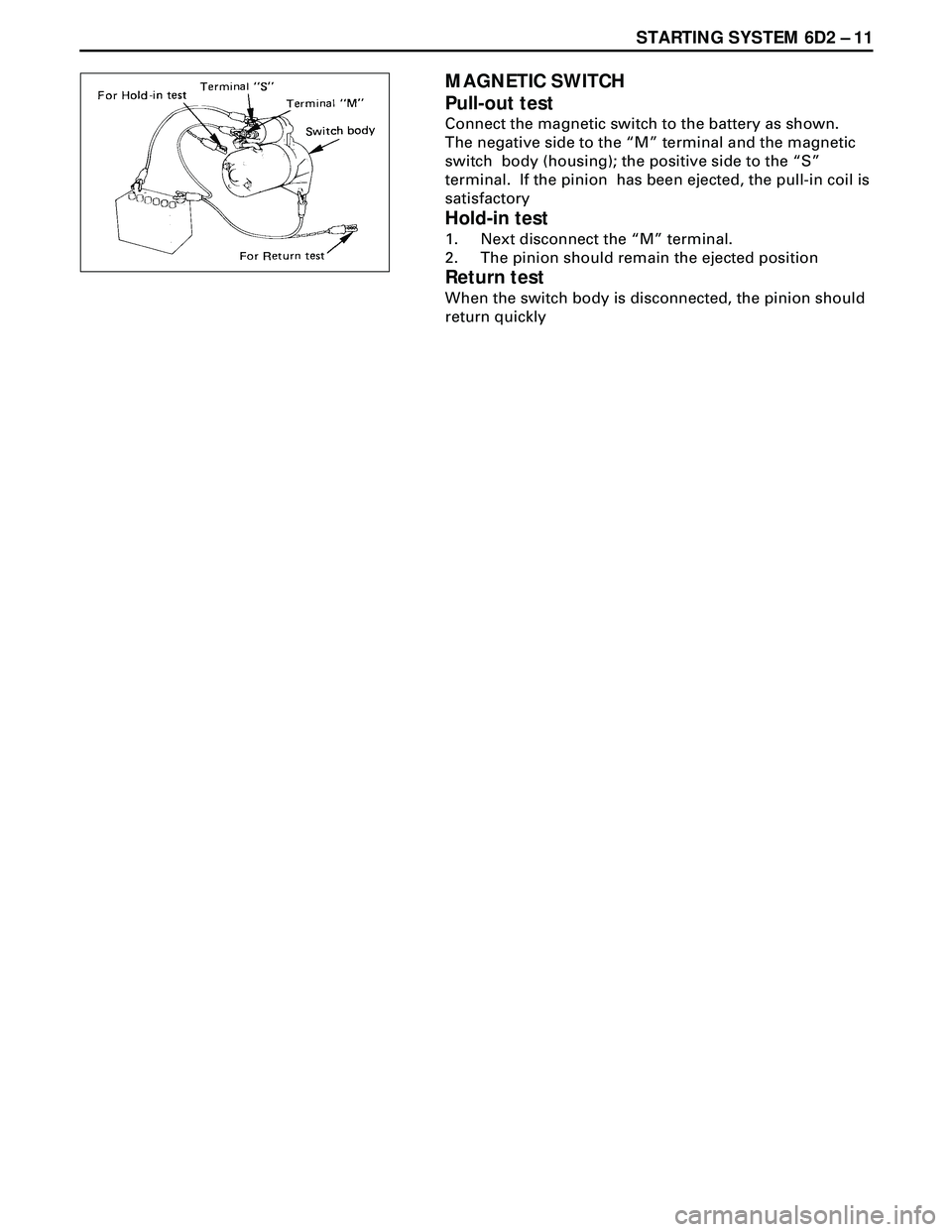

MAGNETIC SWITCH

Pull-out test

Connect the magnetic switch to the battery as shown.

The negative side to the ÒMÓ terminal and the magnetic

switch body (housing); the positive side to the ÒSÓ

terminal. If the pinion has been ejected, the pull-in coil is

satisfactory

Hold-in test

1. Next disconnect the ÒMÓ terminal.

2. The pinion should remain the ejected position

Return test

When the switch body is disconnected, the pinion should

return quickly

Page 1706 of 3573

6D2 Ð 12 STARTING SYSTEM

MEMO

Page 1707 of 3573

CHARGING SYSTEM 6D3 Ð 1

SECTION 6D3

CHARGING SYSTEM

CONTENTS

PAGE

General Description ........................................................................................................ 6D3-1

Diagnosis ......................................................................................................................... 6D3-4

Unit Repair ....................................................................................................................... 6D3-5

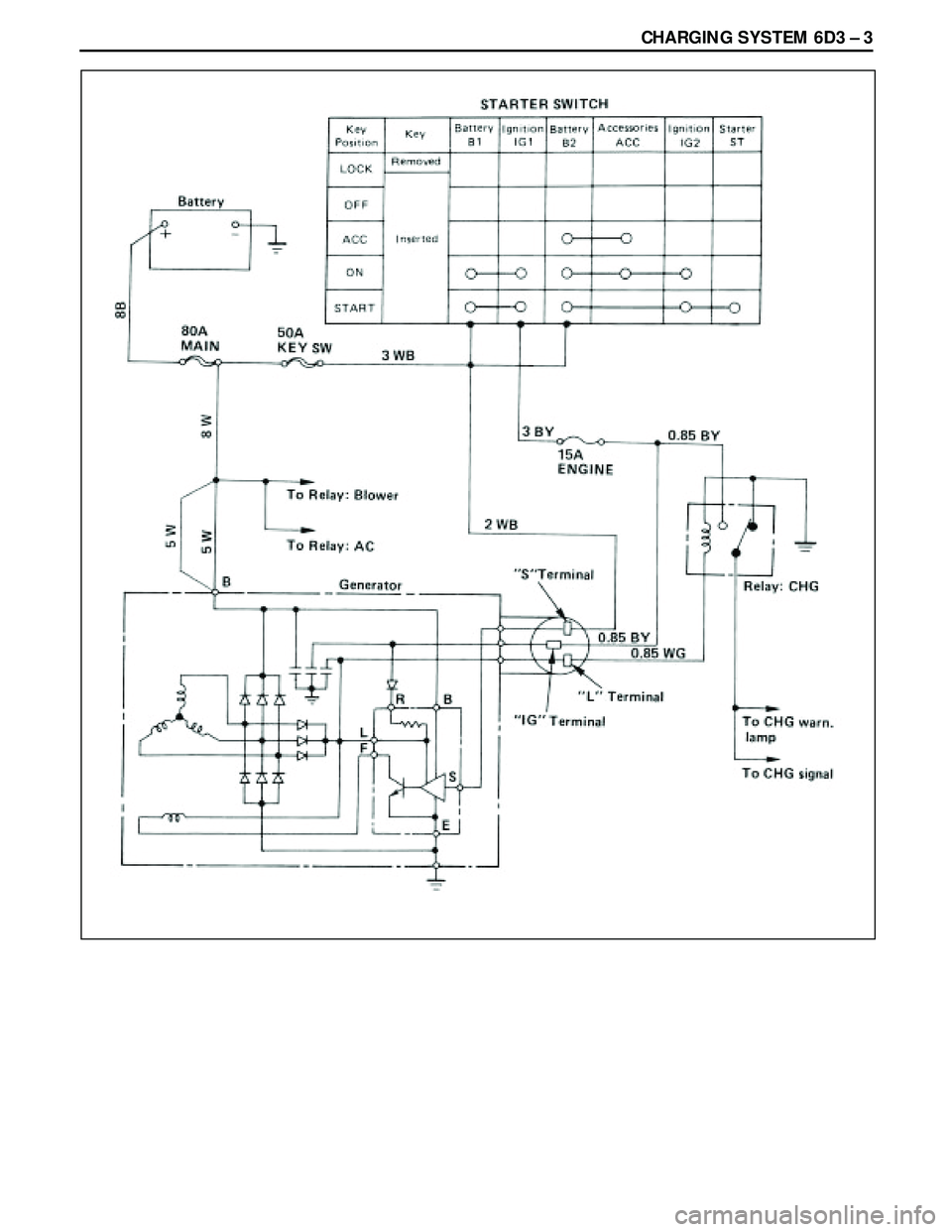

GENERAL DESCRIPTION

The generator does not require particular

maintenance such as voltage adjustment. The

rectifier connected to the stator coil has nine diodes

to transform A.C. voltage into D.C. voltage. This

D.C. voltage is connected to the output terminal of

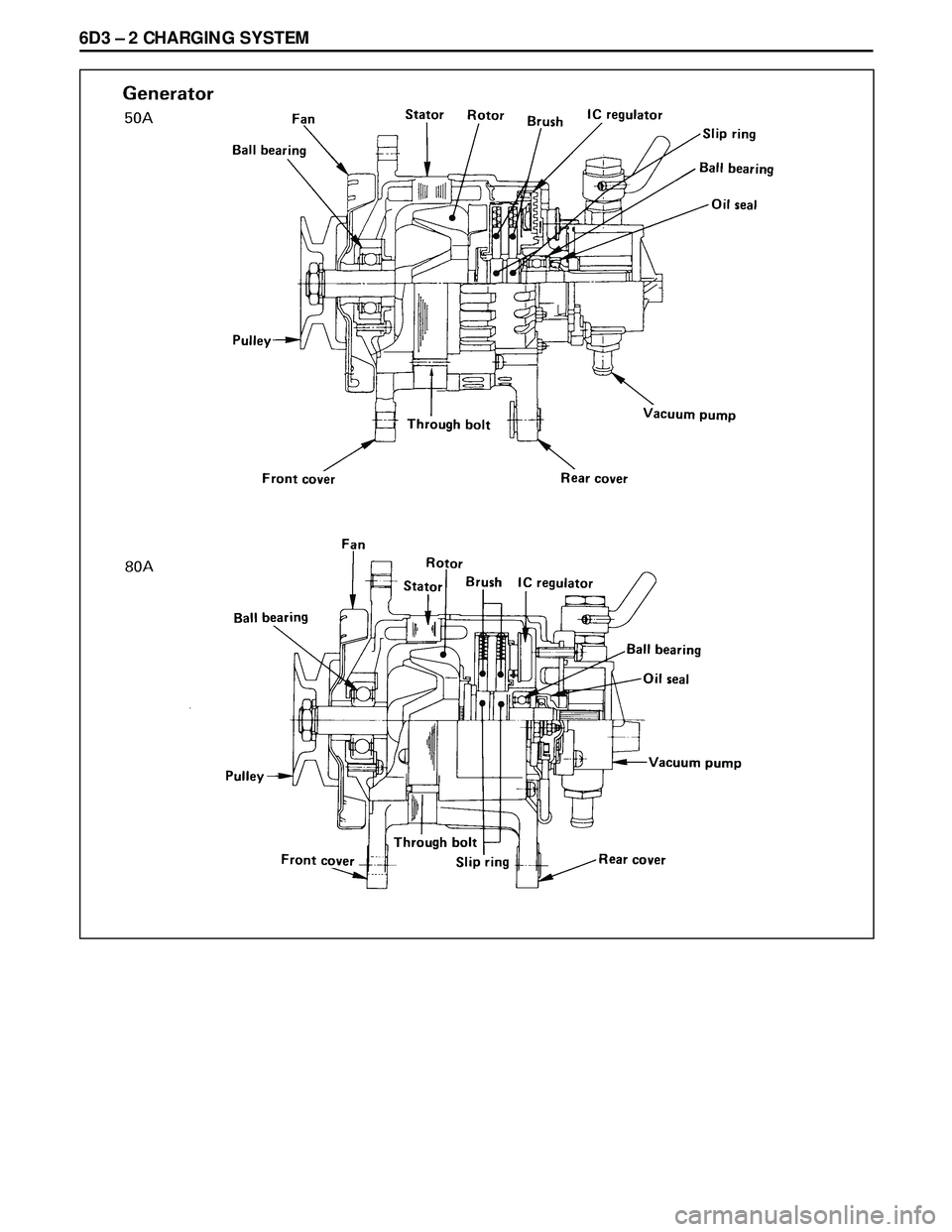

generator. The charging system is the IC integral regulator

charging system and its main components are

connected as shown in Figure.

The regulator is a solid state type and it is mounted

along with the brush holder assembly inside the

generator installed on the rear end cover.

Page 1708 of 3573

Page 1709 of 3573

Page 1710 of 3573

6D3 Ð 4 CHARGING SYSTEM

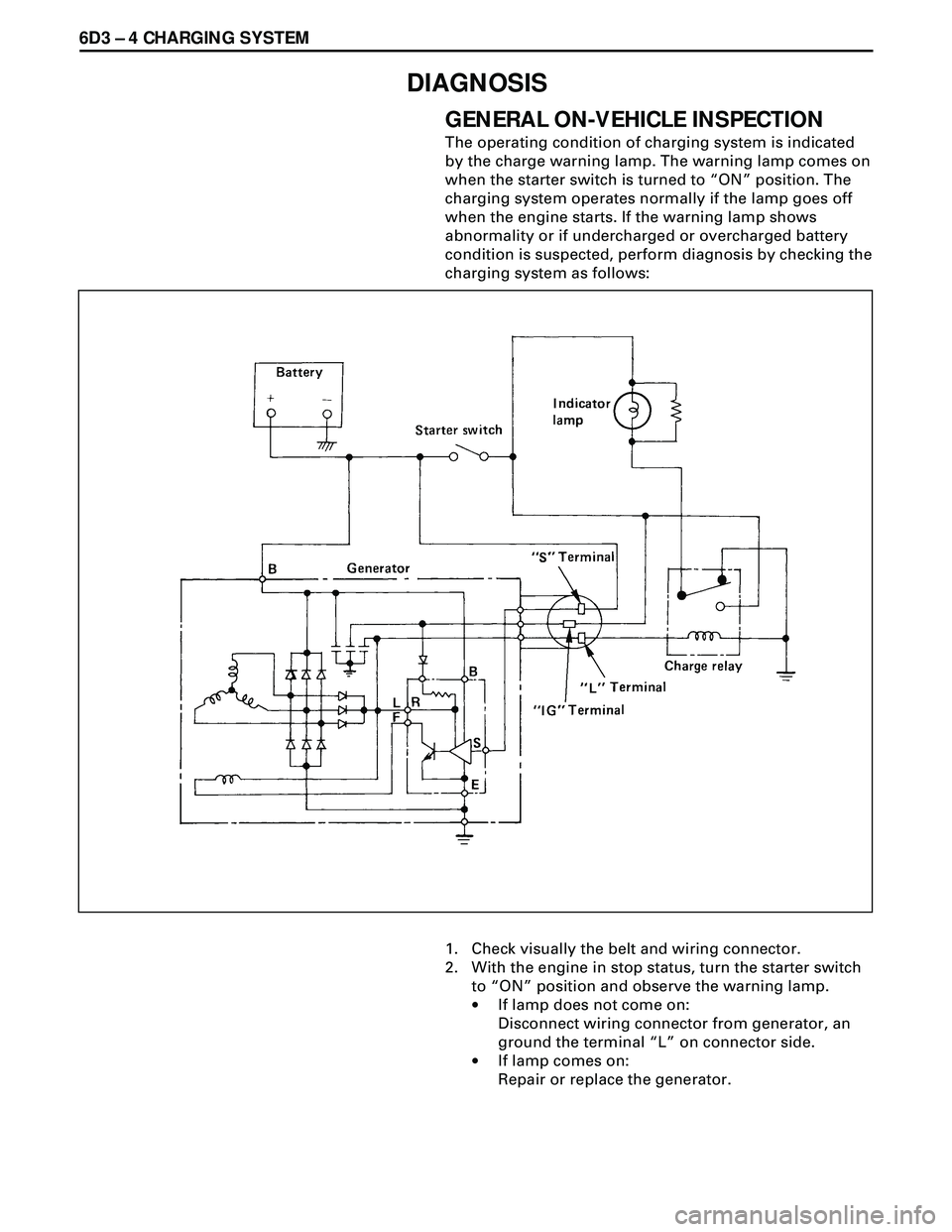

DIAGNOSIS

GENERAL ON-VEHICLE INSPECTION

The operating condition of charging system is indicated

by the charge warning lamp. The warning lamp comes on

when the starter switch is turned to ÒONÓ position. The

charging system operates normally if the lamp goes off

when the engine starts. If the warning lamp shows

abnormality or if undercharged or overcharged battery

condition is suspected, perform diagnosis by checking the

charging system as follows:

1. Check visually the belt and wiring connector.

2. With the engine in stop status, turn the starter switch

to ÒONÓ position and observe the warning lamp.

·If lamp does not come on:

Disconnect wiring connector from generator, an

ground the terminal ÒLÓ on connector side.

·If lamp comes on:

Repair or replace the generator.

Trending: oil change, Coolant system diagram, fuel additives, automatic transmission, instrument cluster, removing engine, fuel reserve